- Offer Profile

-

Augers are our drive!

For over 40 years, we have been committed to sustainability and high-quality products, proudly offering industry-leading solutions. Our focus lies in wear protection, wastewater technology, hydropower systems, mechanical engineering, and specialised coatings. However, we are not only experts in these fields but also your reliable partners for refurbishments and spare parts.

Mechanical and plant engineering

-

Your products in the area of mechanical and plant engineering

For more than 20 years, machine and plant engineering has been part of the REHART story. Starting with the first extruder in 1999, this area has expanded significantly. In the meantime, it includes hydropower screws, hydraulic steel engineering and the field of wastewater technology.

Wastewater technology

Hydropower REHART-Power

Plant engineering recycling

Hydraulic steel structures

Coarse ceramics

Flow pump station - Wastewater technology

-

REHART offers you customised screw pump stations – either as new installations or through sustainable refurbishment of existing systems. Our screw pumps are based on the advanced Archimedean principle and are characterised by high efficiency, low operating costs and long service life. They are ideally suited for conveying wastewater, stormwater, process water or for use in flood protection.

Depending on the installation situation, we supply our screw pumps either integrated into existing concrete structures or as self-supporting compact units. A range of trough types is available – from compact U-shaped and tube trough systems to robust steel and concrete trough systems. All variants can be flexibly adapted to your hydraulic, structural and operational requirements.

Compact U-trough

- Compact U-shaped design with all technical options available (motor, splash guard, etc.)

Hybrid trough

- Fully customisable: screw and trough form a compact unit, while the head and foot bearings are mounted separately.

Compact pipe trough

- Closed pipe design with compact construction – ideal for retrofits, all options available.

Steel trough for backfilling

- Robust steel construction designed to be backfilled with concrete on-site – fully configurable.

Concrete trough

- Classic concrete trough – optionally lined with a special mineral coating or basalt tiles.

Individual consultation

- Every installation is unique. We’re happy to advise you on the optimal screw pump – tailored to your requirements and installation situation.

Hydropower REHART-Power

-

Venturing into new terrain with hydropower

We have been designing and building hydropower screws for over 15 years. Thirtyfive years of experience in the construction of high-quality metal screws for industry and water treatment plants combined with our technological expertise make us one of the leading manufacturers. Our list of references ranging across the four series of hydropower screws is now impressively long and is characterised by a high level of customer satisfaction.

Part of a successful group

A good name lies behind all these machines. REHART Power is a business division of REHART GmbH, a company with a solid ownership structure, which for the entire thirtyfive years of its existence has enjoyed continuous, stable growth and is part of the REHARTGroup.

The hydropower division

Our goal is to use our hydropower screws ecologically to meet the latest criteria and to achieve optimum energy management. In addition, the hydropower screws designed and produced by us in our own production facilities are cost effective and reliable. They are manufactured and put into operation according to international standards.

Achieving great things together

We therefore do not regard ourselves as supplier of an individual component, rather a team member working well in a project alongside other stakeholders (operators, consultancy firms, construction companies). Our business partners are also able to count on our considerable project experience gained in many different countries.

Hydropower screws

-

Hydropower plants based on a screw are considered small hydro. But don’t be fooled by the term “small”. This technology is used to supply 13 million households with electricity across Europe, which is sparing the environment a burden of 29 million tonnes of CO2.

More power with the right technology

Systems from the Rehart-Power series can operate even with a head of just 1 m and a capacity of 500 l/s and then continue to work economically when anywhere else, the switch would long have been in the “OFF” position. Many systems capitulate in lower water levels in hot summers and also fail to cope with flooding in the winter/spring. Cost-effectiveness then drops rapidly.

Cost effectiveness factors- Locational advantage (longitudinal gradients, site development, geology, natural hazards, etc.)

