- Offer Profile

- Core business of our company is the manufacture of customized industrial

trucks, side loaders and special equipment for handling difficult and bulky

goods.

In manufacturing and distribution the world over our machines are designed to facilitate the efficient material flow and turnover of goods, even in very narrow aisles.

Our trucks are tailor-made to exactly match the end users specific needs and characterized by their longevity and funcionality.

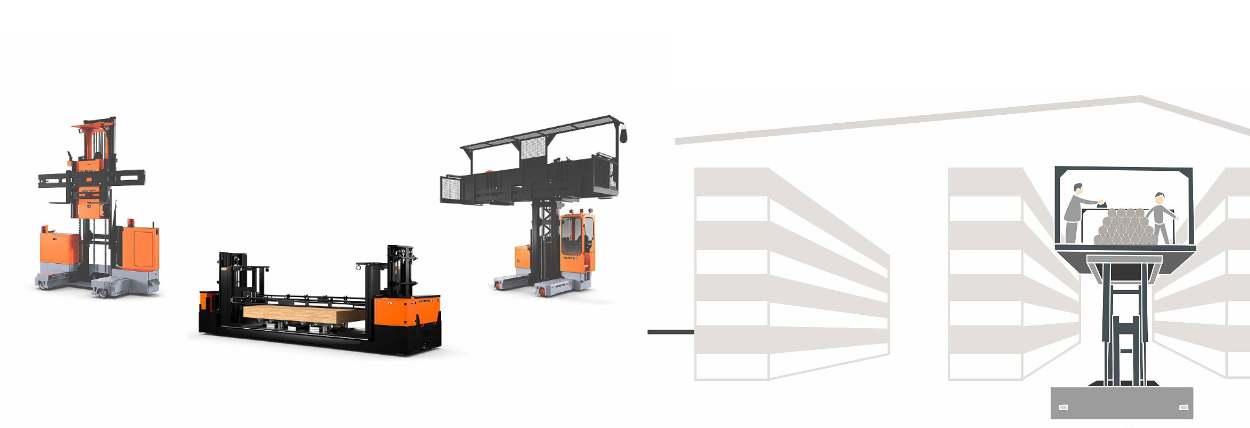

The right product for every application

- From electric multi-directional sideloaders to heavy duty transport vehicles - HUBTEX offers its customers a wide range of products for various handling tasks. Whether long goods, heavy loads or plates, we find the right solution for every customer. And thanks to the HUBTEX modular principle, the right vehicles can be put together for every challenge.

Electric multidirectional lift truck

- The handling of long loads presents users with particular challenges. The loads have different dimensions and have to be transported safely and securely along narrow aisles. This calls for flexible vehicle concepts that can be adapted to suit the application. This is where HUBTEX comes in with its multidirectional lift trucks. Over the past 40 years, the core product has been developed in countless variants. Our multidirectional forklift is ideal for universal handling in specialized industries and helps companies with their warehouse logistics. Among other things, the lift trucks can transport long goods, stacks of metal sheets, chipboard, tools, cable drums, rollers, oversized pallets, and round bars in narrow-aisle rack systems. All lift truck types are freely movable both indoors and outdoors.

ELECTRIC MULTIDIRECTIONAL SIDELOADERS ESTL & PHOENIX

-

With the ESTL andPHOENIX modular systems, our sideloaders with multidirectional steering can be adapted to the individual requirements of our customers with maximum flexibility. A variety of series with application-specific fork carriage variants, cabs, lift masts and individual equipment options are available for selection for the right solution. The almost infinite number of combinations offered by these series mean that a HUBTEX multidirectional sideloader will always be suitable for its application.

- Load capacity up to 77,000 lbs

- Lift height up to 551 in

- Adaptable to all applications

Electric Multi-Directional Sideloader MaxX

-

Priced at entry level, the MaxX multidirectional forklift comes in the most popular effective widths and lift heights and is particularly useful for handling long goods in the 6,600 lbs, 9,900 lbs and 13,200 lbs load capacity classes along narrow warehouse aisles and when loading and unloading trucks outdoors. It is the ideal alternative to diesel vehicles.

The MaxX combines innovation with value for money. This multidirectional forklift provides an incredibly clear view of the load from the cab thanks to its state-of-the-art design and free-view lift mast. The optional 360° HX multidirectional steering enables users to change direction quickly and reduces wheel wear. The forklift is available in several versions with different-sized batteries, enabling it to be tailored precisely to tasks with either medium or long operating times.- Load capacity up to 13,200 lbs

- Lift height up to 295 in

- Multi-Directional steering

fourway sideloader EASY

-

In case of short operating times or multiple drivers, it often requires a fourway sideloader which is easy to operate and inexpensive to purchase. At the same time, the driver must be able to enter and exit the cab quickly. All of these criteria are fulfilled by the new EASY fourway sideloader from HUBTEX for the transport of long goods up to 4,400 lbs.

