- Offer Profile

- KABELSCHLEPP supplies steel, highgrade stainless

steel and solid plastic cable carriers and plastic cable carriers with

aluminium stays (Hybrid cable carriers), in standard sizes or tailor made.

KABELSCHLEPP electrical cables were specially developed, optimized and tested for use in cable carrier systems.

TOTALTRAX is KABELSCHLEPP's complete, fully-harnessed cable carrier system.KABELSCHLEPP supplies fully developed, safe systems that protect guideways, spindles and axles from contamination and damage.

Cable Carrier Systems

- We supply steel, highgrade stainless steel and solid

plastic cable carriers and plastic cable carriers with aluminium stays

(Hybrid cable carriers), in standard sizes or tailormade to an individual

customer’s requirements in millimetre units.

Our scope of supply ranges from small units of only a few millimetres as for an inkjet printer to giant chains for oil platforms where the chain weighs several tonnes.

With properties suited to all application situations, for example stable and robust, with fixed chain widths or variable widths, for long unsupported lengths and 3D applications. Particularly quiet and lightweight, in a covered design and quickly openable. Or for extreme conditions, for example heat-resistant or suitable for clean room environments.

Solid plastic cable carriers with fixed chain widths

-

- Economically priced solutions for standard applications

- Types with fixed or openable brackets

- Many types available immediately ex-stock world wide

- Fast cable laying by simply pulling/pressing the cables in (PLUS)

-

- Economically priced solutions for standard applications

EasyTrax 0320

- Extremely quick cable laying, extra-stable thanks to

two-component technology

- Very fast cable laying by simply pressing in the cables

- Very high utilization factor due to flexible crossbars swivelling in the direction of the carrier and not in the cable space

- Stable chain construction

- Extensive unsupported length

Cable carriers with variable chain widths

- Small, light cable carrier for unsupported

applications

- Low vibration and quiet operation

- Optimal for short travel lengths and high travel speeds

- Gentle on the cables, since there is almost no polygon effect

VARIO-LINE

K Series

- Cost-effective, robust cable carrier – also suitable

for large additional loads

- TÜV design approved in accordance with 2PfG 1036/10.97

MASTER Series

- Quiet and weight-optimized cable carriers

- Low intrinsic weight

- Favorable ratio of inner to outer dimensions

- Standard bend radii, applicationspecific intermediate radii upon request

- Completely enclosed types, see MASTER TUBES

M Series

- Multivariable cable carrier with extensive accessories

and stay variants

- TÜV design approved in accordance with 2PfG 1036/10.97

TKP-Series

- Easy to assemble, stable cable carriers with variable dimensions

QUANTUM

- Cable carrier with large inside height

- Large dimensions

- Low intrinsic weight

- TÜV design approved in accordance with 2PfG 1036/10.97

Covered Cable Carriers

- Cable carrier with large inside height

- Large dimensions

- Low intrinsic weight

- TÜV design approved in accordance with 2PfG 1036/10.97

TUBE SERIES

-

- Covered cable and hose carriers with plastic or aluminium cover systems

and completely enclosed carrier tubes

- For protection of the cables for applications where chips or severe contamination occur

-

- Covered cable and hose carriers with plastic or aluminium cover systems

and completely enclosed carrier tubes

UNIFLEX TUBES

- Proven solid cable carriers with fixed chain widths

- Solid plastic

- Easy to open

- Robust, double stroke system for long unsupported lengths

- Particularly high torsional rigidity

MASTER TUBES

- Quiet and weight-optimized cable carriers

- Extremely quiet due to internal noise damping system

- Favorable ratio of inner to outer dimensions

- Standard bend radii, application specific intermediate radii upon request

- Variable pretension for many different applications possible

MT Series

- Multivariable cable carrier with extensive accessories

- Aluminium cover system in 1 mm width sections, plastic cover system in 8 or 16 mm width sections available

- Can be opened quickly on the inside and outside for cable laying

- Extremely robust due to stable plate construction

- Enclosed stroke system not sensitive to dirt/contamination

TKC-Serie

- Easy to assemble, stable cable carriers with variable

dimensions

- Plastic covers available in 50 mm width sections

- Can be opened quickly on the inside and outside for cable laying

- Extremely robust due to stable plate construction

- Universal connectors (UMB)

