- Offer Profile

- INNOVATION + RELIABILITY =

SUCCESS

Fischer-Brodbeck GmbH (FIBRO) was founded in Weinsberg in 1958 and since 1974 has been part of the Läpple Group. Today FIBRO employees are active worldwide in the fields of standard parts.

THE FIBRO-GROUP AT A GLANCE:- approx. 700 employees worldwide

- Wholly owned subsidiaries in France, the USA, Canada, India, Switzerland, Singapore, Korea and China

- More than 70 representative and service stations worldwide

- Quality management system to DIN ISO 9001

- Environmental Management System to DIN ISO 14001

We love technology

STANDARD PARTS

- With ample stock levels and rapid delivery schedules for standard parts manufactured in its factory in Hassmersheim, Germany, FIBRO has become a household name around the world.

Standard Parts

-

Standards in high-tech perfection

Standard parts are used as standardised products in tool construction, mould making and mechanical engineering. FIBRO standard parts mean ultimate precision.

We are a global market leader working closely with our customers offering high availability, rapid delivery times, a first-class service and an outstanding price/performance ratio.

The Standard Parts business unit is located at the FIBRO factories in Hassmersheim and Weinsberg in Germany. This is where an extensive range of standard parts are produced, stored and shipped worldwide - including just-in-time.

