- Offer Profile

-

Why BPM Manipulators?

Having applied design and technology in a wide variety of production areas since 1988, our company has concentrated its 32 + years of experience and credibility on pneumatic manipulators, which are the indispensable components of modern production.

Both today and tomorrow, Sertechnik shall continue to be at your service with its applications and its reliable services.

It shall render the Sertechnik BPM manipulators, bringing together the confidence of the experience and the dynamism of the youth, a brand of Germany that shall last for many years.

BPM Manipulator

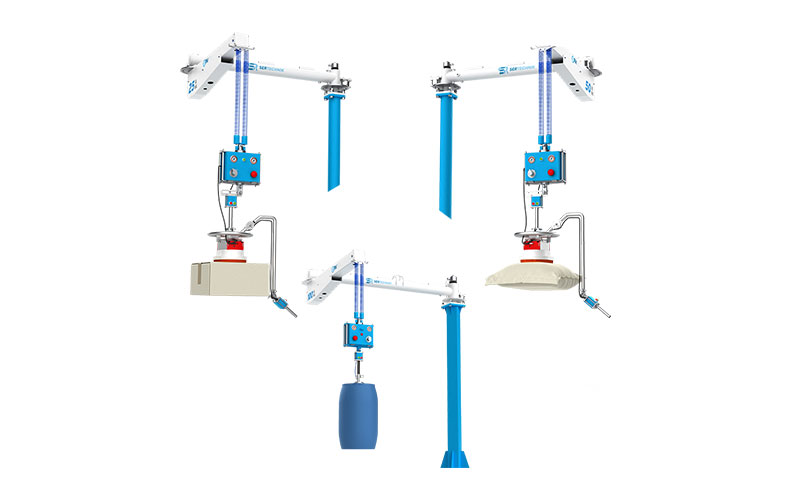

Plug & Play Pneumatic Manipulators – Ready to Work Solutions

Our Plug & Play Manipulators are designed for fast integration, ergonomic operation, and maximum productivity.

Each model comes fully equipped with its own gripping system, pneumatic balance unit, and column or rail mounting options, making it possible to install and start operating in just a few hours.

Unlike traditional manipulators, these systems are pre-engineered for specific applications such as bag handling, panel lifting, drum transportation, bobbin rotation, or magnetic metal handling — eliminating long engineering and installation processes.

Key Advantages

Our Plug & Play manipulators offer fast installation, allowing users to start operations within hours without complex setup. Their pneumatic balance technology ensures smooth and weightless handling, making operation extremely easy for the operator. Thanks to their flexible integration options, they can be mounted on columns, trolleys, overhead structures or rail systems to suit different production layouts. These pre-engineered solutions are also cost-effective, as they eliminate the need for additional design or engineering work. Above all, they are CE certified and equipped with advanced safety valves and braking systems, ensuring maximum reliability and operator safety.

Applications Across Industries

Plug & Play manipulators are used in a wide variety of sectors, including packaging and logistics, where they enable fast and safe handling of bags and boxes. In the automotive and white goods industries, they support assembly lines and reduce manual lifting risks. In metal and foundry applications, they provide reliable handling of heavy or hot components. They are also widely used in glass and panel production, where precise and damage-free handling is required, as well as in chemical and petrochemical plants, where safety and ATEX compliance are critical.

Plug and Play

Vacful

Vacful Pneumatic Manipulator

Safe and Precise Handling Solution with Vacuum Technology

Vacful is a pneumatic manipulator designed to safely, ergonomically, and efficiently transport bags, cartons, boxes, sacks, and other materials with delicate surfaces using vacuum technology. Thanks to its modular structure, which can be mounted on ceilings, columns, or rail systems, Vacful can be easily integrated into various production lines.

Vacful is widely used in industries such as food, chemicals, pharmaceuticals, logistics, packaging, and warehouse management. It minimizes physical effort, reduces operator fatigue, prevents workplace accidents, and improves the efficiency of production processes.

Vacful Models & Technical Specifications

Vacful Box

- Load capacity: Up to 25 kg

- Working radius: 3,000 mm

- Application: Specifically designed for handling small and lightweight boxes, cartons, and packages.

