- Offer Profile

-

Tradition meets innovation

The KULI Hebezeuge name is a synonym for expertise and experience in the design and manufacturing of lifting equipment for 100 years. In all this time, reliability and proven technology have always been essential aspects of the many tens of thousands of KULI products performing lifting tasks in more than 120 countries around the globe – day by day, and often under the most demanding conditions. In many cases, they have been working continuously for more than 40 years.

As a German family owned company, we offer an extensive portfolio of cranes and crane components manufactured in our two factories in Remscheid. We also source our raw materials and accessory components almost exclusively from Germany. That makes us a reliable partner for crane customers as well as crane builders and service companies.

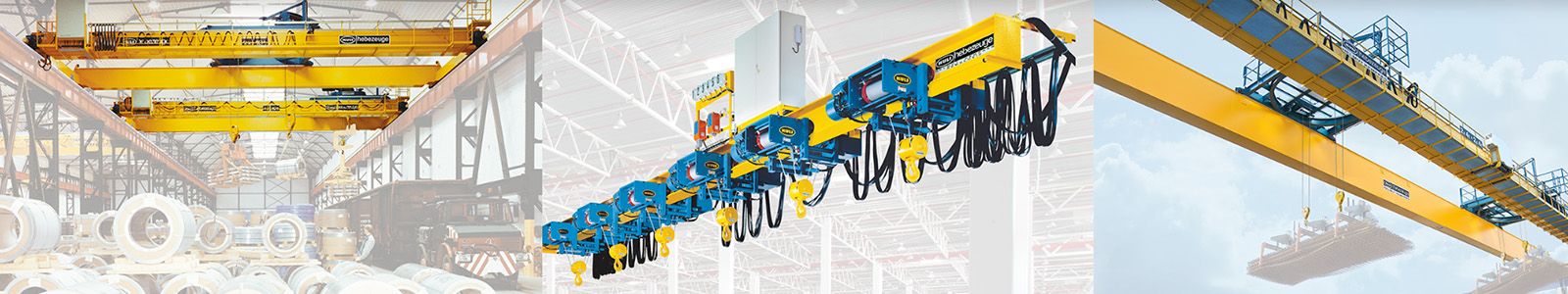

Industrial Cranes

Our cranes consist of standardized components that each constitutes a series product. Thus the industrial crane can be adapted to individual requirements in regard to span width, dimensions, purpose and operating conditions without any problem - also for trade and logistics. We supply single-girder, double-girder, suspension and gantry cranes with a lifting capacity from 1.0 t to 200 t depending on the version.

Single-Girder Cranes

The construction and hook dimensions are adapted to individual needs in a common understanding. By doing so, hall construction and maintenance costs can be kept low.

Double-Girder Cranes

Double-girder cranes are used for more demanding applications with higher loads, larger spans or higher classifications. The use of standardized traveling and hoisting gear enables cost-effective adaptation to the working space and mode of operation. Service-friendly and reliable constructions enable a high operational availability. This means that KULI double-girder cranes can also be configured as process cranes.

KULI Underslung Cranes

Some structural conditions or transport tasks prevent the use of overhead cranes. KULI suspension cranes can offer a practical alternative. Whether with or without outriggers - the use of standardized suspension trolleys and hoists enables cost-effective adaptation to the working space and type of operation.

