- Offer Profile

- The STAHL CraneSystems brand stands for reliable and safe hoists and crane components as well as methodical engineering solutions. The products are used in standard, special and explosion-protected bridge cranes or hoisting systems in industries such as automotive, oil and gas, power station construction, chemical industry, transport and logistics, steel and concrete industry, food industry, mechanical and plant engineering, air and road transport industry as well as in the pharmaceutical and food industry. STAHL CraneSystems is a globally recognized brand for explosion-protected crane technology and comprises one of the most extensive, seamless product portfolios. Customers include crane builders, machine/plant manufacturers as well as planning and general contractors all over the world.

Reliable and safe hoists from STAHL CraneSystems

-

Reliable and safe hoists from STAHL CraneSystems

The STAHL CraneSystems brand stands for reliable and safe hoists and crane components as well as methodical engineering solutions. The products are used in standard, special and explosion-protected bridge cranes or hoisting systems in industries such as automotive, oil and gas, power station construction, chemical industry, transport and logistics, steel and concrete industry, food industry, mechanical and plant engineering, air and road transport industry as well as in the pharmaceutical and food industry. STAHL CraneSystems is a globally recognized brand for explosion-protected crane technology and comprises one of the most extensive, seamless product portfolios. Customers include crane builders, machine/plant manufacturers as well as planning and general contractors all over the world.

Learn more about our products! - Electric chain hoists

-

Our Stahl CraneSystems electric chain hoists offer performance, reliability and long service life for even the most demanding applications and heavy loads. They are available in various load capacities, lifting heights and configurations and can be adapted to your exact requirements. Our electric chain hoists are among the safest on the market and are equipped with a wide range of standard or optional features, such as slipping clutch for overload protection or limit switches to extend the service life and safety.

In addition to the stationary top hook or lug, there are different trolleys (push trolley, geared trolley, electric trolley) for all commercially available beam profiles and cranes in the product range.

Many industries have specific requirements for the electric chain hoists they need, which is why we develop and produce solutions for every industry. Our portfolio also includes special electric chain hoists for use in event and stage technology, for wind turbines, in clean rooms and for the food, beverage and pharmaceutical industries.

ST Chain hoist

- The loyal companion for everyday tasks

The ST chain hoist programme ranks among the most distinctive and comprehensive on offer worldwide. It is strong, reliable and modest when it comes to maintenance and energy consumption. The modular system enables innumerable combinations of the subassemblies for customised solutions. With 6 variants available, the ST chain hoist covers the lifting capacity range from 125 kg to 6,300 kg. The portfolio is supplemented by special models such as the STK extra short headroom trolley and the STD dual chain hoist for long material and lifting beams. The chain hoists are also available in explosion-proof design for Zone 1, Zone 21 and Zone 22.

Features and Benefits- Extensive chain hoist range for lifting capacities from 125 kg to 6,300 kg

- Suspension directly from the chain guide of solid cast iron

- Easy inspection and maintenance of the chain drive thanks to overmounted drive shaft

- Extremely short and compact construction ensures that space can be utilised to the maximum

- High ISO classification according to FEM/ISO standards

- Modern Kanban production, available fast

- Available as an option in explosion protected design complying with ATEX and IECEx

STK Chain Hoist

- The STK chain hoist is a powerful, reliable and robust classic that proves itself day after day in use. Standard components bring economic advantages, but in combination with the precise manufacture of special components, the ST chain hoist is a unique choice.

STD dual chain hoist

-

Safe transport of long loads

The STD dual chain hoist was developed specifically for long material and loads that need to be picked up at two points. It is equipped with two load chains, which are moved synchronously by a hoist motor. The hook spacing can be selected at will in dependence on the material being transported. The two synchronised rope lead-offs lift and transport the load without dangerous slant by design. The two load hooks work absolutely safely and in sync even in the case of materials of different lengths or uneven loading. Thanks to its low headroom, the STD dual chain hoist is also suitable for low buildings and achieves maximum hook paths. The chain hoists are also available in explosionproof design for Zone 1, Zone 21 and Zone 22.

Features and Benefits- Low space requirement permitting maximum height of lift

- Two hook lead-offs running in synch on one hoist

- Synchronous lifting even with uneven loading, no tilting of the load

- Individually adapted to width of load

- Low maintenance

- Optionally available in explosionprotected design complying with ATEX and IECEx

STB Chain Hoist (Big Bag)

-

Lifting bulky loads without obstruction

The Big Bag version, a special variant of the STD dual chain hoist, is designed for safe working loads up to 3,200 kg. Its special features are the freely selectable distance between chain hoist and load hook as well as lifting of bulky loads up to the highest hook position without obstructing edges such as trolley, chain hoist or chain box getting in the way. The chain hoists are also available in explosion-proof design for Zone 1, Zone 21 and Zone 22.