-

Standards in high-tech perfection

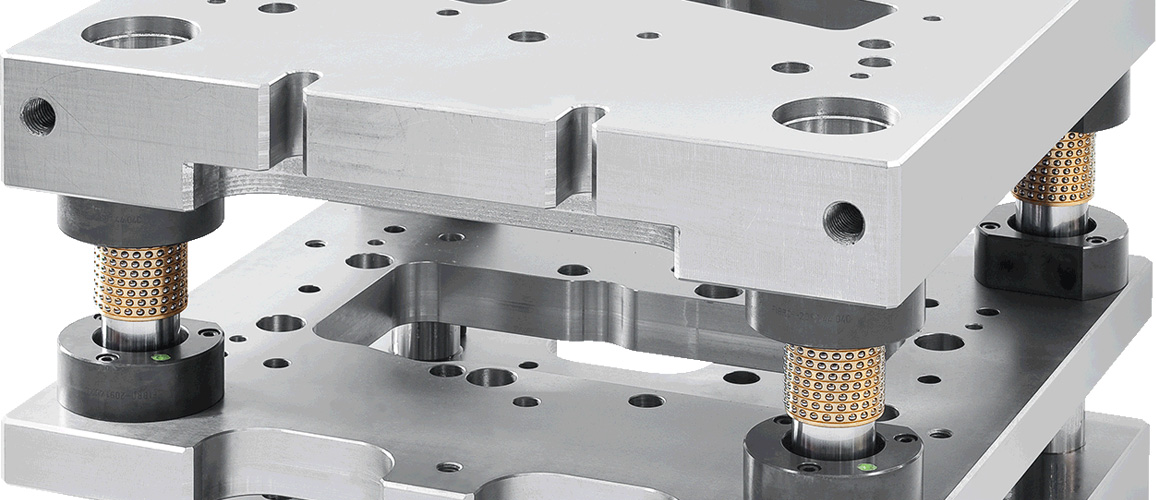

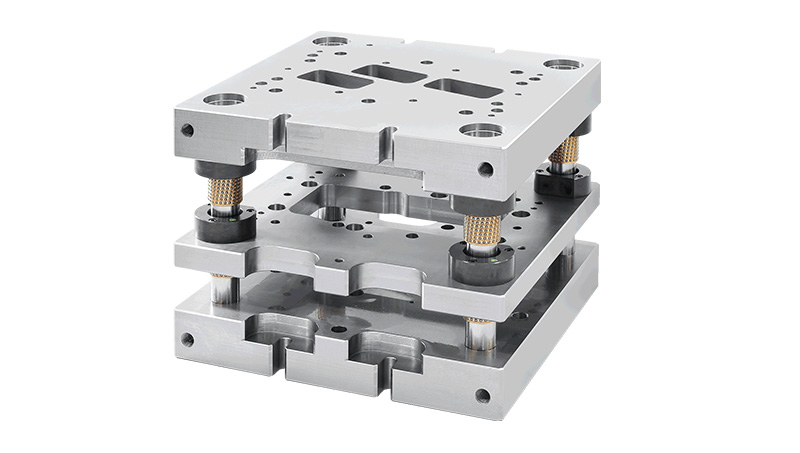

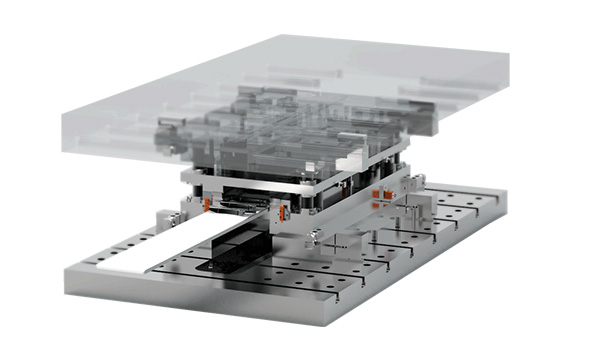

DIE SETS THE STABLE BASE FOR YOUR TOOLS

-

DIE SETS

PER DIN / ISO AND COMPANY STANDARDS- Our product range includes die sets as per DIN / ISO and company standards made of steel, cast or aluminium with slide or ball guide. We also distribute small presses, precision tool assemblies and quick change tool sets.

- On request, we deliver to you these die sets with other guide elements, such as roller guides, for example. Of course, we also manufacture individual custom-made pillar guide sets.

- Those who prefer cost-effective die sets will receive the ECO-Line steel pillar set, a set with bronze-plated sliding guide bushes.

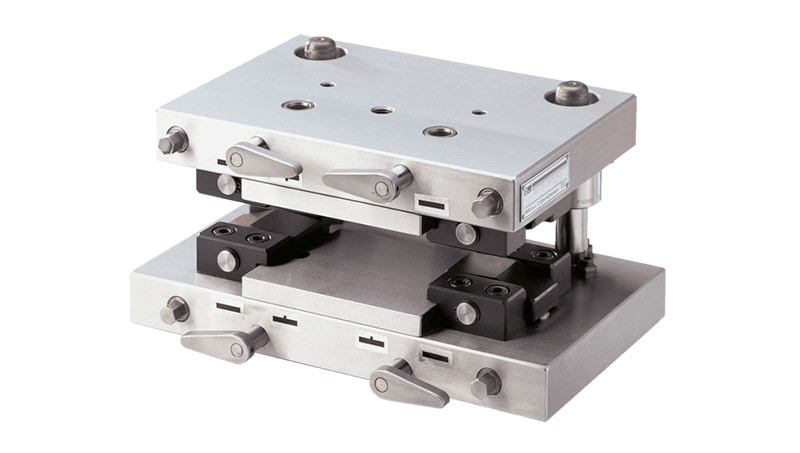

TOOLING PALLET DIE SETSS

-

If you have to be quick again...

… you should not be without our Tolling Pallet Die Set.

The advantages clearly speak for themselves - simple, fast and cost-effective! Market-oriented reaction during the manufacture of small parts series. While the basic set remains in the press, the clamping of slide-in tools can be carried out quickly. This favours a reduction in tool costs and shortening of the set-up times.

Custom-Made Die Sets

-

Made to measure

Up to a size of 2,200 x 950 mm we manufacture die sets and plates according to customer drawings and with the most precise special machining.

If possible, holes, cutouts and / or bores should be done by FIBRO, because subsequent major cutting proccesses can cause distortion, as shown by experience.

Our standard material for steel plates is St52-3. In accordance with your specifications, other materials are possible as well, of course. Naturally, we also manufacture aluminium plates (AlZnMgCu 1.5 F53 - 3.4365).

CAD data exchange

To avoid any transmission errors we would like to ask you to submit your producion drawing and 3D models (if available) with your inquiries / orders in the formats mentioned below:

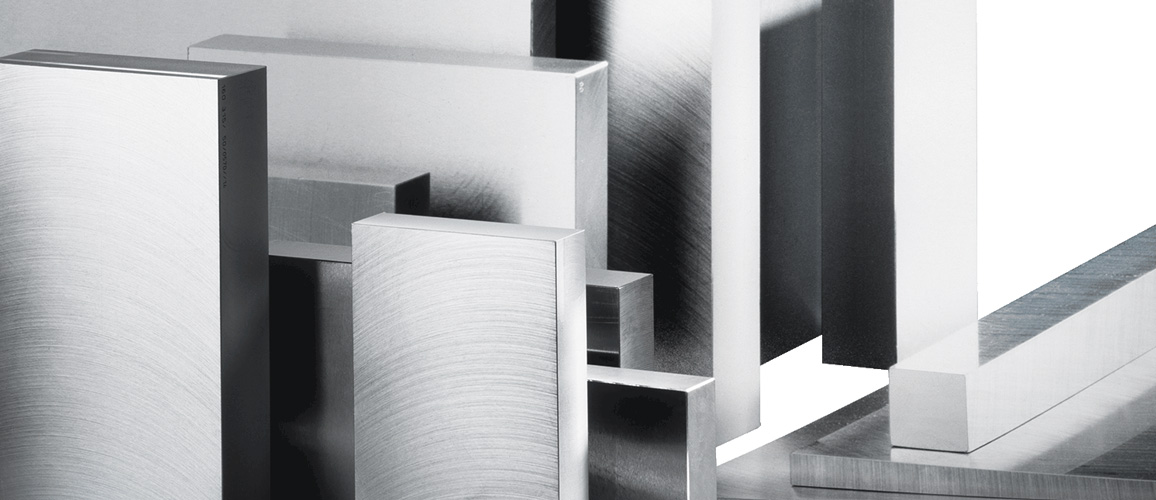

PRECISION GROUND PLATES AND FLAT BARS

-

We can supply to you aluminium plates in standard dimensions (~ ISO 6753-1).

Special dimensions are available on request. Furthermore, we offer flat and

square tool steel, pre-ground or precision-ground as per DIN 59350, in various

dimensions and materials.

Our standard materials for steel plates are St52-3 and aluminium (AlZnMgCu 1,5 F53 - 3.4365). This material is also used for our standard die sets.

Should you prefer another material, this is also available. LIFTING AND CLAMPING DEVICES

-

Our extensive standard parts accessories include, among others, clamping devices, clamping and lifting journals as well as hoisting gear. For required sizes and weight groups, we stock support and mounting elements, which are intended for the safe transport of tools that weigh up to 63,000 kg.

The load handling devices meet the requirements of the Machinery Directive 2006/42 / EC on the CE marking.

GUIDE ELEMENTS

-

Precision at the highest level

The production engineering possibilities of FIBRO allow the manufacture of three even finer tolerance classes for the already exact guide pillars and bushes. This makes it possible to achieve exactly defined guide clearances for sliding guides or initial loads of ball guides.

Depending on the application, we offer guide elements for self-assembly of custom-made die sets or devices in various designs. These include sinter sliding, ball or roller guides as well as low-maintenance sliding elements for round or flat guides.

Especially our ball guides are not only intended for mould making and tool manufacture. It does not matter whether in measuring or dental technologies, mechanical engineering or in the optical industry. If precise movements are to be carried out, our ball guides prove themselves time and again.

Our team will gladly lend you its support, should you have any questions regarding the correct pairing of guide bushes and pillars.

GUIDE UNIT MILLION GUIDE

-

Printed circuit boards, chip cards, LEDÂs, semiconductors or lids for the food industry, all of which are manufactured with foil stamping technology, require a die set with high precision guides in order to achieve an extremely narrow cutting gap.

With a high contact surface for needle rollers, our guide unit MILLION GUIDE is best suited for this purpose.

This way, the guide unit MILLION GUIDE achieves a high level of rigidity, stablility and a very high guidance accuracy.

RECIRCULATING BALL BUSHES

-

For long travel distances with moderate loads, recirculating ball bushes are an excellent alternative to ball guides.

ECO-LINE GUIDE ELEMENTS

-

The ECO-LINE guide elements provide a low cost, but not inferior alternative to the other guide bushes with collar or flange. They are interchangeable with them easily and useful if you do not have high precision requirements.

THE ECO-LINE PRODUCT RANGE INCLUDES SO FAR:

- Guide pillars ECO-LINE

- Guide pillars with collar ECO-LINE

- Guide bushes with collar, bronze plated, ECO-LINE

- Guide bushings with collar / flange, bronze with solid lubricant rings, ECO-LINE

The ECO-LINE guide bushes with solid lubricant rings are the link between the guide bronze guide bushes with solid lubricant nests and the guide bushes to DIN-ISO. They meet the requirement for a stable guiding with low maintenance.

