- Offer Profile

-

How We Power the Future of Commerce

Dematic is your trusted partner in designing, building, and supporting intelligent automated solutions. We help companies like yours power the future of commerce in manufacturing, warehousing, and distribution.

Solutions

Micro-Fulfillment Systems & Solutions

-

Rapid Fulfillment with Automated Technology and Advanced Software

Time, space, and labor costs never decline. In fact, they continually grow and expand, placing pressure on supply chains to figure out how to do more with less. To maximize your resources and assets you must make the decision to automate at a level that’s right for your business. Micro-fulfillment may be the answer.

Distribution Center

-

Fully automated solution for case or pallet store delivery.

Hub and spoke model

Fully-automated solution

Pallet or case to store delivery

Long term planning & investment

Capital Investment: $$$

Dark Store

-

n-store or third-party location that services dense, urban areas with orders batched and delivered the next day.

In-store or third-party location

Services dense, urban areas

Automation and labor-based solution

Batched orders with next day delivery

Capital Investment: $$

Micro-Fulfillment System

-

A small footprint system, located in a retail store, that fulfills orders in one hour.

Located within retail store

Accessible automation with a small footprint

One-hour fulfillment

Fast implementation

Capital Investment: $

Mixed Case Fulfillment

-

Mixed Case Fulfillment – Mixed Case Palletizing Solutions

Managing high labor costs, space constraints and time limitations don’t have be ongoing burdens for companies that want to optimize their warehouses and distribution centers. For mixed pallet loads, ensuring high performance and compact transportation can be difficult without a system to address and mitigate unforeseen circumstances.The Dematic Mixed Case Fulfillment solution optimizes warehouse space with a cube layout that makes use of vertical space. The solution reduces transportation costs with optimally sized pallet loads and decreases the need for warehouse operational staff.

The Dematic Mixed Case Fulfillment solution also improves retail replenishment by building aisle-ready pallets that simplify restocking. The automation provides significant throughput increases and prepares your operations for unforeseen disruptions.

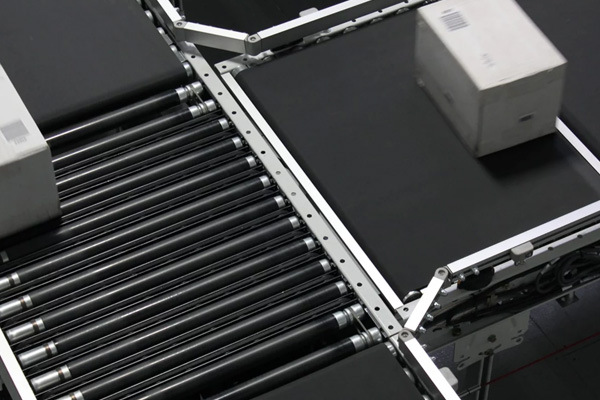

Case and Tote Conveyors

-

Durable and versatile conveyor technology designed for heavy unit-loads

Benefits of pallet conveyor systems

Durable design extends equipment life: Heavy-duty chain-driven units handle contaminates and wide temperature variations. Dematic pallet conveyor systems operate smoothly even in facilities open to dirt, dust, and outdoor temperatures.Compact systems reduce system footprint: Dematic pallet conveyor systems maximize floor space and minimize load handling. Lifts provide transfer positions for forklifts or connect conveyor lines of differing heights. They can also raise or lower loads to feed production equipment, overhead monorail systems, or palletizing stations.

Pallet Conveyor System

- High performance systems for automatic building and deconstructing of mixed-case pallets

Benefits of palletizing and depalletizing systems

Options for full or partial automation

Precise sequencing of cases on the pallet

Reduced labor costs in warehouse

Customized dispatch units for easy in-store replenishment

High pallet density for lower transport costs

Palletizing Systems

-

Highly flexible, energy-efficient storage and retrieval systems

Benefits of mini-load AS/RS

High-density storage: Storage and Retrieval Machines (SRMs) rapidly move loads in and out of a secured rack structure that can be over 20 meters tall. With multi-deep storage options, Dematic Mini-Load AS/RS systems offer outstanding space utilization in ambient, chilled, or freezer environments.Rapid access with minimum labor: Dematic Mini-Load SRMs offer the high-speed rates while moving up to six loads in a single cycle. The patented mast design weighs 20% less than traditional rigid masts and has friction or belt drive options. Intelligent software and controls allow these systems to operate unattended around the clock.

Mini-Load AS/RS

-

Next-generation shuttle AS/RS for automated storage and retrieval of cartons, small parts, or other stored goods

Benefits of multishuttle

Exceptionally high throughput rates: Dual Cycle, Drive Through, and Tandem lift configurations — combined with high-speed shuttles and intelligent controls — provide rapid access to inventory with throughputs as high as 1,200 loads in-and-out per hour.High-density storage: The multi-depth, intelligent storage of varying size cartons creates outstanding space utilization in ambient, chilled, or freezer environments.

