- Offer Profile

-

EnvironTec is a skilled, innovative company from Austria.

Our many years of experience have led to our specialisation in the development, production and marketing of gas-technology components for a wide variety of fermentation gas applications in the bio, sewage and landfill gas area.

Our product portfolio ranges from fermentation gas reactor equipment to all gas purification and gas storage components right through to gas utilisation in flare systems. We are also happy to conduct the planning, conception and delivery of complete gas conduits and systems as well as their maintenance and inspection on behalf of the customer.

EnvironTec - a Global Player from Austria

-

High-performance products "Made in Austria" for worldwide use in the field of environmental technology

Our company EnvironTec, based in Fußach in Vorarlberg/Austria, specialises in the development and production of gas components for a wide range of digester gas applications. Based on our innovative strength and many years of experience, we offer our international customers sophisticated solutions in the following areas:

International export of Austrian know-how

Worldwide - that means from Asia with Indonesia and China over whole Europe up to America we could already equip numerous customers in the past with the following components from the range of the biogas purification, biogas preparation, biogas storage and biogas utilization:

- Digestion equipment: roof manhole RMH, double tube heat exchanger, gas dome GD, ball spray nozzle SU, sight glass IG, foam trap FT as well as lateral manhole LMH

- Gas treatment: activated carbon filter ACF, biological gas cleaning, gas refrigeration dryer GC, ceramic fine filter FF, gravel filter GF, condensate collector CA, condensate pot CP as well as sediment pot ST

- Gas storage: Gas storage models TG or TGZ as well as : Double diaphragm storage tank

- Gas utilisation: biogas and sewage gas flare FA II, manual gas flare FA I and radial fan RV

GAS FLARE

- We offer FAI biogas flares, FAII biogas/biomethane flares and HTFA high-temperature flares. These flares work fully automatically, are supplied plug-and-play and conform to international standards.

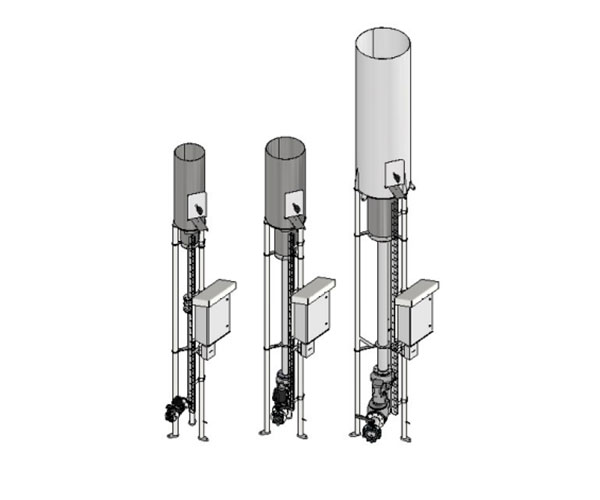

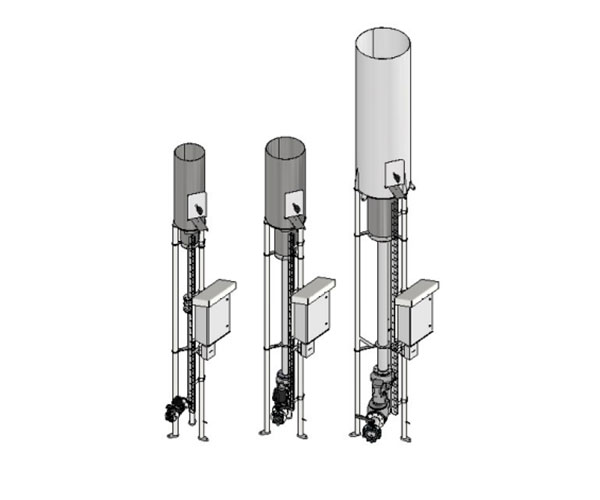

EMERGENCY GAS FLARE FAI

-

When operating biogas or sewage treatment plants, it may be necessary to burn off excess gas safely (e.g. in the start-up phase, during

repairs or in the event of serious consumer damage).The EnvironTec FAI series biogas flare provides the operator with an automatically controlled, open/partially covered gas flare. Gas combustion takes place with a specially developed single-flame injector burner, which enables premixing of air and biogas.