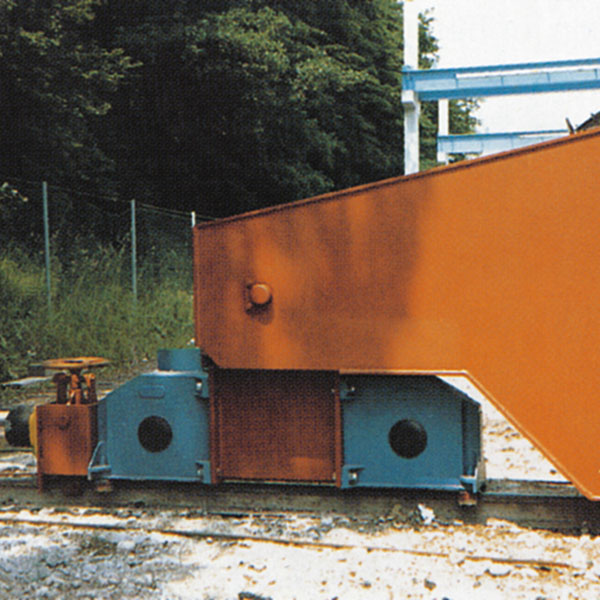

Gantry Cranes

KULI gantry cranes can be manufactured in all possible variants and equipped with single- or double girder crabs or even cantilevered crabs. One or more hoists complete your applications and are also suitable for container transport. Special gantry cranes in a two-legs-execution also allow long loads to be turned on the short.

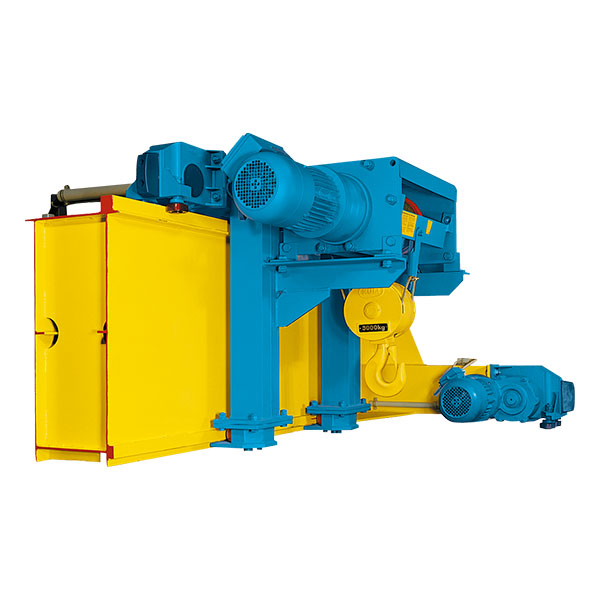

Electric Wire Rope Hoists

KULI electric hoists are the product of 100 years of experience in design and construction of electric hoists. They conform to the German accident prevention regulations, both DIN and EN standards, the FEM calculation rules, the ISO recommendations and most international standards and regulations. The distinguishing characteristic of the RS series is the compact design. The essential basis for the consistently realised modular system is that the comparatively few components allow extremely economically pricing of all upcoming variations of use. The brake motors and planetary gears specially developed for electric hoists are produced in our factory under our own strict production controls. This guarantees safety and quality.

Low Headroom Monorail Trolley 'KE'

The exceptional small hook dimension with that short construction height allows optimum use of the existing room height in almost all applications.

Double Girder Trolley 'ZE'

The practical and maintenance-free design provides optimum construction sizes for all double-girder cranes.

Cantilever Crab 'WE'

For certain load-to-span ratios, the use of a cantilever crab can achieve even better construction sizes than with a short headroom monorail or double-girder trolleys as that special design is situated next to the girder.

Monorail Hoist 'EE'

The standard version for single-girder cranes and monorail tracks. Eight track rollers are used as standard for loads above 10 t, resulting in lower wheel loads and permitting thinner flange thicknesses.

Foot-Mounted Hoist 'F'

The KULI electric hoist as foot-mounted hoist can be used virtually anywhere where loads, equipment or system parts/sections need to be lifted or hoisted. The universal usability is increased by the fact that the foot-mounted hoist can be rotated around the drum axis into any position.