- Many separation options for the cables

- Replaceable glide shoes for long service life for gliding applications

XLT Series

- Cable and hose carrier with large inside height

- Aluminium cover systems available in 1 mm width sections

- Large dimensions

- Can be opened quickly on the inside and outside for cable laying

- Highly wear-resistant, replaceable glide shoes available – resulting in minimal wear at high speeds, sliding in the guide channel

CONDUFLEX

- Closed designer cable carrier

- Attractive appearance owing to high-grade steel brackets and fiberglass reinforced polyamide frame

- Very well sealed design

- With protective straps ideal for hot chips

- Optimum protection for cables and hoses

Steel cable carriers – solutions for extreme applications

- Enclosed cable carrier with flexible metal helical

tube

- Very well sealed design

- Ideal in case of hot metal chips

- Optimum protection for cables and hoses

- Unsupported thanks to the inserted, pre-tensioned steel band

ROBOTRAX

STEEL-LINE

S/SX Series

- Extremely robust and stable steel chains

- Extremely robust and stable steel chains for heavy mechanical loads and harsh environmental conditions

- Very long unsupported lengths also for large additional loads

- Various types available in different dimensions

- Covers with aluminium cover system or steel strip possible for protection of the cables

CONDUFLEX

- Closed designer cable carrier

- Attractive appearance owing to high-grade steel brackets and fiberglass reinforced polyamide frame

- Very well sealed design

- With protective straps ideal for hot chips

Optimum protection for cables and hoses

Ready-to-assemble cable carrier system

- Enclosed cable carrier with flexible metal helical

tube

- Very well sealed design

Ideal in case of hot metal chips - Optimum protection for cables and hoses

- Unsupported thanks to the inserted, pre-tensioned steel band

- Very well sealed design

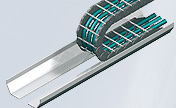

TOTALTRAX Turn-Key Systems

-

- One supplier and contact person for the complete system.

- We develop, design and supply all components required for your individual cable & hose carrier system.

-

- One supplier and contact person for the complete system.

for cable carriers

Accessories

-

- Guide channels

- Support trays

- Strain relief devices

-

- Guide channels

Guide channels

- Guide channels serve to provide operational safety for plastic cable carriers where there are long travel lengths.

Support trays

- A flat surface is required for the safe operation of the cable carrier. If this is not available on site, a support tray must be provided.

Strain relief devices

- The strain relief of the cables depends on the type of cable, the length of the cable carrier and the installation position.

Cables for Motion – cables for cable carriers.

- Durable – reliable – cost-effective

We use our over 50 years of experience to continuously develop and refine the “insides“ – i.e. the Cables for Motion – and to constantly adapt them to the market requirements.

Our cable ranges meet the highest quality standards in order to ensure availability of your systems and installations. With the Cables for Motion range, we offer a selection of cables which are cost-effective, flexible and extremely durable. A key factor for our cables is their tested and proven operational reliability, which meets all applicable standards and directives.

Several hundred cable types, stored constantly in our cable warehouse, secure a fast availability all around the world. We deliver according to your requirements, no minimum quantities, each length without cutting costs.

PVC control cables

Control 200 & Control 200 C-

- Cost-effective standard control cables for a wide range of applications

- Self-supporting and gliding applications with normal load for average bend radii as well as speeds

- Black outer jacket for high UV-resistance, also suitable for outdoor applications; co-extruded ICC color code Identification based on DESINA color code simplifies the correct cable installation into the carrier

-

- Control cables for more challenging applications

- Self-supporting and gliding applications with small bend radii and high speeds

- Black outer jacket for high UV-resistance, also suitable for outdoor applications; co-extruded ICC color code

- Identification based on DESINA color code simplifies the correct cable installation into the carrier

-

- High-quality PUR control cables for even the most challenging applications

- Self-supporting and gliding applications with smallest bend radii and very high speeds; especially suitable for long travel lengths

- For indoor and outdoor applications

- Optimized bundle-stranding > 8 strands for highest availability

- Shielded design with continuous bending hi-flex braided shield

PVC power cables

-

- High-quality, robust PVC motor cables for challenging applications

- Self-supporting and gliding applications for small bend radii and high speeds

- Particularly suitable for long travel lengths

- Suitable for indoor and outdoor applications

- High wear-resistant and robust outer jacket

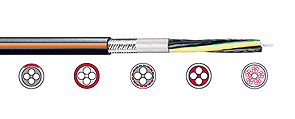

PUR power cables

-

- High-quality, robust PUR motor cables for even the most challenging applications