Features and Benefits- Freely visible distance to the load hook

- Trouble-free lifting up to the highest hook position

- Low height for low halls

- Payload up to 3,200 kg

- Based on the popular STD double chain hoist and the proven ST series

- Explosion-proof design possible

ST Ex Chain Hoist

-

Explosion-proof ST Ex chain hoists rank among the safest technology available on the market for the chemical, petrochemical and pharmaceutical industries, the food processing industry as well as the power supply, shipbuilding, offshore and natural gas liquefaction (LNG) industries. The ST Ex chain hoist programme is based on the modular ST chain hoist programme. The safe working load range for use in Zone 1 and Zone 21 is from 250 kg to 6,300 kg, and from 125 kg to 6,300 kg for use in Zone 22. All components are made by us and add their part to full high-quality explosion protection. The strict ATEX directives and IECEx regulations for mechanical and electrical explosion protection are naturally fulfilled.

Features and Benefits- International specialist for explosion protection technology

- One of the most extensive chain hoist ranges for Zone 1, Zone 21 and Zone 22 worldwide

- Based on the ST chain hoist

- Design to ATEX and IECEx in certified quality

- All equipment available in explosion-protected design

STF Chain Hoist

-

The STF chain hoist combines the proven technology of the ST chain hoist with the advantages of the Magnetek IMPULSE® frequency inverters. Equipped with the IMPULSE®·G+ Mini as standard, the STF chain hoist not only allows precise movements, but also provides valuable diagnostic and performance information such as the current status of the chain hoist via data exchange with IoT networks. You can find further information in our press article.

Features and Benefits- Standard equipment with Magnetek IMPULSE· G+ Mini

- Optional frequency-controlled drive

- Easy connection to IoT networks

- Increased safety through overspeed protection and standstill monitoring (Rotation Control SRC)

- 1024 PPR tachometer for reliable feedback in rough operation

- Simple plug-and-play application

- Optionally available in protection class IP66, brake resistance optionally also available in IP67

Electric Wire Rope Hoists

SH wire rope hoist

-

The tried and tested all-rounder

The SH wire rope hoist programme is used around the world in many different applications. Compact, strong, particularly maintenance-friendly and an ideal when it comes to combining quality, flexibility and performance. The module system enables almost unlimited combinations of the components. Coming in five sizes with 26 S.W.L. variants, the SH series covers the safe working load range from 500 kg to 25,000 kg. The new SH 6080 wire rope hoist extends the versatile SH wire rope hoist range to safe working loads up to 32,000 kg. The wire rope hoists can be used in stationary applications or together with trolleys in standard cranes, off-standard cranes or systems building. If wanted, the complete wire rope hoist programme is also available in explosion-proof design for Zone 1, Zone 2, Zone 21 or Zone 22.

Features and Benefits- 5 sizes, 26 S.W.L. variants

- Stationary version or various trolleys for cranes and systems building

- Compact size thanks to U-shape

- Largely maintenance-free, low wear, long service life according to FEM/ISO standards