Chain Hoists

Eletric Chain Hoists

KULI electric chain hoists can be found in almost all industrial scenarios in which loads need to be moved. In addition to our electric wire rope hoists for heavier loads, this product portfolio covers the range of lifting capacities from 125 to 5,000 kg. The areas of use for KULI electric chain hoists are as diverse as the range of tasks they fulfil. The robust, almost maintenance-free design and simple, safe operating make them valuable helpers, also where only low headroom is available. All KULI lifting equipment is subjected to fully-documented, exhaustive testing programs. To ensure maximum safety, we test our products under conditions that go far beyond the limits of approved operating criteria.

Crane Components

We supply complete kits for building cost-effective cranes: Standardized end carriages, standardized wheel bogies, underslung trolleys, variable travelling drives with pole-changing or frequency-controlled motors, electric hoists up to a load capacity of 200 t, power supplies, contactor controls, frequency inverters, radio controls, etc. KULI crane components are the product of many years of experience and continuous development. Together with the close collaboration and exchange of experience with crane- and steel construction companies throughout the world, our know-how and experience from our own crane construction, benefits our customers.

Twin Suspension Trolley type HF 220

For large wheel loads and for reducing flange stresses. Use of the suspended drive units on the bottom flange of normal rolled sections or welded box girders.

Suspended Trolley type HF

Universal for suspended cranes and crabs.

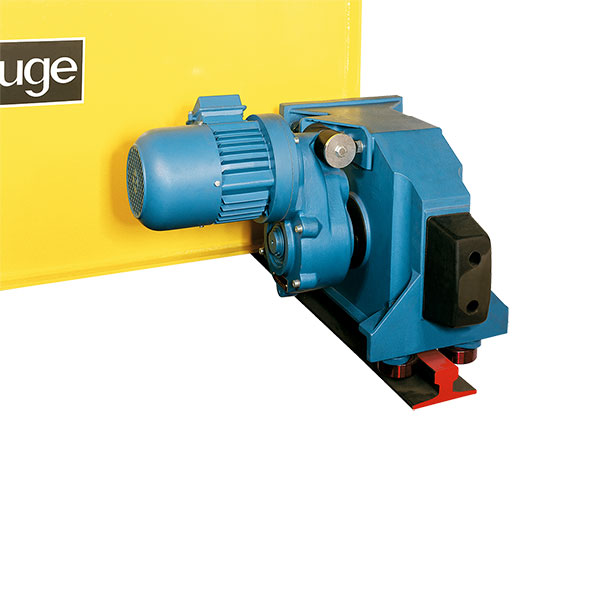

Angular Geared Motor WGF

Robust spur/bevel geared motors for gantry cranes and overhead cranes with heavy loads. Variable, adjustable frequency inverter drives for gentle acceleration and deceleration processes.

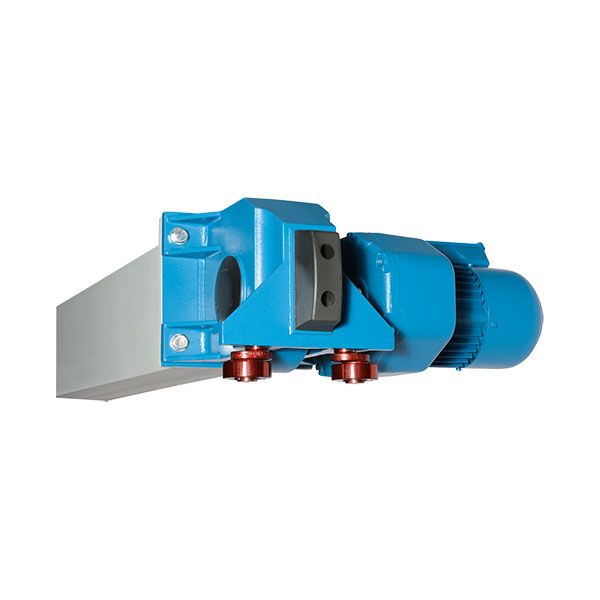

Bogie-Style Wheel Bogies

For heavy-duty overhead or gantry cranes.

Less stress of the crane track due to better wheel load distribution. Drive via two or four drives.

