- Offer Profile

- Over the past 20+ years MEDOtec has been serving a variety of industries to the highest standard and earned a reputation as an specialist for: dosing pumps, mixers, measuring and control technology (pH, redox, conductivity, chlorine, ...), flow metering technology (low flow ranges from 0,2 l/h up to 60.000 l/h) and engineering and manufacturing of dosing skids.

Dosing Pumps

Electromagnetic Dosing Pumps

-

Compact & innovative - accurate & versatile

LMI pumps are used to inject precise quantities of a chemical product in a treatment process.

LMI PD

-

PD Series metering pump is the new standard in water treatment, includes an improved drive design, all new electronics, and proven FASTPRIMEÂ liquid ends.

- output: up 8 ml/h to 7.6 l/h

- pressure: max. 30 bar

- max. stroke: 160 strokes per minute

- repetitive accuracy: +/- 3.0 %

- steady state accuracy: +/- 3.0 %

- protection class: IP65

Excel AD

-

Mechanically Actuated Diaphragm Electromagnetic Pump

- Output: max. 7.6 l/h

- Pressure: max. 17.3 bar

- Adjustable stroke frequency: 1...59 or 1...120 spm

- Adjustable stroke length: 20...100%

- Temperature of pumped chemical: max. 45°C

- Self priming height: 1.5 m

- Accuracy: 2% of adjusted output

- Display of the pump status: LED operating indicator and operating/fault alarm

- Protection class: IP65

LMI B

-

Mechanically Actuated Diaphragm Electromagnetic Pump

- Output: max. 26 l/h

- Pressure: max. 10.3 bar

- Adjustable stroke frequency: 1...100 spm

- Adjustable stroke length: 0...100%

- Temperature of pumped chemical: max. 50°C

- Self priming height: 1.5 m

- Accuracy: 2% of adjusted output

LMI C

-

Mechanically Actuated Diaphragm Electromagnetic Pump

- Output: max. 76 l/h

- Pressure: max. 20.7 bar

- Adjustable stroke frequency: 1...100 spm

- Adjustable stroke length: 0...100%

- Temperature of pumped chemical: max. 50°C

- Self priming height: 1.5 m

- Accuracy: 2% of adjusted output

PROTEUS

- The PROTEUS chemical metering pump is a mechanically actuated diaphragm pump driven by advanced variable speed technology to provide the most accurate and reliable performance in the industry.

Innovative drive system creates superior +/- 1% steady state accuracy over 1000:1 turndown ratio for greater flexibility in handling difficult chemicals.

- output: max. bis 68 l/h

- pressure: max. 12 bar

- turndown ratio: 1000:1

- repetitive accuracy: +/- 3,0 %

- linearity: +/- 3,0 %

- steady state accuracy: approx. 1%

- protection class: IP65

Motor-Driven Dosing Pumps

-

When strength means performance...

The G Series consists of three models of compact and lightweight dosing pumps, and can handle a very wide range of flow rates. These pumps are recommended for low discharge pressures: G Series models are multi-purpose dosing pumps and can handle all known reagents. They are designed for continuous service day in and day out and can run dry without any damage to the pump.

The PTFE diaphragm is directly linked onto the moving parts of the mechanism (the slide and the variable eccentric). This technology allows G Series dosing pumps to cope with high suction head conditions.

G Series dosing pumps offer a wide choice of liquid end materials which are compatible with most chemical substances - such as: polypropylene (PP), PVDF, stainless steel, high viscosity, fluorinated liquids, slurries...