Vacful Bag

- Load capacity: Up to 50 kg

- Working radius: 2,500 mm

- Application: Suitable for handling medium-weight bags and sacks.

Vacful Multi

- Load capacity: Up to 100 kg

- Working radius: 3,000 mm

- Application: Features an easily interchangeable gripper system, enabling ergonomic handling of various drums, kettles, cans, and barrels using vacuum and special hook attachments.

Glassful & Panelful

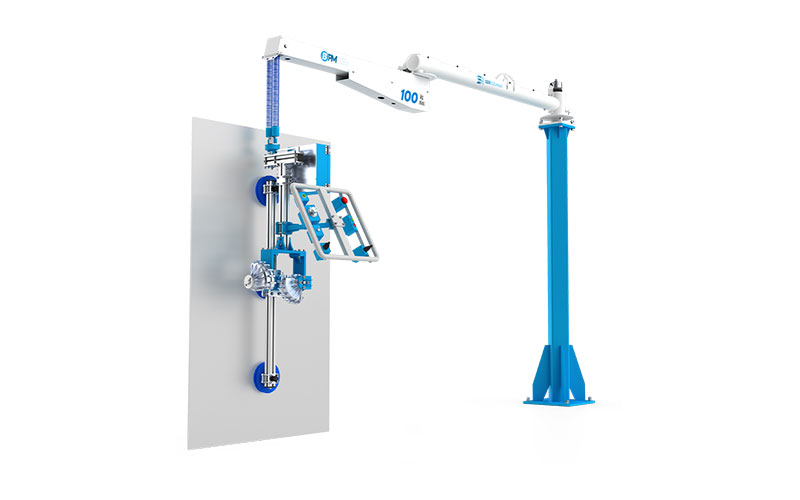

Glassful & Panelful Pneumatic Manipulator

Powerful, Precise, and Safe Solution for Handling Glass and Panels

Glassful & Panelful are pneumatic manipulators specifically designed for the safe, ergonomic, and efficient handling of glass, metal, wood, and composite panels. Using vacuum or specialized gripping systems, they ensure that large, delicate panel surfaces are transported without scratches or damage. Thanks to their modular structure, which can be mounted on ceilings, columns, or rail systems, these manipulators can be easily integrated into various production lines.

Glassful & Panelful are used in glass processing, the furniture industry, the automotive sector, white goods manufacturing, metalworking, and the construction industry. They simplify the handling of heavy and large panels, reduce operator fatigue, prevent workplace accidents, and increase the efficiency of production processes.

Technical Specifications

- Load Capacity: Up to 100 kg (maximum)

- Operating Air: Dry, filtered (40 µm) and oil-free air at a minimum pressure of 0.7/0.8 MPa

- Vacuum or Mechanical Gripping System: Specialized gripping system for glass and metal panels

- Maximum Radius: 3,000 mm

- Vertical Movement: 1,800 mm

- Air Consumption: 50 nl/min

- Mounting Options: Ceiling, column, or rail system

- Energy Efficiency: High performance with low energy consumption

- Control Type: Ergonomic control handle for precise operation

- Safety: CE-certified, durable design optimized for sensitive surface materials

Bobbinful

Bobbinful Pneumatic Manipulator

Powerful, Ergonomic, and Precise Solution for Handling Reels

Bobbinful is a pneumatic manipulator with a rigid arm structure, specifically designed for handling and positioning reels. Its 90° pneumatic rotation function allows easy transfer of reels from vertical to horizontal positions or vice versa. Thanks to its modular structure, which can be mounted on ceilings, columns, or rail systems, Bobbinful can be seamlessly integrated into various production areas.

Bobbinful is widely used in the paper, plastics, textile, packaging, metal, and cable industries. It enables the safe and effortless handling of heavy reels, reduces operator fatigue, and increases production process efficiency.

Bobbinful Models & Technical Specifications

- Bobbinful S

- Load Capacity: 0-100 kg

- Application: Ideal for the ergonomic and safe handling of small and lightweight reels with a 90° rotation function.

- Bobbinful M

- Load Capacity: 100-250 kg

- Application: Suitable for precise handling and positioning of medium-sized reels with a 90° rotation function.

