- Offer Profile

- The AGVR Group is a leading provider of Automated Guided Vehicles (AGV) and control devices, having 60 dedicated employees working on AGV automation worldwide. We keep the AGV design and the manufacturing in-house, and have sold more than 2.500 vehicles and 3.500 control units throughout the world. From single components for automated guided vehicle control, to fully integrated material handling systems, we offer a wide range of products featuring standard, as well as custom built, vehicles.

Our products: Standard to Custom-made AGV's

Save up to 60% on logistic costs, with our Automated Guided Vehicles

At AGVR, our automated guided vehicles are designed to optimize your internal logistic process. Our philosophy is guided by the principles of lean manufacturing and technology 4.0, which offers our customers value maximization at its best.

From Standard to Custom-made Automated Guided Vehicles

We offer a range of basic AGV models that fit a broad variety of logistic settings. Starting from a basic model, we can customize any automated guided vehicle to your desired situation. For example, we work with standard models we can customize to your logistic processes, such as Fork AGVs for pallet-handling in production factories and warehouses; Crawl-Under AGVs for container- and waste-handling; and Outdoor Tugger AGVs to move materials back and forth between buildingsÂbut that is just only a fraction of what we work with. AGVR consists of a team of experts that specializes in optimizing your automated guided vehicle to perfection. By always aiming to improve our existing software technology and production processes, we are highly skilled in offering you the best made-to-order AGVs for any type of job.

Groundbreaking Software

More and more businesses are gradually adapting themselves to an internal tech-savvy environment. Digitalization of logistic processes is becoming increasingly popular as it saves companies a lot of time and money. Technology creates a rapidly changing environment, in which new situations and opportunities are continuously created. To seamlessly keep up with such trends, our software engineers created a system that quickly adapts to any new situation that is relevant to the improvement of our AGVs. That is the reason all our automated guided vehicles are controlled and managed by our fleet manager software BestAGVM. Our software offers you the possibility to use your AGV most efficiently and intelligently, at any time. Regardless of your AGV is integrated into your logistics process for milk-run planning, very complex sequencing of transport, or interfacing an AGV with your existing MES, WMS, or ERP system: at AGVR we dream big together, which makes no challenge too great.AGV tuggers for indoor and outdoor, AGV milkrun systems, AGV tractors from 4 to 60 Ton

AGVR outdoor tuggers 40t-01

AGVR SPIJKSTAAL 6 to 10 ton self driving tuggers

AGVR SPIJKSTAAL-10 to 60 ton self driving tuggers

AGVR SPIJKSTAAL-10 to 60 ton self driving tuggers-02

AGVR-AGV 308 tugger-04

AGVR-SPIJKSTAAL 308 AGV-snow drive-03

AGVR-SPIJKSTAAL 310 AGV-05

AGVR-SPIJKSTAAL 310 AGV-07

Spijkstaal-AGVR_WB-ungraded-61

Spijkstaal-AGVR_WB-ungraded-31

Forklift AGVs

Counterbalance

-

- Various fork configurations

- Optional: fork positioner and/or sideshift

- Weight ranges: 500, 1250, or 2500 kilograms

- Lifting height: up to 10 meters

Forkover

-

- Various fork configurations

- Maximum loading weight: 1500 kilograms

- Lift height: up to 5.5 meters

Straddle

-

- Various fork configurations

- Optional: fork positioner and/or sideshift

- Weight range: 500, 1250, or 2500 kilograms

- Lift height: up to 10 meters

Very Narrow Aisle (VNA)

-

- 3-Sided turret

- Maximum loading weight: 1000 kilograms

- Lift height: up to 8.5 meters

Sideloader

-

- Various fork configurations

- Optional: fork positioner and/or sideshift

- Weight range: 750, 1000, or 1500 kilograms

- Lift height: up to 10 meters

Reach

-

- Various fork configurations

- Optional: fork positioner and/or sideshift

- Weight range: 750, 1000, or 1500 kilograms

- Lift height: up to 10 meters

Tractor AGVs

Tugger Tricycle

-

- Towing force: up to 10 tons

- Hybrid operation: automatic and manual

- Use: indoors and OUTDOORS

Tugger Four-Wheeler

-

- Towing force: up to 60 tons

- Hybrid operation: automatic and manual

- Use: indoors and OUTDOORS

Platform AGVs

Crawl-under

-

- Maximum loading weight: 1000 kilograms

- Height minimum: 0.3 meters

- Lift stroke 0.1 meters

- Use: indoors

Conveyor

-

- Type of conveyor: chain, roller, or belt conveyor

- Maximum loading weight: 2500 kilograms

- Loader: side or front loader

- Use: indoors and outdoors

Clamp AGVs

Round loads

-

- Type of clamp: reel clamp (single or double)

- Maximum loading weight: up to 6 tons

- Lift height: up to 8 meters

Square loads

-

- Type of clamp: plate clamp

- Maximum loading weight: up to 1000 kilograms

- Lift height: up to 8 meters

Custom-Made AGVs

On request

- We are happy to create an out-of-the-box solution for your desired logistic situation. We are specialized in creating unique designs and/or particular functionalities for any given AGV model. Feel free to contact us at any time to discuss your wishes for a customized automated guided vehicle that fully meets your internal logistic requirements or issue.