- Performance / economies of scale (i.e. production costs per kW reduce as production volume increases)

- Transverse gradient (head)

- Rate of utilisation (is incorporated proportionally in the energy generation costs)

- Capital costs parameter (interest rate plus payback period)

Fish Ascending Screw

-

FISH ASCENDING SCREW The FAS

(Fish Ascending Screw System REHART/Strasser) is the space-saving and cost-effective alternative to a conventional fishway. In a new installation, the FAS is placed on the side next to the hydropower screw. Of course, the FAS can be retrofitted to an existing hydropower screw, this is also possible next to a turbine without any problems. The slowly rotating FAS is safely detectable for fish and other bottom-oriented aquatic animals due to the generated attracting current. The size of the tube and the auger are individually designed for the occurring fish species. Even for weakly swimming fish and other river inhabitants such as crayfish or insect larvae, the ascent is possible without any problems, which is impressively proven by excellent monitoring results. The safe descent is, as with all plants from REHARTPOWER, by means of the hydrodynamic screw.

All advantages at a glance- Increases the economic efficiency of your plant

- Virtually maintenance-free even during floods

- Official confirmation of functionality through excellent monitoring results

- Optimal adaptation to the leading fish

- Injury-free ascent due to gapless construction

- Installation in all types of transverse structures & hydropower plant ensures officially required passability

Function

-

Even well into the 19th Century, water was the only reliable means of generating energy. There were 80,000 such sites located along German rivers and streams. As far back as 250 B.C., Archimedes discovered the principle of the screw named after him. It enabled water to be brought up to a higher level. At that time, it was a revolutionary invention for the irrigation and drainage of large fields. The transfer of energy used in Archimedes’ screw-trough pump was later reversed to create a system for generating electrical energy. Now it’s not the screw that moves the water, but the water that moves the screw. The principle is simple A hydropower screw is installed in a trough or tube set at an angle of 20 to 30 degrees. The water flows in from the top and the weight of the falling water acts on the helix of the screw, setting it in motion. The resulting screw rotation of 20 to 40 rpm is transformed by the gearbox to the generator speed. This is an easy and yet very effective way of generating environmentally friendly energy.

All advantages at a glance

- Low-maintenance technology

- Also suitable for low heads

- Favourable acquisition costs

- Long service life, then 100% recyclable

- Versatile

- The ecological value of existing weirs improves if they are converted to incorporate a hydropower screw

- Can be used as a water lifting screw for drainage and flood protection

Sustainability

-

Anyone in the fortunate position of being able to utilise a river for their own use, can produce cost-effectively or significantly reduce their living and running costs. A hydropower plant is built to last decades, is robust and durable, and the operator is therefore aware of its costs long in advance. Security of supply is also very reassuring.

Hydropower operators are aware of their responsibilities

Anyone who invests in a hydropower plant usually does so with a vision. Not only in matters of the economy, but also to the same extent in matters of environmental sustainability. Small hydro makes an important contribution to the European-wide decentralisation of energy production without fossil fuels.

As a manufacturer we also have to take on our share of the responsibility

As a solid, a medium-sized company we deliver quality. Through our own work and the work of our partners and their components. All installed parts are, without exception, of robust production and meet the highest German industry standard. Our customers can therefore rely on a long-lasting system.

Plant engineering recycling

-

PLANT ENGINEERING RECYCLING

We offer various funnels and filling chutes in segmental construction. These are made of wear-resistant, armoured sheet metal (RVP) and therefore have a much longer lifespan compared to conventional filling chutes. In this area, we have already manufactured funnels with a length of 10.00 metres, a width of 2.30 metres and a height of 4.00 metres.

Hydraulic steel structures

-

With hydraulic steel structures by REHARTPOWER you are provided with solutions optimally adapted to your requirements.

We manufacture in all steel types and stainless steel in accordance with the hydraulic steel structure standard DIN 19704 1-3. The drive is either mechanic, electric or hydraulic – according to customer requirements. If requested, we will provide correct electrical wiring and program the system control.