- Up to 4,400lbs load capacit

- 4 wheel

- Solely indoor use

Automated electric multidirectional forklifts

-

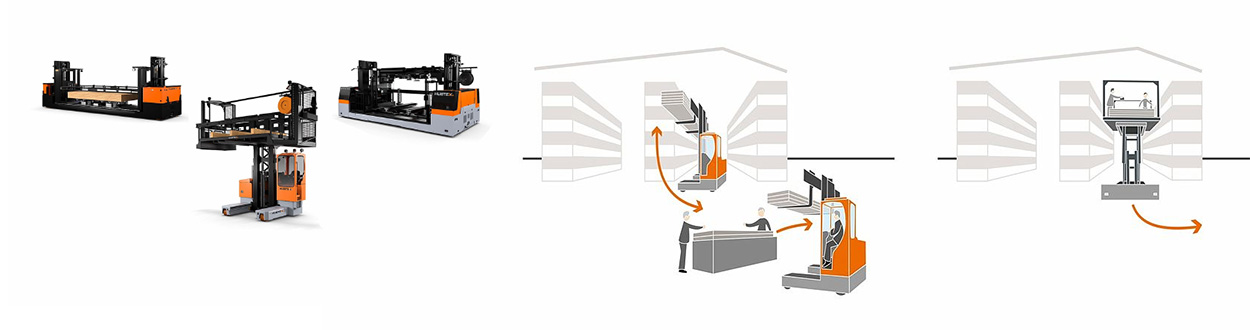

HUBTEX automated guided vehicles (AGVs) based on our electric multidirectional sideloaders provide innovative solutions for the efficient movements of long loads. Our AGVs are ideally suited to applications such as the handling of long goods in multi-shift operations. Typical HUBTEX applications such as the handling of long goods using load carriers can often be easily automated, offering users considerable advantages. Popular areas of application include, for example, steel service centers or facilities handling profiles in long goods cassettes. Drawing on the latest technology and an accumulation of knowledge, HUBTEX offers reliable solutions for demanding logistical challenges. Your company can rely on HUBTEX for efficient and precise material transport.

- Concept creation

- Manufacturing & integration

- Commissioning & service

3-wheel multidirectional sideloader basix

-

As part of the BASIX series, the HUBTEX DS 30 and DS 30 E models are also reduced to the most common effective widths up to 6,600 lbs. They are the entry-level version of electric multidirectional sideloaders with elastic tires for combined indoor and outdoor use. As genuine 3-wheel universal sideloaders, they are the right choice for light applications up to 6,600 lbs. They are used by profile producers, window manufacturers, and much more in DIY stores.

- Load capacity up to 6,600 lbs

- 3-wheel

- Lift height up to 295 in

COUNTERBALANCED FORKLIFTS

-

The FluX 2-in-1 lift truck Electric multidirectional counterbalance forklift truck

The FluX is the perfect solution for handling pallets and long goods. A genuine two-in-one lift truck, it combines the benefits of a forklift and sideloader. The quiet and environmentally friendly electric drive and innovative 360° HX steering enable smooth changes in direction without interrupting the flow, making the FluX extremely manoeuvrable, efficient and user-friendly.

What makes FluX truly unique are its compact dimensions combined with a high load capacity as well as its lift mast with tilt function (on the FluX 30 and FluX 45). The FluX is thus ideal for work such as loading and unloading trucks as a forklift or carrying long loads through narrow warehouse doors as a sideloader.

FluX 30 electric multidirectional counterbalance forklifts

-

The lift truck with 3-wheel chassis is ideal for the combined handling of pallets and long goods. Thanks to a low-noise and environmentally friendly electric drive combined with an innovative 360° HX steering for smooth changes in direction from longitudinal to transverse travel, the truck outperforms all other 3-wheel multidirectional trucks when it comes to maneuverability, efficiency and user-friendliness.

- load capacity up to 6,600 lbs

- The 2-in-1 forklift: Front and Sideloader

- 360° HX multidirectional steering

Flux 45 electric multidirectional forklift

-

With the FLUX, HUBTEX presents the latest generation of multidirectional counterbalance forklift trucks for combined indoor and outdoor use. The FLUX is the ideal forklift whenever you are mainly moving loads on pallets but also routinely need to transport long loads sideways. A genuine 2-in-1 forklift, the multidirectional counterweight forklift can be used flexibly as either a forklift or sideloader.