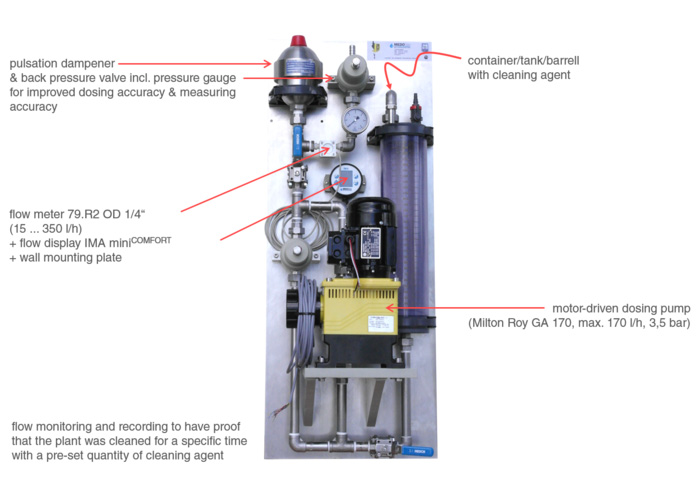

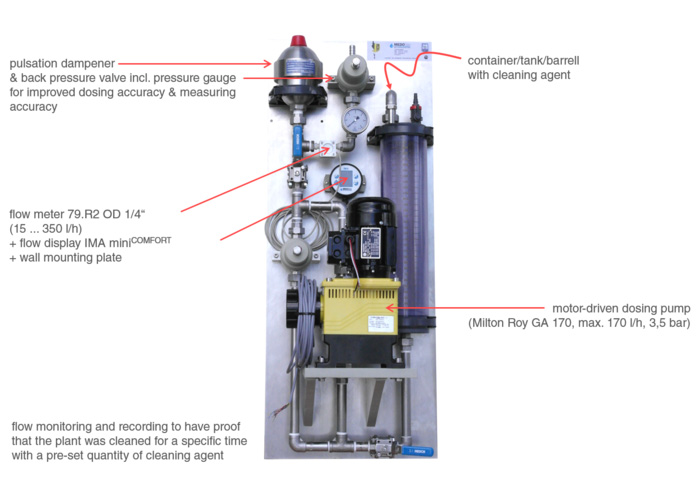

Series GA - Motor-Driven Dosing Pumps

The GA series is the most compact and efficient model of the Milton Roy series G.

Technical specifications:

- Flow rate: max. 170 l/h

- Pressure: max. 12 bar

- Adjustable stroke length: 0...100%

- Temperature: max. 40°C

- Maximum inlet pressure: 2 bar

- Maximum suction height: 4 m water column

- Accuracy: approx. 2%

- Housing made of non-corrosive plastics

- Diaphragm made of PTFE

- Protection class: IP55

Series GM - Motor-Driven Dosing Pumps

The GM series is made of metal. These pumps are offering a wide range of applications with up to 3 identical or different liquid ends.

Technical specifications:

- Flow rate: max. 500 l/h

- Pressure: max. 12 bar

- Adjustable stroke length: 0...100%

- Temperature: max. 40°C

- Maximum inlet pressure: 2 bar

- Maximum suction height: 4 m water column

- Accuracy: approx. 2%

- Housing made of aluminum

- Diaphragm made of PTFE

- Protection class: IP55

Series GB - Motor-Driven Dosing Pumps

The GB series is also made of metal with a housing made of cast aluminum.

Technical specifications:

- Flow rate: max. 1200 l/h

- Pressure: max. 10 bar

- Adjustable stroke length: 0 ... 100%

- Medium temperature: max. 50°C

- Maximum inlet pressure: 2 bar

- Maximum suction height: 4 m water column

- Accuracy: approx. 2%

- Aluminum housing

- Diaphragm made of PTFE

- Protection class: IP55

mRoy - Motor-Driven Metering Pump with Hydraulically Actuated Diaphragm

The A & B models of the mROY dosing pumps are hydraulically operated diaphragm pumps for precise injection of chemical substances.

Technical specifications:

- Flow rate: max. 330 l/h

- Pressure: max. 138 bar

- Adjustable stroke length: 10 ... 100%

- Medium temperature: -7 ... 88 °C (depending on version)

- Accuracy: approx. 1%

- Dust seal cast iron housing

- PTFE diaphragm protected by two contour plates

- Protection class: IP55

MAXROY - Motor-Driven Metering Pump with Hydraulically Actuated Diaphragm

MAXROY dosing pumps are especially designed for pumping specific products, including viscous products.

Technical specifications:

- Flow rate: 16 l/h...1,110 l/h

- pressure: max. 28 bar

- temperature: max. +90°C (Stainless steel liquid end), +50°C (non-metallic liquid end)

- Adjustment while running or stopped, from 0...100% of nominal flow rate

- Accuracy: ± 1% - API 675 compliant

- Internal safety valve

- Single or double diaphragm

- Diaphragm service life can be in excess of 20,000 hours (depending on type of product, service conditions and installation)

- Protection class: IP55

PRIMEROYAL - Motor-Driven Metering Pump with Hydraulically Actuated Diaphragm

Primeroyal series pumps combine robust, field-proven technology, flexible design, and chemical delivery accuracy, making these metering pumps suitable for a large number of industrial processes. The pumps feature a variable eccentric drive that enables precise control of the pump delivery rate while meeting or exceeding industry standards for steady-state accuracy and repeatability.

