- Offer Profile

-

We at agriKomp have been developing groundbreaking biogas systems since the middle of the 1990's. Up to now we have implemented with our customers more than 800 biogas plants with a total installed capacity of around 250 MWel. It was, and is still today our goal to make it possible for agricultural businesses to enter the energy market, quickly and with minimum outlay

SOPHISTICATED BIOGAS PLANTS

MANY VARIANTS TO MEET YOUR REQUIREMENTS!

- The result of our more than 20 years of experience and development in biogas plant and component engineering: a large and versatile portfolio of components and plants. Whether slurry, manure, agricultural residues, grass or silage – powerful technology and a wide range of specially developed components and plants give you a free hand.

BENEFIT FROM UNTAPPED POTENTIAL

- Biogas production from manure and slurry, organic residues and renewable raw materials has become increasingly popular worldwide in recent years. Especially the use of manure, slurry and organic residues makes the operation of a biogas plant profitable for you. If, for example, livestock housing construction measures become necessary, it is advisable to include biogas in the concept. Often, a significantly more economical and sustainable solution can be found with little additional effort.

CUSTOMISED FOR YOUR BUSINESS

- Our consultants are practitioners and know their business. Together with you, they will determine the optimal system configuration for your farm. The various operational conditions and parameters such as crop area, input materials, operational planning and the time you want to invest in the operation of the plant are taken into account in the concept for your biogas plant.

BIOGAS PLANTS

- The result of our more than 20 years of experience and development in biogas plant and component construction: a large and varied component and plant portfolio.

AGRISELECT®

-

SLURRY | MANURE | SMALL | FARM BIOGAS PLANT - OUR MULTITALENT

AGRISELECT®– SELECTED QUALITY

agriSelect® – this is how we have christened our biogas plant with system. “Select” stands for carefully selected components paired with a wide range of choices. Brand components intelligently arranged and flexibly combinable. If you wish, also with your own contribution.

The compact biogas plant can be built in just a few weeks. Pre-assembled modules, turnkey technology and CHP container, unique Formprotect® tank construction system and the deployment of an experienced on-site supervisor ensure that the installation of the plant progresses quickly.

SELECT - SOLID PLATFORM AND A WIDE RANGE OF CHOICES

Standardised system configurations equipped with proven agriKomp brand technology are the foundation. You can configure your agriSelect® individually according to your needs with our proven agriKomp brand components and a wide range of additional packages and options:

Digester construction in Formprotect® design or conventional, Biolene® single-layer membrane or double membrane roof, CHP containers with various agriKomp CHP units of the BGA series, technical and intermediate space containers as well as submersible or paddle agitator. The visually appealing containers are of concrete construction and prefabricated and are therefore quickly ready for operation.

FREE CHOICE OF FEEDSTOCK

The agriSelect® can be operated with 100 % liquid manure. By upgrading the agriSelect with Vielfrass® solid feeder and Paddlegigant® paddle agitator, it can also be operated with solids (e.g. energy crops, agricultural residues, etc.) and even with 100 % manure.

- 3 basic models cover a plant capacity of 55 - 265 kWel

- Equipped with proven agriKomp components

- Wide range of input materials possible

- Individually configurable

- Modular design

- Many additional packages and options

- High degree of standardisation

- Short construction time

- Pre-fabricated containers

- Ready-assembled modules

- Appealing design

INDI-PLANT

-

INDIVIDUAL, LIKE YOU!

WHAT ACTUALLY IS AN INDI-PLANT?

Our comprehensive component portfolio enables a wide range of different system configurations. The exclusive use of our proven components ensures model consistency. This gives you a high degree of security and the necessary flexibility. This is how individual biogas plants are created, tailored to the respective operational requirements.

Plant capacities from 55 kWel to 2.5 MWel and more are possible – whether with a CHP or an upgrading to biomethane.

We develop and manufacture an individual and highly economical solution for you that meets your vision and needs; the result is what we call an „Indi“ plant“.

- Individual Plant design

- Standardised technology

- Highest safety standards

- Powerful and proven agriKomp components

- modular structur

- Many additional packages and options

- Perfecty coordinated interfaces

- Broad CHP portfolio (agriKomp BGA series) and biogas upgrading (agri- Pure®) for efficient biogas utilisation

- Competent service and best spare parts supply

- Continuous updates

GÜLLEWERK

-

FOR SLURRY AND SOLIDS: A COMPACT AND MOBILE POWER PLANT WITH EVERYTHING ALREADY INSIDE.