The low-noise, environmentally friendly electric drive, the innovative 360° HX steering for smooth changes in direction, and the ergonomic driver’s cabin make the FLUX extremely maneuverable, efficient, and user-friendly. Thanks to its very compact dimensions, its high load capacity, and its lift mast with mast tilt, this multidirectional sideloader can be used for a wide rante of applications. Its large tires, generous ground clearance, and all-wheel drive also make the FluX 45 ideal for outdoor use.- Load capacity up to 4.5 tons

- The 2-in-1 forklift: forklift and sideloader

- 360° HX multidirectional steering

Flux 70 electric multidirectional forklift

-

The FluX 70 multidirectional counterbalance forklift is ideal for handling wooden materials and combines the advantages of an electric multidirectional forklift with those of a heavy-duty truck with combustion engine. Much more compact than comparable front loaders, the 15,000 lbs multidirectional front loader is a truly excellent performer, especially when handling loads with high centers of gravity, where it takes up much less width along aisles. The 360° HX multidirectional steering enables large steering angles and the smallest possible turning radii in all driving directions as well as smooth changes in direction without an intermediate stop. The FluX 70 is highly flexible in use and can be deployed indoors and outdoors, including in block storage and on challenging terrain. With a lift height of up to 295 in, it is also well suited to work in high-bay warehouses.

- Load capacity up to 15,400 lbs

- The 2-in-1 forklift: a forklfit and sideloader

- 360° HX multidirectional steering

SPECIAL PURPOSE FORKLIFTS

ELECTRIC HEAVY-DUTY COMPACT FORKLIFT

-

Wherever heavy loads need to be transported, handled or loaded in confined spaces, the HUBTEX RoxX electric heavy-duty compact forklift comes into its own. The RoxX is used both indoors and outdoors. In comparison with conventional forklift trucks, the RoxX is characterized by very compact external dimensions in length and width. In short: The HUBTEX compact forklift is used anywhere where conventional frontloaders cannot be used due to their significantly larger dimensions. All vehicles in the RoxX series have a sturdy, robust free-view lift mast and offer maximum maneuverability as well as optimum all-round visibility from the driver's cab. The purely electric drive results in extremely energy-efficient, low-maintenance and quiet operation.

HUBTEX ELECTRIC HEAVY-DUTY COMPACT FORKLIFTS: STRONG, ROBUST AND EXTREMELY MANEUVERABLE

Heavy loads are often transported by frontloaders. But when space is limited, these trucks quickly reach their limits due to their vehicle length. a robustHUBTEX's RoxX heavy-duty compact forklifts offer and maneuverable solution. The development is based on a cooperation between HUBTEX and Dimos. The two international manufacturers of industrial trucks have been collaborating on new products and solutions for intralogistics since the end of 2017. One result of this successful cooperation is the new RoxX heavy-duty compact forklift, which, in various series, facilitates the handling of load capacities from 8 to 30 tons in confined spaces. All vehicles in this family have sturdy, robust lift masts and offer maximum maneuverability as well as optimum all-round visibility from the driver's cab.

MAXIMUM MANEUVERABILITY WITH PATENTED STEERING

Whether coils, reels of paper, converters or tools – the new RoxX series from HUBTEX will transport these loads safely and reliably. The vehicle is very maneuverable and suitable for use both indoors and outdoors. The compact design of the RoxX offers significant advantages over conventional frontloaders: it is up to 25% narrower and around 20% shorter with the same load capacity. There are two steering systems available for the RoxX. An electro-hydraulic steering system with one steering axle is fitted as standard. Further space savings can be achieved with the optional electric steering system. A new, patented single-wheel steering system significantly reduces the turning circle, resulting in an additional space saving of 50% in the turning radius compared with standard steering. In this case, the pivot point of the vehicle is ideally located at the center of the drive axle.

Electric Reach trucks

-

The HUBTEX reach truck is characterized by its compact design combined with a high load capacity. It comes into play whenever the load capacities of standard reach trucks from the major series manufacturers reach their limits.

With our SQ series, not only do you benefit from significantly higher load capacities with the same aisle dimensions, but also, for example, from the smallest turning circles promoted by our multidirectional steering system. This means that we can offer you the perfect solution for your “heavy” handling problem and will be by your side with all our expertise as your partner for customer-specific reach trucks.- Up to 13,200lbs load capacity

- Large load centres

- Narrow aisle width

Transport Systems

-

SPECIAL HANDLING SOLUTIONS FOR MANY INDUSTRIES

LONG LOAD ORDER PICKER

-

LONG LOAD ORDER PICKERS FOR PROFILES AND PIPES

HUBTEX offers a wide range of solutions for the picking of aluminum, plastic or steel profiles, strips and pipes. We recommend our MU-OP and MU-SO models for small and medium turnover rates. These two models are specially designed for picking long profiles and pipes, mostly in guided narrow aisles. These vehicles combine the advantages of a multidirectional sideloader with the options of manual order picking in very narrow aisles.

