Ajooni

Videos

Loading the player ...

- Offer Profile

- Ajooni Storage Systems offers

storage, archiving and material handling solutions for use in a wide variety

of industries and applications. From simple good quality shelving, through

efficient office storage and filing, to professional archive systems; from

small parts storage to pallet racking and mezzanine storage areas.

Ajooni Storage Systems is an ISO 9001:2015 Certified Company.

We are committed towards Quality.

Our organization started its business operation with the objective of manufacturing a comprehensive range of storage system that would offer complete solutions to clients' minute to broad storage requirements. Our systems are manufactured with most advanced features that assure quality of highest parameters. The quality control unit works to maximum capacity to scale up the standard to highest industry parameters.

Product Portfolio

AJOONI Storage Systems Racks

Slotted Angle Steel Racks

- Slotted Angle Racks, or Light Duty Racking, are ideal for a variety of applications including offices, Tool rooms, retail environments and storage areas. It’s a cost effective, light duty bolted system, ideal for smaller or bulkier but lighter applications. It is available at a fraction of the cost of Pallet racking.

Shelves can be easily adjustable as per height required of each compartment. Shelves can be customized in a number of standard sizes and heights..

These racks are available in a plethora of sizes, finish and design to meet with the demands of different clients. Our range of slotted angle racks offers a space for storing number of items in an organized manner.

With our technically advanced manufacturing unit, we use the finest quality CR and HR steel for delivering Slotted Angle Storage Systems.

Features:- The front profile is ideal for fixing labels.

- The edges are not sharp, avoiding injuries.

- Shelf / Panel made by 06/08 bend profiles.

- The box shaped edge does not twist under load.

- Easy access to contents / materials from all sides.

- It is economical storage for any kind of hand loaded materials.

- Starter and add-on units combine to form economical rows of shelving.

- The length of the Shelf corresponds with most types of cartons and plastic containers.

- The double folded corners which are clinched provide a high rigidity and resistance against impact loads.

Heavy Duty Pallet Racks

- Heavy Duty Racking, also known as conventional pallet racking is generally laid out with single-entry wall racks on the perimeter sides and double-entry racks in the middle.

The working aisle measurement between each rack and the rack height depends upon the characteristics of the fork-lift trucks or lifting devices, pallet size and the height of the warehouse itself.

Holding stock is an extremely complicated job especially for bulky tools such as auto parts, paper products, liquids and tires.

We offer an extensive range of pallet racking system that helps in keeping the inventory well organized to maximize the storage space.

These racks consist of unbroken lanes of racking with only a single load and retrieval passageway.

Features:- Better space utilization.

- 100% accessibility to individual pallets.

- Configuration for maximum storage, density and efficiency.

- Specialist narrow aisle fork-left trucks are required to work in the reduced aisles.

Long Span Shelving Racks

- Long Span Shelving Racks, or Medium Duty Racking is a strong, durable, versatile and economical shelving system that minimises lost space from uprights making it suitable for a wide variety of storage application in offices, archives, libraries and retail outlets.

Strong, functional, high capacity storage,Long Span Shelving Racks is suited to all applications where space is a premium and can be mounted for even higher density storage.

It is fast and easy to assemble and uses a modular design that provides the maximum storage capacity, no matter what space is available.

These are Modular configuration allows level adjustments vertically at a distance of 50mm.

Features:- Fastening structure, easy to load and unload.

- Can be tailor-made according to customized requirements.

- High strengthened closed steel panel with welded support bars.

- Aesthetically appealing and available in varied colour combinations.

- Configuration of main and add-on modules as per space availability.

- Made of high grade cold rolled steel sheets with powder coated surface.

- Panel and side panel available for closed shape to ensure greater safety.

- Modular configuration allows level adjustments vertically at a distance of 50mm.

- The double folded corners which are clinched provide a high rigidity and resistance against impact loads

Multi-Tier Racks

- Multi-Tier shelving and racking is mainly used for storage and order picking of non-palletized goods, bins, cartons or other storage units containing small parts and components and for bulk storage.

