- Offer Profile

-

We offer a robust portfolio of infrared and through-process

temperature measurement tools, acoustic and thermal imaging devices, as well

as customized solutions

Pyrometers

Spot Pyrometers

-

Fluke Process Instruments spot pyrometers are designed to be flexible and easy-to-install; durable to withstand the most demanding harsh industrial environments; and visual so you can see and understand your process temperature data.

Spot pyrometers are a type of fixed thermal sensor used for measuring a single point on high-temperature surfaces, often in large furnaces or kilns. These devices measure temperature from the thermal radiation emitted, also known as radiometry.

Each pyrometer combines innovative digital technology with standard two-wire installations for all setups. With multiple communication options, these smart infrared measurement sensors provide the features you need to understand your temperature data and control your unique process in a compact, integrated package that is easy to install and operate.

The Thermalert 4.0 Series, for example, includes numerous integrated infrared temperature sensors with our widest selection of spectral ranges that can be used for a wide variety of process control applications.

Each pyrometer conforms to Industry 4.0 standards, combines innovative digital technology with standard two-wire installations for all setups and can be ordered with ATEX and IECEx certification. With multiple communication options, this smart infrared measurement sensor provides the features you need to understand your temperature data and control your unique process in a compact, integrated package that is easy to install and operate.

The Endurance Series, meanwhile, includes low-temperature and high-temperature two-color pyrometers that meet all the requirements of modern industry. It is flexible and easy-to-install; durable to withstand the most demanding harsh industrial environments; and visual – allowing you to see and understand your process temperature data.

The optional camera feature for this sensor allows you to continuously monitor your process visually, while a LED sighting option allows you to see the spot size on the target to make sure you have a clean line of sight. The match function takes the guesswork out of setting the emissivity. Endurance fiber-optic pyrometers allow measurement of targets that would otherwise be inaccessible due to space constraints or harsh environments.

Endurance® High Temperature Infrared Pyrometers

- The Endurance® Series of infrared pyrometers features rugged and flexible instruments designed to meet the demands of harsh industrial environments and provides continuous visual process monitoring in a wide range of applications and temperatures ranging from 50 to 3200°C (122 to 5692°F).

Features- Single color, two color and fiber optic models

- Temperature range: 50 to 3200 °C (122 to 5792 °F)

- Superior optical resolution to 300:1

- Spot sizes down to 0.6mm (0.02 inch)

- Fast response times down to 2 ms

- Easy adjustment with manual variable focus integrated head optics

- Through-the-lens sighting, with optional laser, LED or video aiming function

- Compact, rugged housings with IP65 (NEMA-4) rating

- Ethernet, Profinet and EtherNet/IP options

- Programmable relay output for control

- Simultaneous analog and digital outputs

Thermalert® 4.0 Series Pyrometer

- Each pyrometer conforms to Industry 4.0 standards, combines innovative digital technology with standard two-wire installations for all setups and can be ordered with ATEX and IECEx certification. With multiple communication options, this smart infrared measurement sensor provides the features you need to understand your temperature data and control your unique process in a compact, integrated package that is easy to install and operate.

Rugged, smart and easy-to-install- Improve process control with wide choice of spectral ranges and focus distances designed specifically for your application

- Reduce setup time with plug-and-play technology and integrated laser sighting

- Protect your process and employees with intrinsically safe ATEX/IECEx/CCC-IS certification

- Choose from options of analogue and digital communication protocols

Raytek® Compact MI3

-

The Raytek MI3 digital infrared thermometer represents a new generation of performance and innovation in continuous noncontact temperature monitoring for a broad range of OEM applications and manufacturing processes. Each MI3 infrared temperature thermometer is a two piece system with a miniature sensing head and separate communications electronics. The miniature sensing head can be installed in any system and outperforms much larger sensors, making the Raytek MI3 the best valued IR temperature sensor in its class.

The OEMMI3 version of this digital infrared thermometer allows direct digital communication with the host machine controller without the need for an additional communication box.

The innovative multiple sensing head interface, which can support up to 8 individually addressable heads per communication box, reduces sensor cost, simplifies sensor installation and applications troubleshooting, and provides the lowest cost per measurement point.

Explosive atmospheres at the workplace can be caused by flammable gases, mists or vapors, or by combustible dust. Raytek MI3 ATEX/IECEx certified sensors can be used safely to monitor the right temperature in such explosive processes. All standard MI3 and MI3100 heads can be ordered with optional ATEX/IECEx certification. One specifically provided Ex-proof power supply can be used with 2 sensing heads.

The MI3 infrared thermometer is also available in a convenient DIN-rail mountable package standard with USB digital communications, as well as RS485, Profibus, Modbus, Profinet and Ethernet options. The DIN mountable communication box supports up to 8 heads and provides 4 galvanic isolated analog outputs.

Key Features

- Digital infrared thermometer with wide temperature range from -40 to 1800°C (-40 to 3272°F)

- High temperature resistance for the head up to 180°C (356°F) without cooling

- Precision high resolution optics up to 100:1

- Plug-and play connection of the sensing head

- Intuitive user interface with high resolution LCD

- Rugged IP 65 (NEMA-4) stainless steel sensing head

- Available with Profinet and Ethernet communication interface

- MI3 ATEX/IECEx certified sensors for explosive environments

- Included DataTemp® Multidrop Software

- 10 ms response time

Raytek® Compact CI

-

The Raytek CI noncontact infrared pyrometer is compact and easy to install. Designed for easy integration into a standard 4-wire system, the CI sensor can easily replace traditional contact probes with a J-type or K-type thermocouple output. A 0-5 volt output is available if your is susceptible to noise or requires a longer cable run.

The CI unit's onboard electronics are protected by a rugged IP 65 (NEMA-4) stainless steel housing, allowing the sensor to function in ambient temperatures to 70°C (160°F) without cooling. With water cooling, the CI sensor can withstand ambient temperatures to 260°C (500°F).