Our electric multidirectional sideloaders with removable order picking platform offer even greater flexibility, but with a larger aisle width. As multidirectional sideloaders without a platform, these can transport and store loads and pick individual profiles with a platform.

Another variant for applications with a high rate of turnover is the EZK order picking platform. These vehicles are particularly suitable for applications with a high rate of turnover, as they can pick from both sides of a rack aisle.OPTIMAL USE OF RESOURCES

The use of HUBTEX order pickers increases efficiency when handling long and bulky goods in narrow aisles. HUBTEX follows the principle of bringing the operator to the goods. This reduces the work effort and prevents damage to the goods.

ELECTRIC MULTIDIRECTIONAL ORDER PICKING PLATFORM MU-OP | MU-SO

-

- Up to 5t load capacity

- Up to 12.50m lift height

- Adaptable to all applications

Our multidirectional order picking sideloader in the 1-man version (MU-OP) and the 2-man version (MU-SO) can be adapted to your individual requirements. The models are specially designed for picking profiles and pipes in narrow aisles. At the same time, these trucks can be used as conventional electric multidirectional sideloaders for the stacking of complete packs.

ORDER PICKING DIRECTLY FROM THE CAB

The MU-OP model is designed for one operator for the order picking of lightweight loads, such as aluminum, plastic or steel profiles. Its narrow rear frame, the optimized design of the lift mast and the central standup cab in front of the mast make the vehicle very narrow and therefore ideal for use in guided aisles. The central configuration of the standup cab in front of the lift mast gives the driver a clear view into the rack compartment, enabling him to pick light loads directly from the rack. Despite the slender design of the cab, all functions of the multidirectional sideloader are included, making the truck a fully-fledged electric multidirectional sideloader. This means that this vehicle can transport complete packs and bundles or provide manual assistance for order picking processes.

AVAILABLE WITH TWO CABS FOR LONG LOADS

The MU-SO model with two operators is recommended for the order picking of medium to heavy loads. In this model, the cabs are arranged next to the lift mast. This allows for easy order picking by two people, particularly in the case of longer loads.

When stacking complete packs, the truck is controlled by one driver. Optionally, both cabs can be equipped with all operating controls. However, as both cabs are usually only used when picking long loads, one complete control station is usually sufficient. The second cab is equipped with reduced equipment options but complete safety functions.Furthermore, the MU-OP and MU-SO series are equipped with all proven HUBTEX standards, such as two-part chassis frames, robust lift masts, ergonomic workstations, three-phase AC technology and HUBTEX information terminals with color graphic displays.

ELECTRIC MULTIDIRECTIONAL SIDELOADER WITH REMOVABLE ORDER PICKING PLATFORM

-

- 2in1

- Complete multidirectional sideloader

- Complete order picking vehicle

The multifunctional 2-in-1 solution – on the one hand, the electric multidirectional sideloader with removable order picking platform from HUBTEX can be used as a conventional multidirectional sideloader. On the other hand, by attaching a platform, it can also function as a complete order picking vehicle. During the order picking operation, all functions are controlled from the platform. Lift truck and platform form one unit, providing the operator with maximum flexibility.

In addition to one-sided rack operation in narrow aisles, this order picking truck can also be used for two-sided rack operation in free-range aisles. The ready picked goods are safely removed by a separate lift truck or a transfer station.MAXIMUM FLEXIBILITY

Killing two birds with one stone: Whether used for picking processes with a removable picking platform, or "simply" as an electric multidirectional sideloader for moving and stacking long and heavy loads, our versatile all-rounder combines both capabilities perfectly.

Long loads can be securely moved and stored using the HUBTEX electric multidirectional sideloader without a platform. The detachable platform provides maximum flexibility and an optimum order picking vehicle for every order situation. As soon as the HUBTEX order picking platform is attached, the multidirectional sideloader can be controlled via a control panel on the platform. Order picking directly from the rack saves a considerable amount of time. Without a platform, the complete goods packs would first have to be placed on the floor and then picked from there.MANOEUVRING WITH MOUNTED PLATFORM

Even with the platform mounted, our electric multidirectional sideloader can be easily manoeuvred thanks to the greatest possible overview.