- Bobbinful L

- Load Capacity: 100-450 kg

- Application: Designed for the safe handling of heavy and large reels with a 90° rotation function.

General Technical Specifications

- Operating Air: Dry, filtered (40 µm) and oil-free air at a minimum pressure of 0.7/0.8 MPa

- 90° Pneumatic Rotation: Allows easy transfer of reels from vertical to horizontal positions or vice versa

- Mounting Options: Ceiling, column, or rail system

- Energy Efficiency: High performance with low energy consumption

- Control Type: Ergonomic control handle for precise operation

- Safety: CE-certified, durable design optimized for heavy loads

- Bobbinful S

Drumful

Powerful, Ergonomic, and Safe Solution for Handling Drums

Drumful is a pneumatic manipulator specifically designed for the safe, fast, and ergonomic handling of drums. With its 180° pneumatic rotation function, it allows loads to be effortlessly tilted into vertical or horizontal positions, making filling, emptying, and transport processes more practical. Thanks to its modular structure, which can be mounted on ceilings, columns, or rail systems, Drumful can be seamlessly integrated into various production areas.

Drumful is widely used in the chemical, pharmaceutical, food, petrochemical, logistics, and manufacturing industries. It enables the effortless transport of heavy drums and containers, reduces workplace accidents, and improves the efficiency of production processes.

Drumful Models & Technical Specifications

- Drumful S

- Load Capacity: 0-100 kg

- Application: Ideal for the ergonomic and safe handling of small and medium-sized drums with a 180° rotation function.

- Drumful M

- Load Capacity: 100-250 kg

- Application: Suitable for precise handling and positioning of heavy drums with a 180° rotation function.

General Technical Specifications

- Load Capacity: Up to 250 kg (maximum)

- Operating Air: Dry, filtered (40 µm) and oil-free air at a minimum pressure of 0.7/0.8 MPa

- 180° Pneumatic Rotation: Allows tilting of drums by 180°

- Maximum Reach: 3000 mm

- Vertical Movement: 2000 mm

- Air Consumption: 140 nl/min

- Mounting Options: Ceiling, column, or rail system

- Energy Efficiency: High performance with low energy consumption

- Control Type: Ergonomic control handle for precise operation

- Safety: CE-certified, durable design optimized for heavy loads

- Drumful S

Magnetful

Powerful, Safe, and Ergonomic Handling Solution for Metallic Parts with Magnetic Surfaces

Magnetful is a pneumatic manipulator designed for the safe, fast, and ergonomic handling of metallic parts with magnetic surfaces such as sheets, plates, pipes, and profiles. By combining pneumatic and magnetic gripping technology, it securely lifts, transports, and positions metal loads. Thanks to its modular design, which can be mounted on ceilings, columns, or rail systems, Magnetful can be easily integrated into various production areas.

Magnetful is widely used in metalworking, the automotive industry, heavy industry, shipbuilding, foundries, mechanical engineering, and logistics. It eliminates the need for manual lifting of metal loads, reduces workplace accidents, minimizes operator fatigue, and speeds up production processes.

Magnetful Models & Technical Specifications

- Magnetful 50

- Load Capacity: 0-50 kg

- Application: Ideal for ergonomic and safe handling with a 90° rotation function.

- Magnetful 100

- Load Capacity: 0-100 kg

- Application: Used for precise handling and positioning with a 90° rotation function.

- Magnetful 50

Supporter

-

Supporter: Ergonomic, Safe, and Efficient Handling Solution

The Supporter Pneumatic Manipulator is designed ergonomically and efficiently to ensure that operators can transport loads with maximum safety and speed while using minimal effort. Its dual-rope balancing mechanism, pneumatically controlled lifting system, and precision motion rotating joint structure provide safe and accurate handling. By balancing the load's weight, it enables the operator to carry out the transportation task effortlessly. With various attachments and project solutions that can be integrated into the front of the manipulator, it is adaptable to a wide range of applications using vacuum, gripper, magnetic, and custom-designed handling systems.