The modular system accepts numerous accessories which can also be added later on. Designed to suit diverse requirements, these accessories allow storing of almost all goods.

Multi-Tier shelving and racking provides good space utilization which directly results in multiplication of the available floor space.

Stairs are an integral part of the system and material lift can be used as an option to connect the walkways on different tiers.

Cantilever Racks

- Cantilever racking is specially designed to store long or varying length items, such as metal beams, pipes, moulding, wooden boards, metal and plastic sheets among other materials.

The system basically consists of columns with a vertical beam and one or two horizontal beams at the base to provide stability. A series of arms is attached on which the load is placed.

Loads may be handled manually when they are light weight, or by using lift-trucks or other appropriate lifting systems when heavy items are involved.

We offers a complete range of cantilever racking systems for the storage of long goods. For loads varying from 50 to 2500 kg per cantilever arm and for most types of long goods, an optimised storage systems can be provided.

Advantage:- Easier to use

- More flexible

- More compact

- More economical

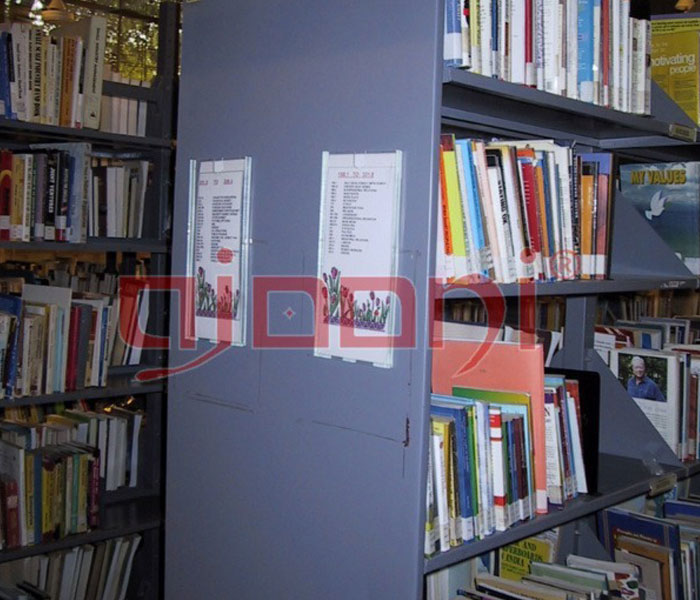

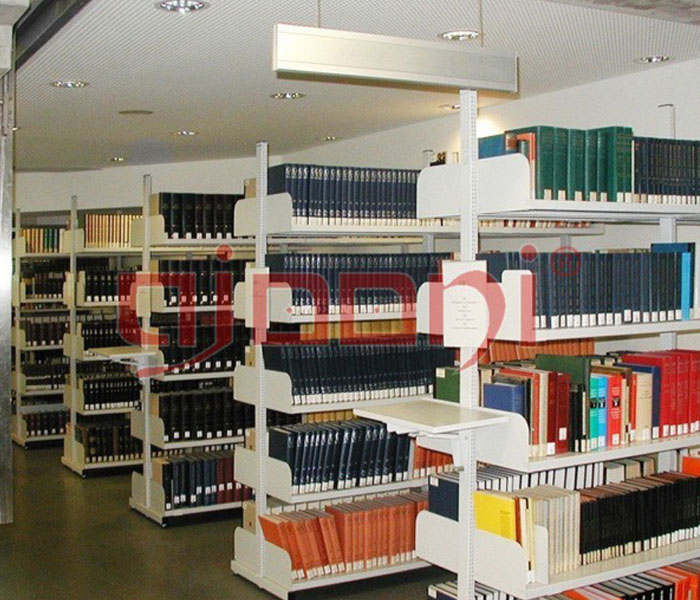

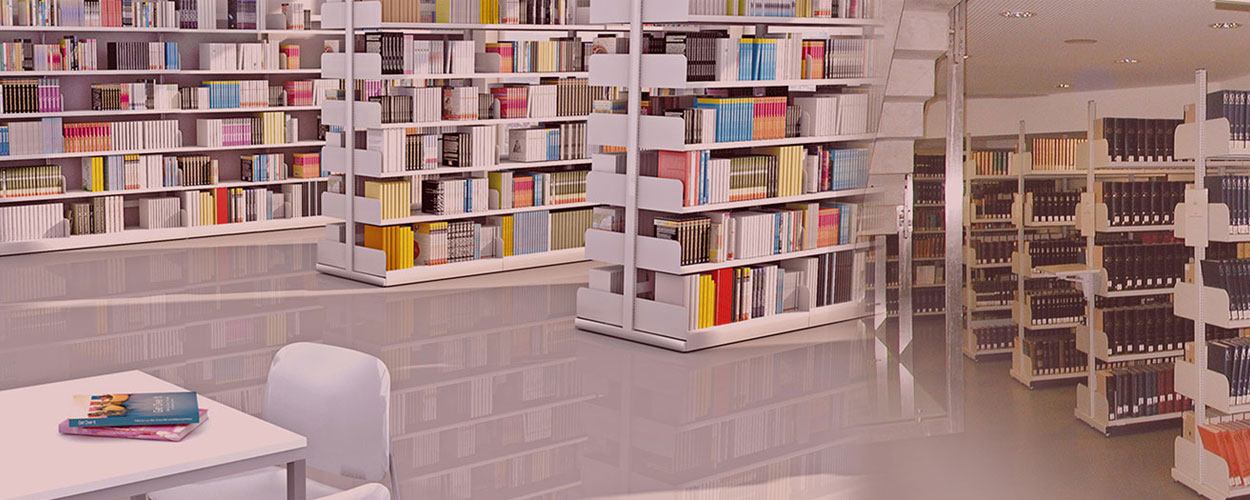

Library Racks

- Library Racks are ideal for libraries, educational institutions, schools, colleges, universities etc. It facilitates systematic storage and easy retrieval of books.

Library Racks are carefully constructed to utilize the minimum of space and books stored can be clearly seen and easily accessible.

Our Library racks are furnished with many book binds to prevent the books from falling and keep them in standing and beautiful condition.

For a continuous block, one basic section is essential while add-on section can be added to have a block of desired length,

The stack can be single faced or double faced, that are operable from one side and from both sides respectively.

Supermarket Rack

- Supermarket Display racks would serve the purpose only if the displayed items are exhibited properly. Our display racks are available in different makes and types.

One such variety is our vertical display different items are displayed systematically in a vertical manner. Along with the standardized sizes these can also be customized as per the requirement of our clients.

We offer exquisitely designed Display Racks that are used to display various items in malls, stores, and other shopping areas.

All metal shelving units are designed with interlocking components that fit together without nut or bolts.

Clients can avail our range in different colours, sizes, and dimensions.