Don't think so? - Then see for yourself!

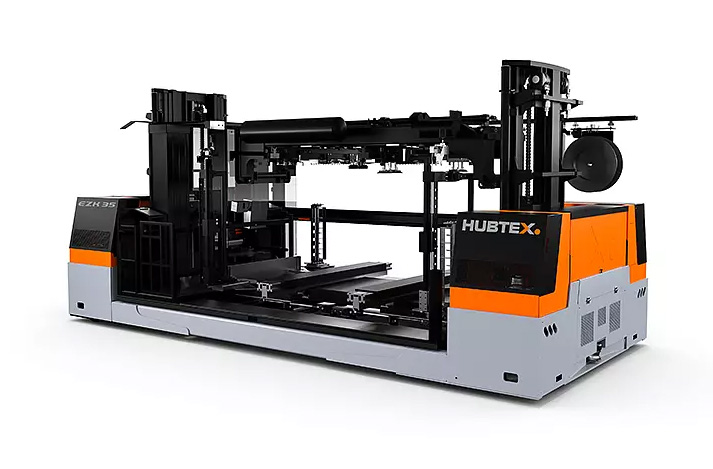

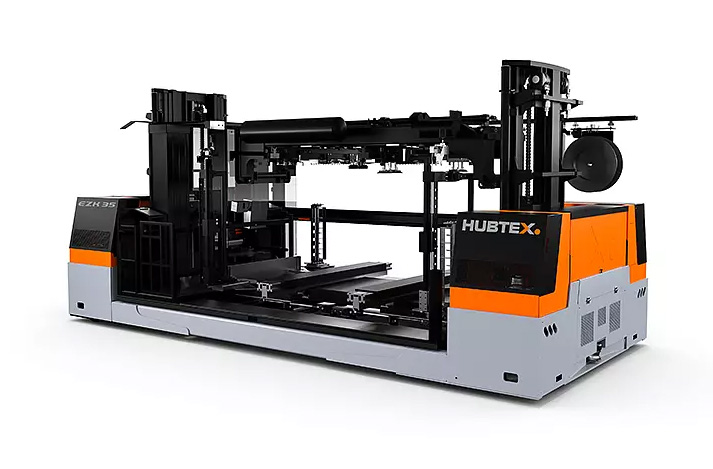

ELECTRIC MULTIDIRECTIONAL ORDER PICKING PLATFORM

-

- Order picking on both sides of the shelf

- High turnover rate

- Narrow shelf aisle width

The electric two-sided order picking platforms of the EZK series are solely order picking platforms. Whether in the 2-mast or scissor lift version, they enable the picking of profiles up to 8 m in length. The goods can be easily picked from either side of the rack aisle. A load shifting device is optionally available for both models to facilitate the removal of the customer consignment by a separate lift truck.

EZK TWO-SIDED ORDER PICKERS

In order to pick profiles quickly and without damage, manufacturers and dealers need an order picking system adapted to the individual requirements of the respective warehouse. With the help of a vehicle concept especially adapted to your needs and requirements, all areas of application can be mapped with the order picking platforms from HUBTEX.

In its basic version, the platform solution from HUBTEX is suitable purely for picking pipes and profiles on both sides of a rack aisle. Two operators stand on the platform and pick the long loads manually. Once the consignment is ready, stacking in this case is with multidirectional sideloaders. In the next expansion stage, the vehicles can optionally be equipped with telescopic tables which stack the consignment in the rack system and enable the direct transfer to the next production stage. Consequently, no additional lift truck is required to unload the goods, meaning that the rack aisles can be particularly narrow if required.

SHEET PICKER

-

BOARD AND DOOR ORDER PICKERS

Manufacturers, dealers and processing companies – they all have logistical value chains which involve the order picking of heavy and bulky sheet stock. This is because valuable wood sheets and decors in particular must arrive damage-free at the next production step or end customer. Today, there is a whole range of solutions for this complex process: from manual order picking by employees to fully automated logistics systems. It is therefore particularly important for decision-makers to have an overview of the systems available on the market and to be familiar with the decisive factors when selecting the right solution.

Another variant for applications with a high rate of turnover are the EZK order picking platforms, as they can pick from both sides of a rack aisle.- saving up to 80% of time

- quick and safely

- efficient use of resources

- reduced damage to goods, less breakage

OPTIMUM ORDER PICKING SOLUTION

We meet your challenge – the removal of heavy and bulky wood materials from the racks and their transport for loading poses numerous challenges for logisticians.

HUBTEX vehicles give you a picking solution that is tailored to your individual needs and economically beneficial.