THE MOBILE BIOGAS PLANT

The special feature: its mobility makes it highly attractive for alternative financing solutions, such as leasing or investor models. The ready-to-use slurry plant, including the digester, is delivered by truck in a standard container and connected to the existing slurry system. We have made the generation of electricity from biogas even easier for you. Our slurry plant is a compact powerhouse with everything already inside. It allows you to quickly and efficiently utilize the monetary value of liquid manure and dung – without any major construction work. The strong remuneration for high manure percentages since the EEG 2014 make the generation of energy from biogas extremely profitable for livestock farms. By using the CHP waste heat, you additionally save heating costs.

EVERYTHING VERY SIMPLE

For the utilization of solids and NawaRo, it is equipped with the “Vielfraß Top” solids feed system. Residual gas potential can be efficiently utilized by means of a covered digestate storage system. A powerful, energy-saving paddle agitator ensures good mixing that is gentle on bacteria. With a sophisticated concept for heat recovery, around 40 – 50 % of the CHP waste heat is available for heating buildings. As with all biogas plants from agriKomp, only our cogeneration units are used to generate electricity. They stand for high availability and absolute reliability!

AGRIFER® PLUS - THE NEXT GENERATION OF DIGESTATE TREATMENT

- Our treatment process significantly improves profitability, is active groundwater protection and sustainable resource management.

AGRIFER® PLUS

-

FROM DIGESTATE TO VALUABLE RESOURCES

OUR INNOVATIVE PROCESS FOR DIGESTATE TREATMENT

The storage and use of slurry and digestate is leading to an increasing financial burden for biogas plant operators. Most of the processes currently available on the market work on volume reduction and concentration of nutrients. So far, however, no process has been able to remove excess nitrogen from agriculture.

EVAPORATION, RECOVERY AND DISCHARGE

The innovative agriKomp complete treatment process

offers an economical solution to the nitrate problem with simultaneous volume reduction. In this process, nitrogen- containing digestate is treated by an evaporation process in combination with reverse osmosis.SUSTAINABLE RESOURCE MANAGEMENT

Compared to existing processes, valuable nutrients are obtained in the form of marketable products. The concept is also characterised by high environmental compatibility, as the addition of chemical additives have been reduced by 90 %. Our treatment process significantly improves profitability, protects groundwater and offers sustainable resource management.

- The digestate volume is significantly reduced

- Upgrading of the digestate to concentrated, high-quality liquid fertiliser and ammonia water (basic chemical for industry)

- The plant operator changes from a producer of problematic substances to a producer of important basic chemicals

- Minimisation of emissions (ammonia)

- Increasing the economic profitability of your plant

- agriFer® Plus is the only process to date that removes nitrogen from agriculture

- Lower treatment costs

- Stable market demand for process products

AGRIPURE® - BIOGAS BECOMES BIOMETHANE

- Our agriPure® upgrades biogas to biomethane. This plant extension has already been successfully installed and operated for years in countries with biogas injection into our intelligent plant systems.

AGRIPURE® - FROM BIOGAS TO BIOMETHANE

-

A PERFECT SYSTEM

The innovative and sustainable agriPure® biogas upgrading plant was originally developed by agriKomp in 2015.

The biogas upgrading process converts biogas produced by anaerobic digestion into biomethane using special membranes. There are several pre-treatment steps to clean and condition the biogas. The biogas is then compressed before entering the membranes which are used to separate the methane (CH4) and carbon dioxide (CO2) gases at a molecular level. After this upgrading process, the product biomethane can be sent to the gas grid or further compressed or liquefied for use as transport fuel.

In general, biomethane can be used after biogas upgrading wherever natural gas is also used. Both variants are chemically equivalent and differ only in their either fossil or biogenic origin. This opens up a wide range of possible applications.

AGRIPURE®: COMPLETE CUTTING EDGE SOLUTION

With agriPure®, we offer a complete solution for anaerobic digestion and biogas upgrading: from biogas plants to biogas pre-treatment to biogas upgrading systems. agriKomp is the right choice for your project!

The result is a first-class, coordinated installation of different components. With a wide-ranging service network, experienced service technicans and good spare parts availability, your agriPure® plant will receive a well-coordinated and reliable service support, providing the best opportunity for a long and trouble-free plant lifespan.

FLEXIBILITY

With the agriPure® upgrading process, we can realise a broad spectrum from small to large biogas upgrading plants. Due to the high flexibility of the process, the membrane technology can be easily adapted to changing volume flows and gas compositions. The standard output range of our agriPure® extends from 150 Nm3/h – 2,000 Nm3/h raw gas.