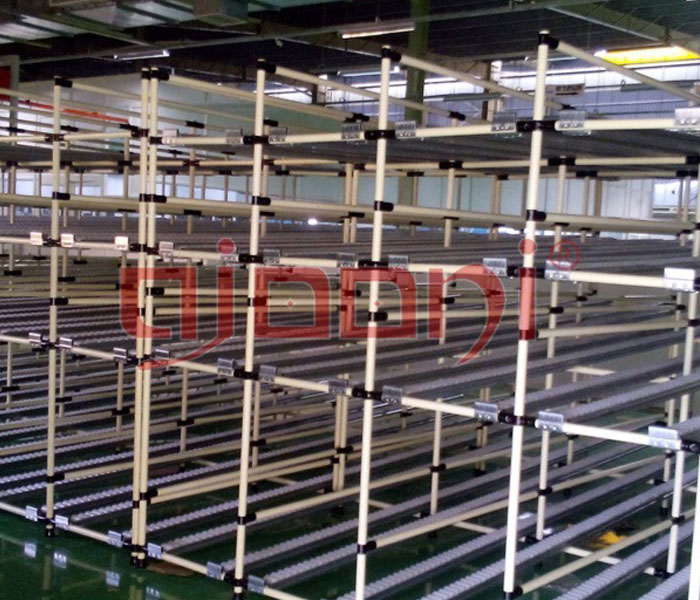

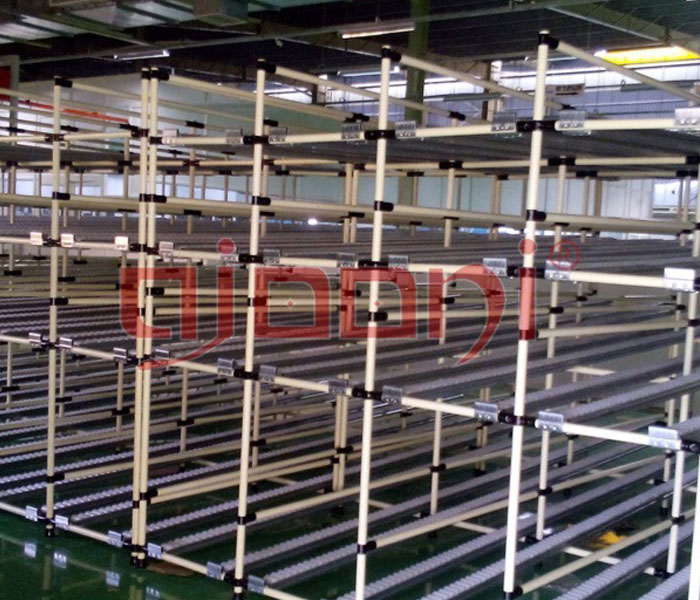

FIFO Rack

- With our years of experience and knowledge of this domain, we are engaged in manufacturing and supplying FIFO Racks. With the consistent improvisation in technology, this system is manufactured using optimum quality components by our deft professionals. This system is used for storing sheds, steel rails and many other metal components. Besides, we provide this FIFO Racks in different specifications at negotiable prices to the clients.

Features:- Its sturdy construction leads to withstand high pressure

- High tensile strength

- Sturdy design with dimensional accuracy

- Abrasion resistance with superior dimensional stability

Fabric Role Rack

- Ajooni Shelving Systems are suitable for the Storage of a wide variety of non-palletized goods. For mini-load you can select Steel shelf & also for medium duty, but for bulky and awkward loads the Panel will be the most economical.

These racks are available in a plethora of sizes, finish and design to meet with the demands of different clients. Our range of slotted angle racks offers a space for storing number of items in an organized manner. We also offer these slotted angle racks in different designs and sizes as per the customers’ demands.

Tyre Rack

- We are engaged in offering a top quality Tire Racks. Find wide usage in heavy duty applications, our offered pallet rack is cautiously designed utilizing the best-in-class needed material and the advance technology at our equipped manufacturing unit. Our beloved customers can avail this pallet rack from us at nominal rates

Features:- Precision engineering

- Corrosion resistance

- Robust construction

Die Mould Racks

- We are the leading manufacturer and supplier of Die Mold Racks. You can organise your Mould in a very sophisticated manner at a very low price.

One of the main advantage of these Racks is, that you can Combine ‘n’ Number of Modules you want, without compromising the Load carrying capacity of each Module. In short, you can add any number of modules till the space limits of your Workplace.

Modular Mezzanine Floor

Double your Floor Space

For proper utilization of availbale height in warehouseModular Mezzanine Floor

- Modular Mezzanine Floors are fabricated, supplied and installed as per the clients demands. These floors can be made on top of heavy duty pallet racks, or just with heavy duty pillars.

Our range can be effortlessly relocated, enlarged or dismantled with the property of high load bearing overhead levels.

The range is comes with heavy duty columns which provide stiff hold, further helping in the operation of the lower level.

These floors are easily installed in the office, storage or manufacturing areas at lesser costs, and can completely utilize the existing overhead space and gain valuable working. It is made with High quality anti corrosive materials.

Compactors

Mobile Compactors

- Mobile Compactors are designed for use in places where there are limitations on available space.