Equipment for flood protection- Control valves

- Spatial coarse and fine screens

- Retention gates

- Inlet valve

- Shut-off valves

- Flushing gates, flushing valves

- Sluice valves with or without retention gate

- All kinds of retention gates

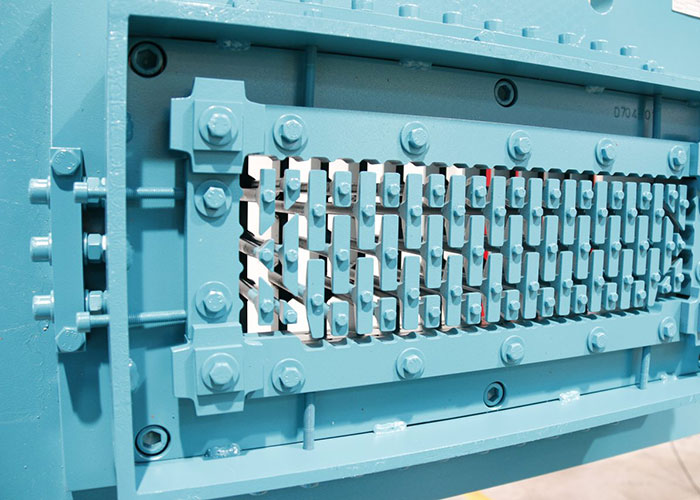

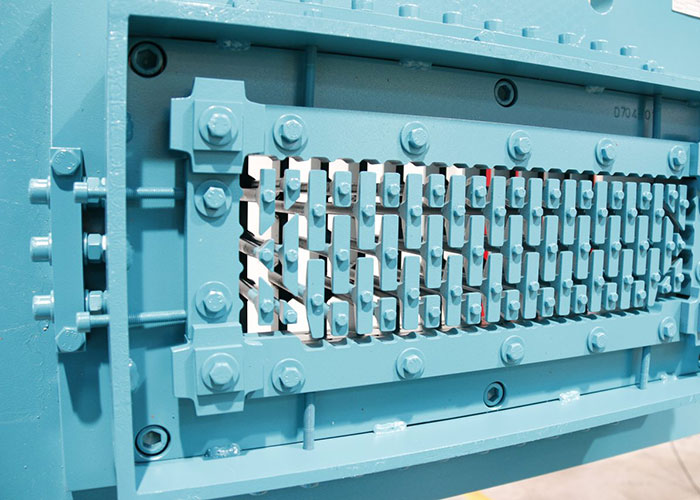

- Grate cleaning systems, telescope and excavator type

- Cross screen cleaning systems

- Grate with coarse and fine screen separation – horizontal and vertical type

Coarse ceramics

-

Petersen Service stands for innovation when it comes to material preparation, moulding and optimization for the coarse and fine ceramics industry. In association with Rehart Group the company has an experienced team of developers, a design department and its own best equipped metal working with a high production depth. Besides the new design of machinery and systems customer-specific ideas and requirements are implemented. All wear parts are delivered from one source – not only for our own products, but also for third-party products spare parts can be produced with dimensional accuracy. The optimization comprises energy savings as well as quality optimization. Petersen Service stands for intelligent solutions – from consulting, needs-oriented tender preparation, to commissioning and support throughout the entire machine time. The company has been the competent partner worldwide with industry knowledge, manufacturer know-how for a comprehensive delivery program for decades.

