- Offer Profile

-

VHT designs, manufactures and distributes electromechanical serialized hoisting components (electric chain hoists, wire rope hoists, jib cranes, sliding components for bridge cranes).

Through the proposal of its serialized components, VHT is able to synthesize perfectly the specialization acquired in years with a modern know-how: that's a special synergy we realized through the direct transfer of "experience & knowledge" between generations.

Cranes and hoists

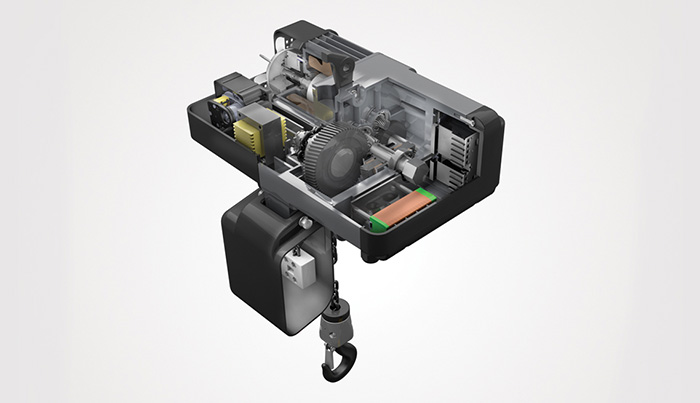

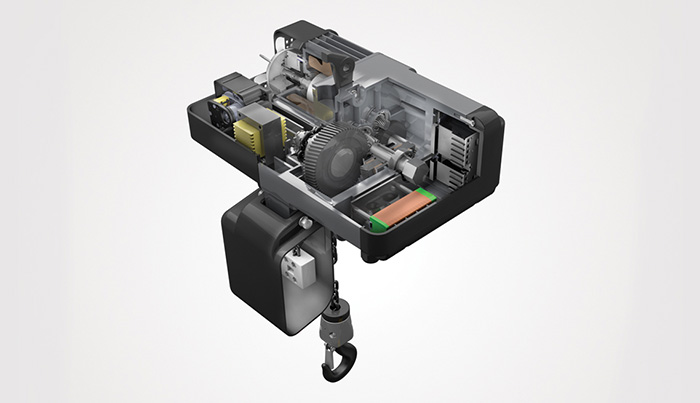

Electric chain hoists "VK" SERIES - capacities up to 2.000 kg

-

- 1 Chain Fall for capacity from 125 kg – 2.000 kg

- Three different executions – Fixed Execution – Manual Trolley – Electric Trolley

The electric chain hoists “VK” series, for capacity from 125 to 2.000 kg, are designed and manufactured using cutting-edge design techniques such as 3D CAD system integrated with finite element calculation.

The electric chain hoists "VK" overcome rigorous life and reliability testing in our modern “Experience Department”, in order to assure compliance to the standard rules and project data, within the highest quality standards.

A RIGOROUS PROCESS CONTROL

VHT Varese Hoisting Technology S.r.l. produces electric chain hoists "VK" in a highly serialized way, with the benefits of industrialized production processes controlled by a quality system conducted in compliance with UNI EN ISO 9001:2000

THE ELECTRIC CHAIN HOISTS “VK” SERIES AND THEIR TROLLEYS “VT” SERIES

- The electric chain hoists “VK” series are generally used to hoist an unguided load by means of a hook or other handling accessories.

- The trolleys “VT” series, electric or manual, suitable to run on a beam, ensures the integrated handling of lifting and horizontal movements of the load when combined with a hoist.

- The electric chain hoists “VK” series with related trolleys “VT” series can be singularly positioned on monorails or can constitute the lifting unit of other machines in which they have been incorporated such as jib cranes, bridges crane, etc.

- The electric chain hoists “VK” series are also used for lifting loads in a fixed position.