After receiving the start signal from the system control unit, the automatic burner control unit opens the corresponding valves and simultaneously initiates the ignition sequence. The flame is continuously monitored by an UV sensor and a safety minimum pressure switch.

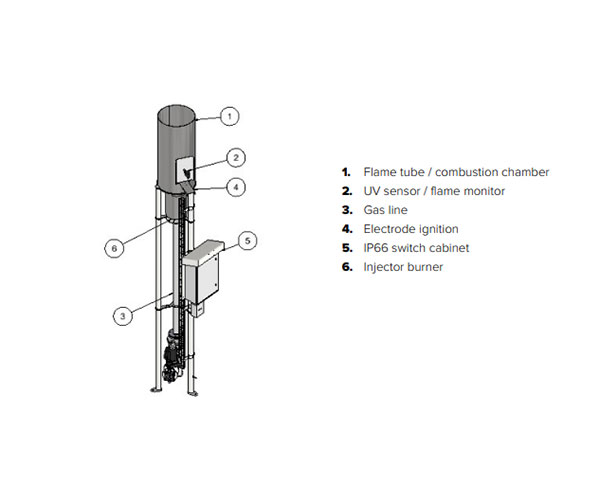

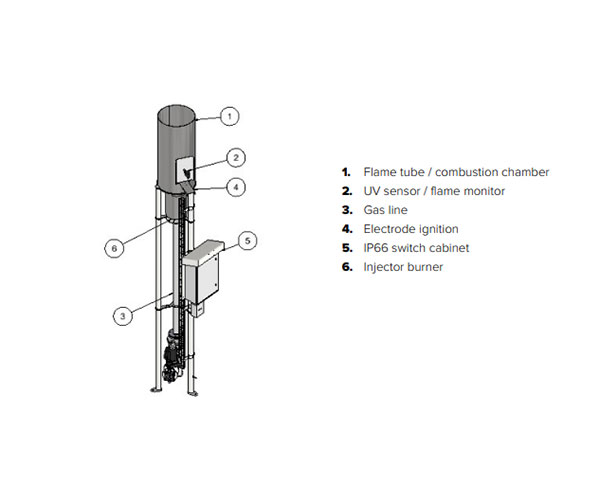

GAS FLARE FAII

-

When operating biogas or sewage treatment plants, it is necessary under certain circumstances (e.g. start-up phase, repairs or consumer damage) to burn off excess gas safely.

The EnvironTec FAII gas flare series provides the operator with an automatically functioning, safe and low-emission gas flare .The FAII biogas/biomethane flare primarily guarantees a long service life due to its robust and functional design.

The flame is continuously monitored by an UV sensor.As standard, the FAII is equipped with a plastic switch cabinet (IP66) with integrated automatic gas burner control in accordance with EN 746-2.

Gas combustion takes place with a specially developed multi-flame injector burner, which enables premixing of air-biogas, resulting in safer, more stable, less noisy and concealed combustion.The FAII flare can be equipped with additional accessories such as pressure control, pilot burner system, electric valve heating or temperature monitoring on request.

HIGH TEMPERATURE GAS FLARE HTFA

-

Fully automatic gas flare for the combustion of biogas and other flammable gases in accordance with TA-Luft 5.4.8.1.3a with automatic exhaust temperature control at 1000°C and dwell time of at least 0.3 sec.

Area of application: Thermal disposal of combustible and surplus gases (e.g. landfill gas plants) or special gases.

HT flares are supplied with heat-resistant ceramic lagging (up to 1400°C) and automatically controlled air flaps. After receiving the start signal from the system control unit, the automatic burner control unit opens the corresponding valves and the ignition sequence is initiated simultaneusly.

Digester equipment

-

The term digestion equipment refers to devices that are used on digestion towers and are necessary to generate digester gas and to use this as an energy source in the subsequent process.

EnvironTec specializes in all the components a digestion tower needs for operation. We have already implemented numerous projects in various countries.

EnvironTec supplied the following products to equip a digestion tower:

- Roof manhole RMH

- HE double-tube heat exchanger

- GD gas dome with hydraulic or mechanical overpressure/underpressure protection

- SU spraying unit

- Digester agitators

- Inspection glass IG

- Foam trap FT

- Lateral manhole LMH / LMH2

ROOF MANHOLE RMH

-

A roof manhole is an opening in the roof that is required for carrying out repair and inspection work and for transporting bulky equipment in and out of the fermentation tanks. With the EnvironTec RMH roof manhole, we have developed a versatile solution with a generous internal opening for safe and convenient access to tanks and containers.

