- Offer Profile

- Since more than 30 years the TAKTOMAT GmbH produces precise, customer-oriented and high-quality products and solutions for the automation industry e. g. bevel gear, rotary tables, rotary indexers, parallel gears or cam mechanism.

This long-standing experience and customer focus makes the company to one of the world's leading manufacturer of handling and drive technology. Approximately 100 employees daily create ideal to the needs of customers´ adapted products.

Because of that TAKTOMAT products not only convince through innovation, but also with first-class quality.

Whether rotary table, rotary indexer, parallel gear or linear unit

– Products made by TAKTOMAT will convince you.

TAKTOMAT. Your specialist for automation.

Rotary indexers with fixed division

- Robust constuction

- Short switching times

- Fixed division

- Different types and sizes

- Low maintenance

Rotary indexers with flexible division

- Robust constuction

- Short switching times

- Flexible division

- Different sizes

- Low maintenance

Linear transfer systems

- High intervals

- Highest reliability

- Different types and sizes

- Low maintenance

Transfer devices

- Lifting and rotating movements

- Linear movements

- Exact positioning

- Individually customizable

- Different types and sizes

Customer-specific cams

- Cylinder cams

- Flat cams

- Globoidal cams

- Barrel cams

Shuttle systems

- Lifting drives

- Longitudinal drives

- With or without cross stroke

- Shuttle components

Accessories TIC

- Cycle time optimization

- Easy handling

- Gentle for machine

- Long life time

Measuring devices, test equipment, control devices

- Control devices

- Depth gauge with tast stage

- Measurement system analysis

- In-house production

Rotary indexers, linear transfer systems and more.

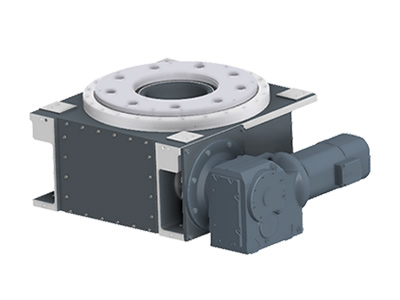

Rotary indexers with fixed division

Type RTX

-

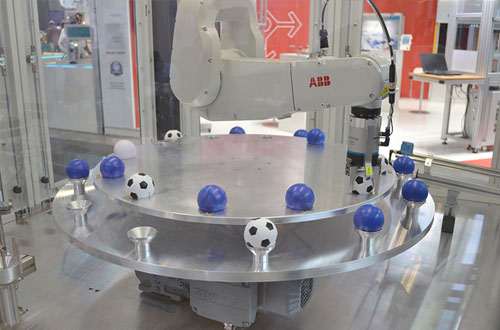

The rotary indexer RTX is often used in the assembly technology, the testing technology, the welding technology, the printing, the pressing, the automotive industry, the microelectronics, the food industry, the medical and the cosmetic industry.Features and user benefits

- Reliable, robust drum cam roundtable for all applications

- Construction diameter 100mm – 5000mm

- Fixed divisions 2 – 96 or flexible through NC technology

- Switching times of 0.16s – 5s

- Gentle starting and stopping across the switching cam

- Large, vertically hollow shaft Ideal for high loads

- Standard accuracy 15" – 35"

- Four-point mounting at the outer diameter of the output flange

- Maintenance free through oil bath lubrication

- Stop operation, continuous operation or reversing design possible

- All installation positions possible

Type TT

- Barell cam

Common applications

The rotary indexer TT is often used in the assembly technology, the testing equipment, the welding technology, the printing, the pressing, the automotive industry, the microelectronics, the food industry, the medical technology and the cosmetic industry.

Features and user benefits- Reliable, robust drum cam roundtable for all applications

- Construction diameter 75mm – 2800mm

- Fixed divisions 2 – 96 or flexible through NC technology

- Switching times of 0,16s – 5s

- Gentle starting and stopping across the switching cam

- Large, vertically hollow shaft

- Standard accuracy 15" – 35"

- New: Extreme indexing accuracy of 0.02mm

– Independent of the construction diameter - Tapered rollers or cross roller bearing at the inner diameter of the roll star

- Low-cost variant with aluminum housing

- Maintenance through oil bath lubrication

- Stop operation, continuous operation or reversing design possible

- All installation positions possible

Type RT

-

The rotary indexer RT is often used in the assembly technology, the testing technology, the welding technology,

the printing, the pressing, the automotive industry, the microelectronics, the food industry, the medical and

the cosmetic industry.Features and user benefits:

- Reliable, robust drum cam roundtable

for all applications - Construction diameter 100 mm – 3500 mm

- Fixed divisions 2 – 96 or flexible

through NC technology - Switching times of 0.16 s – 5 s

- Gentle starting and stopping across

the switching cam - Large, vertically hollow shaft

- Reliable, robust drum cam roundtable

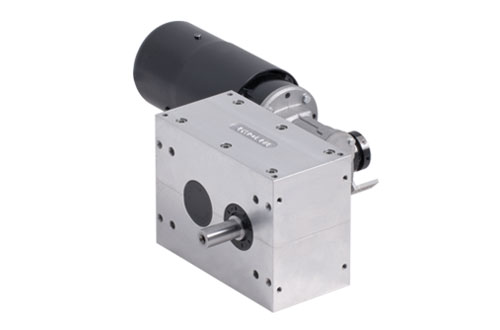

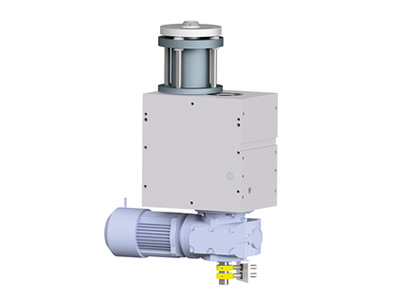

Parallel gears XP, TP and SP

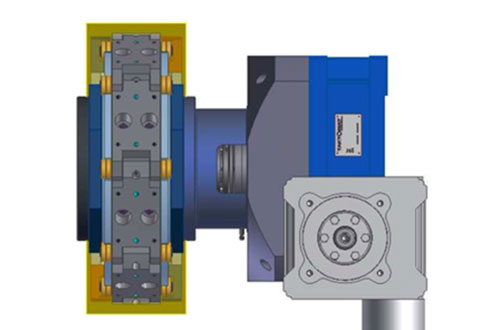

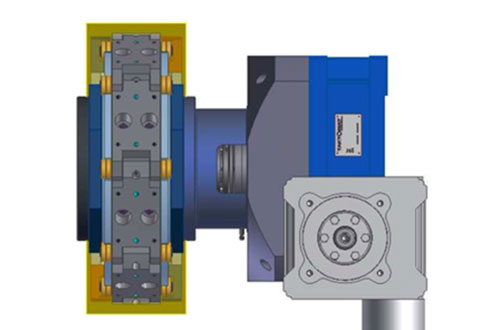

-

The parallel gears are often used for clocking of straps and chains, swinging of gripper arms, converting rotary

to horizontal movements, rotating of components, separating and sorting.Features and user benefits:

- Various design options of the cam

- Short switching angles possible

- Parallel input and output shafts

- Pendulum possible

- Very high accuracy through

backlash-free motion transfer - Gentle starting and stopping

- Various cam laws possible

- High reliability

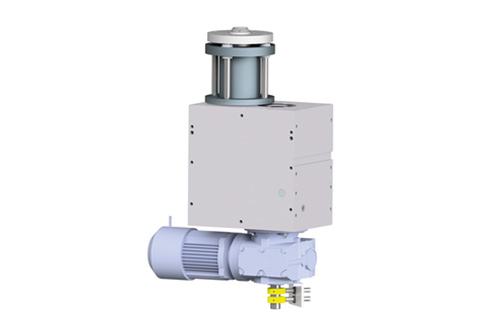

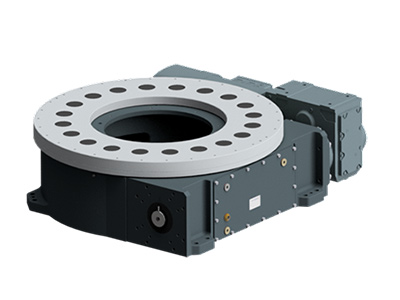

Rotary indexer with flexible division

VTMV

-

The flexible rotary indexer TMF is ideal for using in the assembly, in the automotive industry, for welding machines,

in printing machines, in the food industry, in the medical technology and the microelectronics.Features and user benefits:

- Flexible division

- Low construction height because of a flat output flange

- Large number of cam followers

– Accordingly always at least 4 piece engaged - Almost no margin because of biased cam followers

- Through optimally hardened barrel cams and cam

followers higher transferable torques - Design possible as rotary drum

- Maintenance free through oil bath lubrication

- Simple readjustment of the output bearing through segmental arches in peeling sheet design