COMPONENTS

-

BUILT TO LAST

The holistic and visionary way of thinking of the company‘s founders Robert Bugar and Michael Engelhardt still decisively shape the agriKomp components for biogas plants today. The name agriKomp stands not only for efficient technologies, but also for innovation and practicality.

Pioneering systems such as the Paddelgigant® agitator or the Biolene® gas storage, which were introduced to the market in 2002, are just a few examples of brilliant engineering achievements from agriKomp research and development.

The agriKomp group develops and manufactures all essential components of a biogas plant in its own network. This guarantees absolute reliability and consistently excellent quality. Key components such as the Quetschprofi® separator, the Paddelgigant® agitator and the robust Vielfraß® feeding technology have set international standards in terms of stability, reliability and energy efficiency.

AGITATOR

-

Agitators play a central role in biogas plants. They ensure equal mixing and temperature spreading of the digester load, an even supply of raw materials to the bacteria and that the biogas is stirred out of the substrate.

PROVEN AGITATOR FOR DIGESTERS

The Paddelgigant® from agriKomp, which was already introduced to the market in 2002, is one of the most widely used agitators in biogas plants and has proven its high efficiency in numerous applications. The Paddelgigant ® is available for a wide variety of tanks, whether in different installation heights or also in different lengths of the agitator shaft.FREE SUBSTRATE SELECTION

The Paddelgigant® is a slow-running large agitator that mixes the substrate according to the tank size and the medium in the digester. The bacteria continuously receive new feed and the anaerobic degradation of biomass can proceed undisturbed. The Paddelgigant® was specially designed for structurally substrates and high dry matter contents. This opens up a wider range of feedstock for biogas plant operators and avoids the need for substrate preparation (shredding, chopping, etc.).

FEEDING SYSTEM

-

The feeding of digesters has a key role in the economic and efficient operation of a biogas plant. A safe and reliable – and for the respective biogas plant – optimal solids feeding can increase the gas yield. At the same time, it ensures lower energy consumption and reduces wear on agitators and pumps.

Free choice of feed is available since 2003 with our Vielfraß®!

In order to be able to vary the substrates to be placed, it is becoming increasingly important to select a placement technique that can also handle substrates that are difficult to convey without any problems.THE BASIC PRINCIPLE OF THE VIELFRAS®

Trouble-free feeding of the digester is a challenge for technology. For example, renewable greens often contain stones and sand, which can increase wear and malfunctions. Feeding solid manure and long-fibre grass silage can also push some technology to its limits.The Vielfraß® solids feeding system developed by agriKomp is specially designed to meet these challenges. The basic principle is two counter-rotating screws with knives, also called dissolving screws, which ensure loosening and mixing of the substrate.

FLEXIBLE FEEDING TECHNOLOGY – NUMEROUS OPTIONS

The Vielfraß® can be individually adapted to the system size by installing extension modules. The Vielfraß® Standard can be expanded with up to 4 extension rings to a capacity of up to 12 m³.Our variants with push-off trays offer even more feed volume. Additional feed options allow adaptation to the most diverse substrate conditions. If, for example, more than 50 % solid manure is fed, the Vielfraß® can also be equipped with an additional third disintegrating screw with fangs. Our Vielfraß® LEF, which works with moving floor / walking floor technology, can also be equipped with a Premix unit.

SEPARATION

-

Considerable amounts of substrate are moved during the operation of biogas plants. By means of a solid/liquid partition (separation) of the digestate can achieve several advantages for the operator in terms of transport, storage and energy consumption.

QUETSCHPROFI® SEPARATING INSTEAD OF COMPLEX MIXING

RELIABLE AND ECONOMICAL SEPARATION

With the help of the innovative Quetschprofi® separation technology, digestate can be processed economically up to a desired dry matter content of over 25 percent. Every biogas plant can be optionally equipped with a Quetschprofi®. This enables seamless retrofitting of the plant for value-added utilisation of the digestate.

The substrate is fed via an eccentric screw pump that pulls in the substrate. A robust press screw drives the substrate through a rigidly mounted, fixed slotted filter screen and presses it against the press cone. As a result, the liquid part of the substrate is drained off via the slotted filter screen. The solid part is conveyed out towards the front against the press cone. The minimal distance between the press screw and the slotted filter screen ensures low wear and a long service life of the screen. The dry matter content of the solid fraction can be adjusted from 15 % to over 25 % by means of the infinitely variable contact pressure, which can provide up to 15 % additional storage capacity. Due to the low connected load of the electric motor, the system works in a very energy-saving way.