Application- Manufacturer-independent optimization of moulding process

- Special mechanical engineering

- Spare parts and wear protection even for third-party products

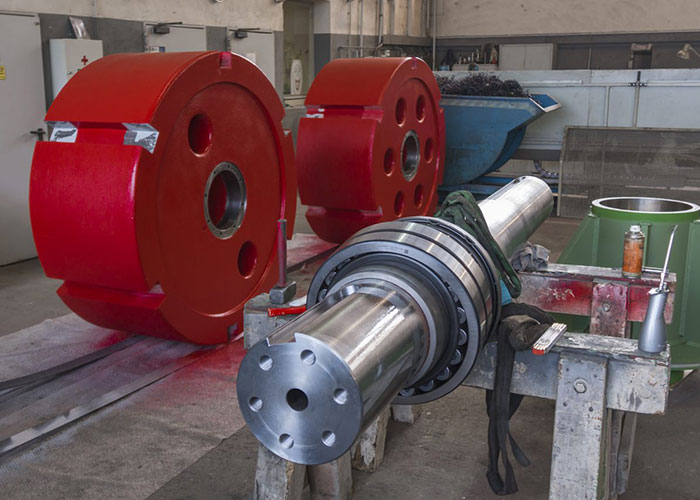

Roll lathe

- When being launched for the first time the roll lathe (WDM) had been a milestone. Backlash-free guidance combined with backlash-free belt drive stand for vibration-free and low-vibration turning of roller shells on rolling mills. In addition vibration-reducing materials are used, even by its dead weight, thus vibrations are absorbed especially well. Optionally the roll lathe can be equipped with a lifting device. In rolling operation the vibration-free bearing directly in the roll lathe is permitted.

Used maschines

Roller mill

- Ceramic bodies are finely grinded up to a roller gap of 0.6 mm with the roller mill (PWF-H). The robustly welded rigid structure stands for the compliance with set gap widths. The clearance can be easily adapted with the mono rocker routed in parallel. Overload protection is safely realized with the hydraulic cylinder and hydraulic accumulator. Depending on the type of hard material to be grinded either synchronized or differential operation is possible. The hydraulic scraper position enables low vibration scraping of the rollers. Particularly effective grinding is achieved in combination with the roll lathe (WDM). Emphasis should be given here to the short downtimes for maintenance.

Wet pan mill

- The pan mill (DKW) is one of the most effective preparation machines for plastic ceramic bodies. Combined with the high weight of edge rolls, different relative movements under the edge rolls and due to the slow operating mode the body is effectively crushed, sheared and mixed. Moreover water can be added and the body can be plasticized further. Energy expenditure is relatively low and even the specific wear parts costs Euro/t are very low.

Fine roller mill

- In grinding of ceramic bodies the finishing roll mill (FW) covers a large area. It is used as pre-rolling level and suitable without limitations for grinding with a roller gap of up to 0.8 mm. The rigid structure with positive locking bridges enable direct absorption of gap forces. The roller ring shaft is mounted in roller bearings of large size and held in the frame with sliding bearing casings. Overload protection is realized via a disc spring pack or a hydraulic overload protection. It protects the structure in case of unintentional insertion of foreign metal objects. Low vibration operation is ensured by a hydraulic bias.

Roller crusher

- Besides the different raw materials the pre-crushing of clay has another variable, the season and thus meteorogical differences. With these different ceramic bodies many roller crushers reach their limits – other than the roller crusher by Petersen Service. The sophisticated structure has an infinitely variable roller distance and power trains with integrated overload protection that can be controlled continuously. By using crusher plates of different width, number and form of notches a variety of raw materials can be crushed up to a Moh’s hardness of 6. The variable scraper system even enables crushing of viscous and highly plastic clay that have taken up too much moisture through rain.