Key Features

- AVAILABLE IN APAC (ASIA PACIFIC) AND AMERICAS ONLY

- Temperature range: 0°C to 500°C (32°F to 932°F)

- Easily replaces traditional probes and thermocouples

- Accessories for cooling and air purging

- IP 65 (NEMA-4) stainless steel electronics housing

- Response time: 350 mSec (95%)

- Type J or K, or 0-5V output

- Powered by 12-24 VDC at 20 mA

Raytek® Compact CM

-

The Raytek CM IR temperature sensor is designed for continuous temperature monitoring in a broad range of manufacturing processes and OEM applications. This sensor provides the advantages of infrared temperature measurement in a powerful, compact, integrated sensor. The CM sensor can easily replace traditional contact probes with a J-type or K-type thermocouple output, or with a user scaleable 0-5 volt output.

The CM's onboard electronics are protected by a rugged IP 65 (NEMA-4) stainless steel housing, allowing the sensor to function in ambient temperatures to 70°C (160°F) without cooling.

Although small in size, the CM is loaded with advanced features. An RS232 digital interface allows the user to configure all programmable sensor variables with the powerful DataTemp® Multidrop software included with each sensor. The built-in sensor health LED provides a convenient on-line indicator of the sensor's operating status and aids in troubleshooting initial sensor setup.

Key Features

- IR temperature sensor range: -20 to 500°C (-4 to 932°F)

- Advanced feature set for OEM applications

- Accessories for air purging and lens protection

- 150 mSec (95%) response time

- Rugged IP 65 (NEMA-4) stainless steel housing

- DataTemp Multidrop software compatibleSensor status/self diagnostic LED indicator

- Adjustable signal processing

Raytek® Compact GP

-

The Raytek GP infrared pyrometers come with two types of rugged sensors: GPR and GPS. They both provide standard or close focus optics and target temperature readings with 1% accuracy.

In addition, the laser sighted GPS model provides alignment in hard-to-reach locations, or to small or distant targets. The GPS is capable of measuring targets as as small as 4.5 mm (.18 in) and 35:1 spot size at 200 mm (8 in) distance, for the close focus version of the sensor.

The GPS targets temperatures from -18 to 540ºC (0 to 1000ºF) with 1% accuracy, and has a standard optical D:S ratio of 50:1. The GPS integrated coaxial Class 2 laser is connected to the remote activation switch box via the included 4 m (13 ft) cable. An additional 8 m (26 ft) of cable is also included to connect the switch box to the GP monitor.

Key Features

- AVAILABLE IN APAC (ASIA-PACIFIC) AND AMERICAS ONLY

- Temperature range: -18°C to 538°C (0°F to 1000°F)

- Available with standard or close focus optics

- Sensor parameters easily configured through display monitor

- Adjustable emissivity and T-ambient compensation

- Laser sighting available (GPS head)

- Choice of sensing head to match application requirements

- Choice of sensing head to match application requirements

- Adjustable Emissivity, Peak Hold, Valley Hold and Averaging functions

Raytek® Thermalert® TX Intrinsically Safe Sensor (ATEX)

-

The Thermalert TX infrared temperature sensors are available with remote addressability, easily installed in multidrop configurations.

TX Series Smart Sensors communicate over a simple loop-powered 2-wire cable using the HART (Highway Addressable Remote Transducer) protocol. This signal combines industry-standard 4-20 mA output with simultaneous digital communications. They include Raytek DataTemp® Multidrop software, providing an easy-to-use interface for configuration and monitoring. Temperatures can be archived or exported to other applications for analysis and process documentation.

Smart TX sensors feature remotely adjustable temperature and output subranges, adjustable emissivity, ambient temperature check, and a user-defined alarm output. Averaging and Advanced Peak/Valley Hold algorithms are provided for accurate measurement of complex discrete processes.

Key Features

- Intrinsically safe infrared temperature sensor range: -18ºC to 2000°C (0ºF to 3600°F)

- Simple, two-wire installation

- Point-to-point or multidrop installation with up to 15 sensors on a single network

- Advanced signal processing

- Wide choice of focus distances

- Ambient operating temperature: 0 to 70ºC (32 to 160ºF)

- Ambient operating temperature with air cooling up to 120°C (up to 250°F), with water cooling up to 175°C (up to 350°F) and with ThermoJacket up to 315°C (up to 600°F)

- Compatible with standard industrial intrinsically safe (ATEX) barriers

Raytek Marathon MM

-

The Marathon MM series platform consists of five IR temperature sensor models, each with a measurement wavelength and temperature range appropriate for specific application needs, from low temperature plastic processing to high temperature glass and metals processing.

The Marathon MM features Precision Variable Focus that allows fast, easy and accurate adjustment of the focus of measurement targets, either by push-button at the rear of the instrument or remotely via an RS232/RS485 PC connection, where adjustments can be seen in real-time through video. Sensors with variable focus option can be configured according to specific application requirements, reducing the installation time and chance for incorrect installation.

All sensors feature identical installation hardware and include Raytek DataTemp Multidrop software to enable easy and consistent installation, configuration and data capture across the full breadth of an applications.

Key Features

- IR sensor temperature range: -40 to 2250ºC (-40 to 4082ºF)

- High-resolution optics up to 100:1

- Precision Variable Focus

- Real-time video monitoring and recording capability

- Integrated through-the-lens and either video or laser sighting

- Stainless steel housing

- Included Raytek DataTemp® Multidrop software

Ircon® Modline® 4

-

The Ircon Modline® 4 Series is an economical infrared pyrometer for OEM applications. This pyrometer requires two wires, a power supply (range of 16 to 40 Vdc) and an installed compatible output (recording or control instrument) to complete the instrument system loop. A number of instruments can be placed within the series current loop—provided that the total voltage drop for each instrument does not exceed the total loop voltage.

The Modline 4 DC operation has no moving parts, which guarantees stable performance. The solid state electronics incorporates a chopper-stabilized amplifier, which assures long term, accurate, drift-free, stable operation. The instrument is available with 3 optical resolutions, allowing it to measure spots as small as 7.6 mm (0.3“). It can be calibrated in the field using a certified black body.

The digital emissivity control allows adjustments in 0.01 increments and a response time adjustment pot (potentiometer) lets you select values from 0.15 to 10 seconds to match almost any process requirements.