- Large center hole for e. g. accommodation

of supply lines - Large bearing surface for mounting components

- Specially developed for the automotive industry

and other applications in the heavy duty sector - Various installation positions possible

TMF

-

The flexible rotary indexer TMF is ideal for using in the assembly, in the automotive industry, for welding machines,

in printing machines, in the food industry, in the medical technology and the microelectronics.Features and user benefits:

- Flexible division

- Low construction height because of a flat output flange

- Large number of cam followers

– Accordingly always at least 4 pieces engaged - Almost no margin because of biased cam followers

- Through optimally hardened barrel cams and cam

followers higher transferable torques - Design possible as rotary drum

- Maintenance free through oil bath lubrication

- Simple readjustment of the output bearing through segmental arches in peeling sheet design

- Large center hole for e. g. accommodation

of supply lines - Large bearing surface for mounting components

- Specially developed for the automotive industry

and other applications in the heavy duty sector - Various installation positions possible

RTF

-

The flexible RTF rotary indexers are particularly well suited for automated production processes in which the movement path have to change (for example automotive industry).

Features and user benefits:

- Reliable, robust drum cam roundtable

for all applications - Construction diameter 100 mm – 285 mm

- Individually programmable

- High flexibility through NC-Technik

- Mechanical interface on screw drive with freely

selectable connection for customer servo motor - Large, vertically hollow shaft

- High torques

- Ideal for high loads

- High accuracy without and with

absolute encoder (optional) - Four-point mounting at the outer diameter

of the output flange - Maintenance free through oil bath lubrication

- All installation positions possible

- Reliable, robust drum cam roundtable

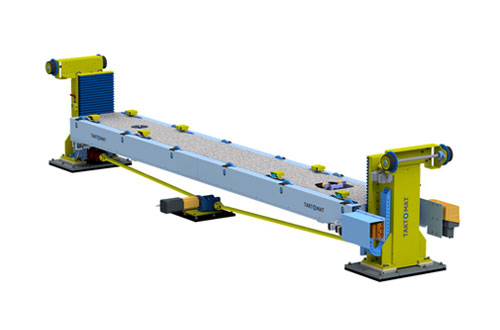

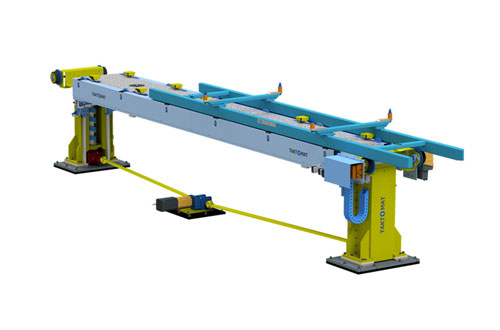

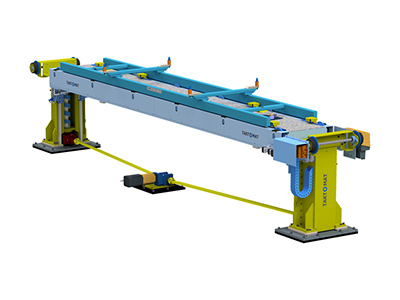

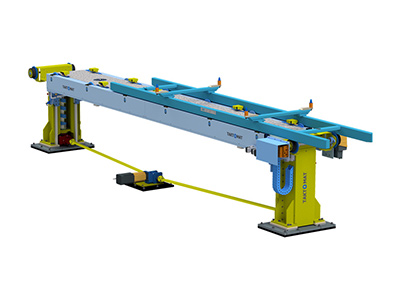

Linear transfer systems

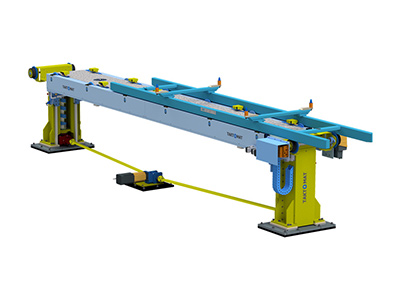

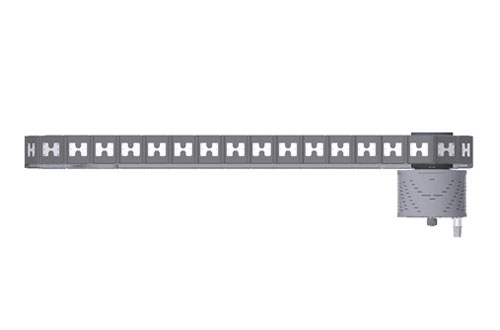

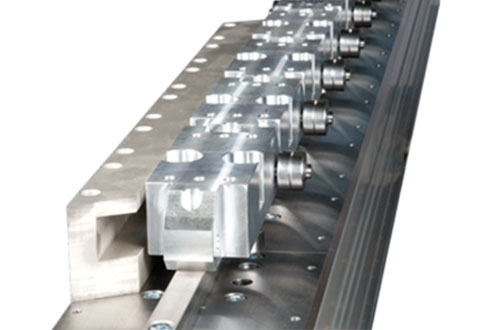

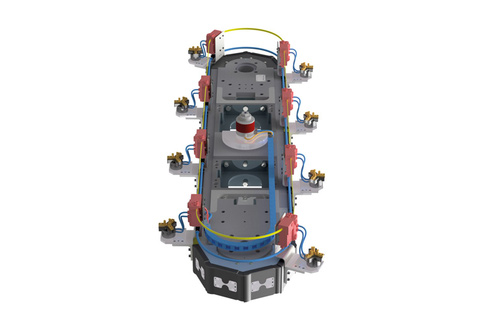

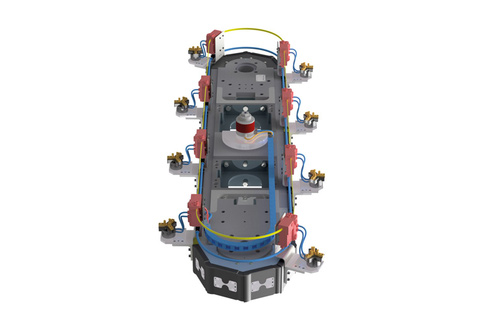

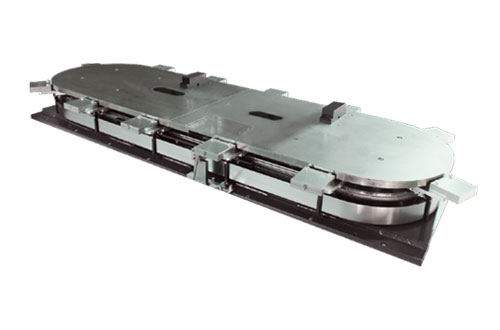

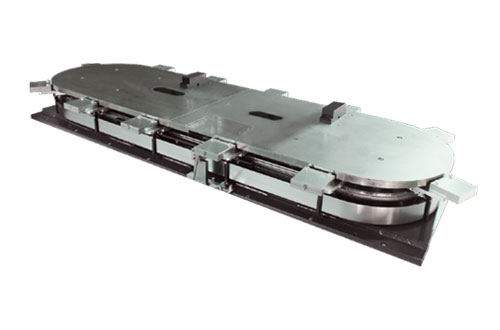

Linear transfer system type RFA075

-

The linear transfer system RFA finds inter alia application in the mechanical engineering, the installation engineering, the packaging technology, the testing, the printing, the presses and the microelectronics.

Furthermore TAKTOMAT provides for the linear transfer system RFA customized solutions for using in clean rooms, in hazardous areas, in the food industry, in medical technology etc.Features and user benefits