ELECTRIC MULTIDIRECTIONAL SIDELOADER WITH REMOVABLE ORDER PICKING PLATFORM AND VACUUM SUCTION DEVICE

-

- 2in1

- Complete multidirectional sideloader

- Complete order picking vehicle

The multifunctional 2-in-1 solution – on the one hand, the electric multidirectional sideloader with removable order picking platform from HUBTEX can be used as a conventional multidirectional sideloader. On the other hand, by attaching a platform, it can also function as a complete order picking vehicle.

In the KP series configuration, the picking process is manual, while in the VK configuration, the picking process is completely automated with the aid of the vacuum suction device.

Our VK models can be used to prevent any damage caused by the manual picking of wood sheets.ANYTHING BUT STANDARD

User report – J. u. A. Frischeis GmbH

J. u. A. Frischeis GmbH relies on flexible electric multidirectional sideloaders from HUBTEX for order picking as well as for the stacking and retrieval of large-format wood sheets.

Maximum delivery capacity, ordering service and optimum flow of goods are just a few of the decisive factors that led J. u. A. Frischeis GmbH from Villach to decide on two HUBTEX wire guided electric multidirectional sideloaders. The great thing with this flexible concept is that one of the two identical MQ 70 Series 2131 PU lift trucks can be extended with the quick addition of an order picking platform if required.

The 4500 mm wide order picking platform has a load capacity of 2.7 tons and can accommodate sheets measuring up to 3000 x 2070 mm. Without a platform, the MQ 70 can move loads up to 13 m in length and 7 tons in weight. “The removable platform gives us excellent flexibility and an optimal fleet for every order situation,” says a spokesperson for J. u. A. Frischeis GmbH.2 IN 1

The multifunctional 2 in 1 solution - the electric multidirectional sideloader with pickable picking platform from HUBTEX. Without a platform, the ESTL can be used as a fully-fledged returnable stacker. Once the platform is picked up, it functions as an order picking stacker.

ELECTRIC MULTIDIRECTIONAL TWO-SIDED ORDER PICKER

-

- Order picking on both sides of the rack

- Robust construction

High carrying capacity

The storage and order picking of mainly doors and frames in pallet racks are the main tasks of the electric multidirectional twosided order pickers of the MK series. This order picker is a classic electric multidirectional sideloader with an integrated liftable cabin for picking individual customer orders.

WELL THOUGHT-OUT SAFETY CONCEPT

The optional installation of various sensors and light barriers can prevent the HUBTEX electric multidirectional twosided order picker from colliding with people or structural obstacles. The all-round protection practically excludes injuries and damage to the vehicle and other objects.

IDEAL BASIS FOR SPECIAL REQUIREMENTS

The MK series vehicle with optional multi-directional steering is characterised by its robust design and high load capacity. The powerful driving motors and the large Vulkollan wheels allow speeds of up to 8 km/h. The truck is equipped with a high load-bearing capacity. The two-stage mast with full free lift can be extended up to a height of 6,600 mm.

PROGRAMMABLE POSITION DATA

The vehicles can optionally be equipped with transponder antennas in the vehicle frame. In addition, transponders must be integrated into the roadway. These transmit signals to the transponders installed in the vehicle, which automatically ensure a dead straight and safe journey in the racking aisle. As soon as the desired rack area has been reached, the driver determines the end position with the help of the cross-line lasers mounted on the picking platform. The desired rack height can be reached with the picking platform. Thanks to the pre-programmed position data, the goods can now be picked quickly and easily with the vacuum suction device.

Electric multidirectional sideloader with removable order picking platform and vacuum suction device

-

The multifunctional 2-in-1 solution – on the one hand, the electric multidirectional sideloader with removable order picking platform from HUBTEX can be used as a conventional multidirectional sideloader. On the other hand, by attaching a platform, it can also function as a complete order picking vehicle.

In the KP series configuration, the picking process is manual, while in the VK configuration, the picking process is completely automated with the aid of the vacuum suction device.

Our VK models can be used to prevent any damage caused by the manual picking of wood sheets.- 2in1

- Complete multidirectional sideloader

- Complete order picking vehicle

Electric two-sided order picking platform with vacuum suction device

-

The electric two-sided order picking platforms of the EZK series are solely order picking platforms. Whether as the 2-mast or scissor lift version, they enable the picking of high-quality sheet materials. The goods can be easily picked from either side of the rack aisle.