An optional Peak Picker Filter is available to provide smooth temperature indications and outputs when measuring intermittent targets.

Aluminum casting rated NEMA 4 (IP56), six different spectral responses and Modline 4 mounting flanges make this IR sensor ideal for a wide variety of OEM application processes in hostile environments.

Key Features

- Infrared pyrometer temperature range: -50°C to 1300°C (-50°F to 2500°F)

- Self-contained, standalone IR sensor

- Versatile, easy-to-install, two-wire transmitter

- Stable drift-free operation

- Provides 4-20 mAdc linear temperature output

- Emissivity & response time adjustment build-in

- Optional Peak Picker Filter

- Operating Ambient Temperatures: 0 to 66ºC (32 to 150ºF) and with optional water cooling: 0 to 200ºC (32 to 400ºF)

Ircon® Modline® 7

-

The Ircon Modline®7 infrared thermometers are designed for continuous temperature monitoring in nearly any application in industrial temperature process control. Offering four different models to choose from these rugged pyrometers feature an IP65 (NEMA 4) enclosure, standard motorized focus control, as well as through-the-lens and laser sighting.

With extended temperature ranges, high resolution optics and fast response times, the Modline 7 provides the versatility to solve your most demanding applications. An intuitive sensor design, with integral water cooling in a stainless steel enclosure or high temperature waterjacket, reduces installation and setup time. Standardized installation accessories and common ModView™ Pro software platform minimize multiple product configurations at your factory.

Key Features

- Infrared thermometer temperature range: -40 to 2250°C (-40 to 4082°F)

- Integral stainless steel cooling enclosure

- Standard through-the-lens and laser sighting on all models

- Remote motorized focus and high resolution optics

- Simultaneous analog and digital outputs

- Communications utilities to monitor up to 32 Modline 7 sensors

- Advanced signal conditioning filters (peak hold, valley hold and averaging)

- System or process alarm outputs directly from the sensing head

- Included ModView™ Pro Software

- Background compensation

- 5 year warranty included

- Operating ambient temperatures without cooling: 5 to 65ºC (41 to 150ºF)

- Operating ambient temperatures with integral air cooling: 10 to 120ºC (50 to 250ºF)

- Operating ambient temperatures with integral water cooling: 10 to 175ºC (50 to 350ºF) and with high temperature waterjacket cooling: 10 to 315ºC (50 to 600ºF)

Handheld Pyrometers

-

Fluke Process Instruments handheld pyrometers are designed to be an easy-to-use, portable device that can withstand hot industrial environments while ensuring operator safety and efficiency with heat resistant warning detectors and alarms.

See and understand your temperature data in a wide range of applications with high-optical resolution and real-time readings for temperatures ranging 400°C to 3000°C (752°F to 5432°F). With a superior distance-to-spot (D:S) ratio, users can measure high temperature targets from longer distances, ensuring accurate temperature readings.

Raytek® Raynger® 3i Plus

-

The Raytek® Raynger 3i Plus high temperature handheld infrared thermometer is designed to meet process performance requirements in many industrial applications, including highly demanding hot environments in primary and secondary metal processing, as well as petrochemical and power plant operations.

The strong and rugged design of this new generation of portable pyrometers withstands a 1m (3.2ft) drop test and provides longer operational cycle for up to 24 hours when powered with rechargeable batteries.

Raynger 3i Plus laser temperature gun features intuitive user interface for easy parameter setup and enables ‘on-site’ display of data analysis and trending, as well as fast and easy data transfer to PC or smartphone using USB or Bluetooth®.

To meet the highly demanding requirements of hot industrial environments, the Raytek 3i Plus IR thermometer features high optical resolution 250:1, which ensures accurate temperature readings at longer distances. Heat resistant “Red Nose” warning detector ensures operator safety and efficiency. Dual laser and scope sighting, visible even against "red hot" backgrounds, make this IR thermometer a perfect choice for hot temperature applications.

Key Features

- Laser temperature gun temperature range: 400 to 3000ºC (752 to 5432ºF)

- Flexible for wide range of applications/temperatures

- Rugged design reducing risk of damage (withstands 1m (3.2ft) drop)

- Dual laser and scope sighting options for fast and simple target aiming

- Red Dot sighting technology for accurate targeting against “red hot” backgrounds

- "Red Nose" heat resistant warning-detector and alarm

- High optical resolution ensures accurate temperature readings at longer distances

- Ambient operating temperatures: 0 to 50ºC (32 to 120ºF)

Imaging Solutions

Acoustic Imaging Solutions

-

Visualize the unheard and the unseen with the power of fixed acoustic imaging solutions from Fluke Process Instruments. Fixed acoustic imaging enables users to detect, locate and visualize air and gas leaks or changes in mechanical sound signatures across their process and equipment in real-time before they become costly problems.

By using an array of sophisticated sound sensors and powerful SoundMap™ technology, our acoustic imaging solutions translate the sounds they hear into visual representations so users can quickly locate changes and problem areas across compressors, pumps, pipes, conveyors and more.

In addition to 24/7 remote monitoring, our fixed acoustic imaging solutions can integrate into factory systems seamlessly and user-defined alarms can be established to alert users when sound signatures have changed, even in the facility areas that are hard to reach.

By serving as an early warning system, facilities can continuously monitor equipment to optimize performance, perform preventative maintenance or detect mechanical anomalies, such as bearing wear, well before a failure occurs to keep your processes up and running.

SV600 Fixed Acoustic Imager

- Detect, locate and visualize the unheard and unseen air and gas leaks or sound signature changes in your process

See what you’ve been missing- Minimize operator intervention with a fully automated and integrated solution

- Capture data from inaccessible or dangerous areas to keep your team safe

- Monitor sound signature changes in real-time to prevent unscheduled maintenance

Infrared Linescanners

MP Linescanner Series

- Designed for the harshest environments, the MP Linescanner Series provides accurate, edge-to-edge and real-time thermal imaging and temperature measurements for continuous processes. See it all with up to 300Hz scan speed and 1024 data points per scan, allowing you to find faulty temperatures, such as hot spots, before an error occurs.