Dematic Multishuttle

-

Next-generation shuttle AS/RS for automated storage and retrieval of cartons, small parts, or other stored goods

Benefits of multishuttle

Exceptionally high throughput rates: Dual Cycle, Drive Through, and Tandem lift configurations — combined with high-speed shuttles and intelligent controls — provide rapid access to inventory with throughputs as high as 1,200 loads in-and-out per hour.High-density storage: The multi-depth, intelligent storage of varying size cartons creates outstanding space utilization in ambient, chilled, or freezer environments.

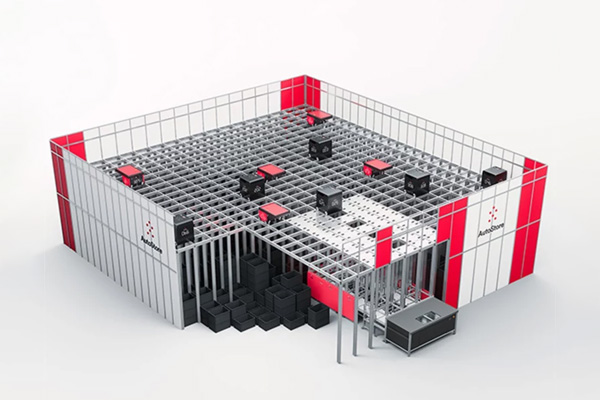

Autostore

-

Ultra-high density storage and buffer system ideal for piece picking

Benefits of AutoStore

Space optimization: AutoStore optimizes storage density to maximum capacity, allowing four times the inventory in the same space compared to conventional storage systems – and twice that of other automated systems.Maximized productivity and accuracy: Order fulfillment with AutoStore is based on the goods-to-person (GTP) principle, eliminating worker travel time to pick locations and supporting high picking productivity, the removal of dedicated pick faces (no slotting, re-slotting, manual replenishment), excellent product security/inventory accuracy, increased order processing speed, and improved order accuracy. Workers get a quiet, clean environment, reduced fatigue factors, and ergonomically designed workstations.

Software

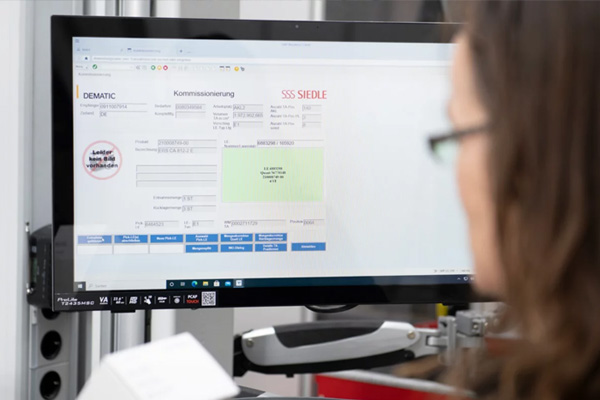

- Dematic software optimizes labor, equipment, and processes. It unifies all operational, maintenance, and equipment data within and across facilities.

Benefits of Dematic software

Dematic Operate makes decisions in real-time throughout the facility. The software also provides advanced reporting and analytics to help you make informed and insightful decisions. Once in place, Dematic Operate increases throughput and reduces operational costs using these and other optimization features: Space, Labor, Workflow, Uptime

Systems

Receiving

-

Optimize Operations Right from the Start

The labor crisis is shrinking your business profits every day, and manual inventory management produce unpredictable fulfillment results. In the end, your receiving strategy affects customer satisfaction and loyalty…and your bottom line.Automated receiving systems reduce your dependence on labor and reduce the high operating costs of manual processes. With Dematic receiving systems, you have predictability from the time inventory enters your facility, setting the optimal course for every order that leaves your operation.

Receiving

-

Whether bringing raw materials into a production facility or finished goods into a distribution center, efficient management of your supply chain starts at receiving.

All incoming materials are verified and checked for quality and quantity before being sent to high-density storage. Dematic iQ software ensures inventory accuracy, provides real-time inventory visibility, and intelligently routes the inventory for efficient retrieval. Dematic Receiving solutions support a range of manual to fully automated receiving and putaway of your inbound goods.

woman packing pallet at station

How Receiving Works

Incoming pallets (unit loads) and cases are unloaded and verified against manifests and purchase orders.

Items are inspected for quality, quantity, and damage.

If necessary, items are removed from original packaging (detrash) and placed in totes for storage in high-density buffers.

Items are directed to the most optimal storage location or dispatch area (cross-dock).

Returns Handling

-

Dematic returns handling solutions process items quickly and efficiently so you can restore salable merchandise to primary or short-term storage, depending on demand.

Dematic software guides each process and reduces the labor associated with processing inbound handling materials. It also facilitates inspection and reconditioning workflows before items are returned to stock. Finally, the software directs the workflow and ensures that items are returned to inventory accurately — whether for storage or sending back to a store.

returns-handling-1.jpg

How Returns Handling Works

Operators open the incoming packages and check each item against the expected receipt.

Items may undergo a detailed inspection and reconditioning (repack, labeling, etc.) before they can be returned to stock.

Salable products are returned to the primary storage locations or, if in high demand, placed in high-density short-term buffers for rapid fulfillment of incoming orders.

Cross-Docking

-

When cross-docking, Dematic solutions eliminate costly, space-intensive storage of inbound products. Whether you’re moving pallets of product or sorting high volumes of incoming cartons/cases to outbound trailers, Dematic has the cost-effective solution for fast, accurate cross docking.