- Optimisation of storage capacities

- Lower investment costs for digestate storage

- Separation of high-quality nitrogen and phosphate fertiliser

- Reduction of transport and application costs for digestates

- Commercialisation possibilities for the digestate

- Savings in electricity consumption

TANK CONSTRUCTION SYSTEM

-

Save yourself time and effort with the formwork system exclusively available from us for a wide variety of concrete structures! With the new system, containers up to a diameter of 40 metres and with wall thicknesses of approx. 5 – 30 cm are created in free design with a sophisticated technology and the highest demands.

INNOVATIVE SYSTEM BRINGS ADVANTAGES

Additional coating, insulation and impregnation, is not necessary as all elements are already integrated. The system is absolutely gas- and water-tight as well as acidresistant. The exterior wall does not need to be insulated, painted or cladded with wood.

Formprotect® is also available as a revision system, e. g. for the renovation of existing tanks. During refurbishment, profile rails are placed at specific intervals over the entire surface of the concrete wall. Then the formwork structure is built up from special brackets and formwork panels. The cavity between the concrete wall and the formwork is filled with lightweight concrete, resulting in a strong and stable bond.

- In contrary to conventional tank construction, the easy-to-clean formwork remains as the inner and outer cladding

- The exterior wall does not need to be insulated, painted or cladded

- Chemical-resistant PVC elements: absolutely gasand water-tight as well as acid-resistant

- Concrete and weather protection already integrated, no concrete curing required

- Easy to clean

- Tanks are equipped with leakage detection as standard

- Easy installation of insulation: simply slides between concrete and external formwork

- Weather-independent assembly of the formwork

- The appearance impresses with its modern design and colour (RAL 1013 pearl white)

- The appearance impresses with its modern design and colour (RAL 1013 pearl white)

- Complete and ready – from day one; without any subsequent work

GAS STORAGE

-

Flexible and efficient biogas plant operation is closely related to the storage of biogas. The biogas production in the digester is subject to fluctuations, especially if the biogas plant is operated in a flexible or demand-oriented mode.

BIOLENE® THE FLEXIBLE GAS STORAGE

SAFE AND ECONOMICAL

Our single-shell Biolene® biogas storage membrane, proven thousands of times in practice, is an economical solution for your biogas plant. Biolene® is a gas storage tank and tank cover in one and thus offers a highly efficient solution for small agricultural and industrial biogas plants.

Due to weather influences, high demands are placed on the outer skin of the digester roof. Our Biolene® meets these high demands: it is made of high-quality EPDM rubber. The material impresses with its UV, ozone and temperature stability, is highly elastic and durable.

COMPENSATES FOR FLUCTUATIONS

Depending on the biogas production, the operating mode of the CHP unit or due to maintenance, the stored gas volume changes constantly. The flexible outer skin rises and falls depending on the filling quantity and the filling level is always immediately visible. In addition, it is possible to precisely determine and evaluate the fill level with the help of an electronic fill level measurement.

A wooden beam ceiling serves as a substructure. The laid planks and the ceiling are a very large colonisation area where sulphur bacteria can settle. The biogas produced is thus cheaply and reliably pre-desulphurised.