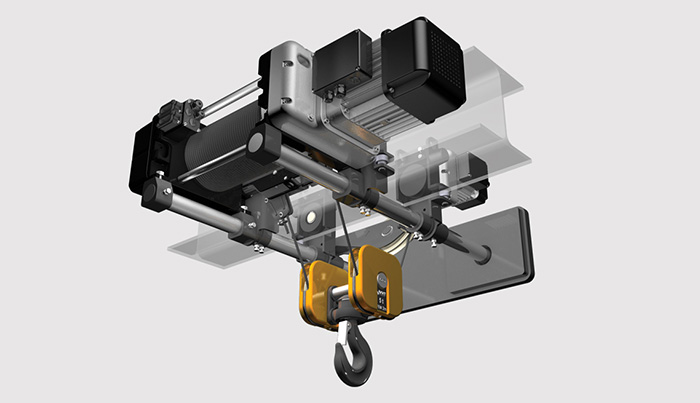

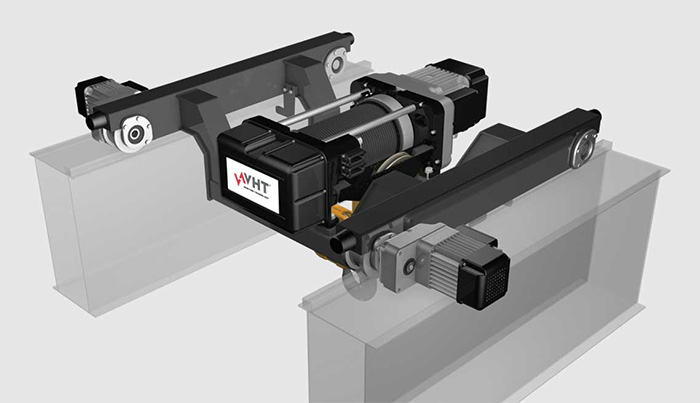

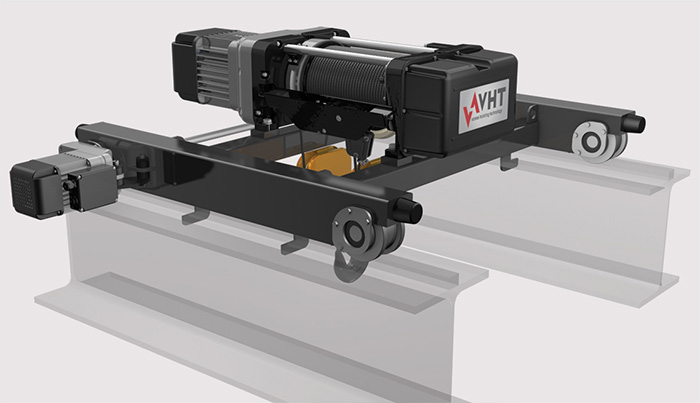

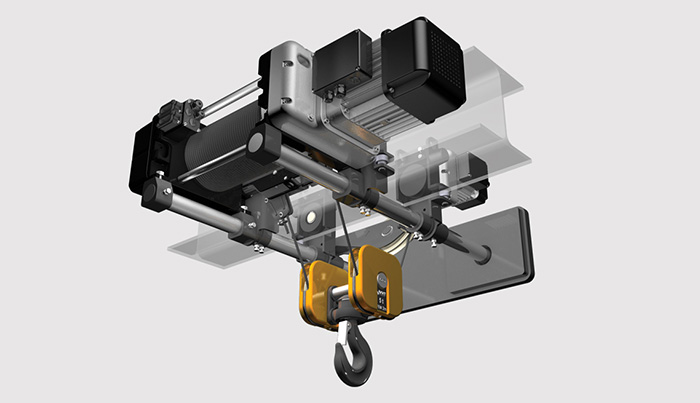

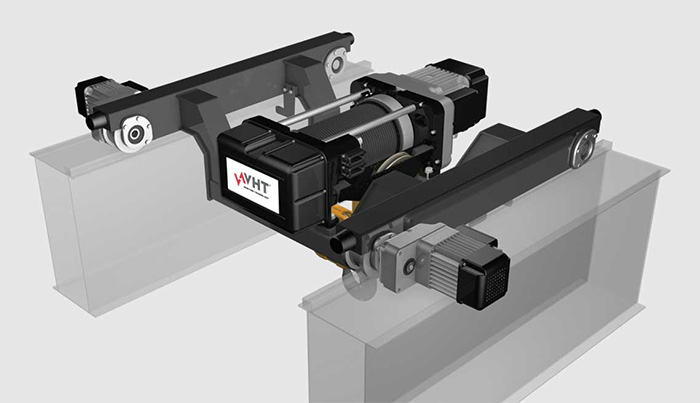

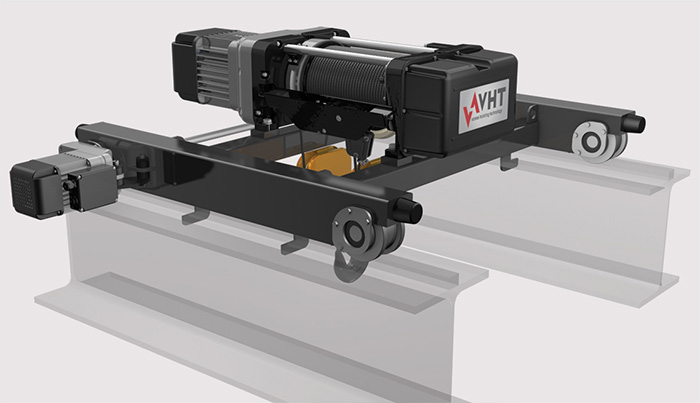

Electric wire rope hoists "VF" SERIES - capacities up to 50.000 kg

-

- For capacity from 1.000 – 50.000 kg

1 / 2 / 4/ 8 Falls in fixed execution - Single Girder electric Trolley

- Double Girder electric Trolley

The electric wire rope hoists “VF” series are designed and manufactured using cutting-edge design techniques such as 3D CAD system integrated with finite element calculations.The electric wire rope hoists “VF” series overcome rigorous life and reliability testing in our modern “Experience Department”, in order to assure compliance to the standard rules and project data, within the highest quality standards.

A RIGOROUS PROCESS CONTROL

VHT Varese Hoisting Technology S.r.l. produces electric wire rope hoists “VF” in a highly serialized way, with the benefits of industrialized production processes controlled by a quality system conducted in compliance with UNI EN ISO 9001:2000

THE ELECTRIC HOISTS “VF” SERIES AND THEIR TROLLEYS “VT” SERIES

- The electric wire rope hoists “VF” series are generally used to hoist an unguided load by means of a hook or other handling accessories.

- The electric trolleys “VT” series, single or double girder, suitable to run on a beam at high altitude, ensures the integrated handling of lifting and horizontal movements of the load when combined with a hoist.

- The electric wire rope hoists “VF” series with related trolleys “VT” series can be singularly positioned on monorails or can constitute the lifting unit of other machines in which they have been incorporated such as jib cranes, bridges crane, etc.