Dematic software fully automates sortation by adjusting equipment speed depending on demand and volume. The result is an energy-efficient solution that reduces equipment wear and minimizes labor costs.

Shipping conveyor shown in front of dock doors

How Cross-Docking Works

Inbound cases are unloaded from incoming trailers and placed on induction conveyors.

Cases are scanned to identify destination.

Dematic high-speed sortation systems route the cases to shipping lanes.

Transport

-

Seamless. Safe. Reliable. Optimizing Your Facility for Today and Beyond.

Maintaining seamless facility performance and keeping product moving quickly, accurately, and safely are important for all organizations. The success of your business depends on knowing where your items are and where they’re going, and then trusting that the technology you’ve invested in will protect your goods from damage.It’s not always easy to monitor what’s happening within your facility’s four walls, but automation provides that critical visibility while also simplifying your processes and reducing errors. With automation, you can streamline your operations, gain immediate value from your investment, and reduce the number of wasted movements in your facility.

Automated Guided Vehicles (AGVs)

-

AGVs are automated industrial trucks used to lift, rotate, and shift materials in your facility. Dematic AGVs fetch and carry loads to and from racking, store and retrieve in block-stacks or deep-stack lanes, and deliver and collect at conveyors or process machines. They safely and securely increase process efficiency and improve business profitability — all without human intervention.

Typical AGV applications include:

Transport from receiving to production/warehouse

Transport between production areas/work-in-process buffers

Transport between production areas and warehouse areas

Stacking and storing (very narrow aisle, wide aisle and drive-in racking, deep stacking, block storage)

Roll handling

End-of-line automation (packing machines, palletizers, stretch wrappers)

Transport in consolidation and dispatch areas

Autonomous Mobile Robots (AMRs)

-

AMRs are industrial robots that lift and transport materials in your facility. Dematic AMRs safely navigate around people, equipment, and inventory by reading QR codes on the facility floor or by using Simultaneous Localization and Mapping (SLAM) to sense surroundings and obstructions.

Typical AMR applications include:

Moving pallets between functional areas (receiving to storage, picking to shipping)

Line-side supply and delivery

What is the difference between an AMRs & AGVs?

AMRs are similar to AGVs, but with two major exceptions:AMRs typically move lighter loads faster.

AMRs are more adaptable, especially when selecting routes and avoiding obstacles.

AMRs open up expanses of warehouse space typically consumed by conveyors.

Conveyors and Sorters

-

Conveyors

Dematic conveyors provide simple operational capabilities that keep distribution centers running at peak capacity for daily on-time fulfillment.Typical conveyor applications include:

General routing and transport of product

Cross-docking

Pallet transport

Embedded Towline

-

Embedded towlines automatically carry goods to destinations using carriers connected to an in-floor chain conveyor. The Dematic Embedded Towline system follows a fixed route based on clearly defined floor markings.

Typical embedded towline applications include:

Repetitive forklift truck transport over long distances

Support for very high throughput operations

Continuous transport between different zones

Transport of heavy and difficult-to-move loads

Transport between different levels

Cross-docking

Storage

-

Secure Your Stock, Reduce Damage, Optimize Space, Increase Productivity and Accuracy

Whether for heavy unit loads like pallets or smaller loads like totes and cases, storage is a fundamental requirement of every distribution center.Yet storage is a paradox. On one hand it adds value by providing a critical buffer between your processes and your customer. But on the other, it adds significant real estate, building, and inventory costs.

Dematic offers a wide range of storage solutions designed to minimize and mobilize your stock. We can help you organize and control inventory on pallets, cartons (totes), and garments-on-hangers. No matter the scale of your facility, the type of inventory, or how it's packaged, our storage solutions offer your business important advantages.

Automated Storage and Retrieval Systems

-

AS/RSs help organize stock, access it quickly, optimize space, and reduce reliance on labor.

A typical automated warehouse storage system includes a high-density shelving system and robotic load handling devices, which move products in and out of shelving. For pallets, this is likely to be a storage-retrieval machine (SRM) such as the Dematic 1200-U. SRMs are also referred to as cranes. For smaller items stored in cartons or totes, this could be a miniload AS/RS or a multishuttle system.

Switching to an automated warehouse storage system from a forklift or fully manual system can vastly improve product handling efficiency and provide a safer warehouse.

Miniload AS/RS

-

Dematic provides a comprehensive portfolio of Mini-Load Automated Storage/Retrieval Systems (AS/RS) to handle the most challenging storage needs.

Ideal for manufacturing or distribution operations, Dematic Mini-Load AS/RS systems provide rapid access to trays, totes, or varying size cartons in a high-density and energy efficient storage structure.

Multishuttle

-

The Dematic Multishuttle® stores, buffers, and sequences products between bulk stock and other functions such as picking and order assembly.

The system can dramatically increase speed, storage density, accuracy, and throughput in warehouses, factories or distribution centers.

Benefits of Dematic Multishuttle

Exceptionally High Throughput Rates: Dual Cycle, Drive Through, and Tandem lift configurations — combined with high-speed shuttles and intelligent controls —provide rapid access to inventory with throughputs as high as 1,200 loads in-and-out per hour.