Edge-to-Edge Thermal Imaging to See it All- Real-time thermal imaging for continuous or discrete processes

- Built-in line laser for rapid alignment, resulting in lower installation costs

- Ensure products are manufactured to specifications to improve quality

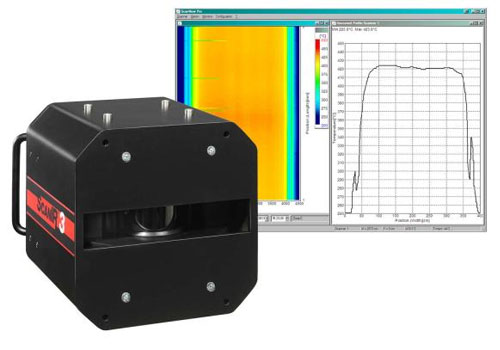

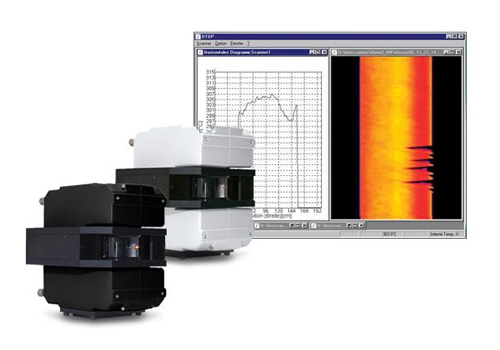

Ircon® ScanIR®3 Thermal Scanner

-

The ScanIR®3 thermal scanner is designed for a wide variety of noncontact temperature measurement applications, including those in harsh industrial environments. Its robust housing incorporates standard water-cooling and air purge and features built-in laser sighting. A rugged processor box provides universal input and output (I/O) capabilities in the field without the need for an external computer.

The ScanIR3 linescanner and thermal imaging system has one of the fastest scan speeds in the industry and offers complete data about even the highest-speed manufacturing processes. Unlike point sensors that measure a single point, the linescanner measures multiple temperature points across a scan line. Its motorized mirror scans at rates up to 150 lines per second, allowing rapid detection of temperature non-uniformities and hot spots. Rotating optics collect infrared radiation at 1024 points within a 90-degree field of view, and industry-leading optical resolution (up to 200:1) enables detection of smaller temperature anomalies.

Key Features

- Thermal scanner temperature range: 20 to 1200°C (68 to 2192°F)

- Fast scan speed up to 150 lines per second

- Up to 1024 measurement points per line

- High optical resolution up to 200:1

- PC independent input/output capabilities

- Reliable Ethernet Communication

- Rugged, waterproof housing with built-in laser

- Built-in air purge and water cooling as standard

- Operating ambient temperatures without cooling: 5 to 50ºC (32 to 122ºF) and with integral water-cooling: 180ºC (356ºF) maximum

- Operating ambient temperatures with optional internal heater: -40ºC (-40ºF) minimum

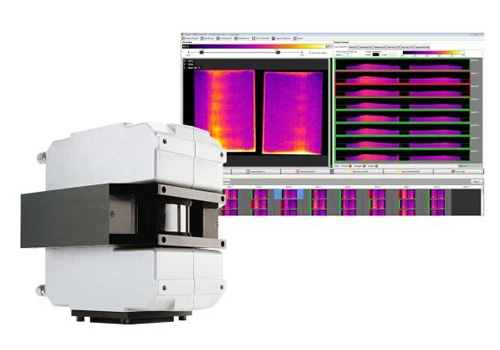

Infrared Process Imaging Systems

TF Thermoforming Thermal Imaging System

-

Automate your quality monitoring with real-time thermal imaging for thermoforming processes.

Designed for the harshest environments, the TF Thermal Imaging System provides accurate, edge-to-edge and real-time thermal imaging and temperature measurements for continuous processes. See it all with up to 300Hz scan speed and 1024 data points per scan, allowing you to find faulty temperatures, such as hot spots, before an error occurs.Key Features

- Real-time thermal imaging for continuous or discrete processes

- Built-in line laser for rapid alignment, resulting in lower installation costs

- Ensure products are manufactured to specifications to improve quality

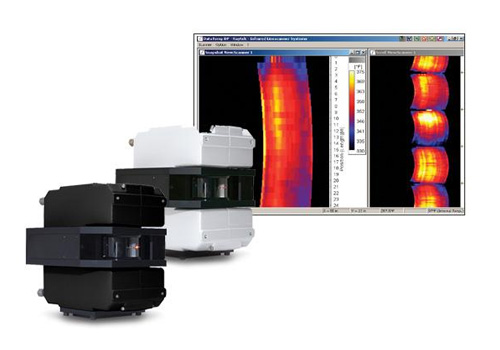

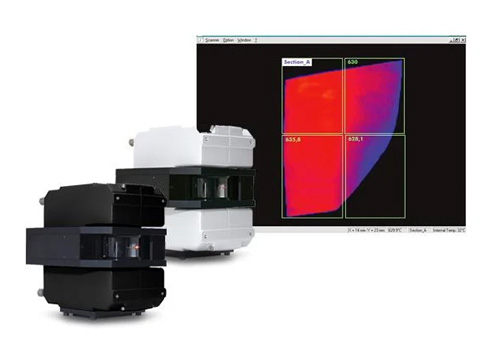

CS400 Kiln Shell Imaging System

-

Picture every brick in your kiln in real-time with continuous infrared monitoring.

Picture every brick in your kiln in real-time with continuous infrared monitoring that can help prevent costly shutdowns and extend production runs. Specifically designed for harsh kiln environments, the CS400 Kiln Shell Imaging System is a fully integrated solution that continuously monitors kilns for hot spots – helping your team avoid costly damage and unscheduled downtime.

Complete Kiln Monitoring

- Avoid costly shutdowns with continuous hot spot detection on kiln refractory.

- Reduce set up time with intuitive configurations and temperature profile calculations.

- Optimize and manage maintenance schedules to extend the kiln’s operational life.