- Order picking on both sides of the rack

- High rate of turnover

- Narrow rack aisle width

Glass transport systems

- We have more than 40 years of experience in the development and production of multidirectional sideloaders and special-purpose vehicles and we have devoted this to offering our customers in the plate glass industry a complete product portfolio of innovative solutions from the transport of glass packs through warehousing to dispatch. The product range is divided into special electric multidirectional sideloaders and glass frame transporters.

HUBTEX multidirectional sideloaders are used for the internal transport of glass packs weighing up to 44,000 lbs. Unpackaged glass packs, packaged glass in so-called end caps and glass packs on stillages are transported.

HUBTEX glass frame transporters are used in the plate glass industry for the transport of A and L stillages of up to 92,500 lbs. These transporters can be used for indoor or combined indoor and outdoor applications.

HUBTEX offers various vehicle solutions along the value chain. Consulting in these vertical markets poses particular challenges. Our consultants convince with their sound industry knowledge within the logistics chain in the plate glass industry.

Electric multidirectional sideloader M series

-

The modular system for our electric multidirectional sideloader offers many variants. This truck can be flexibly adapted to the requirements of the application in almost all features. M series vehicles store glass packs on floor bearers to increase storage density and therefore raise storage capacity. In addition, M series vehicles are used for order picking, with the glass packs retrieved and placed on dispatch stillages.

The electric multidirectional sideloaders from HUBTEX convince with their energy-efficient, low-noise and powerful electric drive. The 360° all-round visibility provided by the electric multidirectional sideloader ensures safe handling of glass packs with load capacities of up to 44,000 lbs. The sensitive control of all travel and lift mast movements enables the exact positioning of the vehicle and also helps to prevent glass breakage. The patented HUBTEX multidirectional steering system also increases the warehouse capacity, as the electric multidirectional sideloaders can also be used in narrow aisles.

GTR glass frame transporter

-

HUBTEX glass frame transporters are used in the plate glass industry for the transport of inloader stillages in A and L form of up to 92,500 lbs.

With its energy-efficient, low-noise and powerful electric drive, the GTI glass frame transporter from HUBTEX achieves load capacities of up to 42 tons. The elevated driver position provides the best possible visibility and highest safety standard during operation. The ergonomic cab entry with non-slip steps and handrail helps to protect the safety of the operator. The synchronous vertical lift of the frame eliminates displacement and ensures maximum precision during the lifting movement. The strengthened glass clamps with ultrasonic sensors prevent glass breaking and other damage during transport. We offer an optimized tire alternative based on how the vehicle is used.

GTT glass frame transporter

-

The GTT frame transporters are used for glass stillages with stillage feet which it is possible to drive under.

With load capacities up to 114,600 lbs, our GTT glass frame transporter is a true heavyweight champion. Thanks to the low-noise, environmentally friendly and, above all, powerful electric drive of the GTT, heavy glass stillages can also be moved with ease. The layout of the frame transporter can be perfectly adapted to any customer-specific platform dimension. The driver’s stand or the sit-down cab provide the best-possible view and highest safety standards when moving the glass packs. The lifting without displacement and maximum precision takes place via a synchronous vertical lift of the frame. And to further improve the glass clamp, ultrasonic sensors are used to monitor the load handling and the transport.

AIR CARGO VEHICLES

X-Way Mover

- From unloading the trucks and placing in storage to loading the goods on the aircraft, there are a number of different vehicles carrying out a variety of tasks in the air cargo sector.

Can you imagine a single vehicle taking over the different tasks in the air cargo sector? With the X-WAY-Mover, the complete ULD handling process from the landside to the airside can be handled. The versatile device of the latest generation is a joint product of the companies HUBTEX from Fulda and DIMOS from Petersberg. The internationally active manufacturers of industrial trucks and special vehicles have been working closely together in the air cargo sector since 2017. Already in 2004 DIMOS designed a combined handling vehicle for the air cargo sector, which has now been extended by functions and thus optimized.

Aircraft Construction Vehicles

Fuselage transporters

-

Platform transporter and track wagons are self-propelled vehicles that transport loads on and with the help of their large loading area. They are used for handling and transporting heavy loads of all kinds. In the aviation industry, for example, these include wing segments, fuselages and other components. An application example is the HUBTEX platform truck SL-AGV with a load capacity of 35 t and a height of only 457 mm. The vehicle transports aircraft fuselage parts and work platforms in a large production hall. The platform trucks can also be interconnected to form a system with a higher load capacity. The vehicles are controlled via radio remote controls. If no assembly frame is available, the HUBTEX fuselage transport trolleys transport the aircraft fuselages weighing up to 70 t from one assembly station to the next in coupled operation.