Plant control and regulating components

-

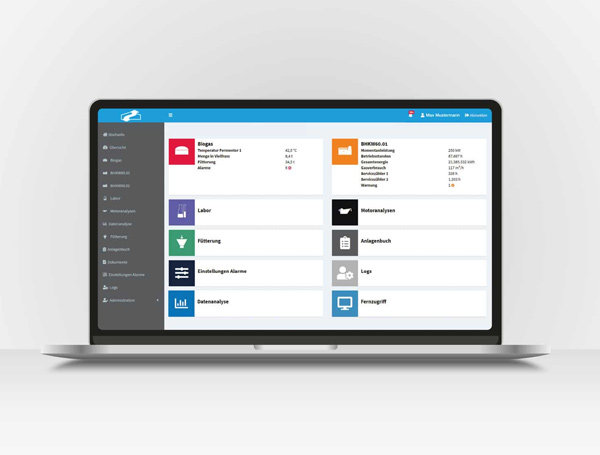

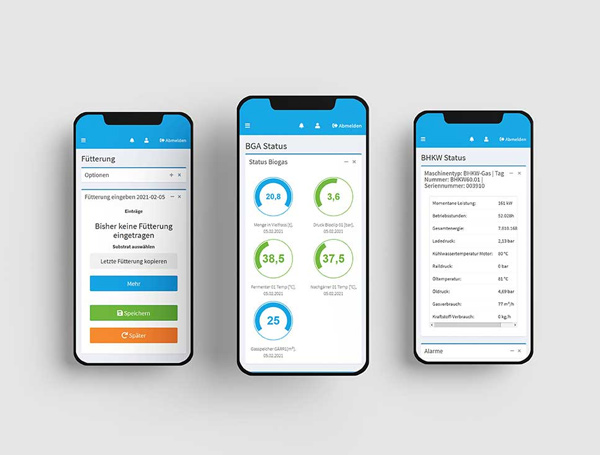

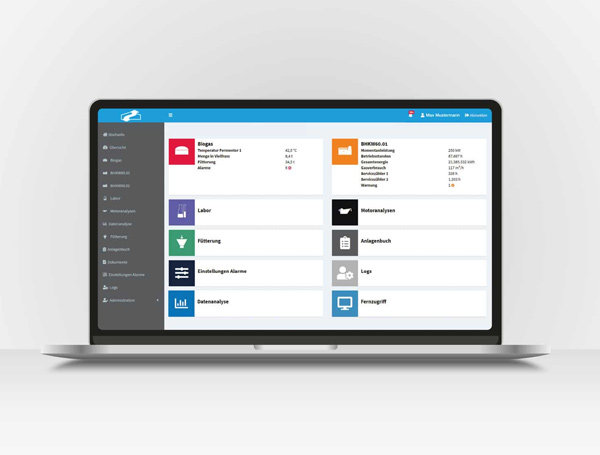

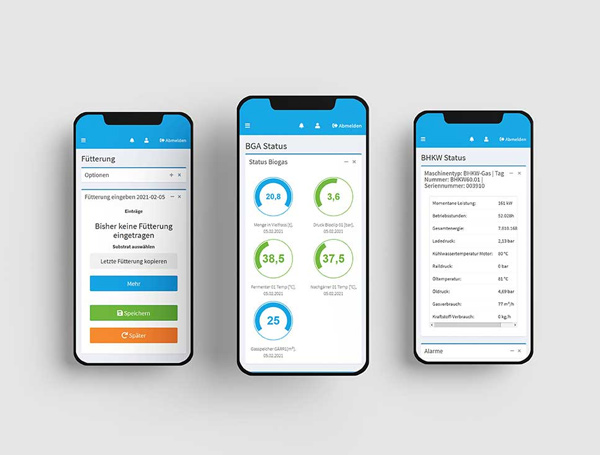

The akCockpit web application is the complete solution for monitoring and controlling biogas plants. Process, feedstock and feeding quantity, gas quality, results of laboratory tests, CHP or biogas upgrading: akCockpit collects all important information about your plant at a glance and saves a lot of time.

THE COMPLETE SYSTEM AT A GLANCE: SAVE TIME WITH AKCOCKPIT!

The akCockpit web application is the complete solution for monitoring and controlling biogas plants. Process, feedstock and feeding quantity, gas quality, results of laboratory tests, CHP or biogas upgrading: akCockpit collects all important information about your plant at a glance and saves a lot of time. Target-performance comparisons and analyses of historical data facilitate the assessment of the technical and economic efficiency of your biogas plant.

OPTIMISED INTERFACE

akCockpit is easily accessible via a web browser and optimised for use on mobile devices (smartphone, tablet, etc.). You do not need to install any additional software. aKCockpit can simply be integrated into the operation of the plant, e.g. for entry or operating data acquisition directly at the respective component, for remote monitoring of the plant or for data analysis in the office.

- Free starter package incl.

- Remote access to the system control

- Overview of plant status / plant parameters

- Integrated messaging system and data exchange platform (with agriKomp service)

- Feeding diary

- Reports from laboratory or oil analyses - Various software upgrade packages to choose from

- Software application available around the clock

- No installation of additional software

- Device-independent access via web browser (PC, tablet or smartphone)

- Free starter package incl.

UTILISATION

-

Our contribution to the circular economy in the agricultural sector. Our solutions get the most out of your biogas and digestate. Put your trust in over 20 years of experience and innovative strength.

The agricultural industry is a significant consumer of fossil fuels and chemical fertilizers. It is the objective of most countries through government policy to reduce this reliance from an environmental and sustainability perspective. Renewable energy sources are simply inexhaustible – we only have to use them!