- For capacity from 1.000 – 50.000 kg

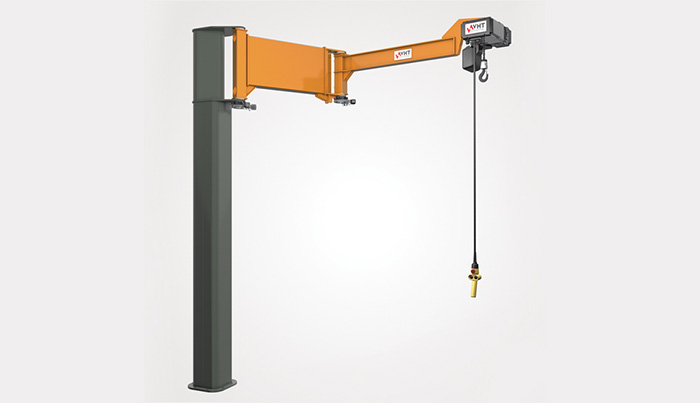

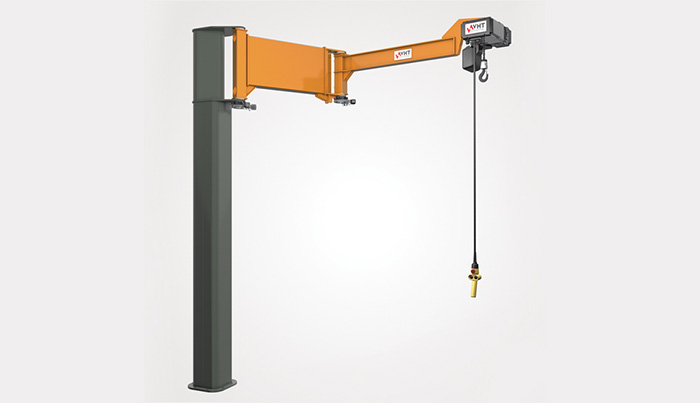

Jib cranes "VB" SERIES - capacities up to 2000 kg

-

- Column Mounted – Manually rotated up to 300°

- Wall Mounted – Manually rotated up to 270°

- Manual or electrical Rotation

- For capacities 125 kg – 2.000 kg

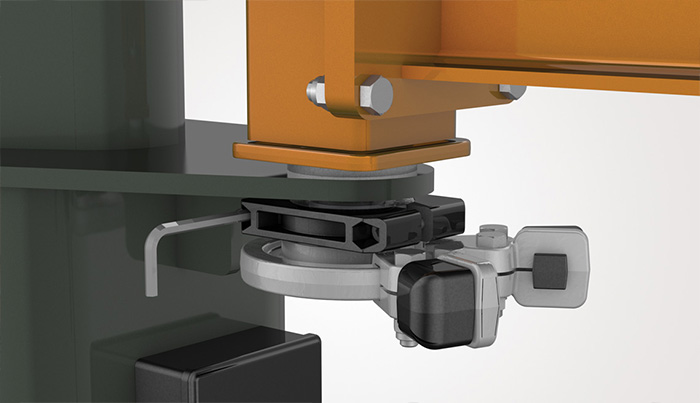

Special execution with 360° rotation:

- VB-S Series

- with articulated arm 125 kg, 250 kg, 500 kg with arm ranging from 3-7 meters

- with articulated arm 1.000 kg with arm ranging from 3-5 meters

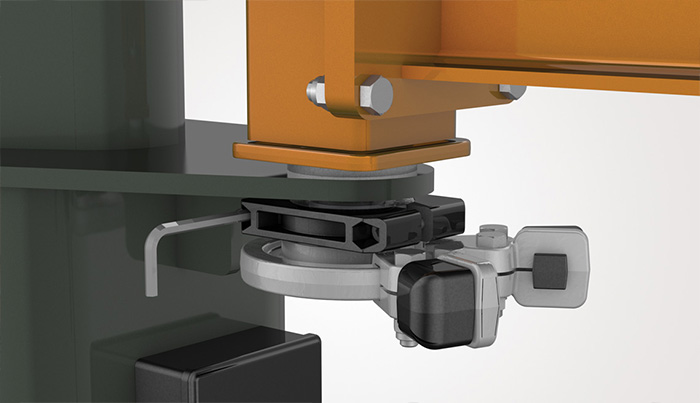

- VB-R Series Electric Rotation on Slewing Bearing

- VB-R Series Electric Rotation 2.000 – 20.000 kg with arm length 4-12 meters

The jib cranes “VB” series, for capacity from 125 to 2.000 kg, are designed and manufactured using cutting-edge design techniques, 3D CAD system integrated with finite element calculations. The electric jib cranes “VB” series overcome rigorous life and reliability testing in our modern “Experience Department”, in order to assure compliance to the standard rules and project data, within the highest quality standards.

