- Offer Profile

-

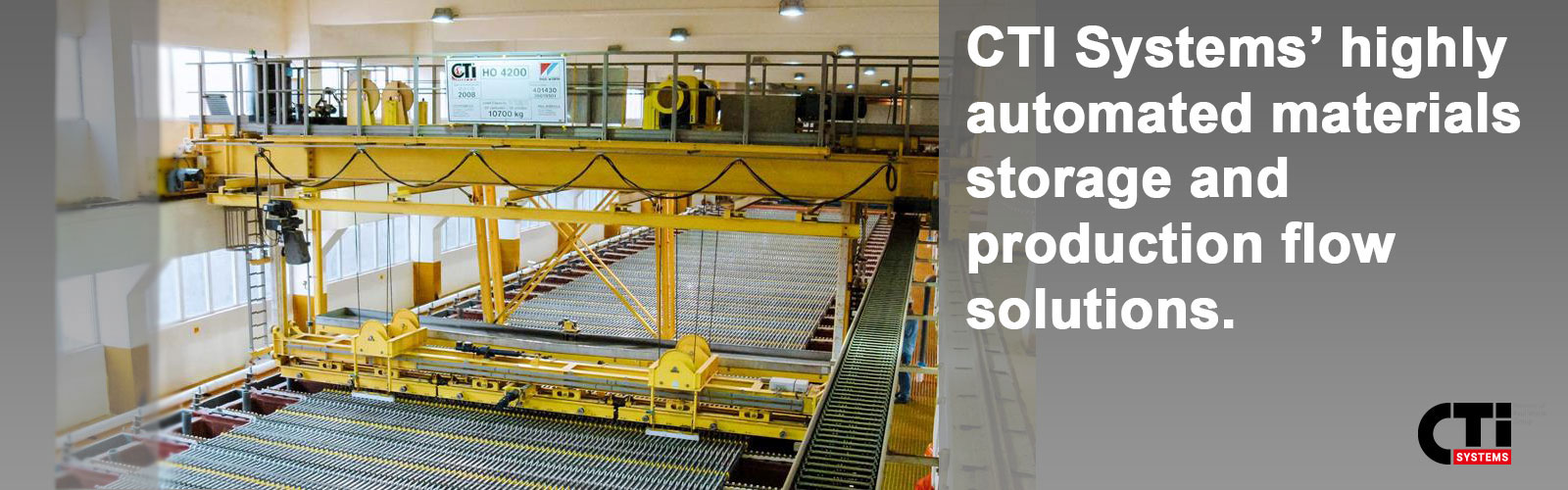

CTI Systems is a leading supplier of integrated automated handling and processing systems, with a focus on heavy and bulky loads.

Our portfolio includes:

- Automated material handling solutions

- Aircraft servicing systems

- Storage systems

- Surface treatment plants

- Assembly lines

- Software solutions for production control or for optimisation of storage Distribution systems (MES & WMS), including the integration of machinery from other suppliers.

CTI Solutions

- CTI Systems’ highly automated materials storage and production flow solutions deliver efficiency, sustainability and optimum profitability for various industries. Learn more about our company.

Long Profiles - Aluminium and PVC

- The expert engineering at the heart of CTI Systems' picking and preparation, storage, handling and transport solutions ensures that - from the store to the production line - the flow of even the longest aluminium or PVC profiles is safe, smooth, efficient and highly cost-effective – whatever your application.

Lift and Run Dynamic Storage System

-

CTI Systems has pioneered lift and run dynamic storage technology for long profiles. Designed for facilities where a significant number of different product lines have to be organised and processed, sophisticated lift and run solutions are an ideal choice for production sites where batches of profile have to be prepared for trimming. The systems are particularly suitable for the manufacturing and construction sectors.

Consisting of a highly innovative combination of honeycomb racking served by high speed shuttles and goods lifts, lift and run storage systems deliver ultra-efficient long profile handling performance and optimum flow speeds to ensure minimum ‘dead time’ at every stage of the production process.

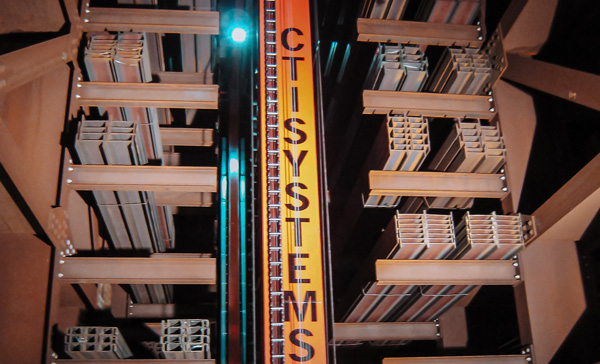

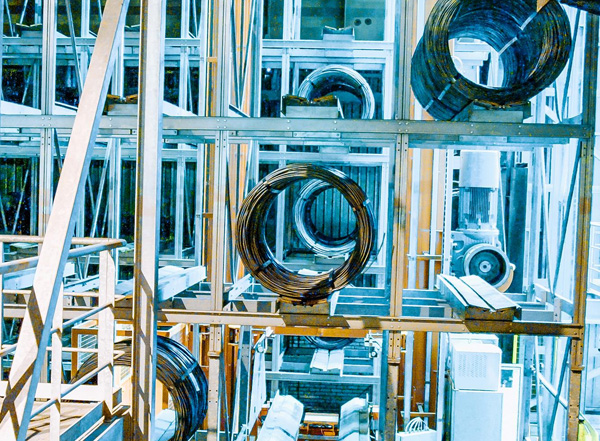

Honeycomb Storage System

-

A well-proven solution used by companies operating across a wide range of industry sectors worldwide, high density honeycomb systems allow large quantities of long items to be stored safely and efficiently. And, because honeycomb solutions provide direct access to the product, the storage and retrieval process is highly efficient, which makes this type of system the ideal option at facilities where optimum cycle times are required.