Our Services

Customizing AGVs to your situation

- Our AGVs are configured to fully navigate and operate in your factory. To do so, interfaces are used to connect the AGVs to your host system and equipment, such as production machines, conveyors, elevators, fire alarms et cetera. We have been experts in optimizing our services since 1987 and are therefore more than ready to take on your challenge.

Digital training for your operators

- Investing in your staff is essential. We train your team thoroughly before they start operating the AGVs. To be able to do this most efficiently, we will recreate a virtual version of your companyÂs site in which your operators will complete our training program. They can try out new operating strategies within the site simulation, without disrupting the actual production process. This optimizes the preparation process to be able to operate the AGVs in real-time.

24/7 Customer service & maintenance

- We know problems can arise at any time. Therefore, our trained support team is available for you 24/7. From experience, we have learned that the majority of incoming calls are software- or operation-related. Our professional software engineers are more than happy to help solve your problem within an hour. When our support team determines an electrical or mechanical problem, a service engineer is sent to you right away.

Industries

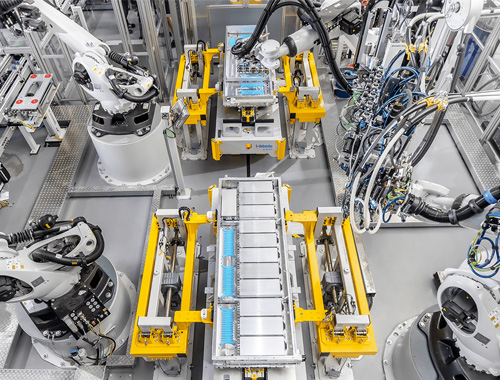

Automotive

-

Logistical automation is one of the last major automation steps in the automotive industry, and we can certainly help you with that. Automation within the automotive industry requires seamless cooperation between the AGV and mechanical staff. Primary safety measures are thus met by equipping our vehicles with safety scanners, to ensure a completely safe on-site workflow.

Our AGVs serve a variety of purposes within the automotive industry. Our AGV solutions are highly suitable for:

- Milk-run processes

- Handling pallets and parts racks

- High flow, long-distance transports indoors and outdoors

The abovementioned examples are just a few of a multitude of possibilities. We are aware that there are many unique logistic circumstances. At AGVR, we, therefore, offer the possibility to fully customize any AGV and its functions to your particular wishes.

Chemical

-

Whether it concerns handling pallets, tanks, or reels, our AGV solutions are suitable for any purpose. Aside from custom-made AGVs, we also supply typical forklift trucks to handle pallets and tanks in and between your production lines, warehouses and buffer storage areas.

The chemical industry frequently involves compound processes and operations where specific requirements have to be met regarding, for example, safety. Our AGVs are made and used for the transportation of chemical tanks and their derivatives that were used in the production processes.

Our AGVs serve a variety of purposes within the chemical industry. Our AGV solutions are highly suitable for:

- Big-bag and pallet handling of raw materials and finished goods

- Tank handling and IBC container handling

- Automating filling and emptying processes

The abovementioned examples are just a few of a multitude of possibilities. We are aware that there are many unique logistic circumstances. At AGVR, we, therefore, offer the possibility to fully customize any AGV and its functions to your particular wishes.

Food

-

Our AGVs serve a variety of purposes within the food and beverage industry, as there are endless possibilities for applicating an AGV in these logistic processes. Our AGV solutions are highly suitable for:

- Handling raw materials, finished goods, and packaging materials

- Automating cheese ripening warehouses

- Tote stack handling and buffering without pallets

The abovementioned examples are just a few of a multitude of possibilities. We are aware that there are many unique logistic circumstances. At AGVR, we, therefore, offer the possibility to fully customize any AGV and its functions to your particular wishes.

From custom-made AGVs, we also supply typical forklift trucks to handle pallets, tanks, and big-bags in and between your production lines, warehouses and buffer storage areas.

Glass

-

Whether it concerns handling pallets or reels, our AGV solutions are suitable for any purpose. Aside from custom-made AGVs, we also supply typical forklift trucks to handle pallets in and between your production lines, warehouses, and buffer storage areas.

The glass industry frequently involves operations where specific requirements have to be met regarding, for example, safety. Our AGVs are made and used for the careful transportation of palletized glass to prevent it from toppling over.

Our AGVs serve a variety of purposes within the glass industry. Our AGV solutions are highly suitable for:

- Handling of finished goods and packaging materials

- Connecting palletizer lines with centralized wrap, strap, or shrink lines

- Automating packaging materials warehouses

The abovementioned examples are just a few of a multitude of possibilities. We are aware that there are many unique logistic circumstances. At AGVR, we, therefore, offer the possibility to fully customize any AGV and its functions to your particular wishes.