CHP - UTILISATION OF BIOGAS

-

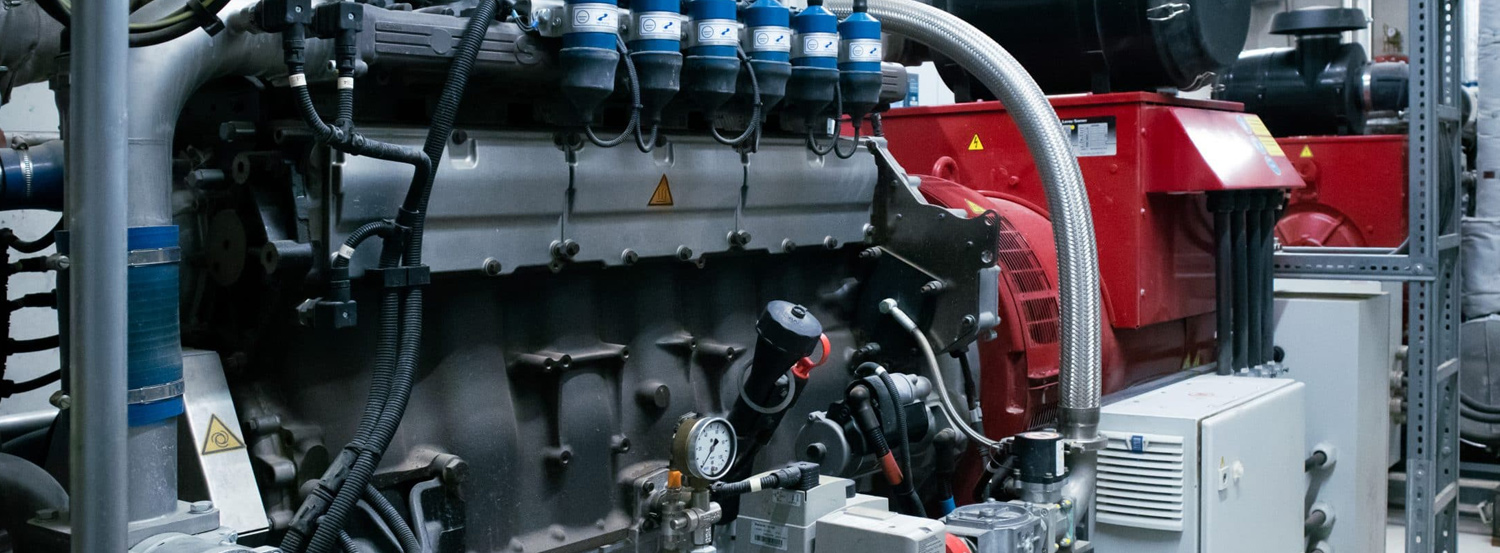

Combined heat and power units (CHP), with their versatile applications, currently represent an economical and efficient climate protection technology. All CHP units work according to the principle of combined heat and power (CHP), a decentralised generation of electricity and heat available directly on site where it is consumed. agriKomp offers you customised energy concepts for CHP applications. We develop optimised CHP units with modern engine technology from renowned manufacturers, such as SCANIA, in the small and medium power range.

NGA 136

-

With the CHP series 136, first manufactured in 2016, we serve an essential and popular power range.

CHP units of type NGA 136 are suitable for medium-sized applications and are ideal for flex and biomethane operation in double or even multiple versions.- The NGA 136 product range is based on the latest Scania DC13 engine generation

- Electrical efficiency up to 41,9 %

- Optimized hydraulic system, especially for flexible operation

- Exhaust gas temperature measurement

- Interface for balancing energy

BGA 095 ETA

-

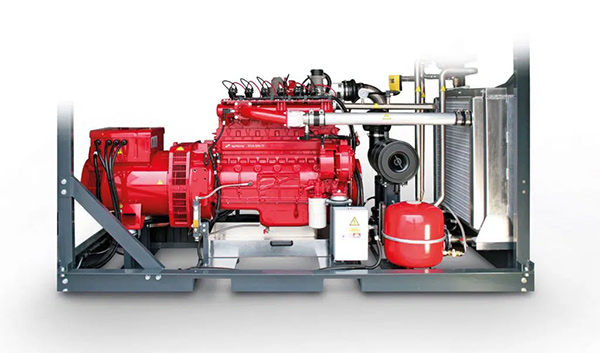

55 KWel – 100 KWel and 100 – 180 kWel

Our CHP series BGA 095 is optimized for best possible performance and availability. “ETA” stands for a SCANIA OC09 5-cylinder engine that has been further developed by us and does not allow any compromises when it comes to efficiency.