OILLESS GUIDE ELEMENTS

-

Our maintenance-free sliding elements found in tool and machine for linear and rotary movements for years use. The base material is supplemented by solid lubricant depots, which provide lubrication. After this one-time initial lubrication sliding elements over a long period maintenance free. The fullness of this product range is vast range of applications. In addition, of course, also special designs according to your wishes at any time.

GROUND PRECISION COMPONENTS

-

THE BE-ALL AND END-ALL GROUND PRECISION COMPONENTS

Our range of precision parts include punches with bevel/flat head or cylinder head according to DIN regulations or made to drawing in 8 different material qualities as well as quick-change punches.

All these high-wear parts benefit from the constant monitoring of quality that characterizes our entire standard parts fabrication process, from receipt of raw materials through to dispatch of the finished product. The result - an exceptionally long die life - cuts costs dramatically in the punching shop by reducing the need for tool changes.

ALSO AVAILABLE

- Retainers for punches and ball-locked punches

- Gauge pins with and without handle, as single pins and also in sets

- Gauge pins DIN 2269

- Dynamic stripper elements (DAE)

- ACCU-LOCK Fixture device for ball-lock punches

- Punches with tapered head

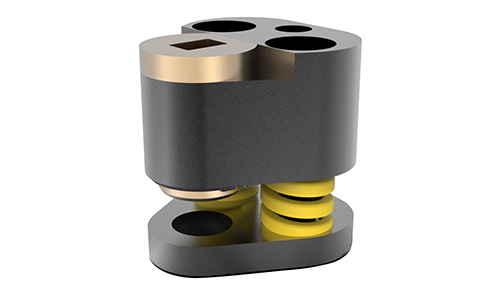

STRIPPER UNIT: POLY STRIP

-

The bronze scraper bush also avoids undesirable silicone deposits on the exterior components.

The compact design allows the cutting elements to be organised in a minimal space.

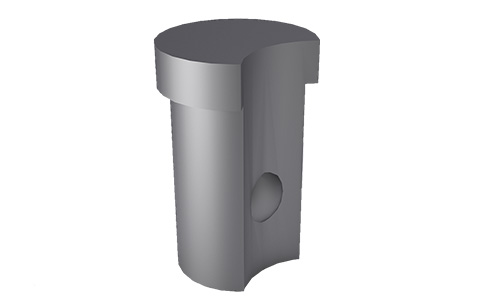

DAE: DYNAMIC STRIPPER ELEMENTS

-

The Dynamic Stripper (DAE) is used in stamping tools for stamping processes with a material thickness of up to 2 mm. The

DAE is located beneath the matrix.

The shape can be compared with a slotted sleeve (similar to collet chucks). After the actual stamping process, the cutting punch, together with the adherent slug, dips into the DAE. In doing so, the DAE expands and rests against the cutting punch. During the return stroke, the DAE removes the slug from the cutting punch, protecting the tool and the product from damages

FOR BALL-LOCK PUNCHES: ACCU-LOCK FIXTURE DEVICE

-

The new holding inserts for quick-change punches are available in two versions, light and heavy-duty. They are installed directly in the tool plate; the previously neccessary additional mounting plate is no longer required. Only two holes for the punch and the holder/bracket have to be drilled.

Was it in the past not possible to place quick-change punches close to each other due to the external shape of the mounting late, the ACCU-LOCK holding inserts are practically no longer an obstacle.

Due to the design of the mounting plates, it is not possible to place the punches close together - now a few millimeters distance are no longer a problem. For example, the entire structure of tool slides can be made significantly more compact. FIBRO offers the holding inserts as individual parts and also in the future, with a multiple mounting plate made according to customer requirements, fully assembled.

DIFFERENT SPRINGS AND SECURITY FEATURES

-

- Steel Springs

We manufacture and deliver steel springs and spring shape elements for stamping and forming technology as well as High Performance Compression Springs made of special steel, disc springs and spring shape elements. - Elastomer Springs

We offer a wide range of elastomer springs, spring shape elements, ejectors and stripping units made of polyurethane rubber. - Gas Springs

The extensive range of FIBRO Gas Springs constitutes an ideal supplement to and expansion of the traditional programmes of springs elements such als helical springs, disc springs and elastomer units.