- Self-supporting and gliding applications for very small bend radii and very high speeds

- Particularly suitable for long travel lengths

- For indoor and outdoor applications

- High wear-resistant and nick-resistant outer jacket

- Individual strands with double-jacket

- Shielded design with continuous bending hi-flex braided shield

PUR data cables

-

- Super-flexible, continuous bending hi-flex and robust PUR data cables; i = with inner jacket

- Pair-stranding cabling and complete shielding – suitable for critical EMC environments

- For universal and extremely challenging applications in cable carriers

- For self-supporting and very long gliding applications with small bend radii

- Particularly suitable for high speeds and accelerations

- Double shielded CD version

BUS-/LWL-/Coaxial cables

-

- Super-flexible, continuous bending hi-flex and robust PUR-BUS-/Koax-/LWL cables

- For universal and extremely challenging applications in cable carriers

- For self-supporting and long gliding applications with small bend radii

PUR system cables

-

- High-quality PUR combi-cables for challenging system applications

- Self-supporting and gliding applications for small bend radii and high speeds

- For indoor and outdoor applications

AReliable transmission according to SIEMENS-, INDRAMAT, Heidenhain or Baumüller specifications

Pre-assembled cables

- You need connection-ready harnessed bus cables?

Or harnessed signal- or power cables for drives – in accordance to SIEMENS specifications?

Connection-ready harnessed cables:- easy to order with just order number and cable length

- based on SIEMENS specifications

- Just-in-time delivery of three work days

- no minimum order quantities

- individual cable lengths without surcharge

- checked and monitored for reliable connection

TOTALTRAX Turn-Key Systems - Ready-to-assemble cable carrier system

- You know what product you need – we supply it to

you completely harnessed

One supplier and contact person for the complete system. We develop, design and supply all components required for your individual cable & hose carrier system.

Everything from a single source- Consulting

- Planning

- Design

- Cable carriers

- Electrical cables

- Complete guarantee

- Hydraulic hoses

- Pneumatic hoses

- Plug-and-socket connectors

- Assembly plates

- Complete assembly of all components

Conveyor systems

- Reliability and experience based on tradition

Our scraper belt, hinged belt and belt conveyors embody more than 30 years of experience. Systematic further development of our products and adaptation of their functions for use with the latest generation of machines guarantees you the utmost level of reliability.

Hinged belt conveyors

- Proven for a wide range of disposal tasks

Structure- Stable metal plate construction

- Standardized housing cross-section with variable width

- Robust worm gear motor with torque switching

- Customized discharge height

- Customized incline standards = 30°, 45° and 60°

- Floor mounting or as a push-in version into the machine base

Transportation of the material takes place on the upper trough of a revolving hinged belt. Drivers ensure transport of the material up the inclined section. For wet machining the cooling lubrications are collected in the conveyor housing and can be fed back into the machine circuit via an optionally available coolant container or a pump station.

Our hinged belt conveyors can be used either as stand-alone conveyors at machine tools, or as linked conveyor systems. Depending on the design, the material to be conveyed is brought to the required height at a defined incline and then discharged.

Scraper conveyors

- For disposal of small materials

Structure- Stable metal plate construction

- Standardized housing cross-section with variable width

- Robust worm gear motor with torque switching

- Customized discharge height

- Customized incline standards = 30°, 45° and 60°

- Floor mounting or as a push-in version into the machine bas

Transport of the material takes place via drivers which push the material along the floor of the housing towards the discharge.

Cooling lubricants are collected in the conveyor housing and can be fed back into the machine circuit via an added-on container or a pumping unit. Our scraper conveyors can be used as stand-alone conveyors at machine tools or as linked conveyor systems.

Depending on the design, the material to be conveyed is brought to the required height at a defined incline and then discharged.

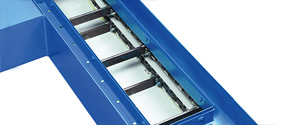

Belt conveyors

- The all-rounders – also for parts with sharp edges

Structure- Housing made of steel plate

- Oil-resistant belt

- Protective motor switch

- Convex return shafts

- Shafts with ball bearings

- Adjustable belt tension

Our belt conveyors are predominantly used on punch-nibbling machines, for transporting punching scrap and punching trimmings.

However, other parts can also be transported, such as waste parts from plastic injection machines. The transport belt of the conveyor is resistant to oil and grease.