- Offer Profile

- We provide functional and economical mass finishing technology. It is our aim to fulfill your specific demands with economical processes, solid machines and a few tools. Here we focus on easy-to-use and functional technology that enables consistent processing results and perfect surfaces. We are pleased to advise you on technical and processing questions and demonstrate our expertise in mass finishing by putting your sample pieces to the test. More than 20 years of experience in surface finishing technology do us credit. Contact us - we will find the right solution!

Disc finishing systems TE

- Workpieces and grinding material are put into an opentopped working bowl with a disc-shaped bottom which puts the whole mixture into a toroid-shaped flow. The centrifugal force accelerates workpieces together with the abrasives to the stationary streamlined inner wall of the working bowl. An effective grinding is achived by a relative movement of workpieces and abrasives

caused by their different specific densities. This dynamic flow facilitates a high, selective grinding with very short cycle times compared to vibratory or drum finishing systems.

Centrifugal Disc Finishing Machine TE 6 HD

-

for wet processing (benchtop machine)

with 1 working container (6 l volume)- thermally highly cross linking polyurethane working container, inner diameter 230 mm

- concave working container for a high grinding pressure

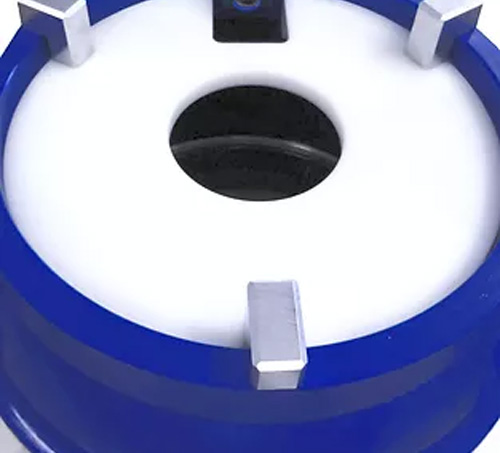

- centrifugal disc with curved carrier peg for an efficient stream

- precise gap system for thin parts and fine media with a precise distance of 0.1 to 0.3 mm

- exact and robust bearing, low-maintenance

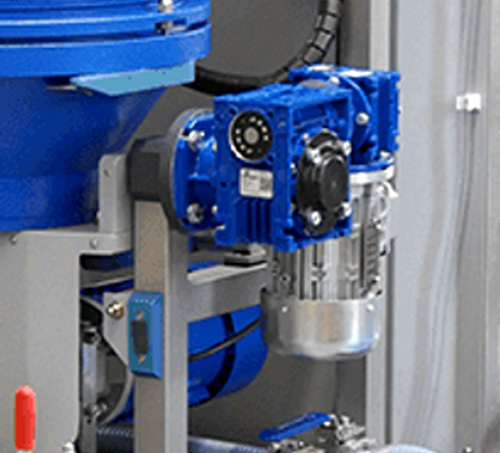

- dosing pump for process fluid

- robust chassis made of welded stainless steel

- motor 0.25 kVA

- color working container: blue

- color casing: light grey

Dimensions:- Width: 520 mm

- Depth: 450 mm

- Height: 702 mm

- Weight: approx. 35 kg

Centrifugal Disc Finishing Machine TE 10 HD

-

for wet processing (benchtop machine)

with 1 working container (10 l volume)- thermally highly cross linking polyurethane working container, inner diameter 265 mm

- concave working container for a high grinding pressure

- centrifugal disc with carrier peg for an efficient stream

- precise gap system for thin parts and fine media with a precise distance of 0.1 to 0.3 mm

- exact and robust bearing, low-maintenance

- dosing pump for process fluid

- robust chassis made of welded stainless steel

- motor 0.6 kVA

- color working container: blue

- color casing: light grey

Dimensions:- Width: 550 mm

- Depth: 600 mm

- Height: 720 mm

- Weight: approx. 60 kg

Centrifugal disc finishing machine TE 18 N

- for wet processing

with 1 working container (18 l volume)- thermally highly cross linking polyurethane working container, inner diameter 320 mm

- concave working container for a high grinding pressure

- centrifugal disc with carrier peg for an efficient stream

- precise gap system for thin parts and fine media with a precise distance of 0.1 to 0.3 mm

- exact and robust bearing, low-maintenance

- dosing pump with level monitoring for process fluid

- connection for external process fluid supply via

- solenoid valve with hand lever valve(pressure max. 100kPa)