The main characteristics of a honeycomb storage system are:

- High storage density

- A capacity of 800 to 8000 storage locations

- Optimum throughput rates

Stacked Storage System

-

A stacked storage system is a cost-efficient, compact, simple – yet highly effective – method of storing long profiles in bundles or within various types of cassette. Suitable for manufacturing facilities in all industry sectors, it is an ideal solution for small or medium-sized storage and dispatch systems.

Typically, systems are built 5 to7 levels high and most projects are not restricted by the weight of the products to be stored. Ground level picking locations are accessed directly, while upper levels are reached by a shuttle that automatically raises or lowers the operator platform to the correct position within the system from where pre-programmed order batches can be retrieved in safety and comfort.

Warehouse management system (WMS) software interfaces with the user’s manufacturing system or ERP software to control inventory movement and organise product flow to optimise storage and retrieval performance.

Long Profiles - Steel

- CTI Systems designs and delivers flexible, safe, economical and throughput-efficient solutions that overcome the unique challenges that the storage and handling of long steel profiles bring to manufacturing operations across a wide range of industries.

Honeycomb Storage System

-

A well-proven solution used by companies operating across a wide range of industry sectors worldwide, high density honeycomb systems allow large quantities of long items to be stored safely and efficiently. And, because honeycomb solutions provide direct access to the product, the storage and retrieval process is highly efficient, which makes this type of system the ideal option at facilities where optimum cycle times are required.

The main characteristics of a honeycomb storage system are:

- High storage density

- A capacity of 800 to 8000 storage locations

- Optimum throughput rates

Honeycomb storage projects offer various design options. For example:

- Systems can be supplied in single or double-sided aisle formats;

- The system’s flexibility allows the most suitable configuration of storage and retrieval machines to be deployed as well as single or double-swap tables if required;

- Free-standing, roof- and wall-bearing construction options guarantee maximum design flexibility within existing buildings or new-build units;

- Partitioned cassettes give users additional system adaptability;

- Systems can be adapted to any length of profile – from standard size to 24 metres;

Dedicated stock management software ensures pick accuracy.

Automated Storage and Retrieval Systems (AS/RS)

-

Capable of moving items weighing as much as 40 tonnes at speeds of up to 20 metres per minute, Automated Storage and Retrieval Systems (AS/RS) technology increases productivity and minimises picking and put-away errors.

AS/RS can be configured to meet a user’s load capacity, the size of the storage system and the type of products being handled – and this flexibility makes the technology suitable for a wide range of applications across many different industry sectors.

The right material handling equipment is fundemental to the efficient performance of any busy production facility.

Stacked Storage System

-

Typically, systems are built 5 to7 levels high and most projects are not restricted by the weight of the products to be stored. Ground level picking locations are accessed directly, while upper levels are reached by a shuttle that automatically raises or lowers the operator platform to the correct position within the system from where pre-programmed order batches can be retrieved in safety and comfort.

Warehouse management system (WMS) software interfaces with the user’s manufacturing system or ERP software to control inventory movement and organise product flow to optimise storage and retrieval performance.

A stacked storage system offers:

- The most compact storage solution;

- A storage capacity ranging from 50 to more than 300 stillage locations;

- Compatibility with buildings with an eaves height of 5.5 metres or more;

- Single or multiple stacking rows;

- A modular, flexible and scalable design that can be adapted to keep pace with a business’s changing needs.