- Standard series with two lifting and two travel speeds

- Particularly soft starting and braking

- Standard series with high-quality safety components for improved work safety

- Optionally available in explosion-proof design according to ATEX and IECEx

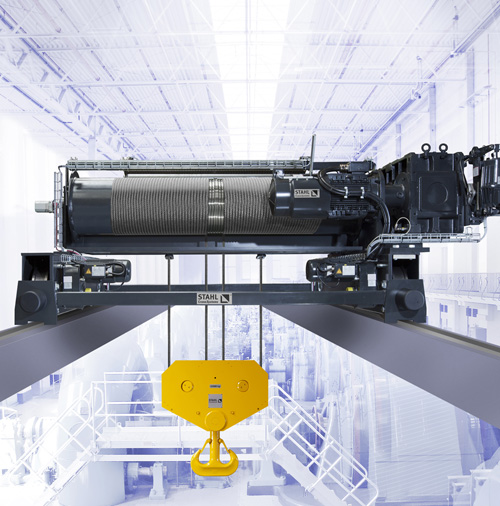

AS 7 wire rope hoist

-

The compact powerhouse

The AS 7 series is designed in two variants for the upper lifting capacity range to 125,000 kg. The ASR 7 wire rope hoist is the reduced version of the tried-and-tested AS 7 wire rope hoist. It is designed for a safe working load range from 20,000 kg to 32,000 kg and closes the gap between efficient use of the SH wire rope hoist programme and the AS 7 wire rope hoist programme. The revised design as twin hoist covers the same fields of application as the AS 7 wire rope hoist, albeit with higher lifting capacities, greater lifting heights and faster lifting movements. One important safety feature of the AS 7 wire rope hoist when designed as twin hoist is its exact positioning of the load. As the rope of the twin hoist runs in opposite directions simultaneously, the load is lifted and lowered without any sideways movement of the hook. If wanted, the complete wire rope hoist programme is also available in explosion-proof design for Zone 1, Zone 2, Zone 21 or Zone 22.

Features and Benefits- Two designs for load capacities up to 125,000 kg

- Reduced-size ASR 7 for a safe working load range from 20,000 kg to 32,000 kg, with larger height of lift, standard with exact load measurement at the rope anchorage (entry-level model)

- Innovative drive technology with cylindrical rotor motor with monodisc spring-loaded brake

- Stationary version or double rail crab for systems and crane building, optionally available as underslung trolley or articulated trolley

- Compact construction and low approach dimensions

- Higher load capacity, hoisting speed and lifting height as twin hoist

- Largely maintenance-free, low wear, long service life according to FEM/ISO standards

- Optionally available in explosion-proof design according to ATEX, IECEx

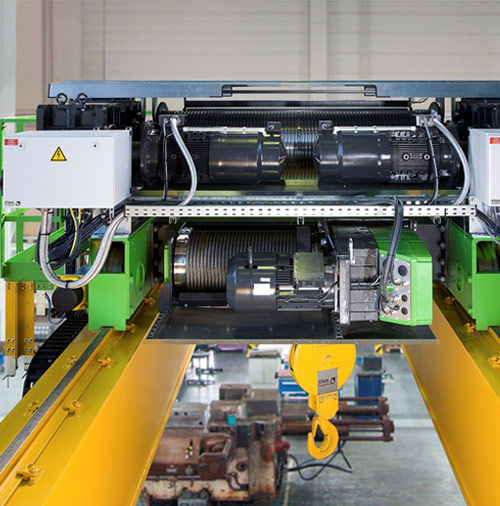

SHW 8 winch

-

Top technology for the heaviest of loads and high demands

The SHW 8 winch program is based on the tried-and-tested SH wire rope hoist program and is designed for the high-load bracket up to 160,000 kg. Its strong hoist motors and robust, low-maintenance design make it ideal for tough everyday use. Compared to wire rope hoists, winches only need a few rope reevings even for high loads, making a very compact construction possible. To enable a variety of different economical solutions, there are three motors up to 38 kW with two speeds in a ratio of 1:6 available for the SHW 8 winch. For higher ease of use, there are six hoist motors up to 98 kW with stepless speed control. All travel drives are equipped as standard with soft start. The SHW 8 winch is available on request with high-performance frequency inverters or with individually adapted speeds. The winch programme is also available in explosion-proof design for Zone 1, Zone 2, Zone 21 or Zone 22.

Features and Benefits- Thousands of proven series components of the SH series

- Modular design for economical individual solutions, easy transport and fast assembly

- Versatile drive technology meets demanding specifications: 3 lifting motors up to 38 kW with two speeds in a ratio of 1:6 and 6 lifting motors up to 98 kW and infinitely variable speed control

- All travel drives with smooth start-up behaviour

- Overload shutdown is already preset during production

- Compact height due to innovative design of the cable drive

TDC Twin Drive Concept

-

Twice as safe and reliable

The TDC Twin Drive Concept is the uncompromising solution for hoists according to DIN EN 14492-2, Annex B. TDC wire rope hoists are suitable for the transport of molten metals and for use in high-risk applications: e.g. acids, alkalis, gases or transport through gas and acid pipelines. They are equipped as standard with two redundant motor/gearbox units. Generally, both motors are actuated synchronously. Each of the brakes mounted on the two motors are designed such that they are able to brake or hold the load on their own in an emergency. Both brakes are actuated together and serve as operating and holding brake. All drives in Twin Drive Concept wire rope hoists are monitored by condition monitoring systems from STAHL CraneSystems.