Technical specifications:

- Flow rate: from 0.2 l/h...15,660 l/h in simplex configuration

- Pressure: up to 1,379 bar

- Multiplexable

- Accuracy: ± 1%, even for low flow rates and high pressures

- Stroke adjustment: from 0...100% of nominal flow rate

- Explosion-proof version: conforming to ATEX CE EX II 2 G/D c T3 or T4 upon request

- API 675

Air Operated Double Diaphragm Pump

-

many fields of application, many advantages

Air operated double diaphragm pumps (AODD) are operated by compressed air or nitrogen. Thus, the AODD pumps are perfectly suited to be used in a wide variety of industries.

Air Operated Double Diaphragm Pumps in PE or PTFE

-

Features:

- flow rates: depending on version, up to max. 48,000 l/h

- temperature: up to + 120 °C

- pressure: up to 16 bar (standard versions: 8 bar)

- lubrication-free operation

- low air consumption

- special version: ATEX pumps

Air Operated Double Diaphragm Pumps in Aluminum, Cast Iron or Stainless Steel

-

Features:

- flow rates: depending on version, up to max. 33,900 l/h

- temperature: up to + 120 °C

- pressure: up to 16 bar (standard versions: 8 bar)

- lubrication-free operation

- low air consumption

Air Operated Double Diaphragm Pumps in Polished Stainless Steel - the "Sanitary Pump"

-

Features:

- flow rates: depending on version, up to max. 33,900 l/h

- pressure: up to 16 bar (standard versions: 8 bar)

- quick dismantling without any tools

- plain surface (prevents the formation and growth of bacteria and germs - diaphragms are approved according to FDA)

- superior surface finish (all media-bearing components are made of polished stainless steel and meet the standards of the food and pharmaceutical industry)

- lubrication-free operation (the air motor requires no lubricated compressed air and no lubrication)

- CIP and SIP capable

Pulsation Dampers

The operation of an air operated double diaphram pump (short: AODD pump) creates a pulsating flow caused by the oscillating movement of the diaphragm. By installing an active pulsation dampener the pulsation can be easily reduced resulting in a constant flow rate for a safe process.

Series HELISEM Mixers

- The range applies to tanks from 50 liters to 400 m3, for viscosities up to 1000 mPas (cP).

Applications:

- water treatment (flocculation, reagent preparation, milk of lime storage, pH control ...

- formulation of consumable products (detergents, paints, inks ...)

- chemical industry

- all additive preparations

Mixer "Helisem VDA"

VDA agitators are fitted with a high-efficiency marine propeller. It's direct power drive offers simplicity. These mixers are designed to work 24 hours per day, seven days a week. The VDA is a multipurpose mixer due to a simple but efficient impeller and high speed, allowing for a powerful jet and rapid dissolution of powders.

Technical Specifications:

- tank volume: 50 ... 2,000 L

- impeller diameter: 80 ... 160 mm

- rated power: 0.25 ... 1.5 kW

- rotation speed: 900, 1800 rpm (60 Hz) / 1500 rpm (50 Hz)

- material: SS316L

Mixers "Helisem VRP"

-

VRP agitators are equipped with a gear reducer and a solid shaft, designed to run 24/7. It's a simple design with removable turbine blades (it's position can be adjusted along the shaft).

Technical Specifications:

- tank volume: 100 ... 5,000 L

- impeller diameter: 200 ... 500 mm

- rated power: 0.18 ... 0.37 kW

- rotation speed: 100 ... 280 rpm

- material: SS316L

- PBT (Pitch Blade Turbine) with 4 blades, each with a 45° angle

Mixers "Helisem VRH"

-

VRH mixers are fitted with a low footprint gear reducer, with several models life lubricated, they are designed to run 24/7.

For the same pumping flow rate, we note an energy saving of over 70% - the cost effective reduction is excellent. The blade mounting is simplified and safer.