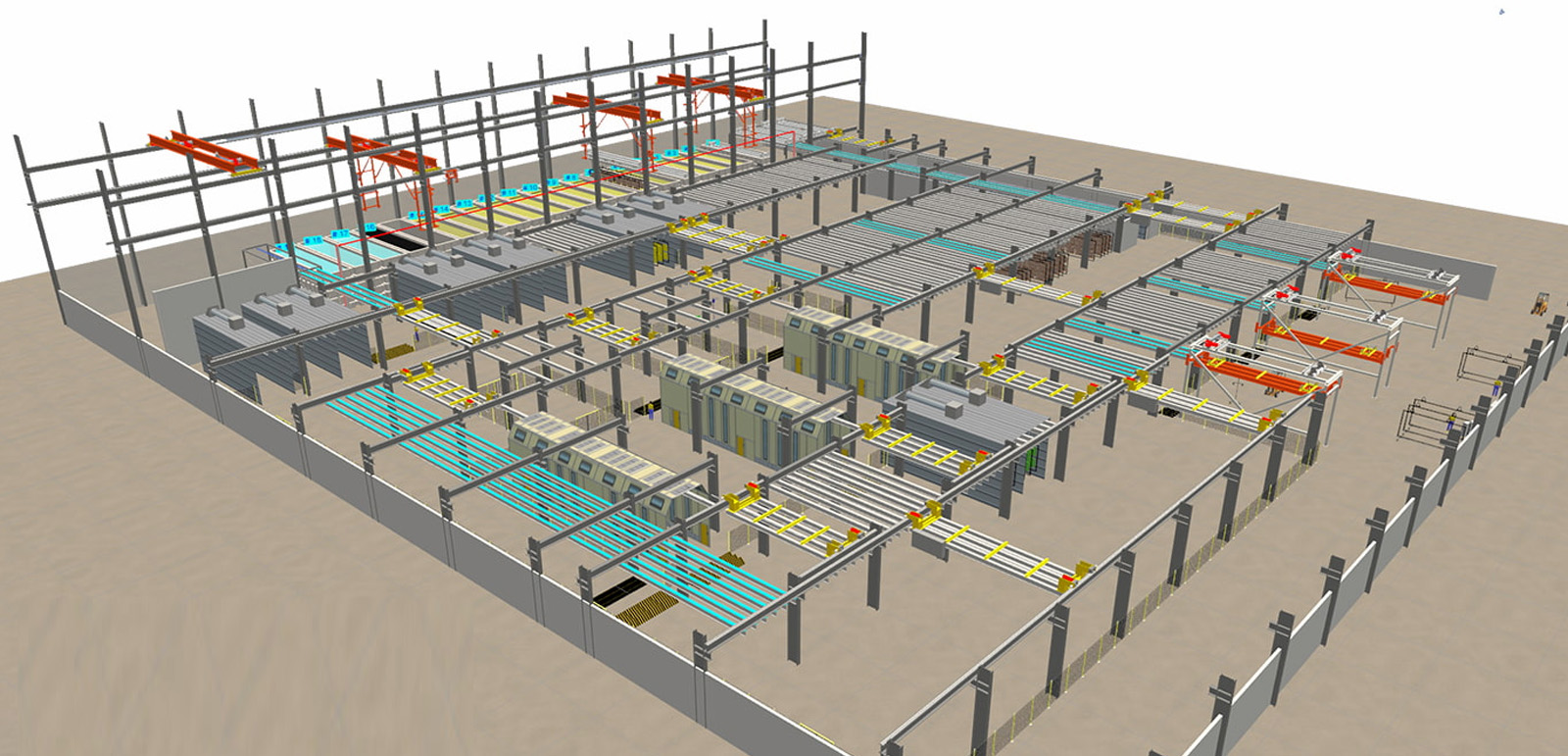

Floor-based and Overhead Conveyor Systems

-

CTI Systems' extensive range of floor-mounted conveyor systems allow even the bulkiest loads to be transported throughout a production site quickly and efficiently.

Used within pre-production buffer storage zones, production lines and testing, commissioning and shipping areas, CTI Systems' conveyor solutions are designed to undertake the most complex tasks and every component part’s robust design and build quality ensures that CTI's conveyor-based handling systems perform reliably and effectively even when deployed within the harshest industrial environments.

Conveyor technology available from CTI Systems includes:

- Monorails

- Roller conveyors, heavy duty conveyors, skid conveyors

- Bespoke chain conveyors

- Lifting systems

- Turntables

- Closed chain conveyors

- Belt conveyors

- Shuttle systems

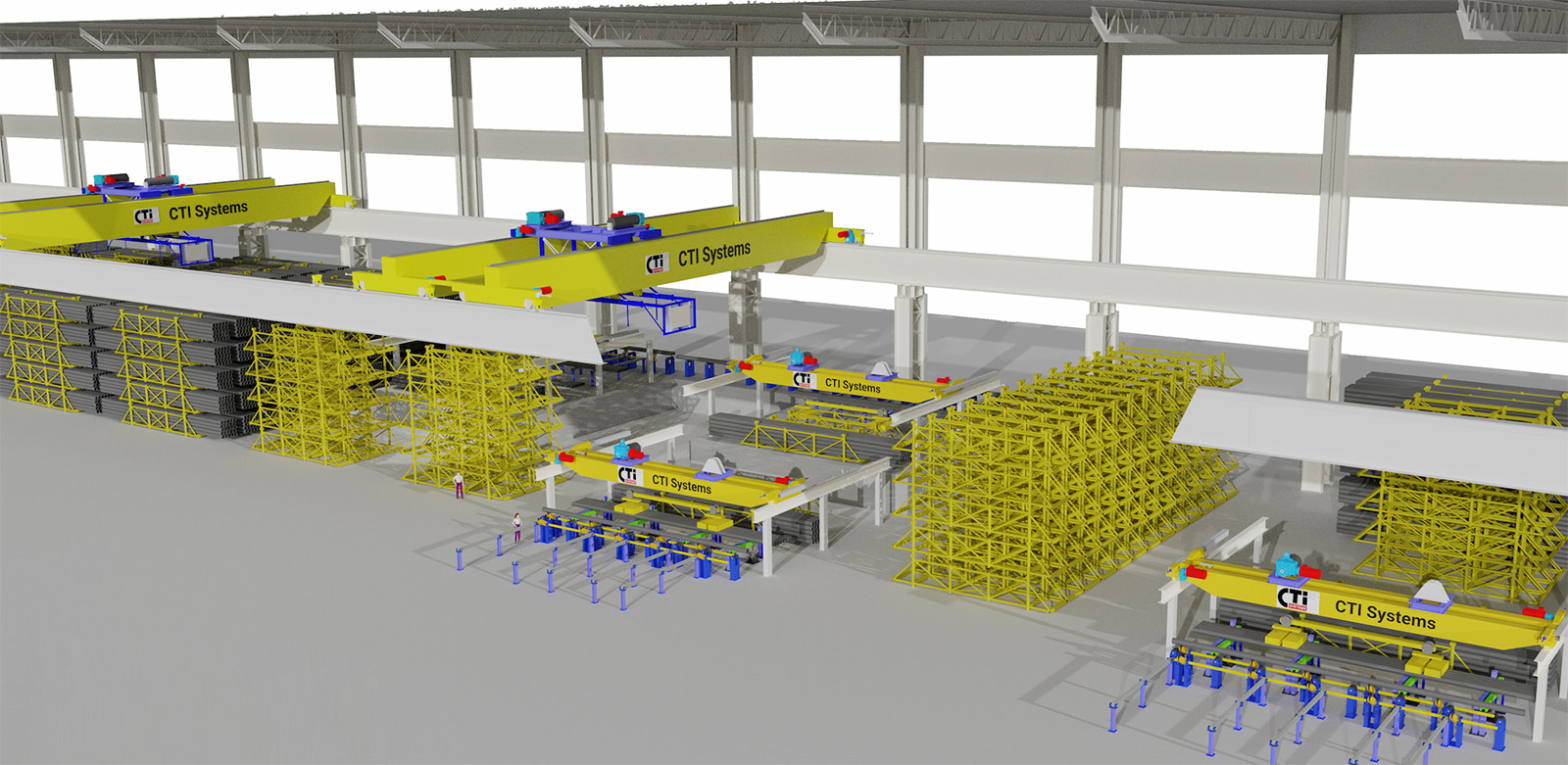

Overhead and Suspended Cranes

-

At facilities with varied handling requirements, automatic crane technology can represent the optimum transport solution.

CTI’s crane systems perform a range of highly complex tasks that are vital to the safe and efficient production cycles of a range of clients operating across all kinds of manufacturing industries.

Able to transport loads weighing up to 65 tonnes quickly and safely, the range of cranes within CTI Systems' portfolio can be incorporated within a manual, semi-automated or fully-automated production process, while CTI Systems' ‘grab and load’ suspension systems are tailored to meet the precise requirements of every application and the load to be transported.

Often referred to as ‘process cranes’, automatic cranes can be built around a choice of overhead, interlocking or travelling crane design, but they are fully integrated within the production process.

With PLC-controlled operation, automatic cranes are usually fitted with a custom-built grab attachment, interlocking systems, indexing units or other devices to suit the required application.

Manipulators and other handling devices

- A range of handling devices that enable loads to be transported, rotated, lifted or turned can be supplied to feed and remove materials, components to and from production machinery, furnaces, presses, etc. with precision and maximum on-site safety.

Panels - Wood

-

Ensure that the flow of essential parts will be safe, smooth, efficient and highly cost-effective

Long shaped products or industrial components require bespoke storage systems that allow goods to be stored and retrieved quickly, safely and efficiently and, of course, make optimum use of the available floor space.

CTI Systems offer a variety of long goods storage schemes that ensure that the flow of essential parts from the store to the production line will be safe, smooth, efficient and highly cost-effective – whatever your application.

Floor-based and Overhead Conveyor Systems

-

CTI Systems' extensive range of floor-mounted conveyor systems allow even the bulkiest loads to be transported throughout a production site quickly and efficiently.

Used within pre-production buffer storage zones, production lines and testing, commissioning and shipping areas, CTI Systems' conveyor solutions are designed to undertake the most complex tasks and every component part’s robust design and build quality ensures that CTI's conveyor-based handling systems perform reliably and effectively even when deployed within the harshest industrial environments.

Conveyor technology available from CTI Systems includes:

- Monorails

- Roller conveyors, heavy duty conveyors, skid conveyors

- Bespoke chain conveyors

- Lifting systems

- Turntables

- Closed chain conveyors

- Belt conveyors

- Shuttle systems

Manipulators and other handling devices

- A range of handling devices that enable loads to be transported, rotated, lifted or turned can be supplied to feed and remove materials, components to and from production machinery, furnaces, presses, etc. with precision and maximum on-site safety.

High-bay Storage System

-

While often a feature of new clad-rack building projects, high-bay storage systems can also be designed to operate within existing facilities. Solutions can be developed that are compatible with the physical dimensions of the customer’s site as well as the characteristics of the products stored within it. The aisles of high-bay storage systems are served by stacker cranes that access each storage position or picking location and can operate up to a height of 40 metres.

High-bay warehouses can – among other solutions - feature Honeycomb or Cantilever racking. Honeycomb storage is a proven solution at sites where long products are stored in depth and direct access to the product is required. However, depending on the product, Cantilever racking may represent the best option. Facilitating easy storage and retrieval of even the most complex or bulky materials of almost any length, Cantilever arms are connected to the upright sections of the racking structure to create the required storage levels.

Automated Storage and Retrieval Systems (AS/RS)

-

Capable of moving items weighing as much as 40 tonnes at speeds of up to 20 metres per minute, Automated Storage and Retrieval Systems (AS/RS) technology increases productivity and minimises picking and put-away errors.

AS/RS can be configured to meet a user’s load capacity, the size of the storage system and the type of products being handled – and this flexibility makes the technology suitable for a wide range of applications across many different industry sectors.

The right material handling equipment is fundemental to the efficient performance of any busy production facility.

