- Offer Profile

-

AAT builds biogas plants for food waste, whey, sugar beet, organic waste, stillage, sewage sludge, spent grain, molasses, press cake and many other substrates. AAT has designed and implemented biogas plants for over 150 substrates.

We deliver everything from one source. From design, supply of plant components, assembly, start up, biological support to after sales service. Our speciality is the unique hydraulic mixing digester.

Our core business is the treatment of industrial and municipal sludge, biowaste, agriculture feedstock and energy crops.

Digester systems

Hydraulic digester

-

The AAT hydraulic digester produces more gas for almost zero operation costs.

The AAT system creates optimal process and mixing conditions for anaerobic degradation of organic matter without moving parts placed inside the digester and without external mixing energy. By separating the digester into a main and secondary compartment with an integrated substrate recycle a process environment ideal for anaerobic bacteria is created. Special design features provide dilution of scum and sediment layer as well as mechanical scum and sediment destruction. Long plant life, minimal maintenance and operator attendance result from the fact that no moving parts are located inside the digester.

Flat digester

-

AAT Flat digester

Features

- Digester dimensions: low height / diameter ratio

- Construction: steel reinforced concrete floor, walls and ceiling with centre column

- Agitation: AAT vertical shaft mixer combined with submersible mixer

- Feeding system: dry material feeder

- Heating: heating coils inside digester

- Desulphurization: integrated in digester or external biological desulphurization

CSTR Digester

-

Features

- build from prefabricated, enamelled, epoxy-coated steel segments or from concrete

- fully mixed with AAT agitator

- short construction time

- use in systems from 250 m³ to 9,000 m³

- permanently corrosion-resistant

- epoxy-coated or glass-enamelled with stainless steel roof

- concrete with PE protective film

Dry digester

-

Our components are known for their outstanding operational reliability, availability and high-quality workmanship. We set technological standards that stand out on the practical level with exceptional efficiency standards. And all this at a price in line with the market.

Our core business is dry digester technology and landfill gas technology. Municipal solid waste (MSW) is converted into energy by separating inert materials and treating the organic fraction by anaerobic digestion. Produced biogas and landfill gas can be used for electricity and heat generation or is upgraded to biomethane which is a substitute for fossil natural gas.

Package plant digestion

-

Digester with integrated gas storage.

The AAT package plant digestion combinies the sludge digestion and the gas storage in a simple and maintenance-free system.

The installed inclined agitator in the digester is used for the gentle agitation of the primary sludge and grants a full mixing of the digester volume as well as a continuous degasing of the digestion substrate.Through the frequency converter-operation the agitating intensity can be adjusted optimal to the required conditions and the energy consumption will be reduced to a minimum.

Advantages:- Easy operation and maintenance of the agitator (no access in the digester or opening of the gas hood required.

- Optimal mixing of the fresh substrate into the active biomass.

- Prevention of generation of sediment layer and floating matter.

- Continuous discharg4e of non-degradable matters over the sediment conduit.

- Systematoc ontervention possibilities with changing process conditions e.g. with development of foam.

- Low investment costs.

- Long life duration through gentle operation.

- Low operation and maintenance costs (as no mechanical parts inside)

- Possibility of performance as a Low-pressure gas storage.

UASB digester

-

Optimal sludge retention through newly developed high-performance separator

UASB or EGSB digesters use gas separators and overflow weirs in the upper digester section to remove the biogas from the digester and retain the biomass in the digester.

With the development of a new type of separator, problems such as

- Clogging of the gas separator by fibrous material, oil and grease

- Inaccurate leveling of the overflow weirs and the associated poor distribution of the discharge over the fermenter surface

- Corrosion in the contact zone between wastewater and air at the fermenter overflow, etc.

Equipment

Flares

-

Longevity ensured by high-quality materials.

AAT flares of type FA 50-1800 are used for the combustion of bio,-sewage-or landfill gas.

The flares are made completely of stainless steel which makes them robust to weather influences and heat.

The partially covered combustion protects the flames against wind and prevents failure.

In order to ensure simple handling and a high degree of safety, the AAT flare systems have been fitted with a fully automatic ignition and a flame monitoring system.

High-quality and certified components as well as a fully developed control ensure high security and little susceptibility to interference.