- Flexible arrangement of the

workpiece carriers in 20mm grid - Maintenance-free transport system

- Stable base frame

- For medium switching times or

continuous operation - Positioning accuracy from ± 0.4

- Drive via disc cam gear

or servo motor - Flexibly programmable

- Short delivery times

- Variable center distance

- Space-saving design due to

linear arrangement

- Flexible arrangement of the

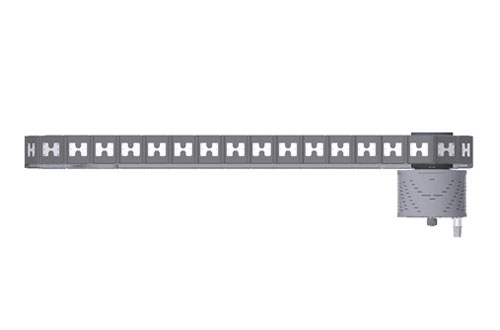

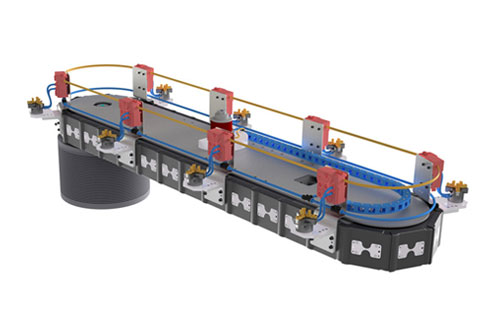

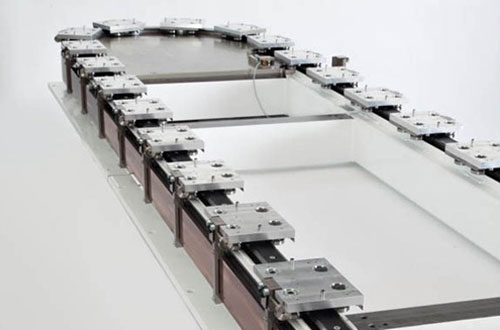

Type LFA

- Common applications

The linear transfer system LFA finds inter alia application in the mechanical engineering, the installation engineering, ÂÂthe packaging technology, the testing, the printing, the presses and the microelectronics.

Furthermore TAKTOMAT provides for the linear transfer system LFA customized solutions for using in clean rooms, in hazardous areas, in the food industry, in medical technology etc.

Features and user benefits- Linear transfer system with highest precision without additional indexing

- Regulated and controlled movements

- Variable total lengths according to customer requirements (max. 10 meters)

- Up to 200 cycles per minute Standard versions available in four different sizes

- Customization possible

- Mechanically synchronized with machine

- CE and UL certified

- Highest reliability

- Very long life time and maintenance

- Driven by proven standard roundtable or torque motor

- Vertical and horizontal using possible

- Drive shaft is synchronized with the chain clock (possibility to use the bevel drive for additional movements)

- Media and energy supply possible through optimal frame construction

- Possibility of free and flexible attaching external components (aluminum profile system)

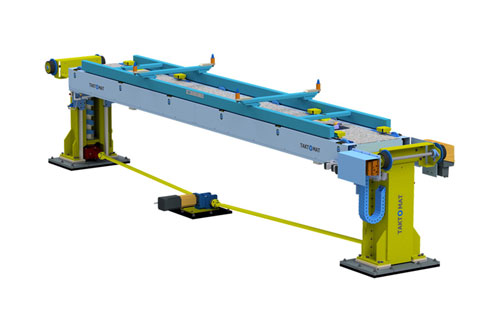

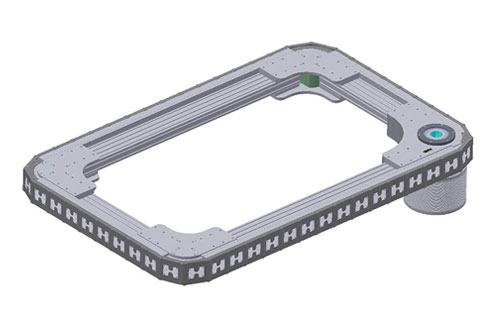

Type LCM

- Common applications

The linear transfer system LCM finds inter alia application in the mechanical engineering, the installation engineering, ÂÂthe packaging technology, the testing, the printing, the presses and the microelectronics.

Furthermore TAKTOMAT provides for the linear transfer system LCM customized solutions for using in clean rooms, in hazardous areas, in the food industry, in medical technology etc.

Features and user benefits- Energy supply for the wpc

- Fast and precise

- Torsion-free

- Low-noise

- Flexible

- Optional available with a second drive

- Positioning time

- Referenceable processing stations

- Robust base frame made from cast steel

- Suitable for clean rooms

- Short delivery times

- Energy supply for the wpc

- Flexible positions

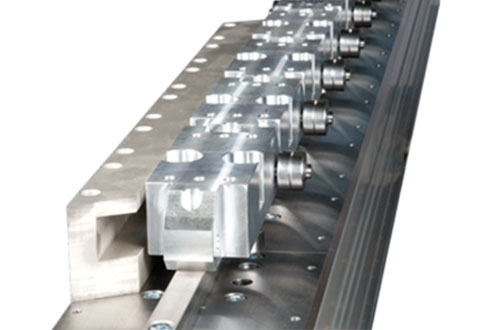

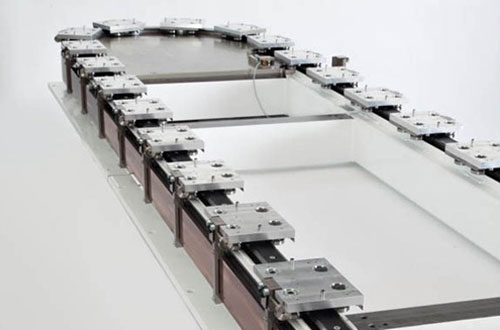

Type LB

- Common applications

The linear transfer system LB is ideal for using in the assembly technology, the pad and screen printing, the microelectronics, the food industry, the medical technology and the cosmetic industry.