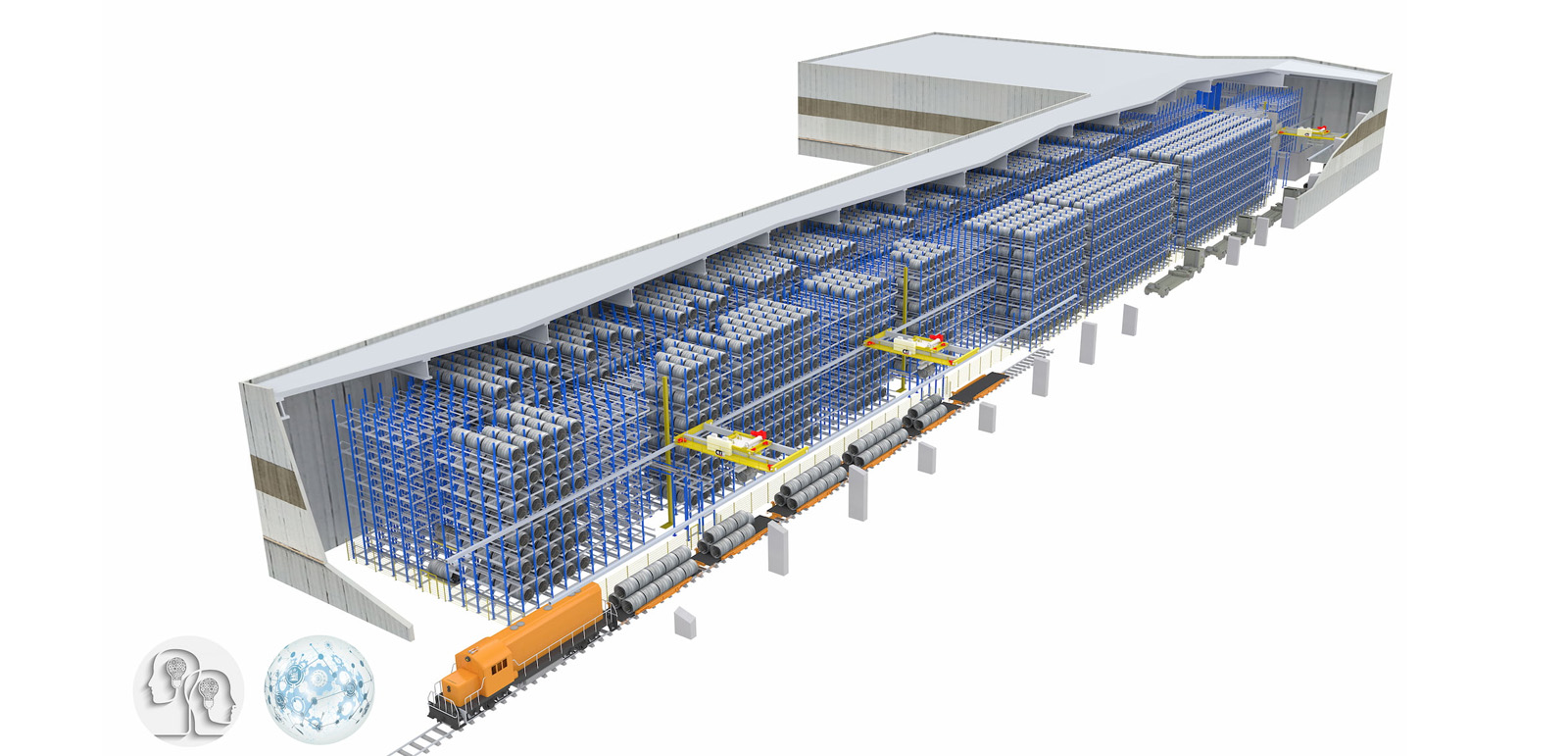

Reels and Coils - Steel

- Reels and coils of steel require specialised storage and handling systems tailored to an individual company’s unique set of requirements. As well as the size and weight of the product, a host of other factors will determine the type of solution that best suits an organisation’s intralogistics needs.

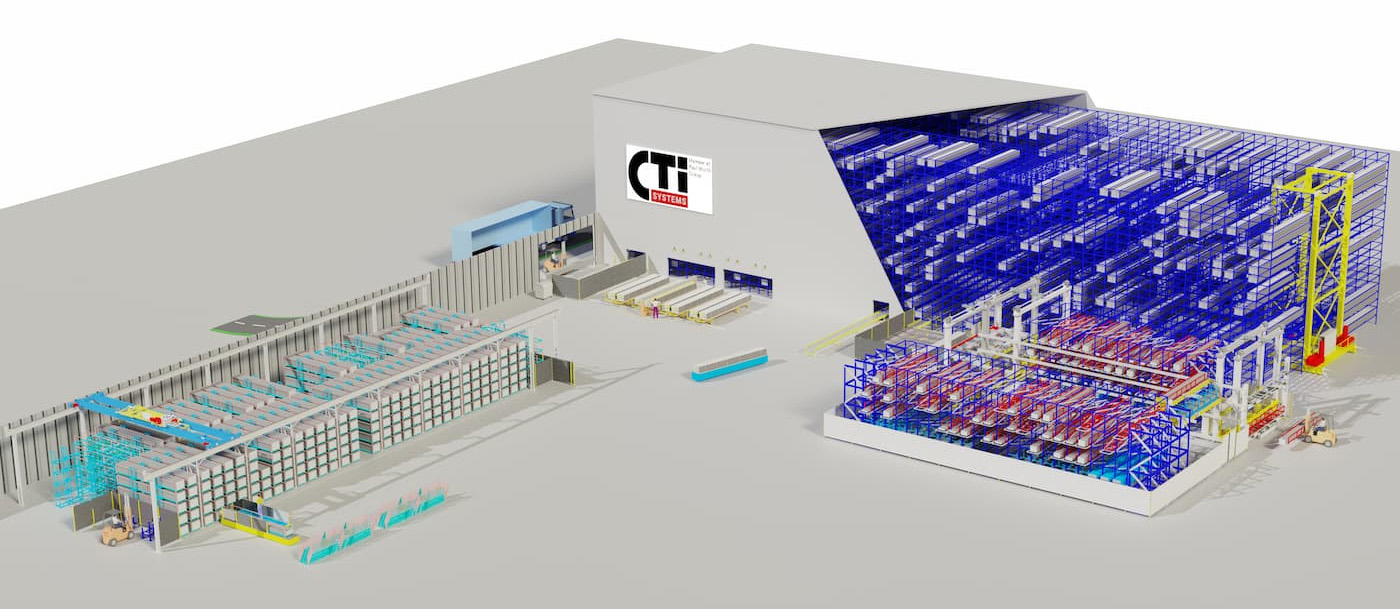

Storage Systems

-

Fulfilling the demands of every unique application

In many countries throughout the world, good quality, industrial buildings with ample floorspace are in short supply. As a result, it is essential to make optimum use of every single cubic metre of storage space available – from the floor to the eaves - within each facility.