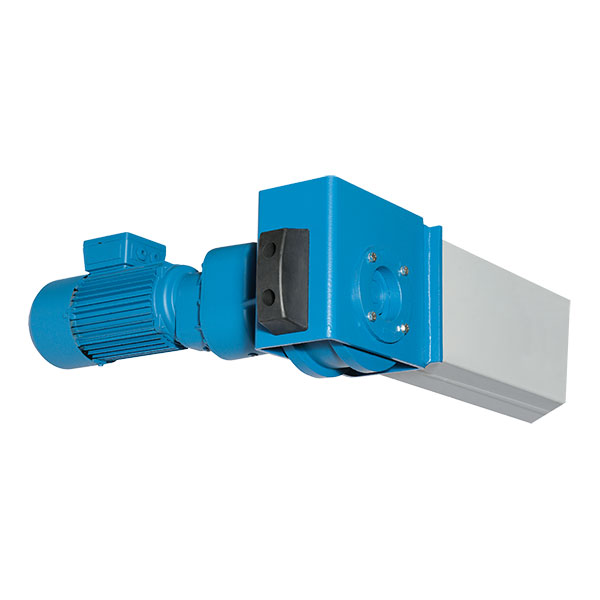

Offset Geared Motor FG

Ideal for crabs and cranes with higher loads. Drive group FEM 3 m. Frequency-controlled or pole-changing drives with soft start. Shaft-to-hub connection via splined shafts with involute flanks.

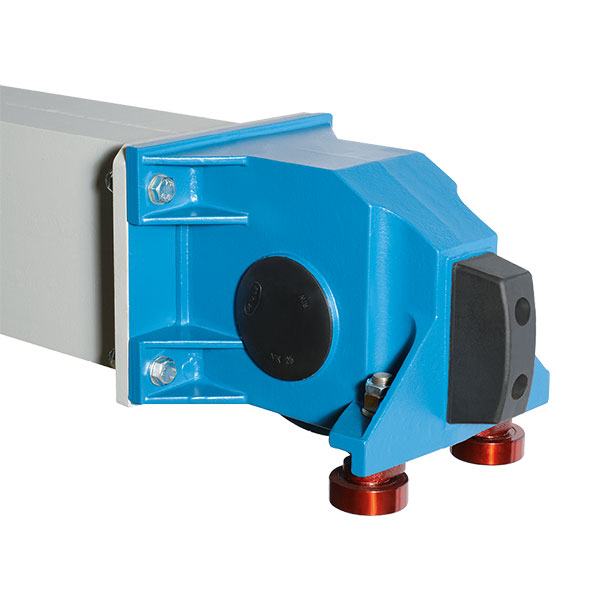

Drive Unit Heads, type K

Can be used anywhere in rail-connected transport systems in machine, equipment and plant construction. Cost-effective use of the screw-on wheel bogies for concrete spreaders, transfer tables, storage and retrieval systems, transport trolleys, automatic assembly lines, welding systems, machines for pre-cast concrete plants, foundries and stone and quarry industries.

Standardized End Carriage type NK

Ideal for cranes with higher wheel loads and stresses as well as larger spans. Screw-on wheel bogies type K with flange-less wheels made of ductile iron. Guide rollers can be adjusted via eccentric cams. Optimum driving performance and low lateral forces.

Standardized End Carriage type NKS

For crabs and EOT cranes.

Direct drive of flanged wheels by brake motors with electromagnetic brakes.

Maintenance-free gearing.

Special Designs

Specialties are one of our strengths. A conventional product doesn't meet your requirements? Then you need a partner who explores the challenges with you, is packed full of innovative ideas and can still call on many years of experience. This is one of our particular strengths. Together with our designers, we develop a customized solution with you for your special needs.

Construction of a Subway

Monorail Curve Hoist

Type RS KEK (X+210) 2x25320 L/12

Lifting Height 139 meter

Accessories