Technical Specifications:

- tank volume: 2,000 ... 100,000 L

- impeller diameter: 600 ... 2350 mm

- rated power: 0.18 ... 3 kW

- rotation speed: 16 ... 76 rpm

- material: SS316L

Mixers "Helisem FRH"

Technical Specifications:

- tank volume: 1,000 ... 400,000 L

- impeller diameter: 400 ... 3,600 mm

- rated power: 0.12 ... 1.1 kW

- rotation speed: 7,5 ... 68 rpm

- material: SS316L

Flow Measuring

- Flow Sensors for all Applications

Flow Sensor R1 D05

Technical Features:

- flow range: 0.2 ... 12 l/h

- measuring range: 1.0 ... 10 l/h

- viscosity: approx. 1 ... 10 cST

- measuring accuracy: +/- 2 %

- repeatability: less than 0.8 %

- operating / burst pressure: 6 bar / > 15 bar

- operating temperature: -10 ... 80°C

- connection: tube connection 4/6 mm

Flow Sensor R2

-

Technical Features:

- flow ranges:1 l/h ... 350 l/h

- measuring ranges: 50 l/h - 300 l/h

- viscosity: approx. 1 ... 10 cST

- measuring accuracy: +/- 2 %

- repeatability: less than 0.8 %

- operating / burst pressure: 10 bar / > 30 bar

- operating temperature: -10 ... 80°C

- connection: 1/4" male, 5/8" UNF

Flow Sensor 79.01 + 79.03

-

Technical Features:

- flow ranges: 1.5 ... 250 l/h

- measuring ranges: 6 ... 200 l/h

- viscosity: approx. 1 ... 10 cST

- measuring accuracy: +/- 2 %

- repeatability: less than 0,8 %

- operating / burst pressure: 10 bar / > 30 bar

- operating temperature: -10 ... 80°C

Flow Sensor R4

-

Technical Features:

- flow range: 30 ... 1.000 l/h

- measuring range: 60 ... 900 l/h

- viscosity: approx. 1 ... 10 cST

- measuring accuracy: +/- 2 %

- repeatability: less than 0.8 %

- operating / burst pressure: 6 bar / > 20 bar

- operating temperature: -10 ... 80°C

Water Meter 72.04 + 72.05

-

Technical Features:

- flow ranges: 72.04: 30 ... 5.000l/h

- measuring ranges: 72.04: 50 ... 3.000 l/h, 72.05: 100 ... 5.000 l/h

- viscosity: approx. 1 ... 10 cST

- measuring accuracy: +/- 2 %

- repeatability: less than 0.8 %

- operating / burst pressure: 10 bar / > 25 bar

- operating temperature: -10 ... 80°C

Flow Sensor DN 25 ... DN 50

-

Technical Features:

- flow ranges: DN 25: 300 ... 15.000 l/h, DN 32: 600 ... 24.000 l/h, DN 40: 900 ... 36.000 l/h, DN 50: 1.200 ... 60.000 l/h

- measuring ranges: DN 25: 900 ... 14.000 l/h, DN 32: 1.800 ... 22.000 l/h, DN 40: 3.500 ... 34.000 l/h, DN 50: 3.000 ... 55.000 l/h

- viscosity: 0.5 ... 20 cST

- measuring accuracy: +/- 3 %

- repeatability: less than 0.5 %

- operating / burst pressure: 10 bar / > 25 bar

- operating temperature: -10 ... 80°C

Flow Sensor OV.01 + OV.02

-

... suitable for viscous products in particular

Technical Features:

- flow ranges: OV.01: 2.0 ... 40 l/h, OV.02: 5.0 ... 80 l/h

- measuring ranges: OV.01: 5.0 ... 40 l/h, OV.02: 10 ... 70 l/h

- viscosity: 5 ... 200 cST

- measuring accuracy: +/- 2.5 %

- repeatability: less than0.8 %

- operating / burst pressure: 10 bar / > 25 bar

- operating temperature: -10 ... 80°C

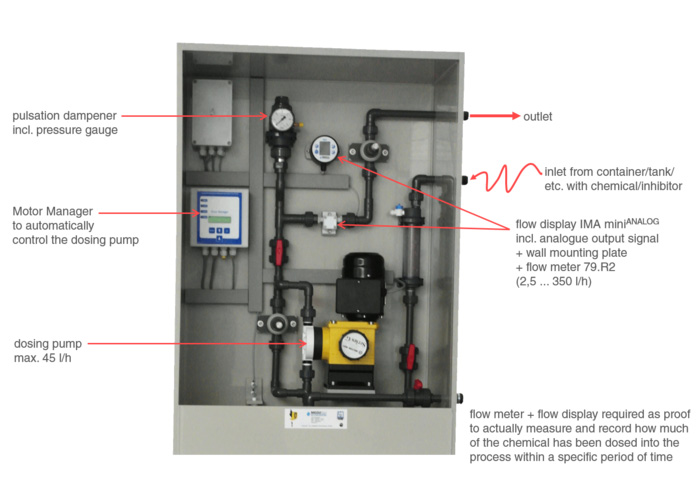

IMA mini - our Intelligent Flow Monitoring Electronic

-

IMA mini is designed for industrial applications in particular. The Impulse-Measuring-Analysis unit is an all-inclusive device offering an enormous variety of features as well as an intuitive menu-driven handling and a robust housing while providing a very attractive price-performance-ration.