Vacuum extruder

-

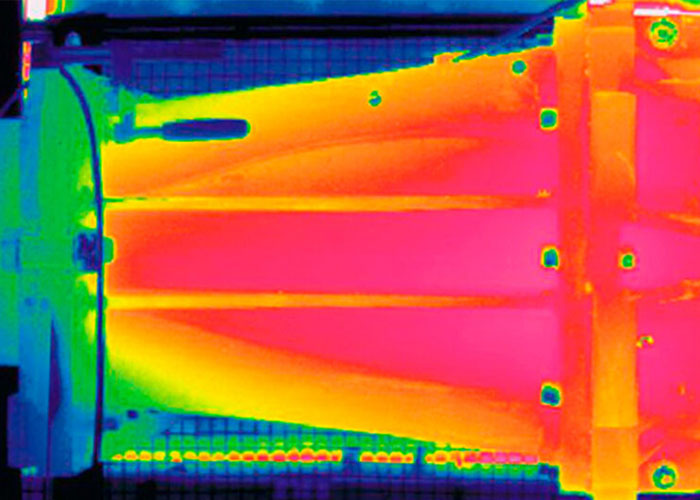

The vacuum extruder (VAP) is the core element for shaping plastic ceramic bodies. It efficiently shapes the required quality of plastic-processed ceramic bodies. With our brand PetersenService we offer extruders with augers that have been specifically designed for the application and allow for low-pulsation and high energy-efficiency production of extrusion profiles.

These extruders are convincing with their high mechanic reliability, as well as their durable and robust gear technology. A special quality feature is the vacuum maintenance that is achieved by wear parts which are internally supported and quickly replaceable. For simple servicing the machine provides direct and quick access to all sectors via many and well-spaced service doors and mounting holes. The correct level of ceramic bodies can be precisely controlled on the auger with the optional level monitoring LEVELTRONIC.

Extrusion heads

-

Extrusion heads for the comprehensive delivery and service program are designed by state-of-the-art CAD systems with our own program PK-Designer. The result is an optimally designed extrusion head even for the most complex extrusion tasks. Nearly every profile can be extruded stress-free. The manufacture of the contour is flexible, precise and designed that no unwanted welding seams are found in the compression areas. Continuous radius transitions and convex contours are a matter of course. The parts have a hydraulic quick-action extrusion die clamping for prompt format change and are delivered with various coating and hard-facing.

Within the REHARTGroup extrusion heads by our brand PetersenService can be permanently coated on the inside with plastic. Thus streamlined free form contours can be realized, PetersenService can produce profiles that were otherwise considered unextrudable. The favourable sliding behaviour from clay to plastic reduces the energy demand by up to 30 %, depending on the application. If necessary, the plastic coating or the inlay can be replaced – simply and cost-efficiently.

Extrusion dies

- Morte, the Spanish manufacturer of extrusion dies, as well as REHARTGroup and affiliated companies, are cooperation partners in the German-speaking markets (D/A/CH) plus Romania and Poland. Morte has a leading position when it comes to the production of extrusion dies, the RehartGroup designs and optimizes worldwide plants for structural ceramics from preparation to moulding, but also for moulding in the fine ceramics sector. Thus both cooperation partners are excellently positioned to further optimize the sensitive interaction between extruder and extrusion die and comply with existing, pending quality requirements of the coarse and fine ceramics industry.

Level measurement

-

With its level meter Leveltronic, our brand PetersenService offers the solution to precisely control overfilling or underfilling in the vacuum chamber. To date the level in the vacuum chamber could not be accurately controlled. Thus it was impossible to provide the extruder auger with the constant rates of filling. Normally the limit switches used are only part of the solution, they prevent a maximum overfilling of the vacuum chamber by switching-off the upstream pre-press or double shaft mixer. However, a control cannot be established since only the upper limit is recorded. An underfilling of the extruder auger is not recorded.

The really reliable solution is Leveltronic the level meter by PetersenService that can be applied under vacuum atmosphere. This technology enables a measurement of the filling level in the vacuum chamber accurate to centimeters and sends an analog 4–20 mA signal. With this signal, incorporated into a control circuit as a regulating variable, the flow rate of the pre-press or double shaft mixer can be controlled and adapted to the discharge behavior of the extruder auger. This way a constant level in the vacuum chamber is achieved and the operational behavior of the extruder balanced, which is noticeable by constant extrusion velocity and even pressure ratios.

Screen mixer

- The screen mixer combines several tasks. In addition to an ample mixing process, mixing in of different components and working in water and vapour, the machine is able to separate hard and soft impurities up to a mesh aperture of 4 mm. Additional shearing of the body at the screen is enabled by the patented RSE effect. This leads to an improved solubilizing of the body and lower energy expenditure of the machine. In comparison to conventional machines a higher output or lower energy demand with the default discharge volume is possible.