No matter how bulky, heavy or unusually-shaped the products that are being stored may be, CTI Systems always uses the most appropriate technology to design bespoke storage solutions that fulfill the demands of every unique application.

Handling and Transport Systems

-

Suit every client’s unique needs

The materials handling equipment and intralogistics processes deployed to transport essential component parts or goods within the factory building are fundamental to the efficient performance of any busy production facility.

Internal handling and transport solutions can be either floor-based or mounted overhead. Both types offer benefits and the system that best suits your organisation’s needs will depend upon a number of factors.

For example, while systems based on ground-level technology tend to require a smaller financial commitment than overhead handling methods, they can take up valuable floor space. Meanwhile, because they make use of the free space below a building’s ceiling or roof, overhead systems optimise a site’s footprint, but can cost more to install than floor-level schemes.

CTI Systems offer a choice of ground-level and overhead solutions to suit every client’s unique needs.

Floor-based and Overhead Conveyor Systems

-

CTI Systems' extensive range of floor-mounted conveyor systems allow even the bulkiest loads to be transported throughout a production site quickly and efficiently.

Used within pre-production buffer storage zones, production lines and testing, commissioning and shipping areas, CTI Systems' conveyor solutions are designed to undertake the most complex tasks and every component part’s robust design and build quality ensures that CTI's conveyor-based handling systems perform reliably and effectively even when deployed within the harshest industrial environments.

Conveyor technology available from CTI Systems includes:

- Monorails

- Roller conveyors, heavy duty conveyors, skid conveyors

- Bespoke chain conveyors

- Lifting systems

- Turntables

- Closed chain conveyors

- Belt conveyors

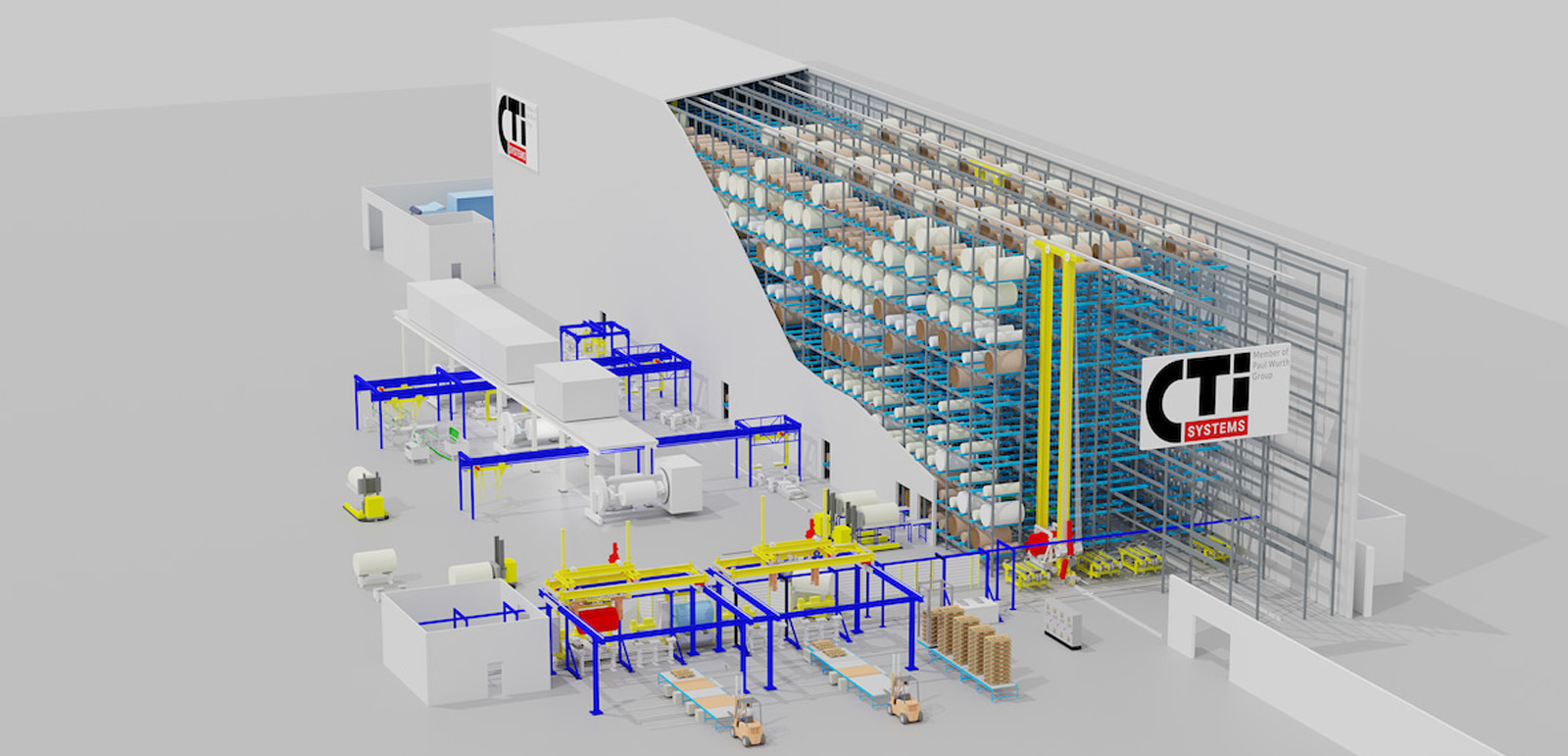

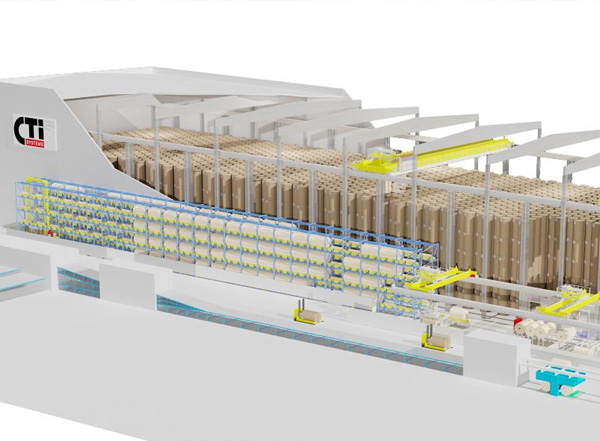

Reels and Coils - Paper, Foil and Cardboard

- Companies that manufacture or use reels of paper, foil or cardboard rely on expertly designed storage, handling and transport systems. By reducing the potential for product damage to an absolute minimum, CTI Systems’ intralogistics solutions for reels and coils minimise waste and losses.

High-bay Storage Systems

-

While often a feature of new clad-rack building projects, high-bay storage systems can also be designed to operate within existing facilities. Solutions can be developed that are compatible with the physical dimensions of the customer’s site as well as the characteristics of the products stored within it. The aisles of high-bay storage systems are served by stacker cranes that access each storage position or picking location and can operate up to a height of 40 metres.

High-bay warehouses can – among other solutions - feature Honeycomb or Cantilever racking. Honeycomb storage is a proven solution at sites where long products are stored in depth and direct access to the product is required. However, depending on the product, Cantilever racking may represent the best option. Facilitating easy storage and retrieval of even the most complex or bulky materials of almost any length, Cantilever arms are connected to the upright sections of the racking structure to create the required storage levels.

While often a feature of new clad-rack building projects, high-bay storage systems can also be designed to operate within existing facilities. Solutions can be developed that are compatible with the physical dimensions of the customer’s site as well as the characteristics of the products stored within it. The aisles of high-bay storage systems are served by stacker cranes that access each storage position or picking location and can operate up to a height of 40 metres.

High-bay warehouses can – among other solutions - feature Honeycomb or Cantilever racking. Honeycomb storage is a proven solution at sites where long products are stored in depth and direct access to the product is required. However, depending on the product, Cantilever racking may represent the best option. Facilitating easy storage and retrieval of even the most complex or bulky materials of almost any length, Cantilever arms are connected to the upright sections of the racking structure to create the required storage levels.

Automated Storage and Retrieval Systems (AS/RS)

-

Capable of moving items weighing as much as 40 tonnes at speeds of up to 20 metres per minute, Automated Storage and Retrieval Systems (AS/RS) technology increases productivity and minimises picking and put-away errors.

AS/RS can be configured to meet a user’s load capacity, the size of the storage system and the type of products being handled – and this flexibility makes the technology suitable for a wide range of applications across many different industry sectors.

The right material handling equipment is fundemental to the efficient performance of any busy production facility.

Stacked Storage Systems

- Because no racking structure is required, floor-stacked storage schemes are a cost-efficient solution. Loads are simply stacked at floor level – one on top of another or in cassettes. Depending on the product, stacking heights of 6 or 7 levels can be achieved with this highly compact solution – which is widely used at facilities where floor space is restricted. CTI Systems' warehouse management software ensures access to the required load.

Floor Storage Systems

- When a building’s floor-to-eaves height is too restricted to accommodate high-bay storage technology, CTI Systems can design automated storage systems that store materials directly on to the facility’s floor. Suitable for many different industries and product-types, floor storage systems are usually served by automated overhead cranes. Offering fast and direct access, each CTI floor storage system is designed to suit site conditions and the application’s throughput requirements.

Automated Guided Vehicles (AGVs)

-

A highly flexible solution for delivering components to assembly lines or transporting inventory within a facility, Automated Guided Vehicles (AGVs) are a popular option with users operating in diverse industries.

Whether they’re being used to transport heavy loads such as steel coils or paper reels, aircraft fuselages or automotive components, AGVs can perform independently or be integrated into the most complex automated material flow systems.

AGVs offer the user a host of benefits. For example:

- Their ability to operate around-the-clock 24/7 increases productivity;

- They enhance the safety of the working environment;

- AGVs deliver reduced operating costs and free up shop-floor personnel to focus on other areas of the business.

Floor-based and Overhead Conveyor Systems

-

CTI Systems' extensive range of floor-mounted conveyor systems allow even the bulkiest loads to be transported throughout a production site quickly and efficiently.

Used within pre-production buffer storage zones, production lines and testing, commissioning and shipping areas, CTI Systems' conveyor solutions are designed to undertake the most complex tasks and every component part’s robust design and build quality ensures that CTI's conveyor-based handling systems perform reliably and effectively even when deployed within the harshest industrial environments.