The Varese Hoisting Technology S.r.l. produces, in a highly serialized way, jib cranes "VB" series, with the benefit of industrialized production processes controlled by a quality system conducted according to UNI EN ISO 9001:2000

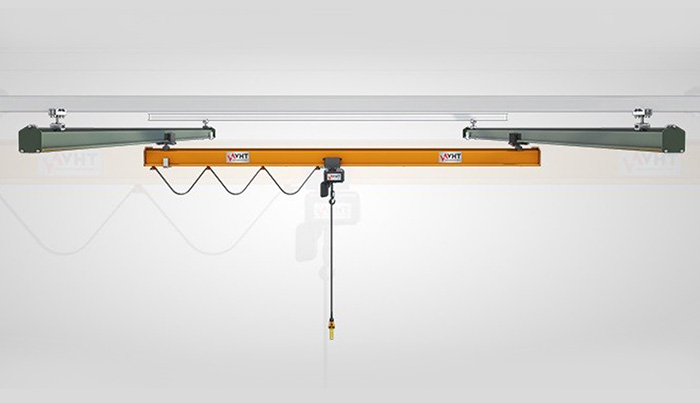

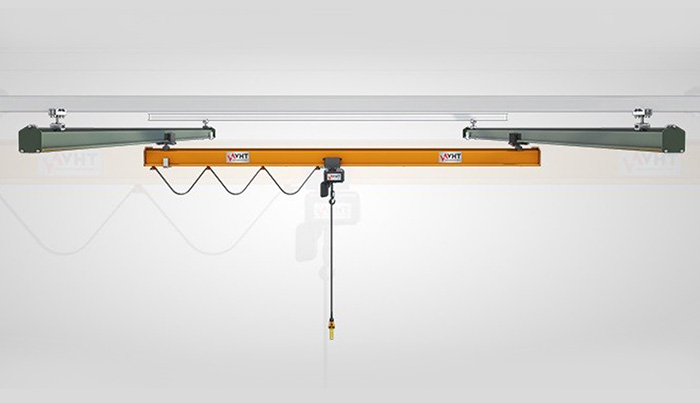

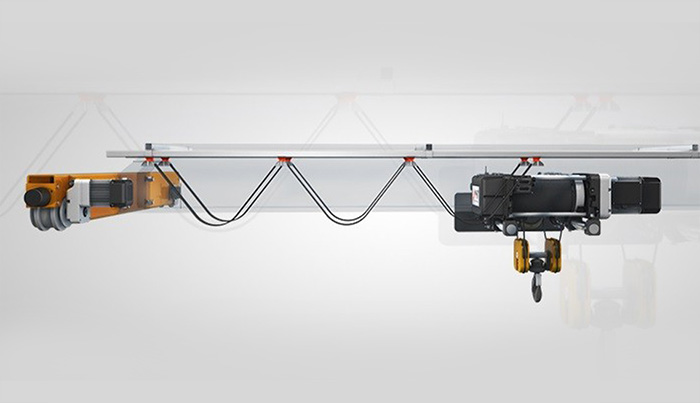

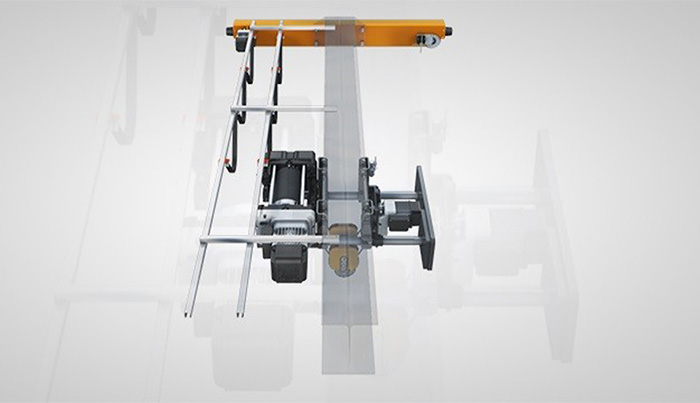

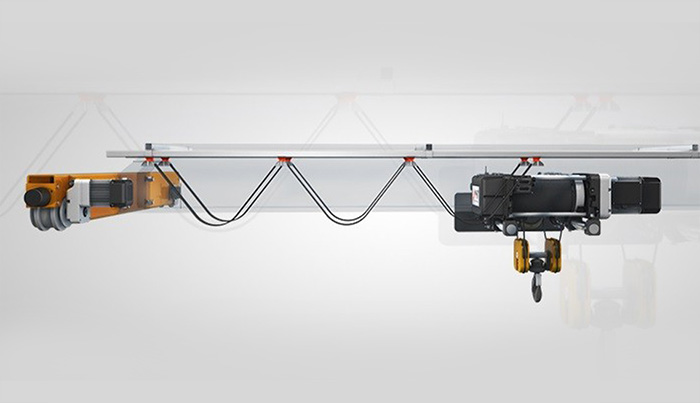

Modular Light Crane System “VS” SERIES - capacities up to 2.000 kg

-

- manual or electric travelling

- Capacity up to 2.000 kg

- Crane Span up to 10 m

- Suspension distance up to 10 m

- Trolleys and Crane travelling hand pushed or electrical

- Single or Double travelling speed up to 16 m/min

Modular lifting system highly flexible, smooth and noiselesswith profile VHT’s patented, with electric power system incorporated

The modular light crane systems “VS”, as far as light crane trolley is concerned, in mono beam and bi-beam execution and the hanging mono rail, in a manual or electric sliding execution for capacity up to 2000 kg and with wheelbase suspension up to 10 m, they are designed and produced thanks to technics of design of forefront, for which it is used a system CAD 3D integrated with calculation methods once parts ended.

Strict tests on their life and reliability of modular light systems “VS” Series grant the legislative and design data feedback, in a high quality standard

A RIGOROUS PROCESS CONTROL

VHT produces electric wire rope hoists “VF” in a highly serialized way, with the benefits of industrialized production processes controlled by a quality system conducted in compliance with UNI EN ISO 9001:2000.

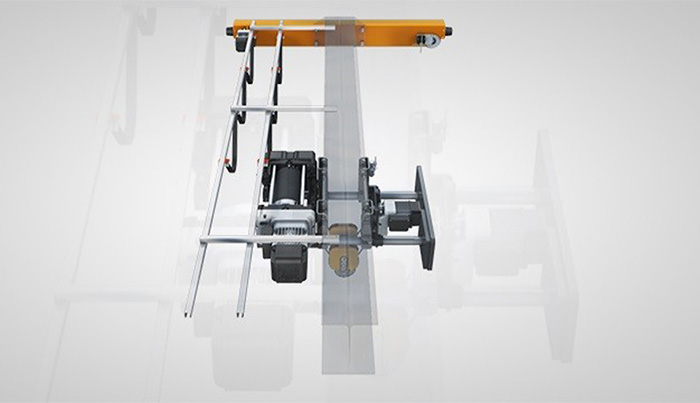