Clay purifier

-

The clay purifier (ZAR) is the ultimate machine for purifying plastic and plasticized bodies. The baskets have slotting holes of 2.0 mm. Thus inclusions and impurities such as stones, silica, pyrite, pebbles, wood, roots, metal and plastic parts can be separated efficiently and removed from the machine without interruption of the cleaning process.

While shelling the body from the auger a shearing effect is created having an additional positive effect on the solubilizing of the mineral body. Compared to other separation methods this is the reason for the low specific energy expenditure.

Circular screen feeder

-

With its circular screen feeder (SRB) Petersen Service offers an innovative drive concept. The machine does not need a large gear and is equipped with wear parts in the screen basket and scraper arm that are completely replaceable. Standard gear drive motors that are also used for wind power plants are synchronized via a gearing bearing. They ensure the long-term operation of the system.

The wear parts of the circular screen feeder that are completely replaceable, in particular the screens on the swivel-out screen carriers, can be replaced within the shortest time. The scraper arm which is coated with wear parts is unique. There is no need for an elaborate disassembly of the arm for subsequent hardfacing. Due to the additional installation of stone collecting bags the machine can also be used as a crushing mixer with screen.

Double shaft mixer

- The open double shaft mixer (DWMO) mixes and kneads different components in the open mixing trough. The mixing knives are freely adjustable. Due to the strong mixing-kneading effect, water and vapour are very well incorporated. If the focus is on mixing, the double shaft mixer DWM is used. Ceramic bodies are kneaded in the auger front section very intensely. When it comes to vacuum moulding, the machine with a vacuum chamber becomes a vacuum double shaft mixer. With this solution the ceramic body is chopped up very finely and well sealed toward the mixing zone. This solution guarantees the safe and strong moulding vacuum Petersen Service is known for.

Wear protection and spare parts

Wastewater technology

- Spare parts in wastewater technology are subject to heavy mechanical and chemical wear. With its many years of experience in this field, Rehart has various solutions for this problem. Benefit from this! We offer you all wear and spare parts for wastewater technology components, whether our brands or those of other manufacturers. Guide plates, pumps, wheels, bearings and much more are part of our delivery programme. Our bearings in particular, which go far beyond the standard, offer you added value. Here, too, we do not only rely on our concept, but will be pleased to submit your individual solution. If you own a GNA lime plant, we can also help you with the appropriate spare parts such as EPS conveying and dosing equipment, wear trays and filter cloths.

Hydropower

- We offer you spare parts made by REHART to ensure that your hydroelectric screw conveyor produces green electricity on a permanent basis. With our high-quality spare parts, you can ensure that your system does not come to a standstill. Thanks to many years of development with a focus on the operational reliability and durability of our systems and spare parts, we are the right manufacturer at your side. It should be emphasised that we manufacture 100% of our spare parts in Germany and produce almost everything ourselves. If possible, we are happy to reuse old parts or refurbish them for renewed use. With us, you get sustainable quality for a sustainable future.

Ceramics

- Plants in the coarse and fine ceramics industry are exposed to enormous abrasive and corrosive forces. Here, the spare parts perform heavy-duty work in the most diverse areas of application, such as in the brick industry. Suitable wear protection in the right places is a major issue here. We select the optimum wear protection material for your needs. To do this, we determine the most economical and promising coating process. Oxyacetylene welding, powder flame spraying and the build-up welding of plasma powder are only three of a multitude of possibilities. The service life of these wear-optimised spare parts is noticeably extended, the downtimes of your machines are shortened and costs are reduced. Rehart has decades of experience in this field and is therefore your competent and right partner when it comes to optimally protected spare parts in the ceramic industry. It does not matter which brand or which manufacturer of the machines that process the ceramic bodies is involved and which spare part you need. Pressing and conveying screws, wear plates, conical hubs, cutter blades and many other spare parts are part of our daily business. We will be happy to advise you on further possibilities of how wear protection can be implemented for you. We would be happy to talk to you. We look forward to meeting you.