The material for the roof manhole is usually stainless steel V4A and an NBR round cord is used as a seal.

- Access openings in concrete tanks for inspections and maintenance work

- Available with different diameters

- Incl. Sealing sleeve for embedding in concrete ceilings or for welding into steel containers

- Incl. Screwed lid with handles

- Made entirely of stainless steel

- Made in Austria

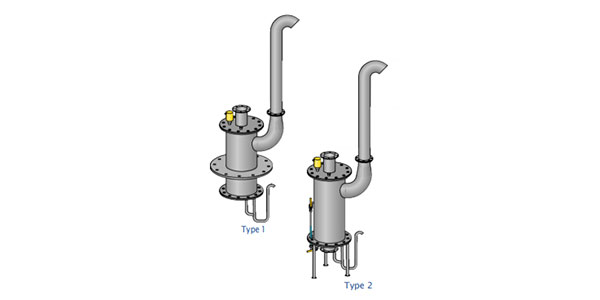

HYDRAULIC SAFETY VALVE CHV

-

A hydraulic safety valve limits the gas pressure in the fermenter with regard to overpressure and underpressure.

As the digestion towers required for the production of biogas must be gas-tight to prevent air contact and gas leaks, a safety device is required which blows off gas when the gas outlet is closed or blocked, thus preventing an impermissible overpressure from building up in the tank.

This also avoids the risk of the tank imploding due to a vacuum caused by a liquid leak.The hydraulic safety valve from EnvironTec offers safe and reliable protection against both overpressure and vacuum.

It consists of a round tank which is divided into two sections by a separating wall.

One section is connected to the gas area, the other to the open air.

The pressures at which the safety valve is activated are determined by the hight of the liquid and the ground areas of the two parts.

In the event of overpressure, the liquid on the gas side is pressed down until the gas can escape under the partition wall.

Under vacuum, the liquid is pressed down on the air side so that air can flow into the fermenter.The described system is available in various sizes and with different options.

- Save protection against overpressure and vacuum

- Two installation types available:

- Type 1 for installation onto a top manhole of a tank

- Type 2 for installation in an open area or into a pit

- Optional inline installation

- Optional local / remote level indication

- Gas contacted parts entirely made of ss 316Ti

- Made in Austria

GAS DOME GD

-

A gas dome is a component of the digestion tower positioned above the digested sludge, with the purpose of allowing the digested gas to escape in a controlled manner.

The EnvironTec gas dome or gas-hood is designed and manufactured specifically to each customer requirement and can be supplied in a wide variety of configurations.

Diameter and frame length can be individually adjusted.- Basis for a wide range of digestion head equipment such as agitator flanges, foam traps, inspection glasses, safety devices, etc.

- Simultaneous access opening for inspections, maintenance and material insertion and removal