Technical Features:

- full color 1,7" LED display

- 4-key menu

- easy calibration of up to 2 connected flow sensors

- freely adjustable display units

- filter functions

- erasable sum counter/totalizer

- limit value monitoring

- SSR output (potential-freecontact)

- 3-stage fluid level monitoring

Measuring & Control Technology

Measuring & Controlling Devices

-

Process Measuring and Controlling

Are you searching for a way to measure one or even more parameters within your process in order to automate and optimize your process? You just came to the right place! Our extensive portfolio of "Measuring & Control Technology" includes probably every product you may need for the task "water treatment" (process water, industrial water, wastewater, drinking water, ...).

Universal Controller

-

PID controller (optionally as 1-channel or 2-channel controller) with intuitive user interface, display and SD memory card for recording of measured data + alarms.

Measuring Values:

- pH

- redox

- conductivity (conductive)

- chlorine

- chlorinedioxid

- ...

Universal Controller Conductivity Inductive

-

PID-Controller, especially for inductive (contactless) conductivity measurements, with SD memory card for documentation of measured values and alarms.

Measuring Values:

- conductivity inductive

Analogue Controller

-

Our analogue controllers measure the actual value, compare the measured value to a pre-set target value, and consequently control the associated dosing systems until the desired value has been reached.

Measuring Values:

- pH

- conductivity

- chlorine

Basic Controller

-

Our basic controller is a measuring and control device for conductivity or pH-measurements with less features than our all-inclusive high-end device Universal Controller, but thus more cost-effective. It can be used for automatic control of a dosing pump or alternatively as a display device with 0/4 ... 20 mA output signal for a higher-level PLC.

Measuring Values:

- conductivity (inductive)

- conductivity (conductive)

- pH

Measurement Converter "Signoscript"

-

The measurement converter Signoscript is a measuring and display device with 4 ... 20 mA output signal for a higher-level PLC.

Measuring Values:

- pH

- redox

- temperature

- chlorine

- chlorinedioxid

- conductivity

- temperature

- hydrogen peroxide

- ozone

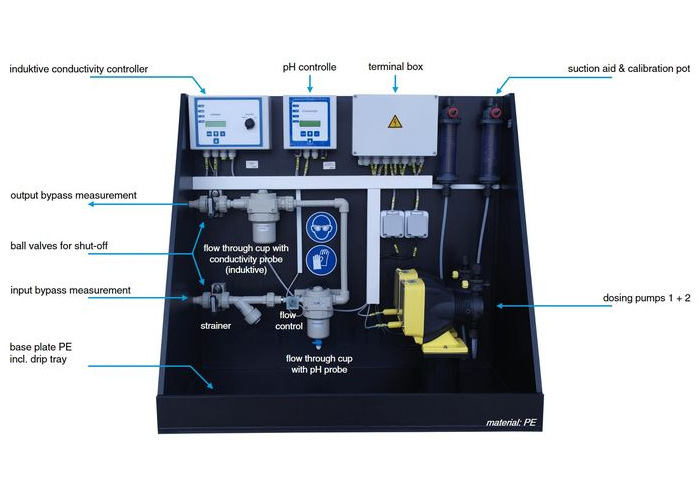

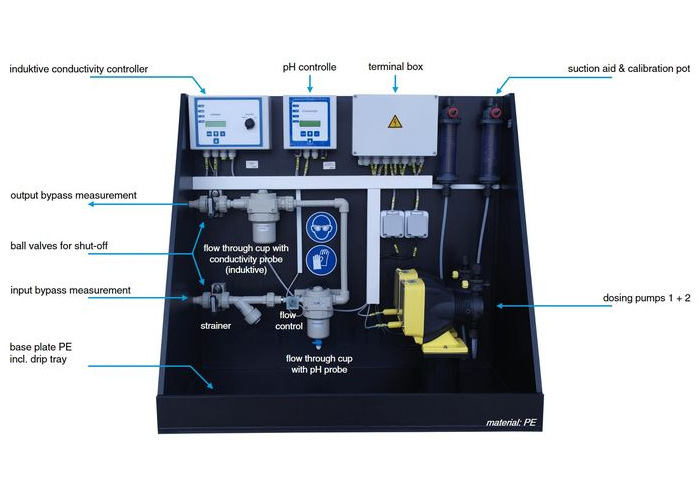

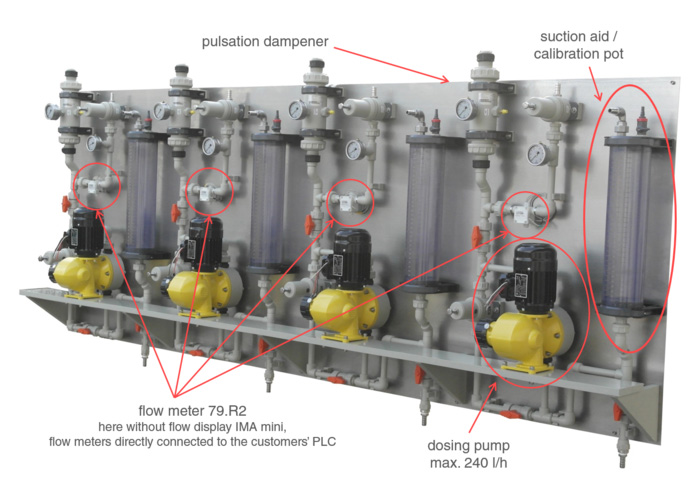

Dosing Skids

Automated Dosing of Liquid Products/Chemicals

-

A significant industry trend of the past few years is the automatically controlled dosing of the chemicals based on specific measuring parameters – manually pre-set, static dosing belongs to the past.

Our measuring and control technology products are here to automate your process by measuring a pH and/or conductivity value within your tank or basin, and subsequently control the dosing pump just as needed via a controller.

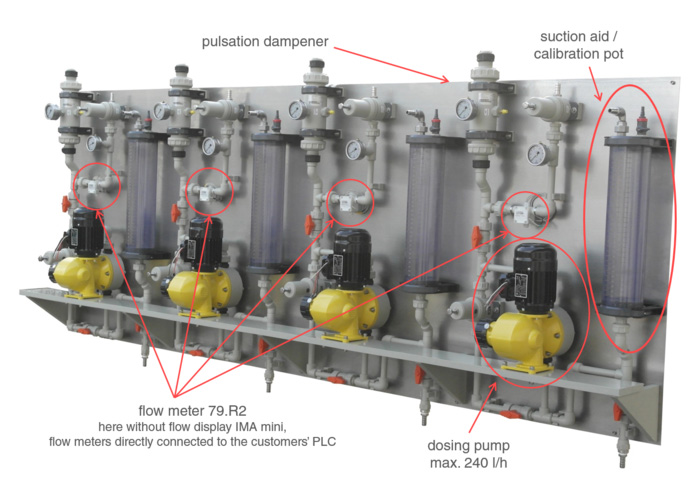

Dosing Unit for a Coagulant Iron(III)-Chloride

-

Area of application: waste water treatment

- dosing box including drip tray

- plexi glas safety protection

- completely pre-wired internally (terminal box)

CIP-Dosing Unit (Cleaning-in-Place)

-

area of application: e.g cosmetic + pharmaceutical Industry

- completely pre-assembled dosing station, produced in our workshop in Roethenbach near Nuremberg

- piping depends on your requirements and / or chemical resistance (PVC, PP, stainless steel, ...).

- including all safety fittings (safety valves, back pressure relief valves, pulsation dampeners)

- ...