RVP wear protection

-

Superior wear protection for maximum durability

The REHART Composite Armor Plate (RVP) is a high-quality two-component assembly, consisting of a base plate and a highly wear-resistant alloy. This combination ensures outstanding protection against wear. Our plates are renowned for their superior quality and exceptional durability. Thanks to their robust design and high efficiency, they are increasingly popular and are the ideal choice for demanding applications where durability and reliability are paramount.

Separators

-

Get the best out of your separator!

Hardly any other part contributes as much to the effectiveness of your system as the separator. The accuracy of fit and the service life of the separator are crucial for long-term use. This is why they are regenerated at regular intervals. As one of the market leaders in regeneration, REHART ensures the long-term yield of your system.

Biogas / Recycling

-

SPARE PARTS BIOGAS / RECYCLING

Your complete wear protection programme and spare parts for the effective operation of biogas and fermentation plants! With customised solutions for screw conveyors, screen baskets and rackets, we adapt flexibly to your individual requirements. Thanks to our more than 40 years of experience and innovative materials, we guarantee optimum protection against wear – even under the highest loads. All parts are both newly manufactured and comprehensively refurbished. The pump housings are refurbished and the rotary lobe wear parts are newly manufactured from hard rubber. We can also provide you with the right screen baskets for your separator. Efficient processing and our personalised on-site service ensure that your request is dealt with reliably. Maximise the service life of your systems and contact us for your individual solution!

Agricultural technology

- Agricultural equipment and machinery are often exposed to very high loads. The use of wear protection in the right place noticeably increases the service life and thus saves money. Skids, ejector plates and drum bases are just a few examples of the use of our products in agricultural technology. You can request spare parts from us for all manufacturers and machine types. Also for the use in forestry and the municipal sector, for example in wood chippers and milling machines, the production of highly stressed spare parts made of our highly wear-resistant RVP (Rehart composite armor plates) brings considerable advantages. If we have aroused your interest, we will be pleased to inform you about the suitable wear protection for your needs.

Coating

nanoseal ceramic composite materials

-

Many companies have already realised that by investing in the surface protection of machinery and equipment, maintenance costs are significantly reduced. nanoseal is a wear protection compound consisting of a 2-component matrix phase and a reinforcing phase made of different fillers. The coating materials are developed according to the required properties and produced in Germany. nanoseal makes use of the characteristics of different materials. Perfectly adapted to the requirements, the coating systems have extreme resilience and adhesive strength.

All advantages at a glance- Highest wear protection properties

- Adaptation to the thermal expansion of different materials

- Highest corrosion protection

- Excellent mechanical properties (pressure, tensile and impact resistant)

- Shrinkage- and tension-free curing

- Slip resistance

- Non-stick and sliding properties

- Electrical conductivity and electrical insulation

- Food approval

- Highest chemical resistance

- Heat conductivity

- High temperature resistance

- Extreme resilience

- Different application methods: trowelled, painted, sprayed

Polyurethane coating

-

A hard coating is not always the best choice. Impact and conveying of solids cause considerable wear of conveying lines and plant components. A highly wear-resistant polyurethane coating offers very high protection against particle erosion here, especially when the impact is vertical and the conveying speed is high. The high elasticity reduces the kinetic energy of the particles. In addition, a sophisticated composition of the protective coatings also prevents material erosion caused by chemical attack.

Application of polyurethane- Pumps

- Centrifuges

- Screw pumps

- Funnels

- Chutes

- Tipping troughs

Refurbishment

Trough refurbishment

-

We construct troughs – customised to your needs

Are you looking for reliable, robust troughs for use in wastewater technology? We supply customised steel troughs and concrete troughs that are precisely tailored to your requirements – whether in the municipal sector or in industrial plants. Our troughs are designed for high loads and can be equipped with modern wear protection on request – for a significantly longer service life and minimised maintenance.