Features and Benefits- Fulfils requirements of industry standard EN 14492-2

- TDC prevents the load dropping even if the gear should break

- Two synchronously controlled hoist motors and brakes

- Continuous monitoring of brakes, drives and load

- Twin gear and braking safety

- Two brakes with manual release for emergency lowering

- Robust, fully enclosed system

- Up to 60 % higher load capacity when not transporting molten metals

Explosion-Proof Products

- The entire product range in explosion-proof design according to ATEX and IECEx.

SH Ex Wire Rope Hoist

- Explosion-proof Ex wire rope hoists and SHW 8 Ex winches rank among the safest technology available on the market for the chemical, petrochemical and pharmaceutical industries, the food processing industry as well as the power supply, shipbuilding, offshore and natural gas liquefaction (LNG) industries. The Ex wire rope hoist programs and SHW 8 Ex winch program are based on the corresponding wire rope hoist programs and SHW winch program respectively. All components are made by us and add their part to full high-quality explosion protection. The strict ATEX directives and IECEx regulations for mechanical and electrical explosion protection are naturally fulfilled.

Features and Benefits- International specialist for explosion-proof crane technology

- Cable pull programs and winch program for Zone 1, Zone 21 and Zone 22

- Everything from a single source and in-house production

- Design according to ATEX and IECEx in certified quality

- All equipment available in explosion-proof version

AS 7 Ex Wire Rope Hoist

- Explosion-proof Ex wire rope hoists and SHW 8 Ex winches rank among the safest technology available on the market for the chemical, petrochemical and pharmaceutical industries, the food processing industry as well as the power supply, shipbuilding, offshore and natural gas liquefaction (LNG) industries. The Ex wire rope hoist programs and SHW 8 Ex winch program are based on the corresponding wire rope hoist programs and SHW winch program respectively. All components are made by us and add their part to full high-quality explosion protection. The strict ATEX directives and IECEx regulations for mechanical and electrical explosion protection are naturally fulfilled.

Features and Benefits- International specialist for explosion-proof crane technology

- Cable pull programs and winch program for Zone 1, Zone 21 and Zone 22

- Everything from a single source and in-house production

- Design according to ATEX and IECEx in certified quality

- All equipment available in explosion-proof version

ST Ex Chain Hoist

- Explosion-proof ST Ex chain hoists rank among the safest technology available on the market for the chemical, petrochemical and pharmaceutical industries, the food processing industry as well as the power supply, shipbuilding, offshore and natural gas liquefaction (LNG) industries. The ST Ex chain hoist programme is based on the modular ST chain hoist programme. The safe working load range for use in Zone 1 and Zone 21 is from 250 kg to 6,300 kg, and from 125 kg to 6,300 kg for use in Zone 22. All components are made by us and add their part to full high-quality explosion protection. The strict ATEX directives and IECEx regulations for mechanical and electrical explosion protection are naturally fulfilled.

Features and Benefits- International specialist for explosion protection technology

- One of the most extensive chain hoist ranges for Zone 1, Zone 21 and Zone 22 worldwide

- Based on the ST chain hoist

- Design to ATEX and IECEx in certified quality

- All equipment available in explosion-protected design

LNG Wire Rope Hoists

- LNG hoists for liquefied gas trains and terminals

The LNG hoists from STAHL CraneSystems are designed specifically for maintenance work on liquefied natural gas (LNG) tanks. Due to their high-quality components, robust construction, corrosion-resistant finishes and many other features, they are ideally suited for use in coastal regions with demanding climatic conditions. The pumps, which pump the cold liquefied natural gas (–164 °C to –161 °C) in a pipe system, must be lifted out of the approximately 70 metre high tanks into the open for maintenance work up to five times a year. In view of the extreme conditions in the tank, special ropes, which are fastened permanently to the liquefied natural gas pump and therefore spend their lives in the tank, are needed for this. When maintenance work needs to be carried out, these ropes are fastened to the rope drum and hoist with quick fasteners.- Sophisticated engineering perfectly tailored to your project

- Matured through the use of proven standard components

- International specialist for explosion-proof lifting and crane technology

- In-house production with certified quality assurance

- All special solutions certified according to ATEX guidelines or IECEx regulations

- Partner for international, regulatory processes

- Complete documentation

Core competencies of STAHL CraneSystems

Competence in Explosion Protection

- STAHL CraneSystems - one of the world market leaders for explosion-protected lifting technology and crane components.

Modernization of Crane Systems

- In the course of their long service life, the requirements placed on crane systems and crane technology change.

Liquefied Natural Gas (LNG)

- LNG is purified natural gas consisting to more than 90 % of methane. It becomes liquid by cooling to –161 to –164°C.