AutoStore™

-

AutoStore is an ultra high-density storage and buffering system for Goods-to-Person piece picking that increases the efficiency of unit picking with maximum flexibility and scalability.

Benefits of AutoStore™

Warehouse Space OptimizationGrow with Your Business

Highest Security

Energy Efficient

Garment on Hanger Storage

-

The Garment on Hanger system is an overhead storage, transport, and sortation system for fast and easy storage, retrieval, sortation, and consolidation of customer orders.

Dematic has a complete product range for all GOH transportation and sortation requirements — for example, pin conveyor, clip conveyor, unisort, and manual slick rail.

The modular design of these systems easily enables different functionalities, such as transportation, accumulation, decline/incline, and sortation.

Racking and Shelving

-

Dematic integrates high-quality storage racks and industrial shelving into turnkey systems with optional automated handling solutions.

Whether you want to maximize unused space or build a new warehouse, Dematic conventional rack solutions can be tailored quickly, easily and economically to your precise needs. Dematic pallet racking solutions are versatile, allowing you to maximize your space while at the same time giving you the flexibility to operate your manual distribution center with complete efficiency.

Light or heavy duty, Dematic gets your valuable products off the floor and into good order. Dematic shelving provides a strong purpose-designed shelving solution with intelligent picking options.

Picking

-

Automated Picking Solutions for More Efficient Operations

Effective order fulfillment has become a top priority for any company dealing with a high volume of e-commerce orders, major labor constraints, and the continual need to do more with less. Companies now are turning to technology to optimize their current operations and improve their inventory management to meet consumer demand.

Case Picking to Conveyor

-

Innovative waveless technology to guide operators by voice commands or by lights. Operators dynamically fill orders based on actual real-time conditions, ensuring accuracy, and reducing fulfillment time from hours to just minutes. Picks are made from pallets and/or case-flow racks in high-density, multi-level pick modules to maximize available space.

These systems are best suited for space-constrained operations that handle high volumes with large numbers of SKUs and work well in both ambient and temperature-controlled environments.

Case Picking to Pallet

-

Computer-generated voice commands guide operators to make quick and precise selections, instructing what to pick and where to send it. Dematic Software guides operators through every step, reducing idle walk and search time.

These systems are best suited for mid-volume operations with large numbers of SKUs and work well in both ambient and temperature-controlled environments.

General Workflow:

Layer Order Picking

Mixed Case Palletizing- Reduces the amount of labor required to build pallets with multiple layers of different SKUs. Robotic layer picking automatically creates compact, high density, store-friendly pallets. Dematic Software ensures fast, seamless, and error free picking.

Case Picking to Conveyor

-

Dramatically reduce picking labor and rapidly build high-density, store-ready pallets and carts. These fully automated or manual palletizing solutions handle a wide variety of packaging material and shapes without the need for expensive trays and tray handling systems. They are highly compact and can operate in a small footprint of facility space.

Dematic Software manages the entire operation, including building high-density pallets that match store planograms and honor crushability and SKU mixing restrictions. The solutions operate in ambient, chilled, or freezer environments and can be added to existing brownfield or greenfield facilities.

Shipping

-

Cost-effective Shipping Systems Facilitate Last Mile Logistics

A successful order fulfillment process requires a balance between hiring, training, and retention of workers while also getting orders out the door quickly, accurately, and in good condition. If the last mile of your supply chain is reliant on labor-intensive, repetitive tasks, both fulfillment efficiency and employee retention are at risk.Drive unpredictability out of the last mile by incorporating automation into your outbound processes. Dematic shipping systems create the efficiencies needed from picking orders, to dock delivery, down to trailer loading and transportation.

Packing

-

Dematic Packing solutions are more than simply preparing items for shipping. Dematic software powers the entire process to improve accuracy, reduce cycle times, use labor efficiently, and select the right-size shipping container to minimize transportation costs.

Dematic is as concerned about customer experience as you are, and value-added packing helps build customer loyalty and repeat business. Packaging options include premium packaging, catalogs, promotional offers, discount vouchers, special tags, customized labels, gifts, product samples, and thank you cards.

Shipping

-

Whether shipping full pallets or high volumes of smaller parcels, Dematic Shipping solutions provide advanced sortation, sequencing, and loading options. Managed by Dematic iQ software, Dematic Shipping solutions deliver near perfect order accuracy and reduce loading times by as much as 300%.

For palletized shipping, Dematic iQ software arranges reverse-sequence staging and loading to create the most efficient delivery. For high volume parcel shipping, Dematic offers an extensive range of case conveyor and sortation systems that can process as many as 24,000 packages per hour. Dematic Shipping solutions provide accurate and real-time information for rapid manifesting and Advanced Shipping Notice (ASN) generation.

Products

Automated Guided Vehicles - AGV Systems

- Whether your goal is reduced labor costs, higher order throughput, increased accuracy, greater productivity, or all the above, you’ve come to the right place. Automated guided vehicles (AGVs) are driverless robots used to transport materials in warehouses, distribution centers (DCs), and manufacturing facilities using designated pickup and delivery routines.