General Features

- Capacity: Up to 60 kg load capacity

- Maximum Reach Distance: 3,000 mm

- Vertical Lifting Distance: 1,600 mm

- Operating Principle: Works with dry, filtered (40 μm), oil-free compressed air (min. 0.7/0.8 MPa)

- Air Consumption: Maximum 21 nl/min

Transporter

-

Transporter: Ergonomic, Safe, and Efficient Handling Solution

The Transporter Pneumatic Manipulator is ergonomically and efficiently designed to ensure operators can transport loads with maximum safety and speed while using minimal effort. Its dual-rope balancing mechanism, pneumatically controlled lifting system, and precision motion rotating joint structure provide safe and precise handling. By balancing the weight of the load, it allows operators to perform the task effortlessly. With various attachments and project solutions that can be integrated into the front of the manipulator, it is adaptable to a wide range of applications using vacuum, gripper, magnetic, and custom-designed handling systems.

General Features

- Capacity: Up to 120 kg load capacity

- Maximum Reach Distance: 4,500 mm

- Vertical Lifting Distance: 1,800 mm

- Operating Principle: Works with dry, filtered (40 μm), oil-free compressed air (min. 0.7/0.8 MPa)

- Air Consumption: Maximum 50 nl/min

Forceful

-

Forceful: A Powerful, Durable, Fast, Efficient, and Flexible Solution for Industrial Handling

The Forceful Pneumatic Manipulator not only offers ergonomic operation but also ensures the safe and precise handling of heavy loads, enhancing flexibility and operational efficiency in production processes. Its rigid arm structure and pneumatic balancing system enable precise load handling, allowing operators to work with greater control. The rigid arm structure ensures stable and secure gripping, even for off-center and offset loads. The pneumatic balancing system allows operators to move loads with minimal effort, maximizing efficiency in the workspace.

Versatile Gripping Solutions

The Forceful model can be equipped with vacuum, gripper, and magnetic end effectors to meet different operational needs:

- Vacuum Systems: Ideal for smooth and delicate surfaces.

- Gripper End Effectors: Used for applications requiring mechanical gripping.

- Magnetic Grippers: Preferred for handling metal sheets, cylindrical parts, and heavy metal components.

Additionally, the manipulator allows movement along various axes, including 90°, 180°, and 360°, providing flexibility in complex material handling operations. This movement capability is enabled by pneumatically controlled actuators and motors. The system automatically adjusts the balance based on the load’s center of gravity, ensuring safe and efficient handling. This flexibility allows it to adapt to customized projects across different industries.

General Features

- Capacity: Up to 450 kg load handling capacity

- Maximum Reach: 4,000 mm

- Vertical Lift Range: 2,450 mm

- Operating Principle: Uses dry, filtered (40 μm), and oil-free compressed air (min. 0.7/0.8 MPa)

- Air Consumption: Maximum 140 nl/min

Powerful

-

Powerful: A Strong, Durable, and Precise Handling Solution for Heavy Loads

The Powerful Pneumatic Manipulator not only provides ergonomic operation but also ensures the safe and precise handling of heavy loads, adding flexibility and operational efficiency to production processes. Its rigid arm structure enables the secure and stable gripping of offset, off-center, and asymmetrical loads. The pneumatic balancing system and precise motion control mechanisms allow operators to transport loads with minimal effort, ensuring maximum efficiency and ergonomics in the workplace.

The Powerful model can be equipped with vacuum, gripper, and magnetic holders to suit different industrial needs. These tools enhance precision during transportation, providing a safe and efficient solution for various load types.

With the ability to move parts at 90°, 180°, and 360° along multiple axes, it offers flexibility in complex handling operations. The rigid arm structure and powerful balancing mechanisms enable the precise movement of heavy loads. This movement capability is provided by pneumatically controlled actuators and motors. The operator can manually adjust the load balance within safety parameters, ensuring secure and efficient transportation.

General Features

- Capacity: Up to 750 kg load capacity

- Maximum Reach Distance: 4,500 mm

- Vertical Lifting Distance: 2,450 mm

- Operating Principle: Works with dry, filtered (40 μm), oil-free compressed air (min. 0.7/0.8 MPa)

- Air Consumption: Maximum 270 nl/min