- Offer Profile

-

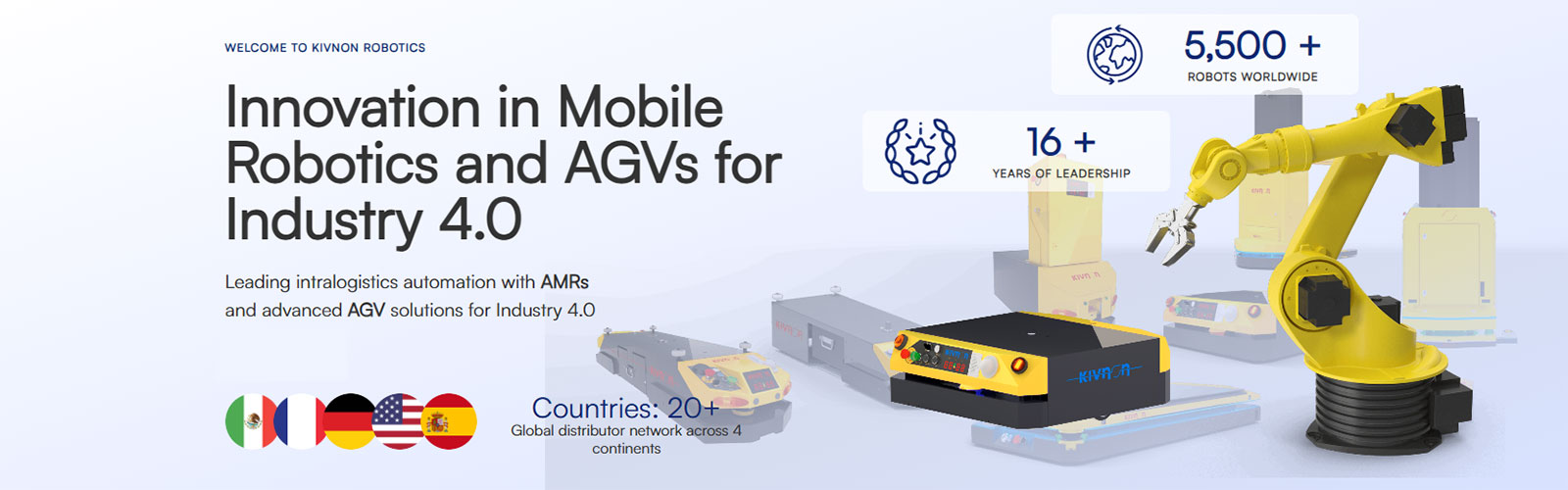

Founded in 2009 in Barcelona, Kivnon was born with a clear vision: to transform industrial mobility through advanced mobile robotics. Over more than a decade, we’ve become an international reference in the design and manufacturing of AGVs and AMRs.

Our journey has been defined by continuous innovation and a strong commitment to intralogistics automation. Today, our solutions are present in over 20 countries, streamlining operations in key sectors such as automotive, warehousing, and smart manufacturing—all aligned with Industry 4.0 principles.

Mobile Robotics Solutions

- Our AGVs and AMRs are deployed across multiple industries, including automotive, food & beverage, pharma, and logistics. Trusted by over 60 global companies to optimize their intralogistics operations with scalable, intelligent mobile robotics.

Robotic Solutions - AGV/AMR

-

KIVNON'S SOLUTIONS CHARACTERISTICS

- Reliability: Kivnon AGVs are trusted by global industries for their long-term performance and safety. With over 13 years of proven operation, our solutions ensure consistent uptime, precision, and adaptability in demanding environments.

- Communication: Kivnon AGVs seamlessly integrate with factory systems through standard protocols. Full compatibility with MES, ERP, and fleet managers, including VDA 5050, ensures real-time communication and centralized control.

- Maintenance: Our AGVs are designed for easy, predictive maintenance. Regular service intervals and remote diagnostics reduce downtime, extend equipment life, and prevent unexpected failures.

K05 Twister

-

K05 Series – Versatile Undercarriage AGV for Mixed Load Handling

Designed for industrial environments with limited space, where maneuverability is essential. All models share a compact square chassis (800x800mm) and are equipped with rotational navigation, ideal for 360° movements. The guidance system can be magnetic or mapping (in the case of the S430 models). They are widely used for light or medium loads on vehicles or wheeled carts.

Main Advantage:- High flexibility to adapt to both fixed and variable transport systems.