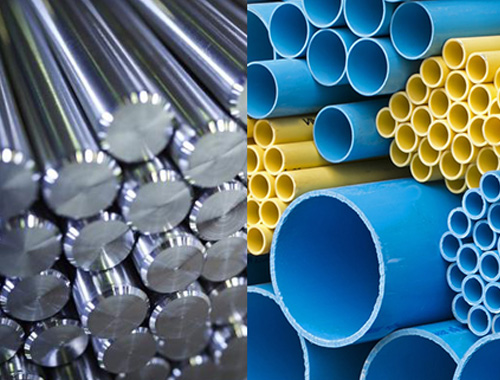

Metal & Plastics

-

Our AGVs regularly transport (semi-)finished parts and raw materials in metal and plastic industries. Due to their high reliability, flexibility, and predictability, AGVs are perfect for transporting critical types of materials. How is this to your advantage? The chances of damaging products whilst in transit are reduced to practically zero. Additionally, transport costs are saved, and all logistic tasks are perfectly traceable.

The metal and plastics industries frequently involve compound processes and operations where specific requirements have to be met regarding, for example, safety. Our AGVs are made and used for the careful transportation of materials.

Our AGVs serve a variety of purposes within the metal and plastics industries. Our AGV solutions are highly suitable for:

- Handling raw materials, finished goods, and packaging material

- Automating packaging materials warehouses

- Block stack palletized beverage cans up to 12 meters high

The abovementioned examples are just a few of a multitude of possibilities. We are aware that there are many unique logistic circumstances. At AGVR, we, therefore, offer the possibility to fully customize any AGV and its functions to your particular wishes.

Paper & Tissue

-

Whether it concerns handling pallets, reels, our AGV solutions are suitable for any purpose. Aside from custom-made AGVs, we also supply typical forklift trucks to handle pallets and reels in and between your production lines, warehouses and buffer storage areas.

The paper & tissue industry frequently involves compound processes and operations where specific requirements have to be met regarding, for example, safety. Our AGVs are made and used for the careful transportation of sealed paper to prevent it from toppling over.

Our AGVs serve a variety of purposes within the paper & tissue industry. Our AGV solutions are highly suitable for:

- Handling raw materials, finished goods, and packaging materials

- Automating WIP buffers

- Pallet and reel handling within the storage area: common pallet racking, drive-in racking, and block-stacking

The abovementioned examples are just a few of a multitude of possibilities. We are aware that there are many unique logistic circumstances. At AGVR, we, therefore, offer the possibility to fully customize any AGV and its functions to your particular wishes.

Pharmaceutical

-

Our AGVs serve a variety of purposes within the pharmaceutical industry. Our AGV solutions are highly suitable for:

- Pallet handling of raw materials, finished goods, and packaging material

- Tank handling of powders and fluids

- Hygienic and 100% fault free traceable transport order handling

The abovementioned examples are just a few of a multitude of possibilities. We are aware that there are many unique logistic circumstances. At AGVR, we, therefore, offer the possibility to fully customize any AGV and its functions to your particular wishes.

Production

-

Our AGVs regularly transport (semi-)finished parts and raw materials in production industry. Due to their high reliability, flexibility, and predictability, AGVs are perfect for transporting critical types of materials. How is this in your advantage? The chances of damaging products whilst in transit is reduced to practically zero. Additionally, transport costs are saved, and all logistic tasks are perfectly traceable.

Production areas frequently involve compound processes and operations where specific requirements have to be met regarding, for example, safety. Our AGVs are made and used for the careful transportation of various types of materials.

Our AGVs serve a variety of purposes within the production industries. Our AGV solutions are highly suitable for:

- Automating WIP buffers

- Automating logistics in (existing) tight areas

- Automating milk-run processes

The abovementioned examples are just a few of a multitude of possibilities. We are aware that there are many unique logistic circumstances. At AGVR, we therefore offer the possibility to fully customize any AGV and its functions to your particular wishes.

Warehouse

-

When working in the logistics industry, you might have noticed the payment of warehouse workers increases every year. Perhaps you even experienced having trouble filling your ranks with competent personnel. We understand that being short-handed on staff can leave you struggling to meet quotas or perform correct compliance checks on transported goods. The increasing tightening of regulations on working conditions and supply chain trends and the increase of labor costs might cause a lot of difficulties on many levels within and outside your business. For you to decrease such unnecessary costs and optimize process controls, your logistics process requires automation, as AGVs are growing to be more reliable and less expensive.

Our AGVs serve a variety of purposes within the warehouse industry. Our AGV solutions are highly suitable for:

- Pallet handling between racking and expedition zones

- Pallet handling within the storage area: common pallet racking, drive-in racking, and block-stacking

- Waste container handling

The abovementioned examples are just a few of a multitude of possibilities. We are aware that there are many unique logistic circumstances. At AGVR, we, therefore, offer the possibility to fully customize any AGV and its functions to your particular wishes.