AAT flare systems are turn-key solutions and include mounting material. It can be mounted and commissioned by local specialists.

Details:- Flow rate: 50-1.800 m³/h

- Material: Stainless steel 1.440X (SS316)

- Gas pressure > 25 mbar

- Condensate outlet by ball valve

- Manual valve

- Motor valve

- ATEX flame arrester

- Automatic ignition equipment

- Temperature measurement by means of thermal element

- Combustion temperature: approx. 900°C

- Anchoring device

- Automatic, manual and semi-automatic control

- Sound pressure level: 65 db (A) at 10 m

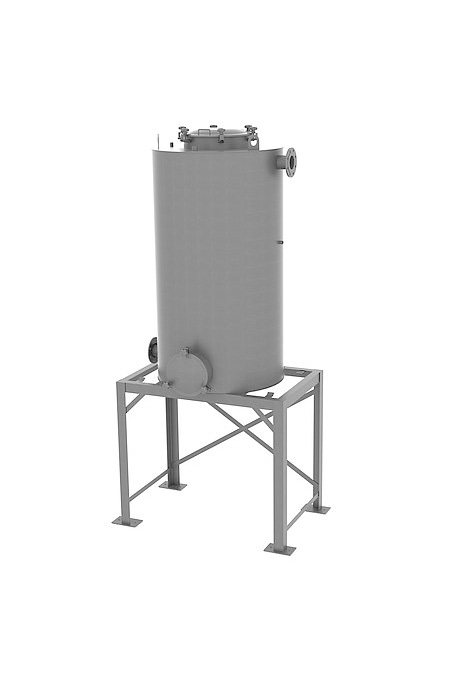

Hygienisation system

-

Pressureless pasteurisation 70°C and pressure sterilisation 133°C.

The AAT hygienisation system is used for (EU conforming) heat treatment of organic waste products which are further processed in biogas plants.

Depending on the use as well as type and quantity of the substrate, a multitude of tried and tested plant configurations are available,

They comprise from the most simple configurations with a double-jackted tank to three-tank plant with seperate heating, hygienisation and cooling.

Depending on the local conditions and the requested performance, the plant can be heated by water, thermal oil or direct stream.

The heath exchangers used have a very high heat transfer performance and large cross-sections for high efficiency.

The agitators are extremely robust and maintenance friendly.

Advantages:- Hygienisation temperature: 70°C or 133°C

- Material: Stainless steel

- Heating by double shell or heat exchanger

- Heat transfer through direct stream, water or thermal oil

- Several filler and relief pipe ends

- Several Measuring socket

- Heat recovery

- Construction from 1 to 500 m³ per day

- Reliable agitators

Activated carbon filter

-

Maximum filter retention time, simple and fast change of the filter material.

The AAT Activated carbon filter removes disturbing matter like e.g. hydrogen sulfide and siloxane out of biogas, sewage gas and landfill gas.

The models are either made as flat absorber or packed bed adsorber. The filter can be installed with a low efforts between the digester and the gas consumer. They are maintenance-free and user-friendly. A high retention time can be achieved through using a special treated activated carbon.

Depending on the contaminationof the gas with sulphur or siloxane the pollutant concentration can be eliminated up to the detection limit. Through this the efficienty of the plant will be increased and the maintenance costs of the consumer will be considerably reduced.

The activated carbon can be filled in from the top and discharged on the bottom by using Big Bags.

Operations data:- Material: 1.440x or plastic

- Gas quantity: 50- 1.600 Nm³/h

- Input temperature: 10-38 °C

- max. operation temperature:up to approx. 50 °C

- operations pressure: up to max. 300 mbar

- High retention time through special treated activated carbon

- Location: indoor and outdoor installation

- Gas tight bulk material gate valve for discharge

Digester Equipment

-

- Gas hood

- View port

- Manhole

- Heat exchanger

Agitators

-

- Sewage sludge digester agitators

- Vertical agitator „Homer"

- Vertical agitator „Bart"

- Submersible mixer

Gas storage

-

- Dry gas storage

- Double membrane gas storage

Desulphurization

-

- Microbial desulphurization

- Desulphurization "air dosage"

Gravel filter

-

The AAT gravel filter are used zo seperate coarse substances as well as to collect and drain condensate. In order to extend the maintenance cycle and the life of the consumer, the gas should be free of coarse particles. In order to ensure this, the gas flow through the filter from the top to the bottom and is cleaned by means of gravel or plastic packing. the arising condensate is removed by a siphon condensate sluice. When the water level drops the gas is passed into the bypass pipe and into the environment. A gas leakage into the installation shaft or into the technic room is thus safely prevented. With increasing soiling of the filter mterial, the maintenance opening can be used to remove it from the front, to clean it and to fill it again from the top.