Counterbalance AGVs

- Counterbalance AGVs have counterweights at the rear of the vehicle to eliminate the need for support legs around loads (such as with Straddle AGVs). This allows the lift mast to be integrated at the front, which keeps the AGV clear of the load. Counterbalance AGVs typically replace repetitive manual forklift tasks for all single, double, or quadruple pallet applications.

Straddle AGVs

- Straddle AGVs are designed to replace repetitive manual forklift tasks. They have support legs that straddle loads with various fork designs and a slim body that provides a tight turning radius. This design allows Straddle AGVs to work in a diversity of areas and carry multiple pallets.

High-Reach AGVs

- High-Reach AGVs are designed specifically for high-bay single selective and double-deep racking, with a reach up to 10 meters. As an ideal alternative to fixed cranes in Automatic Storage and Retrieval Systems (AS/RSs), High-Reach AGVs are best used for put-away and retrieval and interfacing with manual operations.

Very Narrow Aisle AGVs

- Very Narrow Aisle (VNA) AGVs operate in narrow aisles between pallet racking. VNA AGVs operate freely in and out to bring added flexibility to operations requiring high storage density. They require less room, so more floorspace is available footprint to be dedicated to storage.

Tugger AGVs

- Tugger AGVs pull carts to transport multiple loads throughout a facility. The carts receive loads onto their inbuilt rollers either manually or automatically and are linked to the AGV with an actuated hitch. Tugger AGVs have the highest capacity for material transport among AGV types and considerably more capacity than traditional forklifts.

Load Deck AGVs

- Load Deck AGVs move unit loads between workstations in a production environment or between warehouse and production facilities. Load Deck AGVs can typically carry from one to eight unit loads to and from conveyors, stands, end-of-line equipment (palletizers, wrappers, robots), or AS/RSs.

Compact Transfer AGVs

- Compact Transfer AGVs transport materials by point-to-point transfers or between conveyors and production lines. They use lift or belt conveyor transfers, depending on the type of equipment and loads they need to handle. They have the smallest space requirements among AGVs to accommodate requirements for tighter turning circles, narrower pathways, and smaller charging areas.

Custom AGVs

- Custom AGVs are tailored to precisely meet any unique business needs to serve specific requirements for a configured solution. And even though they are customized, they can be built from reliable, off-the-shelf components to ensure easy service and support.

AutoStore™

- Meeting your customers’ demands has never been more challenging and automation is the key to survival in today’s e-commerce driven market. Powered by Dematic, the AutoStore system is a compact, scalable robotic storage and piece picking solution that flexes with your customers’ demands so that your supply chain is always ready.

AutoStore Red Line

- Red Line is the award-winning flagship modules for most users and applications. It is extremely versatile and reliable and designed for low-to-mid throughput systems.

The Red Line features the R5 Robot with its canopy design, opportunity charging, precision driving with track-sensors that recalibrate for every cell, and wireless control.

AutoStore Black Line

-

Black Line the innovative new design and technology that delivers extra performance. It is designed for high throughput systems.

The Black Line features the new B1 Robot, a slimmed down, lighter robot with a Cavity design. The B1 is packed with the latest innovations including exchangeable BattPack™ Lithium-ion battery technology and Direct Drive Wheels.

The Black Line features the RelayPort workstation, a modular workstation with a picking module and three to six buffer modules to support a high capacity and provide more flexibility.

Automated Conveyor Systems

-

Efficient Product Flow from Receiving to Shipping

Increasing throughput and capacity requirements, shorter processing times, and rising operational costs are driving the production and distribution managers to consider automation such as conveyor systems. The task of processing large quantities of conveyable inventory — cartons, cases, totes, bags, and stuffed envelopes — to pallets, skids, gaylords, tubs, and wheeled carts is ideal for convey and sort automation

Package Conveyor System

- An integrated suite of package conveyor technology, Dematic Modular Conveyor transports case, tote, tray, polybag, and parcel envelope loads efficiently and effectively. It provides a complete range of modules that create a highly efficient material flow configuration.

Pallet Conveyor System

- Dematic Pallet Conveyor uses integrated unit load conveyor technology to handle pallets, skids, tubs, or rolling carts. It transports loads efficiently and effectively, providing a full range of modules that converge to create a highly efficient material flow configuration.

Embedded Towline Conveyor System

- Dematic Embedded Towline Conveyor is a fixed path transport system for continuous flow applications. Each system is configured according to the layout and throughput rate requirements of the operation.

Pouch Sorter System

-

Raising the Bar on Complex Order Fulfillment

Customers want their orders fast, omnichannel fulfillment is a competitive advantage, managing high return rates is expensive, and labor is hard to come by. These and other realities are all creating new and unique pressures within the order fulfillment environment.Dematic Pouch Sorter is a flexible storage system that consists of pouches suspended from rolling adapters running in a track. Each pouch carries a single item, which can be identified by its radio frequency identification (RFID) tag. Items of various types can go into the pouches, including folded garments, shoeboxes, accessories, books, and general merchandise.

Items are inducted into the pouch system, which sorts, sequences, and delivers those pouches and hanging items to the packaging station for consolidation and further processing.

Loading

- Items are loaded into a pouch manually or automatically, with the option to manage oversize items in dedicated bags.