- Steel Springs

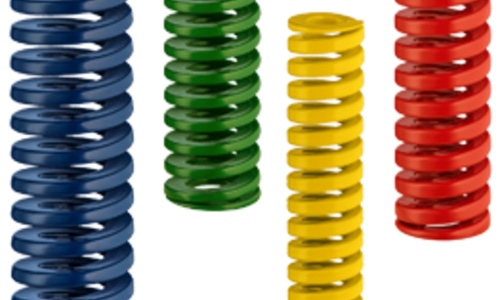

COMPRESSION SPRINGS

-

We manufacture and supply special spiral compression springs, steel springs and spring elements for punching and metal forming technologies as well as diaphragm springs and spring shape elements.

The spring type used depends on the individual requirements. We have four load groups that can be used in either tool manufacture, engineering or in the construction of jigs and fixtures.

The permissible value of the shear stress and the spring oscillating stress differential depends on the spring material used. FIBRO special spiral compression springs are manufactured from 50CrV4. The specially milled profile allows a high level of alternating and continuous loads and is ready for operations at working temperatures of up to 250°C.

The portfolio contains the following sizes:- round cross section

- square cross section

- spring displacement from 30% to 100%

- diameter 10 mm to 63 mm

- lenght 25 mm to 305 mm

ELASTOMER SPRINGS TO DIN ISO 10069-1

-

We offer a wide range of elastomer springs, spring shape elements, ejectors and scrapers made of polyurethane rubber. Under the column "elastomers", you can convince yourself that FIBROFLEX® elastomer springs cannot only be used as pure spring elements but also as forming elements.

During continuous loads, elastomers loose some of their abilitiy to regain the original shape. Over time, deformation residue occures, i. e. the elastomer settles. Depending on the spring displacement utilisation, the tendency towards initial sagging relating to the original spring height amounts to 8 - 10 %.

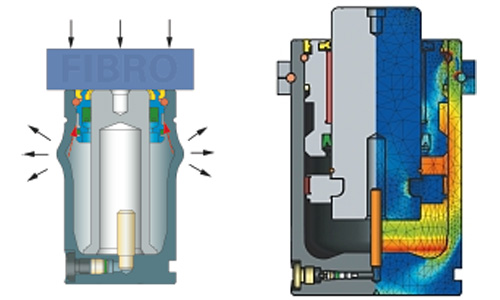

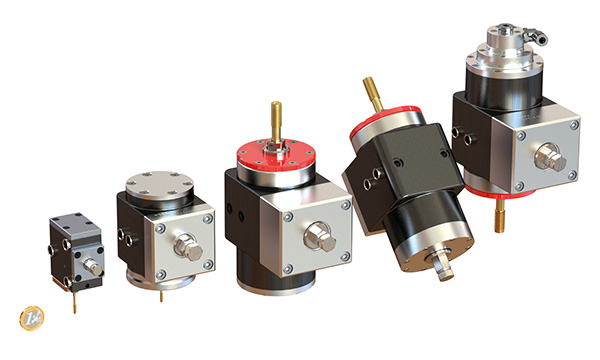

GAS SPRINGS

-

Compact gas springs represent a substantial step forward in spring technology and are also available for high-temperature environments. Apart from the stipulated Pressure Equipment Directive 2014/68/EU, some of our gas springs are equipped with additional safety features. "The Safer Choice" are unique safety advantages that include overstroke protection, overpressure protection and piston rod protection. This puts our spring among the safest on the market.

Wether reshaping, cutting or punching, nearly all renowned tool manufacturers rely on the versatility when using FIBRO gas spring. A gas spring is a self-contained receptacle, which is filled with nitrogen gas. A piston rod moves into the space and compresses the gas located inside. Because the gas wants to expand again, the piston rod is forced out at a defined force (force = pressure x surface).

WIRELESS PRESSURE MONITORING (WPM)

-

The optional Wireless Pressure Monitoring System (WPM) (patent pending) wirelessly monitors the pressure and temperature of FIBRO gas springs. Before a defective part is produced, the press operator receives a message from the WPM and can take appropriate action.

ADVANTAGES

- Around-the-clock monitoring and documentation

- Early warning signalling prevents the production of unacceptable parts.