In our BGA 095 ETA series, 2 model variants are available in different power ranges. “Type 100 ETA” from 55 – 100 kWel and “Type 180 ETA” from 100 – 180 kWel. The models differ, among other things, in the dimensions and the installed generator.

BGA 136 ETA

-

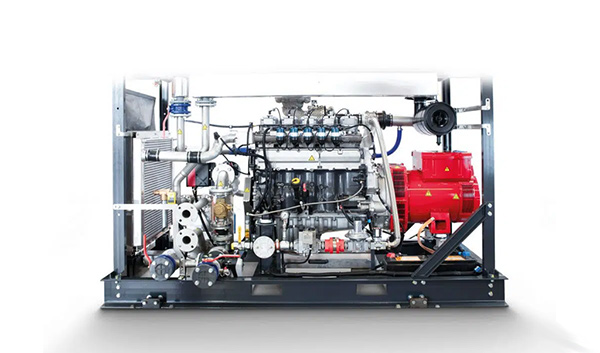

150 KWel – 265 KWel

With the CHP series 136, first manufactured in 2016, we serve an essential and popular power range. Our proven BGA 136 received an efficiency update.

The new “ETA” version with up to 43 % efficiency is available available since 2022. CHP units of the BGA 136 type are suitable for medium-sized farms and are ideal for flexible operation in double or even multiple units.

BGA 168 ETA

-

260 KWel – 350 KWel

The powerful power unit from our portfolio impresses with its stable and robust design. Thanks to its space-saving SCANIA 8-cylinder V-engine and the very good availability, it is a perfect CHP unit in the medium performance range.

With the help of an optimised hydraulic system, which was specially designed for flex operation, a high and stable flow temperature is achieved. This prevents condensation of the exhaust gas in the exhaust gas heat exchanger. Instead of batteries, a standardised mains starter is used in the BGA 168 ETA. This guarantees safe starting behaviour at constant speed, which is indispensable especially in flex operation.

BGA 252

-

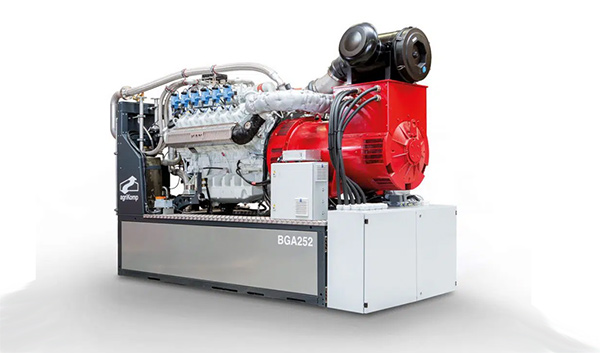

Up to 530 KWel

The powerful unit from our portfolio impresses with its

stable and robust design. Due to its space-saving Liebherr 12-cylinder V-engine and high availability, it is a frequently chosen CHP unit in the medium output range.

Utilisation From Biogas to Biomethane

-

Biogas can be used to generate electricity and heat in suitable CHP units. This type of utilisation is, however, strongly location-dependent and does not tap all the advantages of this primary energy source. By upgrading biogas to biomethane, many other positive properties and uses can be developed.

From Biogas to BiomethaneThe biogas produced, also called raw gas, is first subjected to pre-treatment which removes impurities from the biogas input before it enters the compressor and separation membranes. It includes gas drying, activated carbon filter and pre-compression.

In the subsequent upgrading process, the

CO2 and other gases contained in the raw biogas are separated using membrane technology. The upgraded gas contains up to 99% methane and is now called biomethane or bio natural gas. The other separated gases such as CO2 and H2 can be utilised for further applications.

WHAT IS BIOMETHANE?

- Commercially available natural gas contains a high percentage of methane with smaller amounts of nitrogen and carbon dioxide. Its calorific or energy value can vary depending on where it is sourced across the world. The upgrading of biogas produces biomethane, which can be fed into the natural gas grid as a natural gas substitute and used in the same way.

FROM BIOGAS TO BIOMETHANE

-

The biogas produced, also called raw gas, is first subjected to pre-treatment which removes impurities from the biogas input before it enters the compressor and separation membranes. It includes gas drying, activated carbon filter and pre-compression.