Buffering

-

Long loops (up to 100 meters) hold inducted inventory and circulate continuously. Inventory can be new items or returned items that have been inducted back into the system, and returned items stay in the buffer until needed or processed back to storage.

Items can be stored as eaches

Buffers optimize loading and packing station performance

Transport

-

Transport, divert, and merge product from various areas of the facility. Items can be routed quickly through even the most complex facility layouts.

Transport and sort irregularly shaped items that traditional conveyors and sorters cannot handle.

Sortation

- Sort and sequence items

Incorporate both wave and waveless order fulfillment strategies to meet demand efficiently

Packing

- Pick items out of the pouches and packed them into final orders, and easy integrate value-added services (VAS).

Packing solutions powered by Dematic software improve accuracy, reduce cycle times, efficiently use labor, and minimize transportation costs by selecting the right size shipping container.

Automated Sortation Systems & Solutions

-

Low, Mid, and High-rate Sortation

Every day, production and distribution operations must sort large quantities of inventory contained in cartons, cases, totes, bags, or stuffed envelopes. As service level agreements become more demanding, the pressures to perform at or above expectations grow. These realities along with higher order volumes, shorter processing times, and rising operational costs create a compelling business case for automated sortation.

Diverter Systems

- Designed for low to mid-rate sorting and to support order picking configurations that use the “container to the pick zone” or zone route fulfillment method. Dematic diverters control the flow to and from workstations, storage subsystems, and pack/ship processing. Dematic diverters include steerable wheel, right angle transfer, and horizontal belt diverters.

Linear Sortation Systems

-

Dematic linear sorters include both sliding shoe sorters and steerable wheel sorters.

These products are most often used for:Routing and sortation of inbound goods

Cross docking

Sorting cases and totes to pick modules

Carton sorting from case pick modules

Carton sorting from piece pick modules

Sort to outbound shipping doors

Circular Sortation Systems

-

The Dematic circular sorters consist of split-tray and crossbelt.

Typical applications for these sorters include:Batch pick and sort order consolidation

Crossdocking

Interlink connecting functional areas

Sort to outbound parcel shipper, area code, or route

Sort to outbound shipping doors

Pouch Systems

-

The volume and complexity of omnichannel order fulfillment has driven the need for solutions that streamline piece picking. As a result, solutions that store, transport, sort, sequence, and consolidate eaches (individual units of product) are in high demand. Pouch systems accommodate these requirements.

The Dematic Pouch System uses overhead space effectively in facilities where storage and buffering happen in tight, compact rows. The aluminum rail system allows cost-effective accumulation of inventory. In addition, the system can accommodate low, mid, and high-volume applications (typical systems range from 25,000 to 150,000 pouches). Common throughput processing rates range from 2,500 to 12,000 items per hour.

Autonomous Mobile Robots - AMR Systems

-

Growth Unlocked: Technology that Works for You

Deciding how to respond to changing needs in your business can be a daunting task. With the growth of e-commerce, businesses are facing more challenges to meet consumer demands efficiently and accurately. There is also a growing need to scale operations within current facility layouts and footprints while providing an enhanced experience for your employees - all without impacting operations. The need for warehouse automation has accelerated and reliable technology is essential for you to evolve and modernize your key operations.Like you, Autonomous Mobile Robots (AMRs) detect their environment and adapt accordingly. AMRs are industrial robots that lift and transport materials within your facility. They safely navigate around people, equipment, and inventory by reading QR codes on the facility floor or by using Light Detection and Ranging (LiDAR) to sense surroundings and obstructions.

Pallets

-

Dematic Pallet Mover AMRs offer flexible of transportation within the warehouse and open up expanses of space typically consumed by conveyors. These robots transport goods and materials throughout your warehouse using environmental features to safely navigate around people, equipment, and inventory.

Applications:

- Moving pallets between functional areas

- Line-side supply and delivery

- Small and large assembly platforms

- Moving pallets between functional areas

Dematic Pallet Mover AMR D900

-

Height - 700 mm

Payload - 900 kg

Dematic Pallet Mover AMR D900

- Height - 500 mm

Payload - 900 kg

Dematic Pallet Mover AMR D1300

- Height - 500 mm

Payload - 1300 kg

Dematic Pallet Mover AMR D1300

- Height - 700 mm

Payload - 1300 kg

Totes

-

Dematic Tote Mover AMRs can be deployed quickly and reconfigured for seasonality and scalability as needs change. These robots transport materials in totes, remove waste, and perform non-value-added tasks.

Applications: Conveyor to workstation transport Waste removal

Totes

-

Height - 480 mm

Payload - 30 kg

Case & Piece Picking Solutions

-

Changing business conditions, omnichannel distribution requirements, supply chain disruptions, increased customer expectations and the high cost of order fulfillment are all forcing companies to reimagine their picking operations. Retailers, e-tailers, wholesalers, and manufacturers alike are implementing resilient and responsive on-demand order fulfillment operations that enable flexible and scalable picking processes.

Dematic piece and case pick systems increase pick rates and accuracy and streamline order fulfillment efficiency while reducing the time required to pick, pack and ship orders. Advances in order fulfillment technology combined with new operational methods and management software can drive vast improvements within your picking operation.