- Max Load: 450kg (on top), 500kg/1000kg (on trolley)

- Navigation: Magnetic or Autonomous

- Movement: Rotational optimized for dynamic environments

K10 One-Way

-

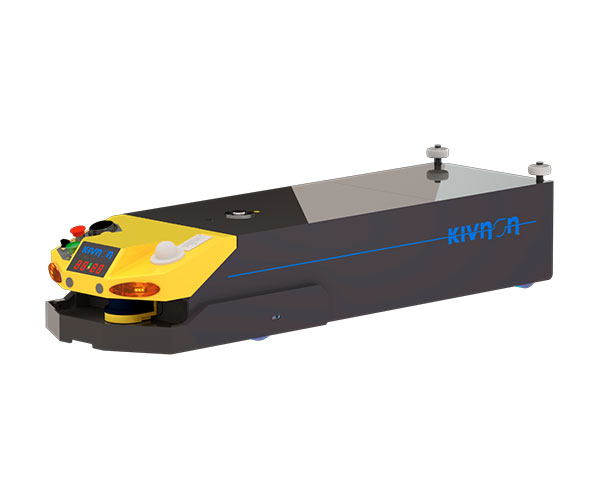

K10 Series – Advanced AGVs for Flexible Production Flows

Designed for linear paths or closed circuits. All models are unidirectional and move by magnetic navigation. Their differences lie in towing capacity and battery configuration. Typical applications include point-to-point movements of heavy materials.

Main Advantage:

- High customization with mapping or magnetic guidance and diverse loading mechanisms.

- Max Load: 1200kg/5000kg (on trolley)

- Navigation: Magnetic

- Movement: Unidirectional, perfect for assembly line automation

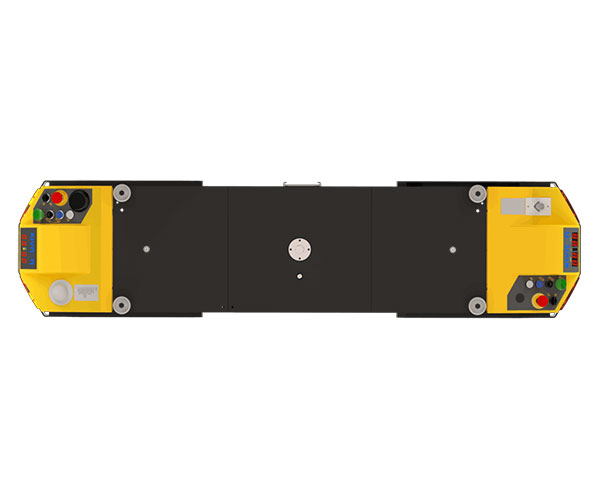

K11 Two-Way

-

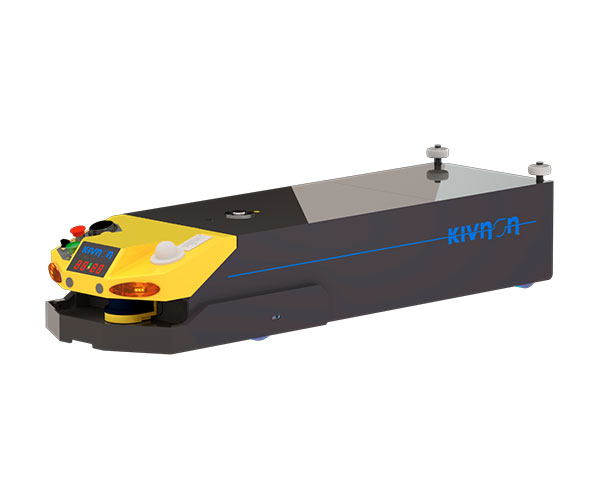

K11 Series – High-Capacity AGVs for Demanding Logistics

This is the most diverse and complete series. All models are bidirectional, allowing for optimized logistics flows without additional maneuvering. Versions are available with magnetic navigation and mapping, adapting to different environments. Load capacities range from 600 kg to 5,000 kg.

Main Advantage:- Robust structure with increased payload capacity and durability.

- Max Load: 600kg/5000kg (on trolley)