Advantages:

- Material: Stainless steel

- Pressure range: up to 100 mbar

- Filter material: Gravel (grain size 30-60 mm) or plastic packing (PP)

- Integrated condensate trap

- Cleanable filter material

- Quick release cover

- Pressure indicator (U-tube pressure gauge)

- Relief pipe to ensure the gas outlet

Condensate traps

-

The AAT manual or electrical condensate trap can be used to drain all condensate from the gas system without gas outlet. In the basic setting the connection between the gas system and the condensate collector tank is open and the condensate is collected in the tank. When emptying the system, the condensate is drained and the connection to the gas system is closed.

Advantages:

- Material: Stainless steel

- Trap is mantenance-free

- Escaping of gas is impossible

- ATEX-approved motor

- Fully automatic

- Level indicator

Agitator

Sewage sludge digester agitators

-

AAT vertical shaft agitators for new or refurbished sewage sludge digesters.

Each agitator is manufactured to suit the specific project requirements.- well suited for flat bottom digesters with flat roof.

- Installation of a properly designed top agitator blade provides a flow pattern capable of destroying (avoiding) scum layers.

- well suited for conical bottom digesters with conical roof.

- Installation of a properly designed top and bottom agitator blades provides a flow pattern capable of destroying (avoiding) scum and sediment layers.

Vertical agitator „Homer"

-

highest efficiency ensured by flow-optimised mixture.

The AAT agitator consists of two-optimised impellers in the bottom an ceiling area. On the one hand this produces an optimised flow from top to bottom, an on the other hand a circular movement is created.

The freshly fed substrate is mixed in the tank immediatley and creates perfect fermentation conditions and increases the output.

High-quality material and robust components make the vertical agitator of AAT into long-life raliable product.

By means of the frequency converter operation, the agitator is substrate-optimised and the energy consumption is reduced to a minimum.

The inside of the tank contains no wearing parts, and thus the tank must not be opened for maintenance.

Advantages- Drive: 15,0 kW

- Revolutions: max. 12 rpm controlled by frequency converter

- Shaft: Ø 220 mm

- Two flow-oriented impeller Ø 4 m

- Bearing block with sphericall roller bearing with automatic permanent librication and positive-contact clutch

- Planetary gear in reinforced execution

- Explosionproof, pressure-tight encapsulated electric motor suitable for frequency converter operation

- Floor storage with maintenance-free special ceramics bearing

- Shaft leadthrough by means of labyrinth seal (water feed)

- ATEX certified

- EC declaration of conformity

- Will completely mix a 3000m³ tank in 5 min.

Vertical agitator „Bart"

-

Highest efficiency through level adjusted agitator blades. Our new developped vertical agitator has been designed especially for the use in hydrolysis tanks, buffer tanks with variable filling levels or direct in the digester.

The agitator consists of flow-optimised stirrer blades in the floor area and an automatic height-adjustable floating blade. On the one hand this produces an optimisted flow from top to bottom, and on the other hand a circular movement is created.

The freshly fed substrate is stirred into the tank immediatley and uniformly, and is kept homogeneous permanently. The floating blade reliably prevents the development of surface crusts.

High-quality materials and robust components make the vertical agitator of AAT into long-life and very reliable product.

By means of the frequency converter operation, the stirrer intensity is substrate-optimised energy consumption is reduced to a minimum.

Advantages:- Material: Triple epoxy resin coated steel and stainless steel parts 1.4462

- Drive: 15,0 kW

- Slow revolutions controlled by frequency converter

- Shaft: 150 mm

- 1 flow-optimisted impeller, 1 floating blade

- Bearing block with spherical roller bearing with automatic permanent lubrication and positive-contact cluch

- Planetary gear in reinforced execution

- Electric motor suitable for frequency converter operation

- Floor storage with maintenance-free special ceramics bearing

- ATEX certified

- EC declaration of conformity

- Shaft leadthrough by means of labyrinth seal (water feed)

Submersible mixer

-

Ideal and cost-efficient mixing.