- Pre-emptive wear detection and targeted troubleshooting

- Avoidance of downtimes and follow-up damage

- Minimisation of points of leakage

- Streamlined construction and assembly

- Optimised maintenance intervals and reduction of maintenance and repair costs.

SAFETY FEATURES

-

At FIBRO, safety has always been a top priority. Below is what we do to help you provide a safer working environment.

FIBRO Safety Features

Designed for controlled gas venting through piston rods with integral safety stops and specially designed guides.

Over-Pressure Protection System

FIBRO Over-Pressure Protection System is designed to vent excessive gas pressure in a controlled manner.

Over-Stroke Protection System

FIBRO has a developed unique System. The cylinder wall is designed to deform in a predefined way, venting the internal gas pressure in a controlled manner.

ELASTOMERS

-

Our product portfolio includes plates, tubes and profiles as forming elements for unconventional solutions, for sensitive surfaces and for special solutions. Our elastomers are also interesting as buffers, scrapers and ejectors. Cutting, stamping and reshaping by means of FIBROFLEX® forming materials is especially suitable for the production of small and medium series.

THE MAIN ADVANTAGES ARE...

- ... favourable expenditure of time and costs. for dimensional workpiece modifications or release series, this also means a quick response to new market or delivery time requirements.

- ... a surface-protecting manufacturing procedure. plates that are pre-coated or have a high gloss finish and must be protected from scratches or damages are gaining an increasing importance. Here, often the only alternative is reshaping by means of FIBROFLEX®.

- ... the considerably longer service life in comparison to natural and synthetic rubber types.

FIBRO-CHEMICAL TOOLING AIDS

-

In addition to our standard parts program, you will receive processing accessories from the ÂFIBROLIT® CHEMIEÂ range to support tool manufacture.

- Tool cast resin

- Metal adhesives

- Quick cleaner

- Rust/corrosion releasing lubricant/agent

- Leak detector spray

- Marking out blue

- Release agent

- Oils and greases

PERIPHERAL EQUIPEMT

-

Select from an extensive product portfolio for presses and tool manufacture. Ball inserts, ball bars, roller inserts and roller bars for a quicker and easier changeof your tools. For the transportation of waste or parts, you can order conveyor belts with different drive types. Serveral motorised versions and one pneumatic version can be selected.

The pneumatically driven and patented transporter was designed as an effective and inexpensive solution for problems associated with the transport of parts and waste disposal. This systems - without any conveyor belt - conveyors only by means of vibration.

The electromechanical conveyor also works with vibration. Due to its great flexibility, the conveyor is an ideal solution, where short product cycles require frequent tool changes. The adjustments of waste disposal is quickly accomplished.

And if you wish to produce threads in a progressive die, then our FIBRO Form Thread Units (FTU) may be of interest to you.

ELECTRIC TRANSPORTER

-

DESIGNED TO SOLVE PROBLEMS EFFECTIVELY AND INEXPENSIVELY.

The electrically driven and patented transporter has been constructed to provide effective and affordable solutions to problems in parts transport, waste disposal as well as parts sorting. This system conveys punched and waste parts out of the tooling area with a rhythmic movement in a straight line.

A specially designed guide channel which is screwed to the body of the conveyor vibrates rhythmically slowly forwards and fast backwards. The mass inertia of the parts is used to move them forwards. In this way the parts in the guide channel progress gently towards the storage containers.

Low energy consumption, infinitely variable speed control, simple automation, low noise (60 dB) and the absence of compressed air ensure high economic efficiency whilst improving the working environment.

Its main areas of application are conveying and separating solid materials in metal processing and the automotive sector. The additional "CLEAN LINE" product range can also be used in the food and pharmaceutical industries.

SENSORS FOR STAMPING AND FORMING TECHNOLOGY

-

Close to the action, sensors convert mechanical parameters such as force, pressure, sound, vibrations, paths, positions or movements into digital or analogue signals.

Sensors are the basis for precise visualization, optimization, measurement, inspection and tracing of all punching and forming processes. FIBRO sensors have been specifically developed for punching and forming. FIBRO offers a wide range of sensors in various designs, complete with the matching installation equipment.

- Light Barriers, digital, Laser

- Light Barriers, Digital, Infrared

- Light Barriers, analogue, laser

- Laser Diffuse Sensor, digital

- Eddy current Sensor, analogue

- PIEZO-Senzor

ELECTRO-MECHANICAL TRANSPORTERS

-

The FIBRO Electromechanical Transporters are designed to effectively solve the

problems of parts transport and removal of stamping and cutting residues from

presses.