Piece Picking Solutions

-

Piece Picking Solutions

Dematic offers a selection of collaborative and fully automated piece picking solutions that meet the needs of your specific application. Collaborative picking solutions incorporate warehouse employees into the pick system operation, while a fully automated picking solutions do not require labor to operate.Goods to Person

Goods to Robot

Dynamic Slotting

Zone Route

Put to Order

Pick Cart

Put Wall Order Consolidation

Automated Piece Picking

Case Picking Solutions

-

Case Picking Solutions

Dematic offers collaborative picking and automated case picking solutions. The most appropriate case pick solution is selected based on your application’s requirements. Collaborative picking solutions incorporate warehouse employees into the pick system operation, while automated picking solutions do not require labor to operate.Goods to Person

Case Pick to Pallet

Case Pick to Conveyor

Put to Pallet

Dynamic Slotting

Automated Case Picking

Human Machine Interface (HMI) for Picking

-

Human Machine Interface (HMI) for Picking

Consisting of a flat screen/touch screen, a tablet computer, and a voice directed device or radiofrequency (RF) device, the HMI instructs associates what to pick and in what quantities.Screen Directed

Voice Directed

Pick to Light

Put to Light

Picking with RF Devices

Picking with Wrist Mounted RF Devices

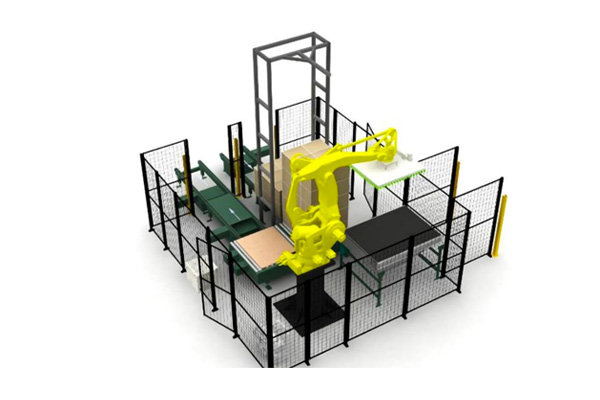

Palletizing & Depalletizing Solutions for Warehouses

-

A Complete Portfolio of User-Friendly, Cost-Effective, High-Performance Solutions for Warehouses

The persistent labor shortage, rising labor costs, and the e-commerce boom are all making warehouse operators reassess how to manage product palletizing and depalletizing. Operations can no longer rely on adding manual labor to increase throughput for production, fulfillment, and shipment. They must look to automation to boost work efficiency, reduce operational costs, and enhance productivity.Dematic Palletizing and Depalletizing systems provide flexible, scalable, labor-saving solutions that address the complexities of distribution operations. They range from semi-automated workstations to comprehensive robotic modules.

Powered by People: Semi-Automated Ergonomic Workstations

-

Low-cost systems that provide safe, efficient throughput

Ideal for distribution operations that ship a large volume of cases of varying size and shape for direct-to-store delivery, and ideal for compact spaces. These ergonomic systems automatically lower the work surface to minimize lifting and increase performance.Automated with Dematic Software, semi-automated ergonomic workstations can:

Organize cases in sequence so operators can simply slide them onto pallets or roll-cages

Organize the palletizing pattern to maximize the number of cases on a pallet, ensuring more product per delivery

Anticipate factors such as crushability and adjust picking operations to preserve product integrity — as each level is built, the pallet or roll cage automatically lowers and is stretch-wrapped to ensure load stability

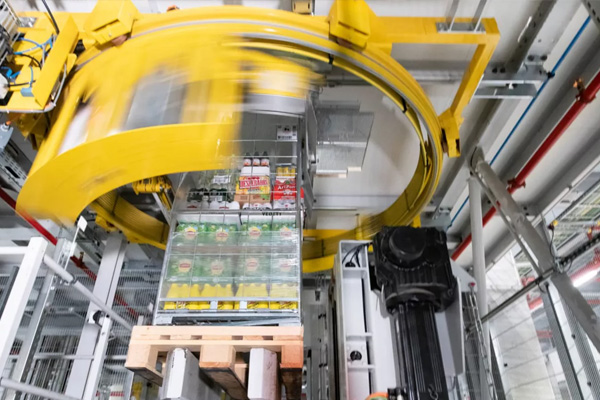

Fully Automated Robotic Palletizing and Depalletizing

-

High-performance systems that increase throughput, maximize accuracy, and reduce operating costs.

Standard robotic modules that include our Layer Depalletizing Robot and our Case Palletizing Robot are ideal for operations in harsh environments, and perform repetitive tasks that would be labor intensive and limit worker productivity. Industrial robots are designed for mission-critical applications that work around the clock without tiring or making mistakes.Automated with Dematic Software, the robotic palletizing and depalletizing systems are able to:

Build store-friendly and aisle-ready pallets, reducing labor needed to restock store shelves

Organize the palletizing pattern to maximize the number of cases on a pallet for more product per delivery

Anticipate factors such as crushability and adjust the picking operation to preserve product integrity

Include a variety of end-of-arm grippers, vacuum, and fork-style tooling that can handle the most delicate and challenging packages

Dematic Mixed Case Palletizing Solution

-

High-performance systems for automatic building and deconstructing of mixed-case pallets