The AAT submersible mixer is used to mix fluids and sludge in basins and tanks.

The directly driven submersible mixers with three-wing propellers ensure optimised mixing of the tank contents. Additionaly, a heigh adjustment is used to mix up floating and suspended layers. On account of the construction for permanent submersed operation, the mixers have an especially long life.

The execution for gas-tight tanks includes also a maintenance shaft with an easy removable cover. This ensures a quick and easy mantenance.

The shaft has an integrated gas-tight cable conduit and fastening equipment for overfill safety device (floating bell). An integrated over- and underpressure security device ensures safe operation, and an inspection glass with flushing device has been integrated for optical check of the process.

Advantages:- Material: tainless steel

- Compact and robust construction

- Long-life components

- Quick and easy maintenance

- ATEX certified

- World-wide service

- Low operating costs

- Low investment costs

Digester equipment

Gas hood

-

Easy pre-installation of various component parts by flange system.

The AAT gas hood with the diameters of 1200 - 3000 mm is a cover on the roof of the digester. It is used as an access and removal opening during maintenance work and offers a compact platform for the installation of gas components.

The various flanges on the gas hood are used to fit the following component parts: Gas dome, foam detector, hydraulic over - and underpressure safety device, view port,gas pressure measurement and overfill switch.

The gas dome is the collection point for draining gas from the digester. An integrated water spraying device and a pressure indicator are available as an optional feature.

The hydraulic over - and underpressure safety device secures the digester against impermissible overpressures or underpressures. It has been fitted with an internal, gas-tight,self-regulating water feed.

View port

-

Optical controll ensured by clear vision.

The AAT view ports are used to look inside various tanks, digester and shafts in biogas plants.

By means of the view port, the contents, the fermentation, the function of the agitators and similar things can be controlled optically.

They are fittet directly to the celling, the outside wall and/or maintenance shaft. Sometimes they can be opened by quick-action locks and they have a protective cover.

A integrated washing nozzle (in case of non-opening view ports) and a wiper ensure that dirt caused by the content can be removable quickly.

Hich-quality materials are used and the glass as well as the frame are extremely resistant. Depending on equipement, different size are available.

Advantages:- Material: Stainless steel, aluminium,

- Gas-tight (EPDM seal)

- Integrated washing nozzle

- Integrated wipers

- Protective cover

Manhole for concrete tank

-

Easy installation by direct integration in the tank wall.

The AAT access opening is used for easy and direct access to the concrete tank for reconstruction or maintenance work.

The frame is adapted individually to the tank diameter and the wall thickness.

The easy installation is a special highlight. The manhole respectively the door is laid poured in concrete as one unit.

The door with hinge opens to the inside which provides an additional seal against tank pressure.

The access to the manhole is fitted with a spindle closure and a seal ehich ensures quick and safe opening and closing.

Heat exchanger

-

optimised energy utilisation ensured by plant specific design.

The AAT heat exchanger is used to heat the digester sludge in the digester.

For perfect fermenterind conditions,a constant sludge temperature is required in the digester.

In order to achieve this, the digester sludge is circulated in a pipe heat exchanger and is heated to the requested temperature through hot water in a counterflow procedure.

With respect to sludge quality, performance and energy efficiency, the heat exchangers are optimisted for the respective case of application.

Advantages:- Material: Stainless steel

- Designed as specified by customer

- Compact construction

Dry gas storage

Dry gas storage

-

Advantages

- minimized investment costs

- long life span due to gentle operation

- low operation and maintenance costs

- no steel parts exposed to biogas

- gas pressure can be adjusted to demand of downstream consumers

- membrane housing can be adapted to local site conditions

- membrane installation in existing building is possible

Components- membrane (un-pressurized)

- safety devices

- level indication

- gas blower

- membrane housing (between membrane and housing an aerated space serves as heat buffer and inspection area)

Double membrane gas storage

-

System description:

The outer membrane forms the actual protective construction and is always under a for the statics necessary positive pressure. Through a built-in viewing window the operations inside can be observed at any time. The actually usable holder forms the inner membrane. This membrane moves up or downwards depending on the filling level. In the gas holder with base plate a bottom membrane seals the storage space to the concrete foundation. With the help of the anchoring ring, the membranes are attached to the foundation. Particular emphasis is on the dimensioning of the membranes. Each holder will be calculated individually in consideration of the loads (internal pressure, wind and snow loads). As a result, membranes with high tensile strength are selected. The PVC-coated membranes are flame retardant according to DIN 4102 B1, fungicide, and equipped with an increased UV protection. To protect the membranes from the substances in the biogas (CH4, CO2, H2S, etc.) the inner- and bottom membranes have a special coating.