These are your options:- Partially or completely hard-faced with REHART-Verbundpanzerplatte (RVP)

- Nanoseal coating

- Stainless steel version

- Wear-resistant special steel

Auger refurbishment

-

With our sustainable screw conveyor refurbishment, you can significantly extend the service life of your screw conveyor – economically and in an environmentally friendly way. Compared to a completely new screw conveyor, our refurbishment solution significantly reduces CO₂ emissions and thus actively contributes to climate protection. Customised screw conveyors for every application Our screw conveyors are ideal for transporting powdery, semi-solid or liquid materials. We manufacture screws in a wide variety of designs – precisely customised to your requirements and conveying quantities.

We produce screws depending on the area of application:- Made of stainless steel – ideal for the food industry and technical ceramics

- Made of wear-resistant special steel – with armoured outer edges on request

- With spirals made of REHART composite armour plates for maximum load-bearing capacity

- Made of steel for hydropower plants, in sizes up to 22 metres in length and 4 metres in diameter

Pump refurbishment

-

Erosion, abrasion and cavitation damage often occurs in centrifugal, screw and vacuum pumps. To avoid expensive breakdowns and consequential damage, we offer professional pump refurbishment with the high-performance ceramic composite material nanoseal. The nanoseal coating permanently protects the pump material from further attack – and significantly extends the service life of the refurbished pump.

We also refurbish the following parts to become highly wear resistant:- Pressure cap

- Wear plate

- Impeller

- Drive shaft

- Bearing seat

Bearing refurbishment

-

Save the cost of a new bearing thanks to our professional bearing refurbishment! In most cases, a bearing refurbishment of the lifting auger is possible without any problems – a complete replacement of the bearing bracket, drive shaft and bearing is rarely necessary. In most cases, it is sufficient to replace the bronze bushes or roller bearings. Even worn shafts can be repaired by welding and reworking. We refurbish both the upper and lower auger bearing – regardless of the manufacturer and with a precise fit. With our many years of experience, we provide an economical and sustainable solution that minimises downtimes and significantly extends the service life of your system.

Your advantages at a glance- Customised for all manufacturers

- Cost effective

- Sustainable

- Extended service life

Service

Consulting

- We are happy to offer you the opportunity to receive advice tailored to your needs from our sales staff. Whether in person at REHART, at your location or in a video meeting, our great strength is that we have many experienced employees and can therefore offer you the perfect advice for your application. From wear protection to mechanical engineering to hydropower plants. REHART does not offer the standard off-the-shelf product, but the best product for your needs.

Installation

- We not only build your machines and offer you the appropriate spare parts, but we are also happy to support you with assembly, installation and commissioning. We are particularly proud of the fact that we cover almost all operations with our own employees. Our field of application ranges from the installation of spare parts in ceramics to waste water technology and hydroelectric power plants. We look forward to the next assignment with you.

Support contracts

- Operational safety, preventive maintenance and parts availability are just a few of today’s buzzwords. Through our support contracts, we can help you keep an eye on these issues so that your plant/machine does not break down, you provide for replacements in good time and generate planned instead of unplanned downtimes. Our experts will be happy to take a look at your plant and draw up a report on spare parts, necessary repairs and problems that may occur. You will also receive one or two tips free of charge.

Optimization

- The requirements for components and production processes in brick production are constantly increasing. What used to be compensated for with mortar is no longer acceptable today due to stricter quality standards. The market demands maximum precision – and we support you in achieving this reliably. Even minor adjustments can have a major impact. However, adjustments to the screw itself often also reveal great potential, which we are happy to realise for you by optimally adapting the screw geometry to your machine and requirements. Our independent production consulting helps companies to optimise their production processes. We analyse measurement data and key production figures directly on site – neutrally, objectively and independently of manufacturers. This provides you with a sound basis for decision-making to ensure quality, minimise rejects and increase the efficiency of your systems.