- robust chassis made of welded stainless steel

- manual separating unit with

- screen box for changeable sieves,

- collection tray, plastic,

- 2 changeable sieves (size per definition)

- motor 0.6 kVA with motor protection

- color working container: blue

- color casing: light grey

Dimensions:- Width: 500 mm

- Depth: 950 mm

- Height: 1800 mm

- Weight: approx. 120 kg

Centrifugal disc finishing machine TE 30 N

-

for wet processing

with 1 working container (30 l volume)

- thermally highly cross linking polyurethane working container, inner diameter 400 mm

- concave working container for a high grinding pressure

- centrifugal disc with carrier peg for an efficient stream

- precise ring gap system for thin parts and fine media with a precise distance of 0.1 to 0.3 mm

- exact and robust bearing, low-maintenance

- dosing pump with level monitoring for process fluid

- connection for external process fluid supply via

solenoid valve with hand lever valve (inlet pressure max. 100kPa)

- robust chassis made of welded stainless steel

- manual separating unit with

screen box for changeable sieves

collection tray, plastic

2 changeable sieves (size per definition)- motor 2.2 kVA with motor protection

- color working container: blue

- color control cabinet: light greyDimensions:

- Width: 500 mm

- Depth: 1150 mm

- Height: 1800 mm

- Weight: approx. 170 kg

Centrifugal disc finishing machine TE 60 N

-

for wet processing (benchtop machine)

with 1 working container (60 l volume)- thermally highly cross linking polyurethane working container, inner diameter 525 mm

- concave working container for a high grinding pressure

- centrifugal disc with carrier peg for an efficient stream

- precise gap system for thin parts and fine media with an adjustable distance to 0.1 - 0.3 mm

- exact and robust bearing, low-maintenance

- dosing pump with level monitoring for process fluid

- connection for circulation via solenoid valve with hand lever valve

- large swivel angle for optimum emptying of the working container

- robust chassis made of welded stainless steel

- motor for disc 4 kVA with motor protection

- motor for emptying 0.25 kVA

- color working container: blue

- color casing: light grey

Dimensions:- Width: 1390 mm

- Depth: 1200 mm

- Height: 1750 mm

- Weight: approx. 430 kg

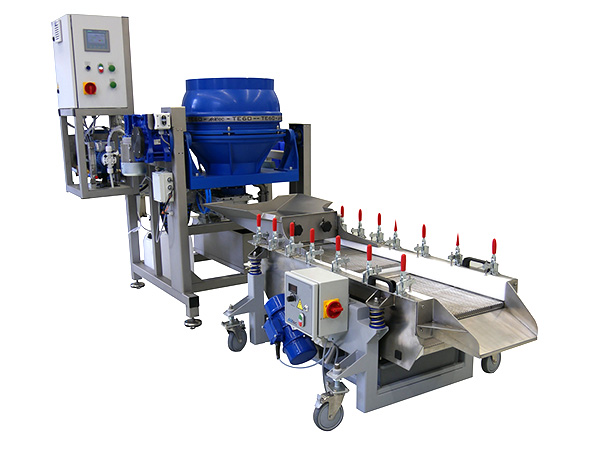

Centrifugal disc finishing machine TE 60 N R

-

with integrated separation unit and media return

for wet processing (benchtop machine)

consisting of:- 1 working container (60 l volume)

- thermally highly cross linking polyurethane working container, inner diameter 525 mm

- concave working container for a high grinding pressure

- centrifugal disc with carrier peg for an efficient stream

- precise gap system for thin parts and fine media with an adjustable distance to 0.15 - 0.3 mm

- exact and robust bearing, low-maintenance

- gentle emptying of the working container by stepwise tilting

- large swivel angle for optimum emptying of the working container

- rinsing of working container while rotating the disc into emptying position

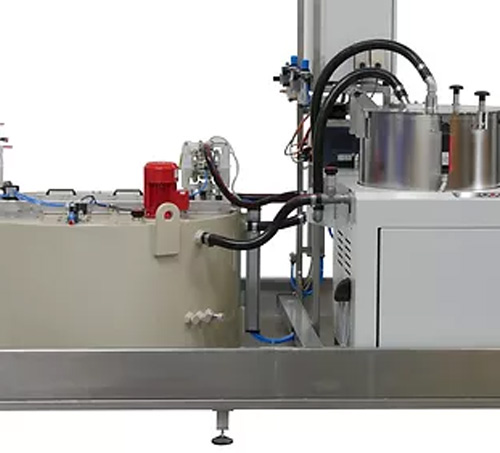

- Connection for external supply of the process fluid (e.g. centrifuge) with pressure regulator, pressure gauge for the adjustment of the inflow water pressure