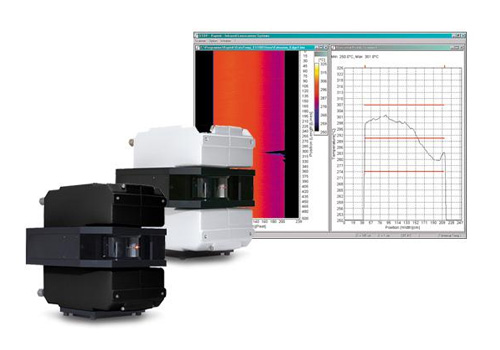

EC Extrusion Coating Thermal Imaging System

-

Improve product quality by finding thermal features and defects in real-time with continuous monitoring.

Designed for the harshest environments, the EC Series provides accurate, edge-to-edge and real-time thermal imaging and temperature measurements for continuous processes. See it all with up to 300Hz scan speed and 1024 data points per scan, allowing you to find faulty temperatures, such as hot spots, before an error occurs.

Edge-to-Edge Thermal Imaging to See it All

- Real-time thermal imaging for continuous or discrete processes

- Built-in line laser for rapid alignment, resulting in lower installation costs

- Ensure products are manufactured to specifications to improve quality

ES Sheet Extrusion Thermal Imaging System

-

Improve product quality by finding thermal features and defects in real-time with continuous monitoring.

Designed for the harshest environments, the ES System provides accurate, edge-to-edge and real-time thermal imaging and temperature measurements for continuous processes. See it all with up to 300Hz scan speed and 1024 data points per scan, allowing you to find faulty temperatures, such as hot spots, before an error occurs.Key Features

- Real-time thermal imaging for continuous or discrete processes

- Built-in line laser for rapid alignment, resulting in lower installation costs

- Ensure products are manufactured to specifications to improve quality

GS Glass Processes Thermal Imaging System

-

Automate your product quality inspections with real-time thermal imaging specifically for low emissivity glass applications.

Designed for the harshest environments, the MP Linescanner Series provides accurate, edge-to-edge and real-time thermal imaging and temperature measurements for continuous processes. See it all with up to 300Hz scan speed and 1024 data points per scan, allowing you to find faulty temperatures, such as hot spots, before an error occurs.Edge-to-Edge Thermal Imaging to See it All

- Significantly reduce setup time with rapid alignment features

- Ensure products are manufactured to specifications to improve quality

- Quickly find material defects to help reduce scrap

TIP900 Wallboard Profiling System

-

The TIP900 system is a comprehensive thermal imaging and noncontact profiling system designed to supervise the temperature of wallboards coming out of the oven. It uses an infrared thermal imager to continuously scan the entire board surface temperatures and allows the detection in real time of moisture and density variations inside each board.

The powerful TIP900 software provides sophisticated data integration, visualization and event analysis, and offers users a complete solution of real-time monitoring, detection and traceability. It also analyzes and provides optimal oven dryer profile balance.Key Features

- Complete turnkey industrially designed hardware & software system for wallboard production

- User-friendly software with clear graphical overview on a single screen

- Detailed continuous board quality monitoring

- Real-time detection of bubbles, blisters and clumps

- Failure identification function tracked in database

- Automatic live rejection of defective boards

- Database LogViewer for historical and quality analysis

- High resolution thermal imager for accurate infrared images

- Complete hardware system configured for harsh environments

- Network connectivity for remote communication

- Onsite TIP900 system configuration and training of your operators

- Accuracy: ±2% of measured value or ±2 ºC (4 ºF), whichever is greater

- Temperature Range: 350 ºC max. (662 ºF max.)

- Ambient Temperature: 0 to 50 °C (32 to 122 °F)

Thermal Imaging Solutions

ThermoView TV40 Thermal Imager

-

ThermoView TV40 is a high performance industrial infrared camera designed by the brand you trust, backed by 150 years of industrial application experience. Designed for the most challenging environmental conditions and supported by an intuitive and powerful analysis software, ThermoView TV40 provides the performance and personalization to meet the needs of process monitoring and control. If the need is for laboratory analysis and research that allows MATLAB® and LabVIEW® software plug-ins, consider the Fluke RSE300 and RSE600 Infrared Cameras, click to compare solutions.

This system, consisting of ThermoView software and TV40 thermal imager, provides fully integrated thermal imaging solution for thermal profiling, temperature control, monitoring and archiving capabilities to ensure process traceability and product quality.

The standard ThermoView TV40 thermal imager is offered with an “on-board” lens, which means that there are no external moving parts. This infrared camera is housed in an IP67 enclosure using industrial sealed connectors. The GigE interface allows for high-speed data transfer at 60 frames per second and Power over Ethernet (PoE) option. ThermoView TV40 thermal imager offers two sighting options -- simultaneous thermal and visible sighting for easy alignment.

Included with this thermal imaging camera is the ThermoView software, which interfaces to process control equipment receiving synchronization inputs and providing pass/fail logic outputs, performing product inspections, and process temperature monitoring, alarming and archiving. Several temperature analysis and tools are available to provide trending and product troubleshooting, I/O alarming for over and under heating conditions.

This system can be used in applications where multiple infrared cameras need to be displayed and stitched together.

Key Features

- IR-Fusion® technology (thermal and visible sighting) for easy alignment and added detail on blended images

- Pre-calibrated lens with remote motorized focus and multiple available field interchangeable lens options

- Discreet I/O alarms to interface to PLC

- IP67 (NEMA 4) rated with rugged housing allows for installation into harsh environments with air purge and other accessories available

ThermoView TV40 Thermal Imager Pan and Tilt Housing

-

Building on the versatile, high-performance ThermoView TV40 Thermal Imager, the Pan and Tilt is a new integrated system and housing accessory designed for remote temperature monitoring in substations and electric utility applications.