The advantages of FIBRO Electromechanical Transporters are:- Enormous flexibility through the possibility of several and different

- to use their own transport channels

- Short changeover times when changing tools

- Reliable

- Low volume

ELECTRONIC TAPPING UNIT - FETU

-

Versatile and flexible thread production of the new generation

The electronic thread tapping unit, specially designed for punching and forming processes, stands out thanks to its excellent process integration. Regardless of whether the electronic thread tapping unit is used in progressive dies or progression tools, in presses or in automatic punching and bending machines, the desired threads are created in a reliable and controlled fashion. This improves thread quality, increases reliability and ensures quick, cost-effective production.- Versatile and flexible application

- Autonomous system

- Large spectrum of thread sizes M2-M24 (larger upon request)

- Simple programming and control

- High quality

- Stability and strength

- Surface quality

- Integrated quality control

- Cost effective

- Cost savings

- Short production times

- A high level of investment security

PNEUMATIC CONVEYORS

-

This pneumatic conveyor is unique and is patented. It was designed to provide an effective and affordable solution to the problems of conveying parts and disposing of waste. This beltless system conveys stampings and waste from the tool area by vibration alone

A specially designed guide channel which is screwed to the body of the conveyor vibrates rhythmically slowly forwards and fast backwards. The mass inertia of the parts is used to move them forwards. In this way the parts in the guide channel progress gently towards the storage containers.

The conveyor is maintenance-free and has a very low air consumption so is extremely economical in operation. The pneumatic conveyor is quiet running and very user friendly.

The conveyor was originally designed for press shop use but can be used as a conveyor with any tool. Blockages are a thing of the past whether the conveyor is feeding parts for assembly or removing and disposing of stampings and waste parts.

CONVEYOR BELTS

-

The conveyor belts are used to remove parts and waste from presses.

They are also suitable for any other use where parts or wastes are extracted.

The conveyor belt consists of a glass fiber fabric with a coating of polyurethane.

The power take-offs are designed for continuous operation and temporary operation.

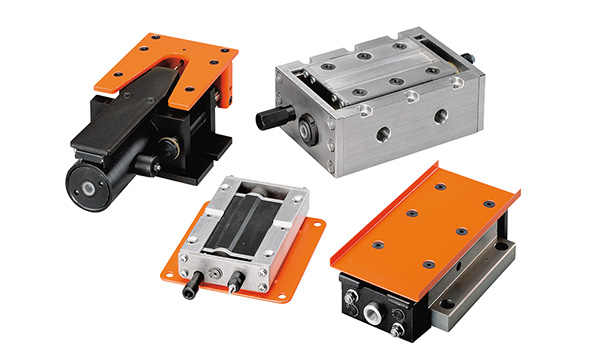

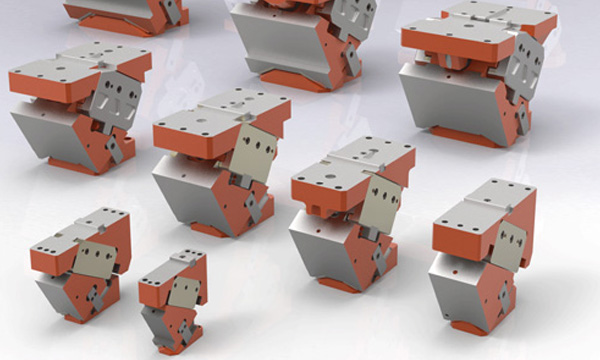

CAM SLIDE UNITS

-

Due to the limited movements of every press tool, often not all special forming processes can be performed with one tool. Only the introduction of tool slides, which allow a forming process of more complex geometries via a change of direction, makes it possible to reduce the number of tools and the associated costs.