- Navigation: Magnetic or Autonomous

- Movement: Bidirectional, with cyclic or conditioned circuits

K32 Tractor

-

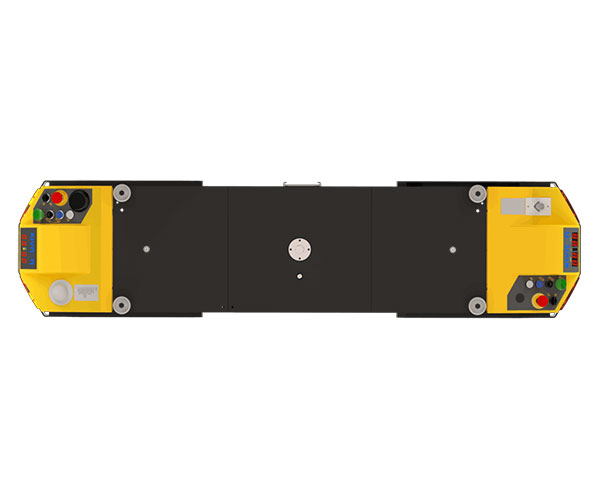

K32 Series – Powerful AGVs for Heavy-Duty Towing

Designed for logistics circuits that require towing wheeled trolleys. All models are unidirectional and can navigate using magnetic or mapping technology. Their differences lie in towing capacity and battery configuration. Typical applications include the transport of heavy materials between different workstations.

Main Advantage:

- High power and flexibility to automate the transport of heavy loads on repetitive routes.

- Max Load: 600kg/2000kg (on trolley)

- Navigation: Magnetic or Autonomous

- Movement: Unidirectional, perfect for repetitive and cost-effective operations.

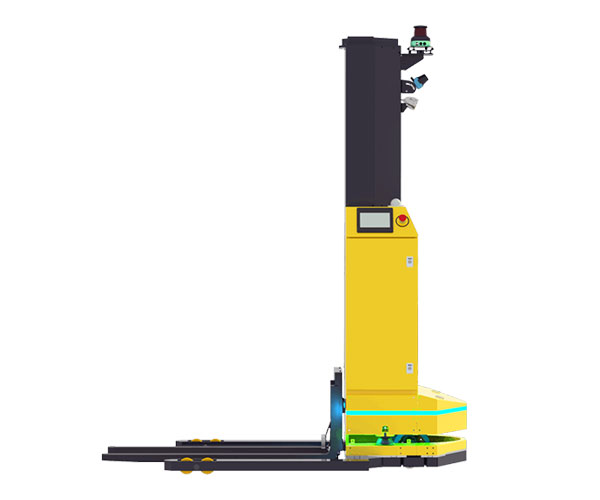

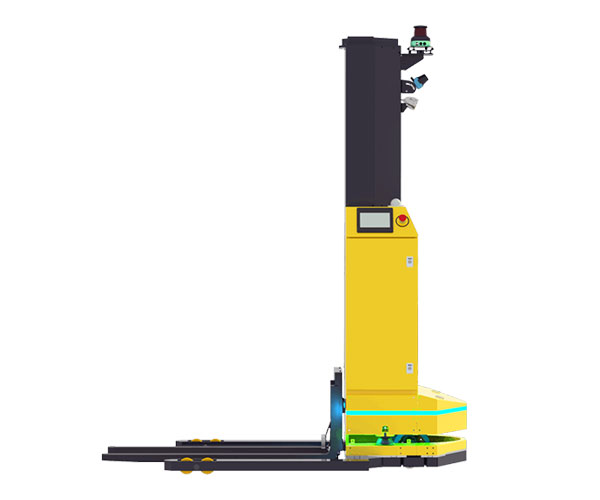

K55A & K55B Pallet Mover

-

K55A & K55B – Stacker AGV for Automated Pallet Handling

The only stacker-type model, specifically designed to lift pallets and position them on racks or docks. Available in European and American versions, both with a mapping navigation system and perimeter sensors.

Main Advantage:

- Integrated lifting system with high load capacity and precise placement.

- Max Load: 1200kg

- Navigation: Autonomous

- Movement: Bidirectional, ideal for intralogistics automation

Industries

-

Mobile robotics solutions tailored to each industry

Kivnon offers comprehensive solutions for process automation and optimization in various sectors and across multiple industrial applications. Our AGVs/AMRs have become a key tool in Industry 4.0. We have a broad portfolio of mobile robots with which we can develop customized applications to optimize any industrial environment.

Automotive Industry

- Optimization of part transport on assembly lines. Our AGVs/AMRs integrate seamlessly with automotive production systems, reducing downtime and improving efficiency.

Food and Beverage

- Reliable mobility in refrigerated or humid environments. Our robots are designed to operate in temperature-controlled environments and comply with strict food regulations.

Pharmaceutical

- Safe automation in clean rooms and controlled environments. Our AGVs/AMRs comply with GMP standards and can operate in clean rooms, minimizing human intervention and the risk of contamination.

Logistics and Warehousing

- Flow optimization, traceability, and error reduction. Our robots improve order picking efficiency, reduce errors, and optimize storage space in logistics centers.

Smart Manufacturing

- Efficient handling of heavy materials and automated processes. Our high-capacity AGVs/AMRs are designed to handle heavy loads with precision and safety, improving ergonomics for workers.