- Design and manufacture tailored to customer requirements

- Completely in stainless steel – pickled in an immersion bath

- Made in Austria

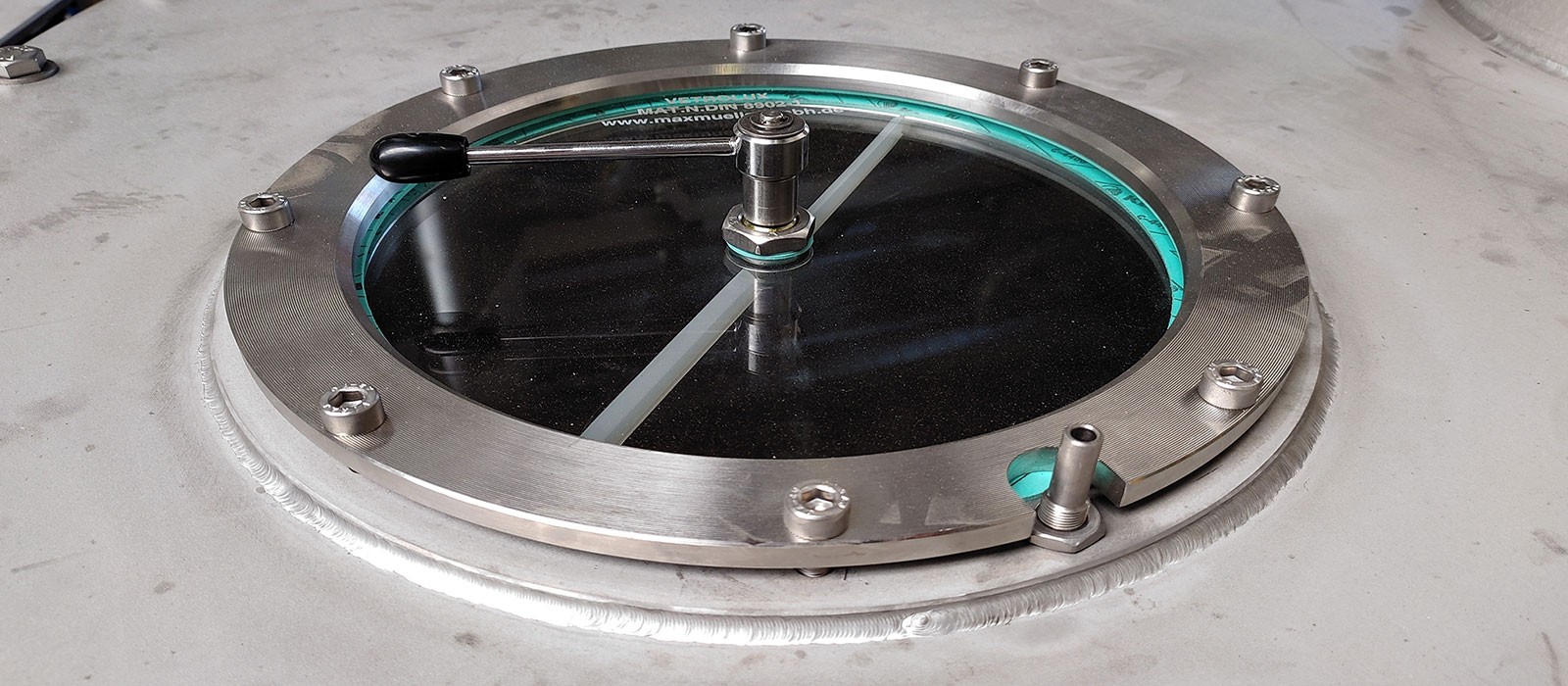

INSPECTION GLASS IG

-

An inspection glass is used for simple and unhindered observation of the processes inside digesters (e.g. formation of floating layers).

The EnvironTec inspection glass system can be integrated into a manhole lid or gas dome or simply installed in the reactor roof or outer wall using a separate insert. EnvironTec inspection glasses are available in various sizes.

Windshield wipers, spraying devices, inspection glass lights (also explosion-proof) and protective covers can be supplied as additional equipment. The soda lime glass material in accordance with DIN 8902 is highly resistant and break-proof.

- Simple observation of processes in containers / reactor rooms

- High-strength glass material

- Windshield wiper inside/outside optional

- Spraying device optional

- Can be equipped with explosion-proof inspection glass light or camera system

- Entirely made of stainless steel

LATERAL MANHOLE LMH

-

The EnvironTec lateral manhole LMH ensures quick and easy opening / closing of the manhole cover by means of spindle lock.

During the construction phase of digester gas tanks, but also during operation and for conversion work , safe and easy access to the inside of the tank must be provided.

To achieve this, it is necessary to provide side entry and exit for people, as well as the insertion and removal of materials and equipment.The high-quality NBR seal ensures an impermeable seal of the manhole, preventing liquid from escaping at hydrostatic pressures of up to 4 bar.

The LMH side manholes are supplied with free diameters between 600 mm – 1200 mm.

The frame width can be ordered individually.- Easy opening / closing with spindle-operated locking mechanism

- For hydrostatic pressure up to approx. 4 bar

- Application range up to 100°C

- Perfect sealing due to static pressure of the medium

- Lid can be swiveled and does not need to be removed

- Completely in stainless steel – pickled in an immersion bath

- Made in Austria

Foam trap FT / FTII

-

During operation of digesters, foam may form in the gas compartmentunder certain circumstances (e.g. during mixing processes in the reactor, due to gas injection processes, disadvantageous composition of the digested sludge, temperature influence, etc.).