Advantages:- price-performance ratio

- mean wind and snow load possible

- short installation times

- integrated service for submersible agitator shaft

Desulphurization

Microbial desulphurization

-

Low operations costs ath high degree of purification.

AAT microbial desulphurization is used to reduce hydrogen sulphide in biogas, WWTP and landfill plants on an ecological basis.

Apart from methane and carbon dioxide, toxic hydrogen sulphide is produced in fermentation process as well. This acts corrosively on the consumers and equipment.

The hydrogen sulphide containing biogas is passed through a packing tank. Microorganisms settle on the surface of the packing, which by the use of oxygen oxidise the hydrogen sulphide to elementary sulphur and sulphate.

By adding artificial fertiliser as nutritional component for the organisms and circulating water the sulphur and the sulphate is continuously washed out. The sulphate suspension developing is passed to the inlet of the sewage treatment plant or to the fermentation residue tank in case of biogas plants.

Details:- Material: plastic (PP)

- Acid-resistand circulation pump

- Air blower (including non-return valve and deflagation arrester)

- Water inlet

- Reciever thank for nutrient solution

- Flushing lance in tank

- Heat exchanger

- Control cabinet

- Max. hydrogen sulphide feed 20.000 ppm

- hydrogen sulphide reduction down to 50 ppm

Desulphurization „air dosage"

-

Easy and low-budget desulphurization.

The AAT air pump ensures the dosage of the air requiered for the deluphurisation in the gas chamber of the digester.

During the fermentering process in biogas plants, tho course of the anerobic degradation of organic substances creates toxic hydrogen sulphide. Blowing in air causes the micro-organisms to oxidise the hydrogen sulphide zo elementary sulphur and sulphate.

For this reason, air dosage is an especially easy and yet very effective and economical method of desulphurization.

The air pump used has been designet for continuours operation and is thus especially long-lasting.

Advantages:- Air pump

- Flow indicator

- Condensate trap

- Non-return valve

- Fully mounted on console

Project services

Project studies

-

For new construction and extensions to agricultural biogas plants (including co-substrates and energy corps), plants for organic waste disposal, municipal sludge treatment, industrial waste sludge fermentation and wastewater treatment plants AAT offers:

- feasibility studies

- concept creation

- calculation of profitability

Project design

- From your idea to build a biogas plant up to the realization of it you will have a competent partner with us. We have more than 25 years of experience. Our plants process 150 different substrates. Please send us your project sketch and we will design your plant according to the latest state of the art.

If you are already a few steps ahead with your project you will find the right partner in us to plan your plant in detail.

Thereby we set a high value on reliability, durability, maintainability and a flexible planning for future requirements.

Of course we guarantee for the plants designed by us.- elaboration of plant concepts

- permit application engineering

- process engineering

- detail engineering

- formwork drawings

- piping drawings

- tank structural analysis

- tenders

- building supervision

- EPCM

Research

- AAT is involved in the following research projects at the moment:

VARESI: Valorisation of industrial residues for a sustainable industry

After the European Union climate and energy package (“the three 20 targets”), the zero carbon economy in the European Union by 2050 was suggested in 2018-19 to reach the reduction of climate change. The proposal “VARESI” aiming to valorise industrial residues onsite the production plant and to integrate the energy vectors, mainly into the production process. To realise this target the consortium combines anaerobic treatment technologies, hydrothermal carbonisation and energetical process integration by the simulation IPSEpro. Additionally, to the energetical aspects, water recovery plays an important role during the project. The project is completed by a techno-economic assessment. The focused industries are breweries, dairies, meat processing industry, pharmaceutical industry, pulp and paper industry and sugar industry.