Retailers often receive thousands of single SKU pallets from suppliers and must then reassemble the pallets into mixed case orders for their stores. The solution to your mixed case order fulfillment problems, Dematic Mixed Case Palletizing Solution assembles cases on-pallet—and in strategic positions—for efficient store replenishment.Mixed pallet building software allows easy shelf restocking at retail stores and features:

Case placement that correlates with store planograms

High order accuracy

Reduction in warehouse labor and injuries

A compact footprint in an existing space

Less potential for product damage

High-density pallets with lower transport costs

Lower cost per case handled

Accommodations for various pallet sizes

Automatic loading of roller containers

Scalability to accommodate change and growth

Dematic Ergonomic Palletizer for Manual Palletizing

-

Safety with productivity gains

When manual palletizing is in place and unable to automate, make the process safer and easier for your workforce. Simplify the work and reduce the burden on your staff by integrating a Dematic Ergonomic Palletizer, a station specifically built for manually creating mixed pallets. Single or dual operators can place and assemble mixed case pallets optimally while the automated station does the rest — shrink wrapping, stacking, and conveying pallet-ready shipments quickly and efficiently.800 picks per hour

Two operators at one station equates to over 800 picks per hour.

Single operators can manage up to 500 picks per hour.

25 cases per hourAutomatic pallet changing and integrated wrapping for continuous work.

The next empty pallet loads automatically.

Robotic Picking Systems

-

Introducing Your Next High-Performing Team Member

Technological advancements are empowering humans and machines to work side-by-side, running efficient operations that can run three shifts per day, 365 days per year. By integrating robotics systems into your operations, you gain an intelligent addition to your workforce, 24/7 picking capacity, and the benefits that fully automated, dependable operation can deliver.Robotics systems can seamlessly integrate into your operation to deliver faster and more accurate fulfillment while addressing top supply chain concerns like labor constraints and whipsaw changes in consumer demands.

Depalletizer Module

-

Solves

Difficult/Dangerous Work: Manual depalletizing is intense labor that leads to back strain, fatigue, and high employee turnover rates.

Labor Scarcity: Can’t always find enough qualified workers to fill demand.

System overview

The Dematic Robotic Depalletizer module provides automatic unstacking of homogeneous (box size pure) carton pallets or rainbow pallets onto a belted outbound conveyor. The empty pallet is then automatically conveyed out of the cell.

The Dematic Robotic Depalletizer module is available in two variants:

Single Channel: Uses a single inbound and a single outbound conveyor line

Dual channel: Uses two inbound conveyor lines plus either one or two outbound conveyor lines

Depending on the flow of material in the facility, the orientation and direction of flow can be configured in these ways:Material can flow clockwise or counterclockwise

Material can enter and then exit from left or right of the robot

Infeed conveyors and outfeed conveyors can be placed on either side of each other

Palletizer Module

-

Solves

Difficult/Dangerous Work: Manual palletizing is intense labor that leads to back strain, fatigue, and high employee turnover rates.

Labor Scarcity: Can’t always find enough qualified workers to fill demand.

Consumer Demand: Meets the demand for speed and accuracy of delivery to stores.

System overview

The Dematic Robotic Palletizer module provides automatic stacking of homogeneous (box size pure) carton pallets. Empty pallets are individually conveyed into the cell and completed pallets are automatically conveyed out of the cell.

Piece Pick Module

-

Solves

General labor shortages for warehouse picking and replenishment operations

Human error and theft

Need for speed and order accuracy

System overview

Consumers want their orders faster, and your system must be able to individually pick each item accurately and efficiently. The Dematic Each Pick Robotic Module provides automatic picking and placing of the same item from totes or tote compartments and into multiple order containers.The Dematic Robotic Each Pick module provides automatic picking and placing of homogeneous (SKU pure) eaches from totes or tote compartments and into multiple order containers.

Because the system does not have a workstation, it can be used on a wide variety of infeed and outfeed designs.

Workstation Systems

-

High-speed, high-volume designs for worker efficiency

The need to fulfill orders faster and more accurately is driving fulfillment centers and kitting operations to implement efficient, flexible, modular, ergonomic, and scalable goods-to-person workstations. The “put to order” goods-to-person method allows items, pieces, and parts to be presented to a worker or robot for consolidation into an order or kit.

Operational based design

-

An operational-based design approach — engineer sorting solutions focused on operational excellence

Solution development — non-biased, data driven; simulation/emulation tools assure best performance

Best practice sharing — between Dematic global engineering teams creates world-class solutions

Configuration software — speeds/optimizes sorting system solution development through implementation processes

Control the entire process

-

Control the entire process — design, build, implement, support

Modular and standardized sorting sub-systems — defined functionality, easy to support, and scalable

Warehouse Execution Software — optimize with real-time continuous flow, synchronize labor and automation

Expertise with technology suppliers– assures successful integration of load sensors, barcode scanners, cameras and vision systems

Implement the ideal workstation

-

Implement the ideal workstation — appropriate for your business

Guarantee system performance — assure operational results meet/exceed design specifications

Innovation, R&D — creates new high performance sorting technology and solutions

Use experience and expertise across thousands of sorting systems installed worldwide