The modern EnvironTec foam trap can immediately detect the formation of foam and effectively prevent it from entering the gas extraction system.

The interior of the foam trap body is continuously monitored by a photo-optical system or optionally by a conductive rod probe . If the foam formed in the gas compartment rises into the monitored area, it is detected and the cleaning nozzles are automatically and immediately activated.

A spray curtain is used to keep the foam in the foam trap and prevent it from penetrating into the gas pipe system.

The deposited foam falls directly back into the reactor chamber or, in the case of the FTII, leaves the system via the siphon into the septic tank outflow shaft.Delivery is possible in various equipment variants (basic equipment, semi-automatic or fully automatic, as well as including signal output to the control system).

Two types of installation available:

- FT version for installation on a manhole / gas dome of a reactor

- FT II version as “stand alone” version for field installation

LATERAL MANHOLE LMH II

-

The EnvironTec lateral manhole LMHII ensures quick and easy opening / closing of the manhole cover of the manhole cover by means of an optional swivel device.

The LMHII side manhole from EnvironTec offers a widely used solution with a generous internal opening for safe and convenient access to tanks and containers.

The side manholes are supplied with a free diameter of between 600 mm and 1200 mm. The frame height can be ordered individually.

- For hydrostatic pressure up to 4 bar

- Application range up to 100°C

- Completely in stainless steel – pickled in an immersion bath

- Swivel arm optional

- Made in Austria

SPRAYING UNIT SU

HEAT EXCHANGER HE

-

Our double-tube heat exchangers are used for heat exchange in biogas plants and sewage treatment plants.

The medium is heated evenly by means of an energy-efficient counterflow process and fed back into the process flow.The design of our double-tube heat exchanger can be individually adapted to the operational requirements so that optimum integration into the system and maximum heat transfer efficiency can be achieved.

The design and construction is customized, which guarantees a cost-effective and efficient design.

Our heat exchanger is made entirely of stainless steel and is available with or without insulation.

- Customized design and construction

- Versatile application options

- Low pressure loss

- High heat transfer due to large transfer surfaces

Gas purification

-

Gas purification is an essential part of making biogas, sewage gas and landfill gas usable.

We at EnvironTec specialize in systems for the treatment of such gases.

Worldwide, professional and appropriate gas treatment is not only an important task in the field of environmental technology, it is also characterized by numerous challenges that need to be overcome with the right components.

Modern gas treatment with innovative solutions made in Austria.