No aspect of modern society can function without power, so keeping the power distribution grid up and running is essential in order to maintain our day-to-day lives. As renewable energy sources continue to make headlines, traditional power utility companies are facing increased pressure to provide low-cost energy. This, paired with aging infrastructure, is putting additional stress on power generation facilities—which, if critical equipment fails, can ultimately disrupt power supplied to the grid.Key Features

- Sighting: IR-Fusion® technology (thermal and visible sighting) for easy alignment and added detail on blended images

- Alarm notifications through Modbus, EthernetIP, digital outputs, or email

- IP66-rated housing for protection against dust and water in harsh industrial environments

- Base mount or wall mount accessories available

THERMAL PROFILING SYSTEMS

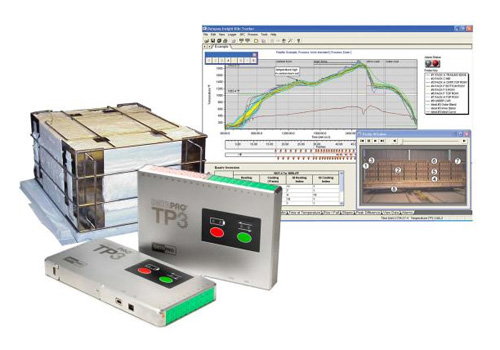

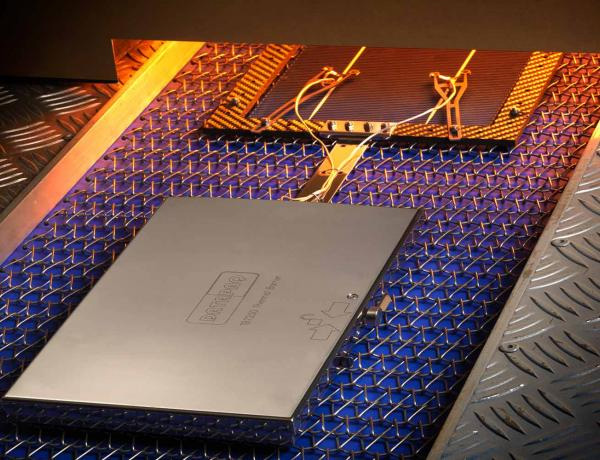

Datapaq® Specialty Kiln Tracker® Thermal Profiling Systems

-

Kiln Tracker® temperature profiling systems are comprised of a data logger, protective thermal barrier and Insight software. In addition to the standard Kiln Tracker system, Datapaq® offers a range of solutions specifically designed to meet your exact process requirements in Roller Hearth Kiln, Hydro Kiln and Clay Block Firing.

Key Features

- Specialty Kiln Systems for specific ceramics firing applications

- Highly accurate state-of-art data loggers

- Specially-engineered rugged thermal barriers

- User-friendly Insight™ software for data analysis

- Specially designed and insulated thermocouples built for repeat use at 1200°C/2192°F

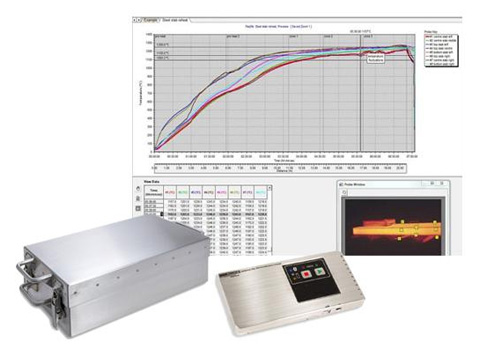

Datapaq® Furnace Tracker Systems

-

For metal heat treatment industries, measuring both product temperature and its environment is critical to ensure both product quality and process efficiency, which is why Fluke Process Instruments has designed the most robust, sophisticated furnace profiling systems. From data loggers and thermal barriers to intuitive software data analysis and reporting, we have everything users need to profile their process, no matter how challenging.

The Datapaq Furnace Tracker System is designed to be used repeatedly, in-process in the most hostile manufacturing environments, while still providing accurate and reliable through-process temperature surveys. Each system can help users improve performance and system accuracy, decrease downtime, reduce TUS reporting times and more.

Manufactured with a 316-grade, stainless-steel case, the Datapaq TP6 is available with 10 or 20 thermocouple channels. The data logger is also fully waterproof (IP67 rated) and equipped with Bluetooth communication to make system setup quick and easy from either a PC or mobile device. Additional features are highlighted for specific products below.

The ideal thermal barrier for high-temperature heat treatment processes is a critical step in improving users’ through-process profiling capabilities. Fluke Process Instruments offers an extensive range of thermal barriers that have been designed to provide maximum thermal protection – including in applications like vacuum and controlled atmosphere, slab reheat and solution aging, among others, with new sealed quench designs.

Datapaq Customized Systems

-

Process engineers worldwide use Datapaq temperature profiling and monitoring systems to optimize product quality, reduce waste, confirm compliance with industry standards and more. If our current offerings of specialty systems do not meet your requirements, the engineering team at Fluke Process Instruments will design a custom thermal profiling solution – complete with data logger, custom thermal barriers and our Insight™ Software. These bespoke systems enable through-process temperature profiles to be obtained in processes where trailing long thermocouples are not an option. Each thermal barrier is designed in close collaboration with the end-user, providing the optimum solution for every application.

Unravel the Mysteries of Your Process

- Work with our design team to ensure the profiling system integrates seamlessly with your process

- Optimize quality and productivity with through-process temperature monitoring

- Optimize the furnace, saving energy

- Analyze data immediately with real-time radio telemetry from inside the process

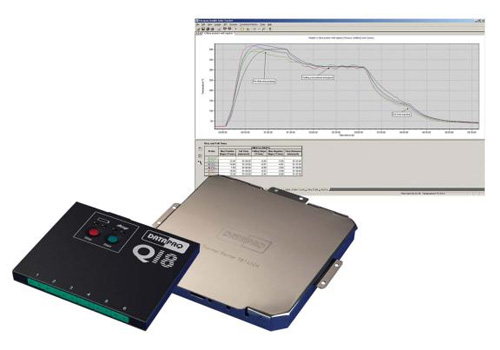

Datapaq Reflow Tracker Thermal Profiling System

-

The Datapaq® Reflow Tracker® temperature profiling system travels through the process, enabling you to monitor wave and reflow soldering, as well as vapor phase, selective soldering and rework stations. Comprised of specifically designed thermocouples, data loggers, protective thermal barriers and Insight software, this system will help you optimize product quality, expedite process setup, increase yields and minimize the need for rework.