- 2 Solenoid and metering valves for process fluid and rinsing container

- Metering unit with sight glass 0-100 liter/h to adjust the incoming process fluid

Dimensions- Width: appr. 2.300 mm

- Depth: appr. 1.650 mm

- Height: appr. 1.400 mm (1.950 mm at top point when loading)

- Weight: appr. 1.200 kg

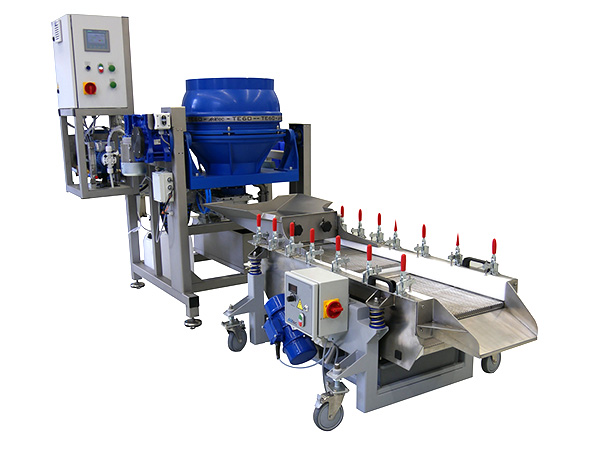

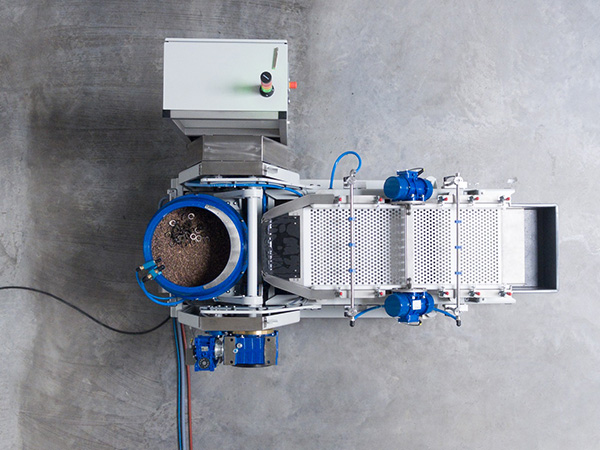

TE 60 NA

- Flow optimized container with wear-resistant polyurethane lining

- Optimal emptying of container(s) with 180° pivot angle

- Loading of the working container via pivoting feeder

- Work pieces and abrasives pass through the controlled dosing tray with bunker

- Screens with height offset support the emptying of scooping parts and are easy and quick to change

- Undersized abrasives are separated on an underlying particle screen into a collection container

- Speed control of the disc via frequency converter

- PLC with touch panel for automatic system operation

- All operating elements easily accessible from the front and clearly arranged

- Economical to purchase and maintain

TE 18N

- Flow optimized container with wear-resistant polyurethane lining

- Optimal emptying of container(s) with 180° pivot angle

- Loading of the working container via pivoting feeder

- Work pieces and abrasives pass through the controlled dosing tray with bunker

- Screens with height offset support the emptying of scooping parts and are easy and quick to change

- Undersized abrasives are separated on an underlying particle screen into a collection container

- Speed control of the disc via frequency converter

- PLC with touch panel for automatic system operation

- All operating elements easily accessible from the front and clearly arranged

- Economical to purchase and maintain

TE 30 X2

- Flow optimized container with wear-resistant polyurethane lining

- Optimal emptying of container(s) with 180° pivot angle

- Loading of the working container via pivoting feeder

- Work pieces and abrasives pass through the controlled dosing tray with bunker

- Screens with height offset support the emptying of scooping parts and are easy and quick to change

- Undersized abrasives are separated on an underlying particle screen into a collection container

- Speed control of the disc via frequency converter

- PLC with touch panel for automatic system operation

- All operating elements easily accessible from the front and clearly arranged

- Economical to purchase and maintain

Trough vibrators TV and RV

- Our trough vibrators can be used universally and are also well suited for larger individual workpieces. Thanks to the robust welded steel construction with low-wear polyurethane lining, they have a long service life. Using the time control with digital display, up to 10 programs can be saved freely. With our trough vibrators, the speed control is regulated by a frequency converter. The finely adjustable dosing pump includes compound level monitoring and is located on a separate frame together with the control. All trough vibrators are easy to use.