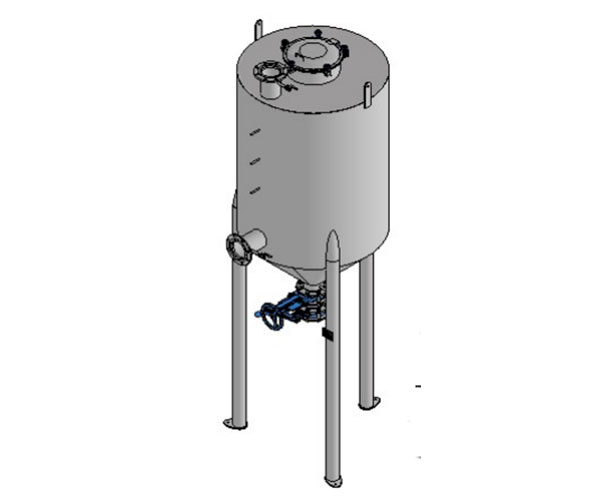

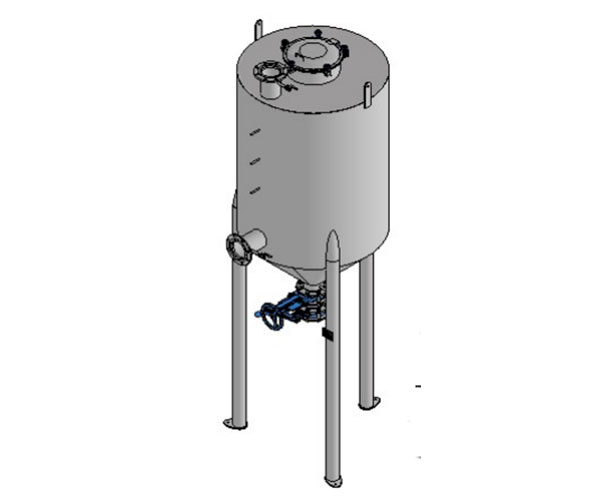

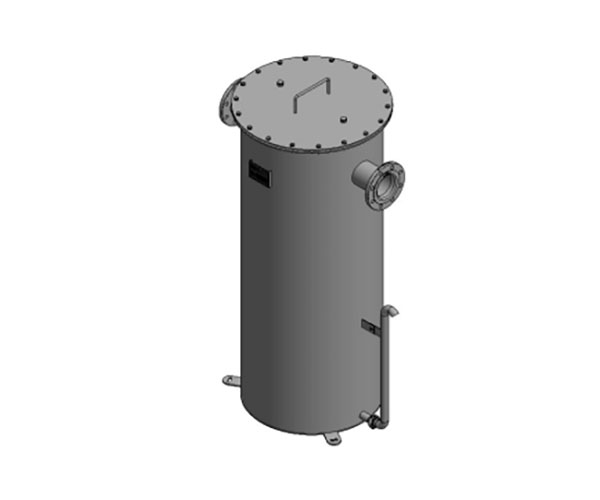

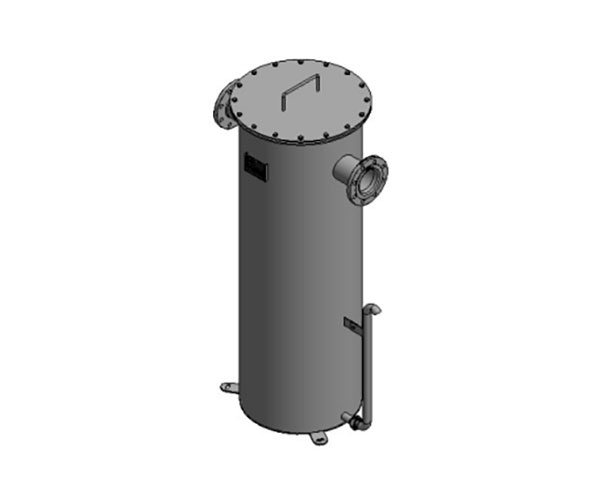

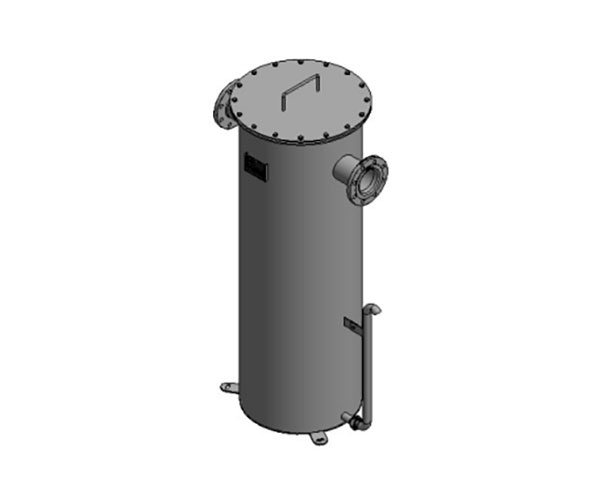

ACTIVATED CARBON FILTER ACF

-

Biogas contains high levels of contaminants like H2S, siloxanes, organic compounds and particles, which can create irreversible damage to the engine.

The EnvironTec’s Activated Carbon Filter can costeffectively remove those contaminants, leading to lower operational costs and longer lifespan of engines and plant’s components.

The EnvironTec filter’s unique 3-legged design and the special disposition on the gas inlet pipe inside the filter, results on an even gas distribution inside the chamber, leading to a higher adsorption efficiency, thereby a lower consumption of activated carbon and ultimately to a significant reduction of the operating costs As an option, insulation and carbon first filling can be provided on request. EnvironTec’s Activated Carbon is available for H2S and siloxane removal, reaching higher loading ratios that the average product available in the market, thus extending the load’s service life

- Supported on three legs, allowing an easy removal of carbon through the bottom

- Multi-chamber system using carbon more efficiently and thus saving in operational costs