Features and user benefits- New, high-precision, flexible series

- Vertical use – the empty value carriers run space-saving back to the bottom of the plant

- Horizontal, as an oval or square – Both sides of the system can be used for mounting

- Available in different sizes

- Self-supporting modular design, modules available with or without frames Distance between the workpiece carrier freely selectable

- Any number of stopping points per workpiece carrier

- Driven by torque motor

- Available with or without control

Parallel gears

Parallel gears: Type XP / TP / SP

-

The parallel gears are often used for clocking of straps and chains, swinging of gripper arms, converting rotary

to horizontal movements, rotating of components, separating and sorting.

Features and user benefits- Various design options of the cam

- Short switching angles possible

- Parallel input and output shafts

- Pendulum possible

- Very high accuracy through backlash-free motion transfer

- Gentle starting and stopping

- Various cam laws possible High reliability

- Directions of rotating are reversible Inexpensive clock drives

- Adjustment of the shafts without eccentric, because of that no skew of the shafts and low adjustment effort

- No skewing of the waves and low adjustment effort

- Maintenance through oil bath lubrication

- Various installation positions possible

Transfer devices

Lift and rotating modules

- Common applications

The main application of the transfer devices is the automotive industry (e. g. filters, piston rings etc.).

Features and user benefits- Linear or rotary lift movements

- Tailored to customer needs

- Easy automation

- Fast acceleration cams

- Fast and precise positioning etc.

Series GH- Common drive for lift and rotation Globoid cam for rotation Disk cam for lift By globoidal cam you can variate the relation between lift and rotation in a big range Compact, durable module Maintenance-free oil filling Through hole is possible Vertical stroke up to 55mm Rotation up to 180° Pendulum angle up to 90°

Series PH- Common drive for lift and rotation Disk cam for rotation Barrel cam for lift Big torque by disk cam Compact, slim module Maintenance-free oil filling Through hole is possible Vertical stroke up to 40 – 80mm Rotation up to 180° Pendulum angle up to 90°

Series RH- Low-priced module Common drive for lift and rotation Barrel cam for rotation Disk cam for lift Compact, durable module Maintenance-free oil filling Through hole is possible Rigid tandem ball bushings for lifting Vertical stroke up to 30mm Rotation up to 90° Pendulum angle up to 60°

Series RT+VT- Extra drive for lift and rotation Suitable for all indexer sizes Disk cam for lift Indexer and lift gear can be synchronized by a timing belt drive Compact, durable module Maintenance-free oil filling Through hole is possible Vertical stroke up to 30mm Rotation up to 180° Pendulum angle up to 90°

Customer-specific cams

Customer-specific cams

- Common applications

The cams from TAKTOMAT are mainly used in the special machine construction, the welding technology, the food industry, the medical technology, the packaging industry and the cosmetic industry. Features and user benefits

TAKTOMAT produces the following custom cams:- Cylinder cams

- Flat cams

- Globoidal cams

- Barrel cams

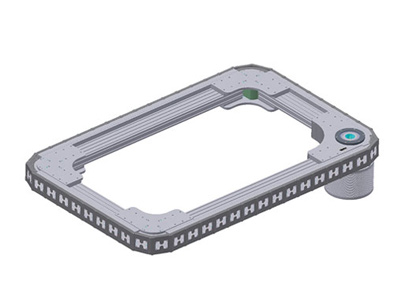

Rotary ring indexer TSR

Rotary ring indexer TSR

-

The rotary ring indexer TSR is often used in the assembly technology, the testing technology, the welding technology,

the printing, the pressing and in the automotive industry.Features and user benefits:

- Reliable, robust rotary ring indexer for

all applications - Fixed divisions 4 – 96 or flexible

through NC technology - Very large center hole for e. g.

accommodation of minirobots - Very small output flange

(Relations innerØ to outerØ)

- Extremely low / flat profile

- Integrated countershaft

- Four-point mounting at the outer diameter

of the output flange - Maintenance through oil bath lubrication

- Reliable, robust rotary ring indexer for

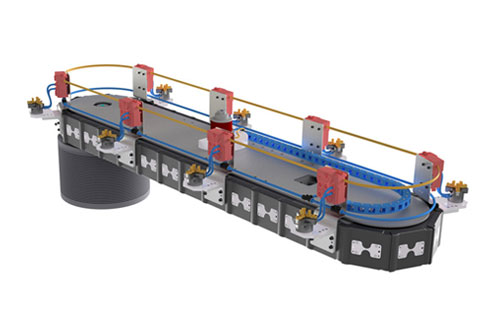

Shuttle systems

Vertical lift and carry systems

- Common applications

The TAKTOMAT shuttle systems are mainly used in the automotive industry.