Trough Vibrator TV 60

- with 1 working container (60 l nominal volume)

- wear-resistant, highly thermally crosslinked polyurethane lining, 10-15mm

- concave side bolster to prevent adhesion of work pieces

- side discharge opening with robust closure

- process water drain at container ground with a fine screen

- process water inlet with quick coupling

- unbalanced motor with robust bearing, low maintenance

- trough as a solid welded steel construction

- Time process control including dosing pump control

- frame for process control and pump

- Machine base/substructure

- Dosing pump

- level control

Dimensions:- Width: 1000 mm

- Depth: 780 mm

- Height: 1260 mm

- Weight: approx. 280 kg

Trough Vibrator TV 30

-

with 1 working container (30l volume)

- wear-resistant, highly thermally crosslinked polyurethane lining, 10-15mm

- concave side bolster to prevent adhesion of work pieces

- discharge opening on the side with robust closure

- process water drain at container ground with a fine screen

- process water inlet with qick coupling

- unbalanced motor with robust bearing, low maintenance

- trough as a solid welded steel construction

- Time process control including dosing pump control

- frame for process control and pump

- Machine base/substructure

- Dosing pump

- level control

Dimensions Machine:- Width: 785 mm

- Depth: 820 mm

- Height: 1220 mm

- Weight: approx. 240 kg

Trough vibrator TV 120

- with 1 working container (120 l nominal volume)

- wear-resistant, highly thermally crosslinked polyurethane lining, 10-15mm

- concave side bolster to prevent adhesion of work pieces

- side discharge opening with robust closure

- process water drain at container ground with a fine screen

- process water inlet with quick coupling

- unbalanced motor with robust storage, maintenance

- trough as a rugged welded steel construction

- Time process control including dosing pump control

- frame for process control and pump

- Machine base

- Dosing pump

- level control

Dimensions:- Width: 1500 mm

- Depth: 610 mm

- Height: 1100 mm

- Weight: approx. 510 kg

Drums ADM

- A new form of dry processing enables the deburring and smoothing of steel, aluminium and zinc die-cast parts. A drum with special plastic abrasives and an absorption granulate for residual grease is used here. Some materials can also be deburred part against part without abrasive bodies. With this process, both small series parts and large individual parts, can be deburred, the edges rounded and the surface homogenised. Various application examples show the wide range of possible uses for small and automated manufacturing.

Drums ADM

- ADM-S, ADM-A, ADM-XA 100, ADM-XA 150, ADM-XA 300

- Container Volume [L]: 100, 100, 100, 150, 300

- Container Dimensions Ø x L [mm]: 360 x 790, 360 x 790, 360 x 750, 360 x 1200, 500 x 1400

- Workpiece Dimensions Ø x L max. [mm]: 200 x 700, 200 x 700, 200 x 700, 200 x 1100, 300 x 1350

- Single Part Load max. [kg]: 5, 5, 15, 15, 30

- Total Load max. [kg]: 100, 100, 100, 150, 300

- Power Consumption [kW]: 2, 2, 2, 3, 5.5

- Voltage [V]: 230V/50Hz, 230V/50Hz, 230V/50Hz, 230V/50Hz, 400V/50Hz

- Compressed Air [bar]: 2, 2, 2, 2, 6

- Weight [kg]: 475, 600, 600, 850, 1570

- Space Requirement LxWxH [mm]: 1965x746x1385, 1970x790x1360, 1970x790x1360, 2430x790x1360, 3230x850x160

Accessories for our systems

- Mass finishing means not only delivering the equipment for the process itself, but also making handling easier. For example through our individual modifications, mobile units or standard accessories for the system types. The processing afterwards with the help of drying centrifuges for drying bulk parts or drying systems with granulate is a further component to complete the mass finishing effectively. Wastewater treatment plays a major role in wet processes. Here, too, we offer individual solutions or various standard products, such as waste water centrifuges or cascades. We will be happy to help you!