Our range of high quality mobile racks have aisles only on one side.

The choice depends on the requirements and space constraints. Our rail mounted racks are suitable for all kinds of storage requirements.

These high storage capacity racks that we manufacture and supply are available in two types::- Manual (Push & Pull type)

- Mechanically operated (chain driven) system

Pallets

For handling of goods by MHEs

Stack, Store, Protect and Transport MaterialsPlastic Pallets

- Plastic Pallets, a flat transport structure that supports goods in a stable fashion & make it easier to move heavy stacks, while being lifted by a forklift, pallet jack, front loader or other jacking device.

Make Shipment, Transportation or Movement of your heavy loads EASIER by stacking on Plastic Pallets.

Advantages of Plastic pallets over traditional wooden pallets.- Safer

- Lighter Weight

- Fire Retardancy

- Easily Sanitized

- Non – Splintering

- Resistance to Odor

- Longer Service Life Span

- More Environmentally Friendly Durability & Better Product Protection

- Save on Transportation and Labor Costs

Quality

Ajooni Storage Systems is an ISO 9001:2015 Certified Company.

We are an ISO 9001:2015 Certified Company, last audited in February’14. We are amongst the few companies who have achieved the certification in a very short span of time.

We are committed towards Quality

Quality is embedded in all our products. We will continuously deliver and continually improve our commitments to all stakeholders every time “on time” with quantifiable measuresWe work on the following principles of Quality Management:

- Customer focus Documentation include with explanations for most of the options.

- Leadership With just a few clicks you can add any color you want.

- Involvement of people Great custom shortcodes which are ment to ease up your work.

- Process approach You can install languages and extend the website's languages.

- System approach to management Documentation include with explanations for most of the options.

- Continual improvement With just a few clicks you can add any color you want.

- Factual approach to decision making Great custom shortcodes which are ment to ease up your work.

- Mutually beneficial supplier relationship. You can install languages and extend the website's languages.

To ensure our commitment towards Quality, following are the steps we follow in process of manufacturing, before any final product roll-out from our Factory

Details of Pre-treatment and Painting Methods.

After necessary machine operations like, shearing, punching and bending there is residue of Oil on products. It is important to remove this to ensure good quality paint finish and long life of the product.

To achieve this, all fabricated components shall be subjected to elaborate surface treatment process by four step seven tank special anti corrosion treatment consisting of the following steps:

Degreasing (Alkaline Cleaning)

This process shall remove oils and other semi solids from metal surface of the rack components. Caustic soda, soda ash, Tri-sodium phosphate and sodium metasilicate in the right concentration under closely controlled temperature limits shall be ensured for this process. This process shall be done in conformity with IS 6005 of 1970.

Removal of alkaline impurities

After degreasing, the components shall be rinsed in water for the removal of any alkaline impurities from the surface of the rack components.

Pickling (Acid cleaning)

All the rack components after degreasing and rinsing shall be subjected to acid cleaning for removal of all rust and scales by using Sulphuric Acid Solution. The process shall be done in conformity with IS 6005 of 1970.

Removal of acidic impurities

After acid cleaning, the components shall be rinsed thoroughly in water for removal of all residual impurities.

Phosphating

The cleaned metallic surface of the rack components shall be subjected to phosphating process to prevent the surface from any type of further corrosion by treating the components in Phosphoric acid tank. Sodium nitrite shall be used as accelerator to impart a fine texture to phosphate coating. The process shall be done in conformity with IS 6005 & 3618 of 191996, class 'D'.

Water Rinsing

After phosphating, all the components shall be rinsed thoroughly in water for the removal of residual phosphoric acid and sodium nitrite.

Passivation

All the components after rinsing the same in shall passivate rinsing dilute chromic acid. The passivation will leave a light chromate coating, which will increase corrosion resistance, humidity resistance and paint adhesion to the metal surface.

After chemical treatment the items are Spray or dipping Painted with high quality Paint purchased from reputed suppliers. After painting, the items are oven baked in our special oven @120 degrees for 30 minutes, to ensure long life and good finish.