Features and user benefits- Lifting / lowering conveyor for accurate positioning transportation of large components with a maximum weight of 500kg of machining cell / station to BZ e. g. in the body shop

Shuttle technology from TAKTOMAT

The TAKTOMAT GmbH has a long history of developing and constructing lift and carry systems.

The offer includes:

Lift systems (picture 3)- Available strokes (7m horizontal / vertical 1250mm)

- Number of stations (3 – 10 stations / up to 70m length system)

- Weights (up to 500 kg per component)

- Special designs: Monorail shuttle

- Availability 99.9%

Carry Systems- Vertical lift and carry systems

- Horizontal lift and carry systems

All shuttle components can be acquired from TAKTOMAT:- Beam

- Safety locking

- Bolt

- Clamping pieces

- Followers

- Beam guide

- Rocker

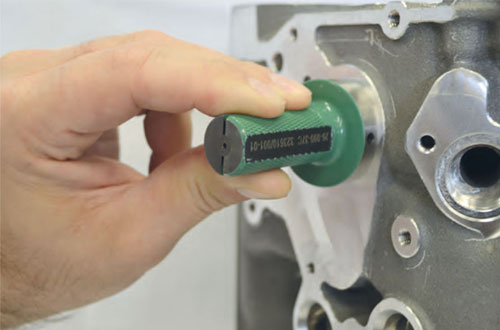

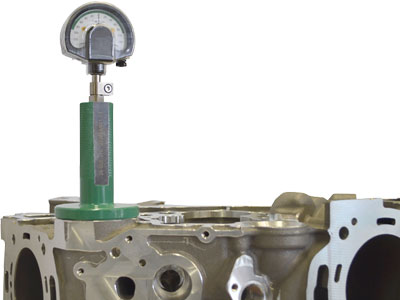

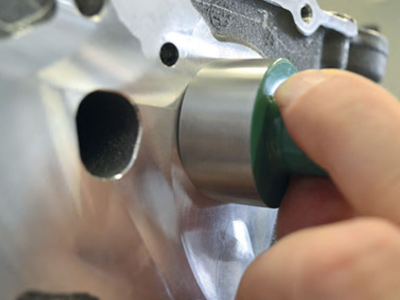

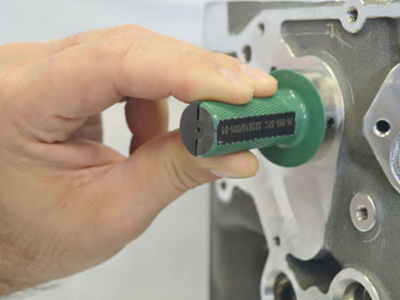

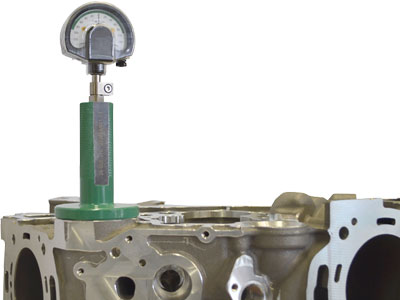

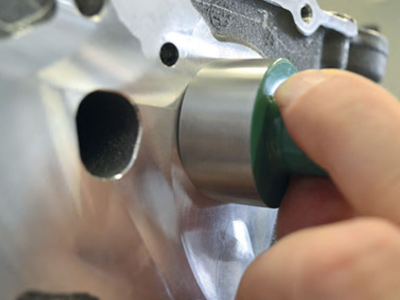

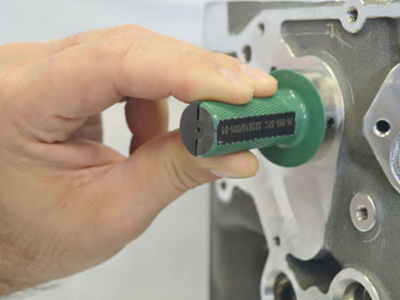

Measuring devices, test equipment, control devices

Measuring devices, test equipment, control devices

-

Common applications

The measuring devices of TAKTOMAT are suitable for conrods, wheel hub, brake disc, crankcase etc.