Mobile units

- Whether long troughs as a compact unit with screening station and wastewater management or a trolley for small table systems. We make you mobile.

Separation

- There are various separation options for our system types. From the manual unit to the fully integrated automated screening line.

Drying

- Dry centrifuges with hot supply air or dry centrifugal disc finishing machines with granules.

Cleaning technology

- Water treatment simply and cleanly with cleaning centrifuges in various designs or with a cascade solution for small quantities.

Accessories TV

- Partition walls, noise protection lids or covers, distributors for the chamber systems, etc.

Accessories TE

- Lids for wet and dry systems, scraper rings, splash protection for sieve units, container spray attachments, etc.

Accessories drums tle

- Partition plates, separation solutions and individual adjustments for drums.

Modifications

-

- Converting disc finishing systems from wet to dry or vice vers

- Automate the tilt function

- Retrofit process water treatment

- Etc.

Consumables

- The choice of process medium in quality and form is the key to the optimum finish in the interaction of workpiece and machine. A large number of grinding and polishing media as well as granulates, compounds and additives are available for your process.

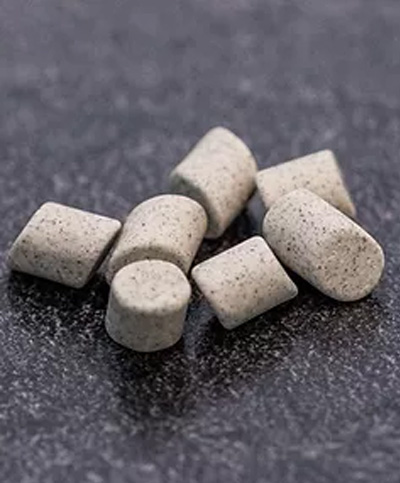

Ceramic

- Vitrified bonded grinding and polishing media are characterized by hardness of 7.3 - 8.5 Mohs and densities of 2.37 - 3.51 g / cm³. This results in a great sanding performance with high sanding pressure. Light and shiny surfaces are typical. Ceramic grinding and polishing media have a long service life and retain their original shape when in use.

Plastic

- Grinding and polishing media bonded in plastic have low densities of 1.61 - 1.89 g / cm³ and, thanks to their differently selectable grinding effect, are the best choice for gentle and splinter-free processing with high demands on the surface quality of non-ferrous metals or soft surfaces.

Granules

-

Nutshell granules are used as a carrier medium for polishing and grinding pastes for dry polishing and grinding. A distinction is made here between unimpregnated and, depending on their application, impregnated with pastes, which have to be sharpened regularly.

For the correct polishing or sanding pressure, there is a wide range of grain sizes that can be used for your application.

Corn meal is used in different versions, especially for drying.

Ceramic granules and high-grade corundum can be used as a grinding additive or as a single ingredient in special processes.

Compound

- Compounds absorb the abrasion of the grinding media and the abrasion of the workpieces that occur during the vibratory grinding process with water and help to transport them away. Through additives in the compound, cleaning, brightening and passivation of the workpieces is associated with this.

Additives

- In dry polishing and grinding processes, additives such as pastes and adhesive oils are used to re-dose the proportion of polishing and grinding particles ("re-sharpening") and bind grinding, dust and dirt particles ("re-greasing").

Our Services

Development

-

We can react quickly and flexibly to your needs and specifications and offer appropriate concepts for individual vibratory grinding systems or entire production lines and individual solutions.

Sample processing

-

In our laboratory we carry out sample processing free of charge for you. You will then receive a log in which the process parameters specifically tailored to your application, including the associated grinding and polishing agents, are listed. The key to your finish.

Subcontracting

-

We are happy to carry out small-scale subcontracting for you in our technical center. You can use larger quantities and batches Inquire at our partner company Strahlcenter Venetis GmbH or send us an email and we will forward your requirements.

Maintenance

-

For our vibratory finishing systems, we offer annual maintenance, maintenance contracts or maintenance as required. You will receive fast repairs and technical support by email or phone and by arrangement on site.

Installation

-

The commissioning of our standard machines is easy to carry out with the help of the operating instructions. On request, we will be happy to offer you assembly and commissioning.

Training / workshops

-

We offer customer-specific instruction and training in machine and process engineering both on-site and in-house. The course participants are instructed in theory and practice, including processes specifically related to machines and workpieces, in vibratory finishing technology.