- Up to 70t load capacity

- Can be used in coupled operation

- Controlled via radio remote control

Mobilization of work platforms and stationary installations

-

These HUBTEX vehicles lift work platforms in coupled operation. The target position under the load is approached accurately and collision-free with the aid of a sensor-supported assistance system. Another mobilization solution is the combination of electrically steered drive units and load wheel units. These units can be retrofitted to stationary work platforms in order to upgrade them to a mobile system through coupling operation.

- Lift height 6m

- Up to 15t load capacity

- Control via control panel

Mobile assembly and supply platforms

-

HUBTEX assembly and work platforms are used in various work steps within the aircraft assembly. They reliably bring the fitters and the material to the desired position on the fuselage.

- Up to 5t load capacity

- Slow- & Line-Moving function available

- Control via radio remote control or workstand

HEAVY LOAD

-

Heavy-duty vehicles are an essential tool for in-plant transportation of heavy and bulky loads in various industries and fields of application. HUBTEX is a leading manufacturer of heavy-duty vehicles. The wide range of different heavy-duty vehicles is designed for transporting loads weighing up to 350 tons. In particular, platform transporters, rail-mounted trucks, tool changers and electric towing tractors play a major role in heavy-duty transport in intralogistics.

Our vehicles are durable and robust. They withstand the toughest operating conditions. HUBTEX heavy-duty vehicles also boast comparatively compact dimensions and high maneuverability. Even working in the tightest of spaces is not a problem.

TOOL CHANGERS

-

- Up to 30t load capacity

- Low platform height

- Precise positioning

HUBTEX tool changers with load capacities of up to 65 tons help to reduce the changing times for pressing and stamping tools and so improve production efficiency. A HUBTEX tool changer is used in particular when changing tools with single presses which, due to their dimensions and mass, do not have a sliding tool platform. The compact chassis also allows for extremely low entry heights below the tools.

EXTREMELY LOW PLATFORM HEIGHTS WITH SIMULTANEOUSLY HIGH LOAD CAPACITIES

Thanks to its innovative chassis, every HUBTEX tool changer can carry very high load capacities with very low platform heights. This is achieved by installing several rows of smaller wheels, which are individually designed and calculated depending on the additional load.

SMALL DIMENSIONS MAINTAINED, LOAD CAPACITY INCREASED

The tool changers from HUBTEX are characterized by their compact dimensions, as the entry situation for pressing and stamping tools or other machines is usually very confined. This is made possible by the individual frame structure of the vehicle.

PRECISE DOCKING WITH ASSISTANCE SYSTEMS

Precise docking at the center of the press is a prerequisite for fast and reliable tool changes. This avoids the need to reposition the tool on the lifting table. The exchange vehicle approaches the press with the tool platform raised. When the tool platform is lowered, the docking hook moves into the holder on the press bed. The precise positioning can be covered by a variety of assistance systems. Simple systems such as a line laser at the control station for precise positioning of the transporter in front of the press bed in combination with a lift height indicator and distance display of the tool platform are just as conceivable as a fully automated positioning system.

SFX platform transporter

-

The transport of heavy and bulky loads presents a particular challenge. HUBTEX is able to meet this challenge with heavy-duty platforms in its new SFX series. The compact, self-propelled heavy-duty transport vehicles for indoor and outdoor use have a large loading area for transporting bulky, heavy loads.

- Electric drive, quiet and environmentally friendly

- Electric battery, maintenance-free AC drive technology

- 2-way and multidirectional steering

- Four different operating variants (cabin, driver station, remote control or automation)

- Robust design

Rail mounted truck

-

The rail-mounted trucks (GW) from HUBTEX are individually configured according to your wishes and requirements. They are designed for in-house transport on straight rails. If cornering is required, this must be considered on a case-by-case basis.

They are controlled by an accompanying operator with cable remote control, but can also be automated. By defining the weight classes, HUBTEX specifies the appropriate rail-wheel-to-rail combination and determines the suitable gearbox and drive motor. The dimensions of the frame are individually designed according to the customer requirements. The load capacity must account for at least 65% of the length and width and be centered and evenly distributed.- Up to 350t load capacity

- Long service life

- Simple automation

Electric towimg tractor

-

The field of application of the electric towing tractor with goose-neck is primarily the automotive industry and its suppliers. The HUBTEX electric towing tractor with hydraulic goose-neck is equipped with a driver's seat and suitable for handling cargo trailers when coils need to be transported frequently, quickly and reliably. Furthermore, the fast and reliable transport of heavy, compact machine parts is part of the tasks of our electric towing tractor. HUBTEX designs the right vehicle for every application and every customer requirement.

- Up to 50 t system load

- Lifting cargo trailers

- Cost effective heavy-duty transport