Conveyor technology available from CTI Systems includes:

- Monorails

- Roller conveyors, heavy duty conveyors, skid conveyors

- Bespoke chain conveyors

- Lifting systems

- Turntables

- Closed chain conveyors

- Belt conveyors

- Shuttle systems

Slabs and Ingot Packs

No matter how bulky, heavy or unusually-shaped the casting products may be, CTI Systems always use the most appropriate technology to design bespoke solutions that fulfil the storage and handling demands of each individual manufacturer’s application.

High-bay Storage Systems

-

While often a feature of new clad-rack building projects, high-bay storage systems can also be designed to operate within existing facilities. Solutions can be developed that are compatible with the physical dimensions of the customer’s site as well as the characteristics of the products stored within it. The aisles of high-bay storage systems are served by stacker cranes that access each storage position or picking location and can operate up to a height of 40 metres.

High-bay warehouses can – among other solutions - feature Honeycomb or Cantilever racking. Honeycomb storage is a proven solution at sites where long products are stored in depth and direct access to the product is required. However, depending on the product, Cantilever racking may represent the best option. Facilitating easy storage and retrieval of even the most complex or bulky materials of almost any length, Cantilever arms are connected to the upright sections of the racking structure to create the required storage levels.

Floor Storage Systems

- When a building’s floor-to-eaves height is too restricted to accommodate high-bay storage technology, CTI Systems can design automated storage systems that store materials directly on to the facility’s floor. Suitable for many different industries and product-types, floor storage systems are usually served by automated overhead cranes. Offering fast and direct access, each CTI floor storage system is designed to suit site conditions and the application’s throughput requirements.

Overhead and Suspended Cranes

-

At facilities with varied handling requirements, automatic crane technology can represent the optimum transport solution.

CTI’s crane systems perform a range of highly complex tasks that are vital to the safe and efficient production cycles of a range of clients operating across all kinds of manufacturing industries.

Able to transport loads weighing up to 65 tonnes quickly and safely, the range of cranes within CTI Systems' portfolio can be incorporated within a manual, semi-automated or fully-automated production process, while CTI’s ‘grab and load’ suspension systems are tailored to meet the precise requirements of every application and the load to be transported.

Often referred to as ‘process cranes’, automatic cranes can be built around a choice of overhead, interlocking or travelling crane design, but they are fully integrated within the production process.

With PLC-controlled operation, automatic cranes are usually fitted with a custom-built grab attachment, interlocking systems, indexing units or other devices to suit the required application.

Suitable for every client’s unique needs

-

The materials handling equipment and intralogistics processes deployed to transport essential component parts or goods within the factory building are fundamental to the efficient performance of any busy production facility.

Internal handling and transport solutions can be either floor-based or mounted overhead. Both types offer benefits and the system that best suits your organisation’s needs will depend upon a number of factors.

For example, while systems based on ground-level technology tend to require a smaller financial commitment than overhead handling methods, they can take up valuable floor space. Meanwhile, because they make use of the free space below a building’s ceiling or roof, overhead systems optimise a site’s footprint, but can cost more to install than floor-level schemes.

CTI Systems offer a choice of ground-level and overhead solutions to suit every client’s unique needs.

Liquid Metals

- Handling hot liquid metals involves many potential hazards. CTI Systems design systems that prioritise safety to mitigate the risk of potentially costly accidents in the iron and steel industries.

Floor-based and Overhead Conveyor Systems

-

CTI Systems' extensive range of floor-mounted conveyor systems allow even the bulkiest loads to be transported throughout a production site quickly and efficiently.

Used within pre-production buffer storage zones, production lines and testing, commissioning and shipping areas, CTI Systems' conveyor solutions are designed to undertake the most complex tasks and every component part’s robust design and build quality ensures that CTI conveyor-based handling systems perform reliably and effectively even when deployed within the harshest industrial environments.

Conveyor technology available from CTI Systems includes:

- Monorail

- Roller conveyors, heavy duty conveyors, skid conveyors

- Bespoke chain conveyors

- Lifting systems

- Turntables

- Closed chain conveyors

- Belt conveyors

- Shuttle systems

Overhead and Suspended Cranes

-

At facilities with varied handling requirements, automatic crane technology can represent the optimum transport solution.

CTI’s crane systems perform a range of highly complex tasks that are vital to the safe and efficient production cycles of a range of clients operating across all kinds of manufacturing industries.

Able to transport loads weighing up to 65 tonnes quickly and safely, the range of cranes within CTI Systems' portfolio can be incorporated within a manual, semi-automated or fully-automated production process, while CTI Systems' ‘grab and load’ suspension systems are tailored to meet the precise requirements of every application and the load to be transported.

Often referred to as ‘process cranes’, automatic cranes can be built around a choice of overhead, interlocking or travelling crane design, but they are fully integrated within the production process.

With PLC-controlled operation, automatic cranes are usually fitted with a custom-built grab attachment, interlocking systems, indexing units or other devices to suit the required application.

Manipulators and other handling devices

- A range of handling devices that enable loads to be transported, rotated, lifted or turned can be supplied to feed and remove materials, components to and from production machinery, furnaces, presses etc. with precision and maximum on-site safety.

Aircraft Manufacturing and Maintenance

- From the assembly of independent components to the efficient storage of aircraft parts, CTI Systems offer individual and flexible concepts and systems that ensure that aircraft are serviced safely, economically and in the most time-efficient way possible.

Commercial Vehicles – Material Flow, Painting and Assembly

-

Every manufacturer of commercial vehicles – from semi-trailers, lorries, vans and buses to agricultural and construction equipment – has to move bulky and heavy component parts through the factory.

And, with the need to maximise output efficiency now more important than ever before, automated processing techniques that reduce component travel times and cut production costs are seen as one of the keys to competitive vehicle production.