Key Features

- Rugged and easy to use profiling systems for all soldering processes

- Powerful and user-friendly Insight™ analysis software

- Fast and highly accurate data logger

- Can be recharged from any USB power source

- Built–in intelligent power management ensures maximum battery life

- Stainless steel thermal barriers

- Live real-time analysis and review of process data with radio telemetry system

Datapaq® Food Tracker® Thermal Profiling System

-

The Datapaq® Food Tracker® temperature profiling systems are comprised of a data logger, protective thermal barrier and Insight software. With a Datapaq system, you can guarantee the quality and safety of your cooked meats, poultry, bakery products and ready-to-eat meals.

Datapaq systems, designed to withstand the harshest environments, travel through the oven or freezer with the food product, making a complete record of product temperatures. You can monitor the product temperature of the entire cook/freeze cycle in either static or conveyorized ovens, as well as in steam cookers, deep fat fryers and blast freezers.

Key Features

- Reliable and accurate HACCP temperature profiling systems for demanding food processing applications

- Data logger (6 or 8 Channels) with IP67 waterproofing rating

- Stores up to eight runs before requiring data download

- Comprehensive thermal barrier range to suit different process demands

- Powerful, yet easy-to-use Insight™ analysis software, including process lethality calculations

- Interchangeable thermocouples to suit your range of product

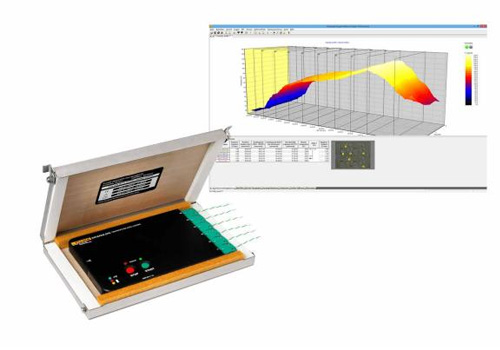

Datapaq® Solar Tracker® Thermal Profiling Systems

-

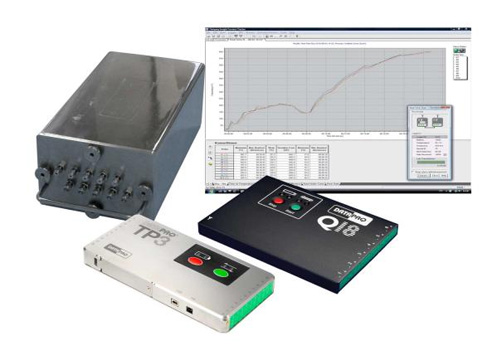

SolarPaq® temperature profiling systems are designed for specific use in solar photovoltaic (PV) manufacturing. These systems, consisting of user-friendly Insight™ software, Datapaq® Q18 data loggers, stainless steel thermal barriers, thermocouples with PTFE or mineral insulation and accessories, provide you with the tools required to obtain the highest production yields.

The Datapaq Q18 logger features rugged, reliable and accurate data acquisition circuits, clear status indicators and an intelligent battery management system. It also features start/stop buttons, time or temperature trigger, memory capacity of 300,000 readings and measures wide temperature ranges from -200°C to 1370°C/-328°F to 2498°F.

Key Features

- Obtain accurate, repeatable results for process optimization

- Save time and money setting up or adjusting process throughput

- Quickly plot changes in oven performance, minimizing downtime

- Maximize cell efficiency and throughput without compromising yields

- Obtain reports showing the exact process conditions experienced in production

Datapaq Oven Tracker Systems

Datapaq® Oven Tracker® XL2 Temperature Profiling System

-

Datapaq® offers the Oven Tracker® XL2 System, the latest generation of Oven Tracker systems for robust, comprehensive, intelligent and easy-to-use oven temperature profiling.

Key Features

- The automotive industry standard in thermal profiling

- Silicone-free technology

- Multiple oven tests possible before returning to PC

- Process Pass/Fail at oven exit

- Up to 16 measurement locations in a single run

- Hard wired real-time data analysis from batch ovens

- Fully customizable and easy-to-use Insight™ analysis software

- Wide range of thermal barriers & thermocouples to suit your process needs Request more information

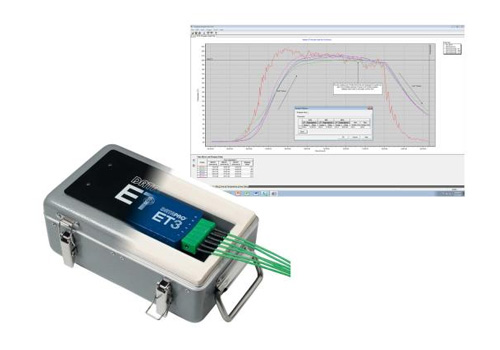

Datapaq EasyTrack3 Thermal Profiling System

-

EasyTrack3 Thermal Profiling System is designed for temperature profiling of powder coating ovens and products. It is the third generation of the globally accepted Datapaq EasyTrack brand successfully used in the powder and paint coating market by applicators and coating suppliers.

With choice 4 or 6 measurement channels, the EasyTrack3 system allows you to monitor and record product temperatures in your curing oven. Use the detailed temperature profile data to:

Monitor and prove QA

- Optimize your powder coating oven performance and save energy costs

- Identify potential problems in your powder coating process and correct them quickly and efficiently

Customize your EasyTrack3 system with ET3 temperature datalogger and a choice of thermal barriers, software and thermocouple range to meet your exact industrial coating process needs.

Key Features

- Easy-to-use thermal profiling system designed for the Industrial Powder Coating market

- Selection of light-weight yet robust thermal barriers to suit specific application needs

- Improved ET3 logger design with more memory, battery life and onboard intelligence

- New EasyTrack Insight Professional Software option with more operation, analysis & reporting power

- New capabilities with Multiple runs & SmartPaq (Run PASS/FAIL directly from logger)

Datapaq® Customized Industrial Oven Thermal Profiling Systems

-

Customers worldwide use Datapaq® temperature profiling and monitoring systems with their powder coating equipment in automotive and industrial powder coating to optimize product quality, reduce waste and prove compliance with ISO9000.