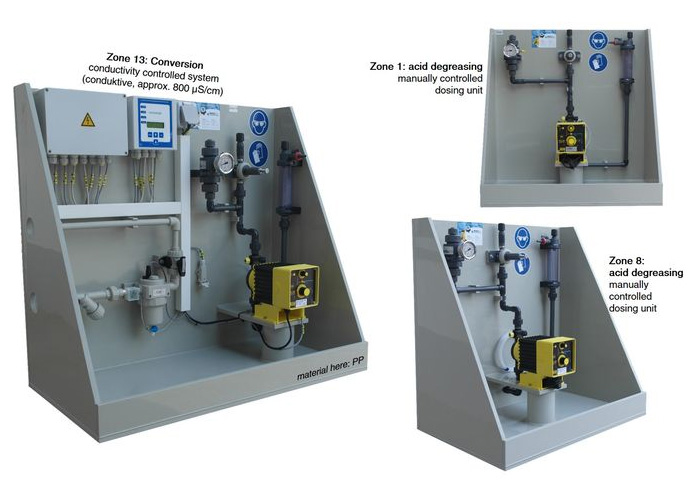

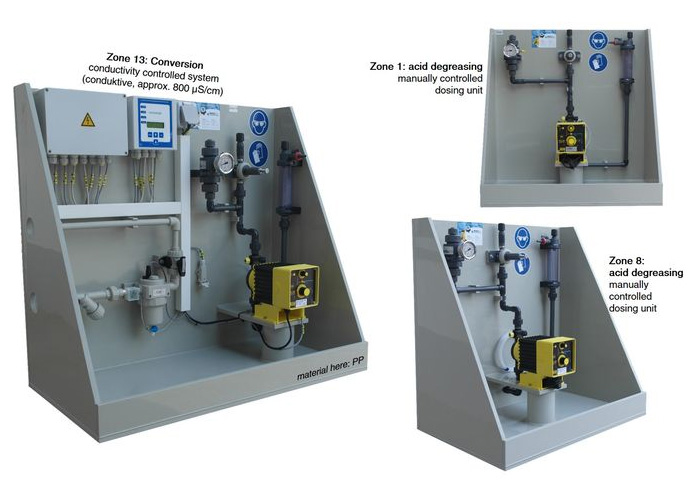

Dosing Skids integrated in Dosing Boxes

-

area of application: water treatment

Our dosing boxes offer numerous safety advantages for operation:

- box resistant to most of corrosive and hazardous chemical products

- lockable doors incl. safety equipment (protective goggles/gloves/protective gown/...)

- drip tray with leakage sensor + drain-ball valve

- complete tubing (including all relevant safety fittings: safety valve, back pressure valve, pulsation dampener, ...)

- optional: stainless steel base frame, heating or cooling for outdoor installations

Pinch Valves

Pinch Valves

-

Pinch valves are used to control the flow of abrasive, corrosive and fibrous fluids and provide a leak-proof seal when closed.

They provide a leak-proof seal in use with liquids, viscous media such as suspensions, granules, pastes, powders, dust, ...

Dosing Tanks

Dosing Tanks

-

Our dosing tanks are made of high-quality plastic (PE) and are resistant to almost all common chemicals, UV-stable for use in outdoor area and food-safe. They have a liter scale and a special bridge for the installation of agitators or dosing pumps. Tanks are available in numerous sizes from 60 ... 3,000 liter.

Dosing Tanks + Dosing Pumps, ready-to-use

-

In addition to plain dosing or storage tanks for liquids that you need to be dosed into your process, we are happy to offer pre-assembled, ready-to-use dosing skids. The following options are just a few examples of the various possibilities:

- reinforcing base plate for the assembly of weighty dosing pumps

- pre-installed suction tubes with ceramic weight, ready-to-use

- pre-installed suction lances with level indication (min, min-min, max)

- electrically pre-wired, integrated terminal box

- ........

Dosing Tanks + Mixers, ready-to-use

-

Storage tanks or preparation processes often require a slow, fast or even continuous mixing. Upon request we can pre-install mixers onto the appropriate dosing or storage tanks, reinforce the dosing tanks's top with mounting plates, install wave breakers for an optimal mixing result if necessary, and equip the tanks with (optical + electronic) level indicators, drain ball-valves and much more.

Sump Pallets

-

Our containment bunds are seamlessly made of high quality plastic (PE) and have a high load bearing capacity. They are resistant to almost all common chemicals and are UV-stable and suitable for outdoor application. Most of the pallets have a DIBt approval (German Institute for Construction). The spill containment pallets consist of a collecting space and, optionally, a high load-bearing grate in the bath height (grates can be removed). Available in standard pallet sizes up to 2000 x 1200 mm.

Safety Containment Pallets with Integrated Dosing Equipment

-

Customized solutions, perfectly fit to your specific needs, are our daily business: we are able to design a complete and ready-to-use package unit including dosing equipment, assembled onto a panel, maybe supported by a stainless steel base frame, readily assembled with the matching sump/containment pallets.