In the subsequent upgrading process, the

CO2 and other gases contained in the raw biogas are separated using membrane technology. The upgraded gas contains up to 99% methane and is now called biomethane or bio natural gas. The other separated gases such as CO2 and H2 can be utilised for further applications.

CHEMICALLY IDENTICAL TO NATURAL GAS

- In general, after biogas upgrading, biomethane can be used wherever natural gas is used. Both variants are chemically equivalent and differ only in their fossil or biogenic origin. Before feeding it into the natural gas grid, it may be necessary, in some jurisdictions, to adjust the calorific value (e.g. by adding propane) and to odorise the biomethane for safety reasons, because methane is ordourless.

MANAGEMENT OF DIGESTATE

-

Our contribution to the circular economy in the agricultural sector. Our solutions get the most out of your digestate.

THE BIG PICTURE CONSISTS OF FOUR SUB-PROCESSES

1. SEPARATION OF DIGESTATES

- In the agriFer® Plus process, the digestate is first mechanically separated into a liquid phase (press water) and a solid phase (pressed material). While the liquid phase, filtered through a sieve, is fed to the evaporators, the separated solid phase can be temporarily stored on a suitable storage area.

2. FRACTIONAL EVAPORATION

- Fractional evaporation uses the different vapour pressures of ammonia and water to separate them in several stages by evaporation. In the evaporators, the press water is heated under negative pressure, which evaporates a large part of the water and thus thickens the press water. This process can take place in 1 – 3 evaporators in parallel at different temperature and pressure levels. In this way, the heat can be used several times and with each additional stage a larger amount of water can be obtained per unit of heat used.

3. RECTIFIKATION

- The task of rectification within the agriFer® Plus plant is to increase the concentration of the ammonia water as required. This reduces storage and transport costs and generates income from the sale of ammonia water. The first condensate fraction (ammonia solution) from the vacuum evaporation is concentrated by rectification. The result is an ammonia solution with up to 25 % NH4-N content. This concentrate contains up to 50 % of the total nitrogen from the original digestate.

4. REVERSE OSMOSIS

- The second condensate from the fractional evaporation is then fed into the reverse osmosis stage. It is a physical process that enables substances dissolved in liquids to be concentrated in the molecular range. In this process the natrual osmosis process is reversed with pressure.

REFERENCES

-

PROVEN AND SUCCESSFUL PLANT SOLUTIONS

We have realized about 1.000 biogas plants with a total installed capacity of about 300 MWel with our customers so far. Take a look at our selection of reference plants from the areas of biomethane, biogas plants and farm biogas plants around the world.

AGRISELECT PRICHSENSTADT, GERMANY

- Input: cattle manure, cattle slurry, pig slurry, fodder residues, grain meal

Power: 75 KWel

Year of construction: 2015

AGRISELECT ZEULENRODA, GERMANY

- Farm: solid manure, cattle manure, slurry

Power: 75 KWel

Year of construction: 2013

INDIVIDUAL PLANT TIMMABSE, GERMANY

- Farm: grass silage, solid manure, cattle slurry

Power: 150 KWel

Year of construction: 2011

INDIVIDUAL PLANT DĚTENICE, CZECH REPUBLIC

- Farm: silage, sugar beet pulp, liquid manure, dung

Power: 1.250 KWel

Year of construction: 2011

INDIVIDUAL PLANT NIEDERBETTINGEN, GERMANY

- Farm: grass silage, corn silage, cattle manure

Power: 500 KWel

Year of construction: 2010

INDIVIDUAL PLANT, TOOMEBRIDGE, NORTHERN IRELAND

- Farm: silage, cattle slurry, grain GPS, fodder beets

Power: 500KWel

Year of construction: 2013

INDIVIDUAL PLANT, ASCEA (SALERNO), ITALY

- Power: 250 KWel

Year of construction: 2012

MÉTHA TREIL SAS Le Treil, France

-

AGRIPURE

Commissioning: 2019 Inst. capacity: 265 Nm³/h biogas

GÜLLEWERK BÖNNINGSTEDT, GERMANY

- Farm: livestock farm

Power: 75 KWel

Year of construction: 2014

GÜLLEWERK HELLMITZHEIM, GERMANY

- Farm: livestock farm

Power: 150 KWel

Year of construction: 2013

GÜLLEWERK BRACHTENDORF, GERMANY

- Input: cattle manure, horse manure, cattle slurry

Power: 75 KWel

Year of construction: 2012