Our product portfolio includes the:- Cam Slide Units

- Roller Slide Units

- Punching units, mechanical

- Hydraulic Cam System

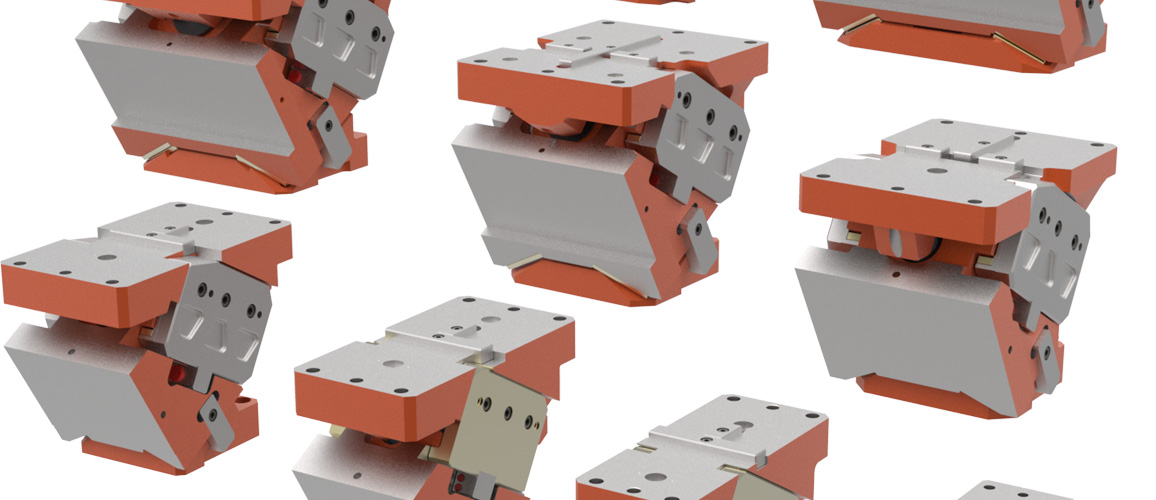

CAM UNIT PROGRAM FIBRO

-

The FIBRO cam unit program offers matching system solutions for the widest

range of applications. From the use in progressive punching tools with the

smallest dimensions up to the demanding use in large tools. From the use in

tools with small piece numbers up to premium applications in the manufacture

of bodywork parts with the highest requirements in terms of precision,

lifetime and process force transmission, our cam unit program offers the

matching solution to your application. The fault-free operation is

guaranteed by FIBRO over the guaranteed, nominal lifetime. The design of the

cam units, in the course of the tool construction, is indispensable in this

regard. Operating conditions of the tool, as well as the expected

environmental influences, must be taken into account to the best extent

possible. Using a precise and conscientious design, it is possible to

achieve a lifetime which extends far beyond the guaranteed stroke rate

FIBRO-ROLLER SLIDE UNIT

-

The FIBRO Roller Slide Unit has been designed to meet the increasing demand for

standard slide units in tool making and the automotive industry. The slides are

available for maximum stamping forces of 30kN, 50kN and 150kN. Gas springs with

a restoring force of 200 daN to 500 daN according to the specific roller slide

unit are used to restore the slide unit.

- Roller slide units are low maintenance and have a service life of 1 Mio. strokes

- Thanks to the guide, loads can be applied off-center

- Seating for the forces acting in the working direction and the return.

- Slide can be dismantled while installed

- Gas spring can be dismantled while installed

- Small dimensions, large working surface

HYDRAULIC CAM SYSTEM

-

Our hydraulic Flex Cam System is suitable for all applications where conventional tool slides are limited with regards to the working angle. Forming and punching processes are possible against the relative movement of the tool. This allows a further reduction in the required number of tools.

- a primary unit in the direct working area is not required

- operations can be performed at any angle and in every direction

- High tool saftey due to overload protection

- Reduces lateral forces and tool loads

- Increases force distribution in the press / tool

STANDARD PARTS FOR MOULD

-

For many years FIBRO earned a reputation for excellence in the selection of standard parts in the field of cutting, stamping tools and machine tools. So it was only logical to add a similar range for mould making

FIBRO mould making range includes:- guide pillars

- guide bushes

- ejector rods

- ejector pins

- bolt guides

- gas springs

- spring plungers

- locating units

- date inserts

- quill holders

FIBRO MOULD LINE GAS SPRING

-

Beside our well-known gas spring for tool manufacturer, we have now the new FML Gas Spring in our product range. This gas spring was developed especially for mould making and is characterised by its high force, its small size, a long service life at least 1,000,000 strokes and a constant operating temperatur of 120°C.

The use of this spring type provides the majority of functions as a latch locking unit.