Modular light crane systems “VS” Series, at translation and manual and/or electrical sliding are designed for moving materials and goods in a store that is to help operative position.

Light crane systems have the following functions:

- lifting load in vertical, through the lifting components which are formed generally with a chain hoist and through lifting devices fit for such activity;

- translation load, through a trolley with hoist, either electrical or manual, which moves along the main beam in “VS” bar of a light crane systems or of a monorail;

- sliding load, through trolleys, manual or electrical, which slide on rail built it in “VS” bar too, positioned higher than the floor so it is completely free and available for the activities below, of the crane either of the monorail either the ways, in order to avoid redundant knots they are hanging through spherical bulbs which form rocking hinge with a wide level of movement, also thanks to adjustable tie-rod and cross bar with clamps.

KIT CRANE

-

VHT Company, part of OLEOMEC S.r.l., thanks to the long experience of its engineers of technical design and production in lifting equipment, is able to offer in the world’s market the most modern technical-technological compendium of hoisting equipment, reliable and economical, in the global market using modular VG series kits.

- Capacity up to 50.000 kg.

- Service Class FEM 1Am (ISO M4) and 2m (ISO M5).

- Single or Double travelling speed from 8 to 50 m/min.

- Execution for Single or Double Girder Cranes.

- Span up to 30 m.

- Wheel Diameter up to 250 mm.

- Application software for sizing and selection crane girder.

- Kit crane “VG” Series includes drive units, electrical panel, power supply line with festoons, control device, accessories for installation.