FeaturesControl devices

- Control device for chamfer depth

- Control device for recess depth

Depth gauge with tast stage- Function thorn for drilling

- Depth gauge with tast stage for inclined holes

- Depth gauge for chamfer depth

- Depth gauge for hole depth

TAKTOMAT measurement system analysis

The measurement method of TAKTOMAT includes the following documentation set:- Measurement system analysis method 1

- Test equipment accompanying card

- Measurement protocol

User benefits- Each measuring equipment is individually designed according to customer requirements, manufactured and tested in-house

- If required, we also offer external support

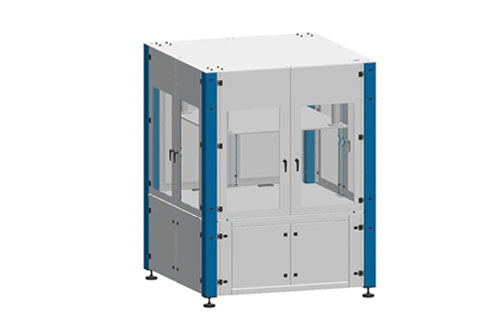

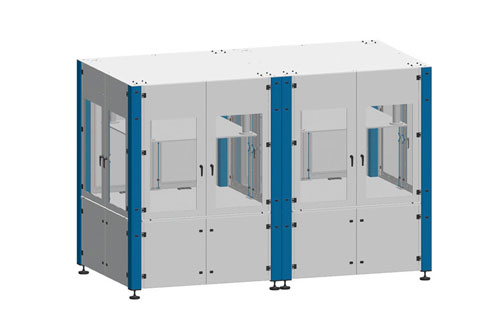

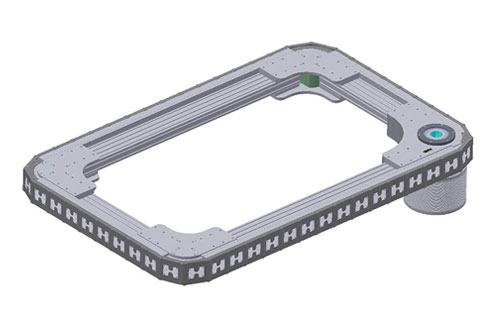

Taktocube

Taktocube by TAKTOMAT

- Discover the new Taktocube

– the modular, flexibly scalable machine cell for fast-cycling assembly systems.

Spacial Features- Dimensions scalable

- Installation within frame

- Modular system

- Short delivery times

Features and user benefits- Dimensions are available in steps of 250mm

- Installation of elektric and media inside the frame

- Modular systems to meet customer requirements

- Robust construction, suitable for robot integration

- Integrated safety doors

- Electrical cabinet integrated

- Self-assembly possible

- For Corporate Design all RAL colors are available

- Transporable

- Gab-free assembly

TAKTOCUBE

TAKTOCUBE

-

The modular, flexible scalable machine cell for fast-cycle assembling systems.

Features and user benefits:

- Dimensions in steps of 250 mm

- Modular design for all customer demands

- Robust design, suitable for robot integration

- Integrated standardised doors

- Electrical cabinet integrable

- Easy and fast assembly

- Custom specific RAL colors for corporate design

- Transportable

- Electricity and other media inside the frame

Accessories

Universal control type tic

- Common applications

The universal control is the ideal solution for all three-phase motor-driven gears:- Rotary indexers type RT and TT

- Rotary indexer

- TSR Globoidal index drives TG

- Parallel gears XT, TP and SP

- Linear transfer system type LFA

Features and user benefits- Cycle time optimization through accurately stopping the drive in Dwell

- Minimizing installation and hardware expenses

- Easy integration through fieldbus connection (ProfiNet, EtherCAT, Ethernet / IP) and integration aids (step by step instructions and video tutorial)

- Motor protection switch and mechanical or electronic contactors can be eliminated. Only line protection necessary.

- Fast, gentle gear brakes with emergency stop

- Safety functions STO, SS1, SLS for max. PL e (SIL 3) at STO

- Soft restart or after emergency stop

- Machine gently jog also possible for large tables

- Oscillation or rotation reversal without additional hardware possible

- Simple change of speed possible

- No brake wear, the brake only closes after emergency stop

- Monitoring the engine temperature

- Compact, space-saving design