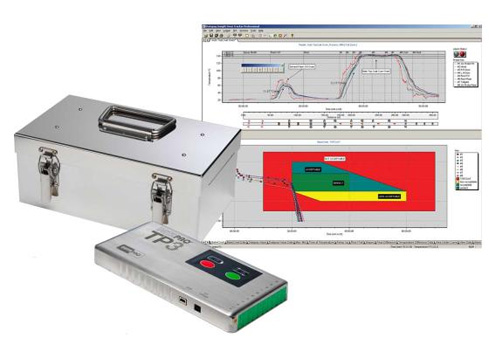

When standard and specialty systems will not meet your exact application requirements, Datapaq will build a custom system using Insight™ thermal profiling software, an extensive range of custom barriers and thermocouples, as well as the Datapaq DP5 and Datapaq TP3 data loggers.

In addition, Datapaq offers a complete thermal profiling system for real-time data analysis -TM21 Radio Telemetry System.

Key Features

- Made-to-order oven systems for unique applications

- Insight™ software for easy and efficient data interpretation and reporting

- Highly accurate and versatile data loggers

- Large selection of thermal barriers to suit nearly any oven or application

- Live real-time analysis and review of process data with Telemetry System

Datapaq® Specialty Thermal Profiling Oven Systems

-

Key Features

- Pre-built solutions for nonstandardized applications

- Highly accurate state of the art data loggers

- Lightweight and compact thermal barriers provide excellent protection from process environments

- Insight™ software makes data interpretation and reporting easy and efficient

Industry Applications

Metals Processing

-

- Accurately gauge metallurgical cooling requirements

- Optimize mathematical models with real temperature data

- Ensure proper bonding/curing temperatures and improved product quality

- Improve throughput yield and profits

- Detect hotspots, avoid costly machinery damage and unscheduled downtime

Construction Materials

-

- Detect hotspots and avoid costly damage and unscheduled downtime

- Assure the proper material viscosity and consistency in asphalt processing

- Maximize product throughput, yield and profits, while minimizing rejects

- Solve temperature imbalance in the kiln car side-to-side and top-to-bottom

- Discover premature overheating in the carbon burn out zone

Industrial Coatings

-

- Improve productivity and efficiency by using accurate profile data to optimize oven performance and final products

- Prove that your oven provides the necessary cure schedule to give the physical and cosmetic coating properties required

- Create the certified traceable profile report to prove to your customers and regulatory body (Qualicoat, ISO9000, CQI-12) that your process is in control

- Highlight oven problems immediately and use data information to recommend corrective action

- Launch new models quicker by efficient optimization of paint oven operation for new body styles and coatings

Glass

-

- Increase product uniformity with instantaneous feedback of operating parameters

- Observe your product in real time during the heat treatment process and optimize production cycles

- Monitor the pack rate and refractory material for deterioration and eliminate costly downtime of glass furnace

- Reduce energy costs and emissions

- Enhance personnel safety and environmental control in hazardous areas

- Plan your maintenance and rebuilding schedules

Automotive

-

- Quickly detect potential problems to avoid scrap, waste and energy loss

- Ensure proper bonding/curing temperatures and improved product quality

- Observe your product in real time during the heat treatment process and optimize production cycles

- Maximize product throughput, yield and profits, while minimizing rejects

- Gain the ability to measure temperatures of individual targets or the complete width of the target

Paper Processing

-

- Monitor temperatures in bed combustion furnace to insure complete burning of the cellulous

- Establish proper drying temperatures in paper conversion process and reduce energy costs

- Ensure proper bonding/curing temperatures and improved product quality

- Measure hot gases and provide a linear output for alarms and controlling

- Avoid product contamination or process interference

- Control temperature of fast moving parts and quickly detect potential problems to reduce scrap and waste

Plastic Processing

-

- Improve productivity and efficiency of plastic processing using accurate temperature data

- Gain the ability to measure temperatures of individual targets or the complete width of the target

- Use noncontact infrared sensors to avoid product contamination or process interference

- Quickly detect potential problems to avoid scrap, waste and energy loss

- Control temperature of fast moving parts

Solar and Semiconductor

-

- Obtain accurate repeatable results for silicon processing optimization

- Optimize final product efficiency by monitoring the correct drying of every cell

- Quickly plot changes in oven performance, minimizing downtime

- Save time and money setting up or adjusting the furnace

- Maximize cell efficiency and throughput without compromising yields

Electronics Industry

-

- Control circuit assembly manufacturing process to ensure high quality end-products

- Compare performance of different soldering machines and ensure their optimization

- Observe and verify process uniformity for consistent and reliable results

- Define and test the correct soldering process settings

Commercial Food Processing

-

- Generate certified and traceable thermal profile reports to satisfy HACCP validation standards

- Get lethality calculations and reporting to ensure your food is of the highest quality

- Monitor food processing temperatures and control equipment performance in roasting/baking/steaming in stationary or rotating “DD” batch ovens, linear mesh belt conveyor ovens and spiral ovens

- Quickly locate the exact position of hot or cold spots in the oven, minimizing production loss

- Observe the exact moment on your PC when your product reaches the required safe cooking temperature

Semiconductor Production

- As the technology sector continues to thrive and evolve, the semiconductor industry has grown alongside it to become one of the largest industries in the world—covering a range of applications beginning with crystal growing, transitioning to wafer manufacturing and ending with circuit board testing, among many other steps. Through the convergence of these applications, manufacturers within the semiconductor space end up with a product that is used in products spanning computers, solar cells, cell phones and most pieces of technology available on the market today. While there are a variety of different applications that make up the entirety of the semiconductor industry, consistent and accurate temperature monitoring and control plays a crucial role in nearly every step of the process. Fluke Process Instruments offers both non-contact temperature measurement and thermal profiling options with robust software solutions so you can confirm your product is being evenly heated or soldered correctly with fewer rework rates, ensure that your oven process is operating at maximum efficiency for both quality control and throughput, and much more.

Other Industries

-

- Enhance personnel safety and environmental control in hazardous areas

- Reduce energy costs, scrap and downtime

- Increase productivity with instantaneous feedback of operating parameters

- Achieve lower operating costs and improve process efficienc