- Made of stainless steel 1.4404

- Including measuring ports with couplings to monitor the load

- Insulation, carbon filling, air dosing and gas pre-heating optional

- Made in Austria

BIOLOGICAL DESULPHURISATION SYSTEM BDS

-

Biogas and landfill gas always contains hydrogen sulphide (H2S). Usually, this is in the range of 1,000 to 6,000 ppm but may also reach 2% Vol or more. This H2S frequently needs to be removed from the gas – either for reasons of environmental protection or because of the corrosion hazard. The EnvironTec desulphurisation process offers a cost-effective yet highly efficient solution for this task. At the core is a biological process requiring no chemicals and almost no consumables. When a limited amount of air (app. 10 - 15% in relation to the gas throughput) is added, special bacteria (e.g. Thiobacillus) convert the H2S to elementary sulphur and sulphuric acid.

These bacteria only need:

- Oxygen

- Nutrients and trace elements ( NPK886)

- Growing surfaces

Oxygen is added in the form of pressurised air. The automatic controller adjusts the amount of air to the current demand in correlation with the amount of gas. Synthetic fertiliser (NPK886), which is available in all countries around the world, is used to supply nutrients and trace elements. The system is built to VDI directive 3478 and the currently applicable ATEX regulations.

APPLICATION AREAS

- Communal or industrial sewage treatment plants

- Chemical industry

- Paper industry

- Landfill sites

- Food industry

- Agriculture

CERAMIC FINE FILTER FF

-

Fine filters are used for the fine purification of sewage gas/biogas. This allows the separation of fine particles ≥8 µm as well as condensate vapour resulting in the availability of gas for further use that is free of foreign matter to the greatest possible extent.

EnvironTec fine filters are fitted with filter candles made from Pantel (special fire clay). As the gas flows through the filter candles from the outside to the inside foreign matter is separated out on the outer wall. The filter material used is chemically resistant/neutral, has a high filtration performance coupled with a low pressure loss and is easy to clean with pressure washers.

Any condensate build-up can be drained via an optional siphon or condensate separator. If required, the fine filters can also be fitted with differential pressure gauging (U-tube or individual pressure gauges). EnvironTec fine filters are entirely made from 1.4404 stainless steel

APPLICATIONS AND SPECIFICATIONS

- Gas purification by removal of solid particles and condensate vapours

- Filtration rating: ≥8 µm

- Optionally available with differential pressure gauging, water level indication and condensate drainage

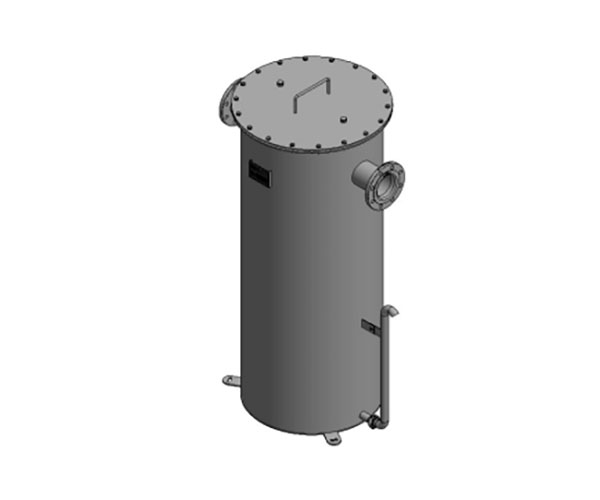

GRAVEL FILTER GF

-

Biogas from fermentation vessels or biogas reactors is saturated with water and partially loaded with dirt particles. In addition, foam may enter the pipeline system.

The EnvironTec GF gravel filter ensures the simple coarse cleansing of the biogas. The gas flows through a gravel filter layer during which process dirt, foam and condensate droplets are separated out. In the case of normal debris levels, the gravel can be cleaned by water injection via the cleaning nozzles or by flushing without the need to open the filter.

EnvironTec offers gravel filters for different flow volumes and pressures. The gravel filter can optionally be fitted with a gravel removal flange as well as differential pressure gauging. EnvironTec gravel filters are entirely made from 1.4404 stainless steel.

- Removal of coarse particles and foam from biogas/sewage gas

- Condensate separation

- Flashback protection device

- Low maintenance

- Optional differential pressure gauging and gravel removal

- Entirely made from 1.4404 stainless steel

- Made in Austria

APPLICATIONS AND SPECIFICATIONS

- Gas coarse cleaning of fermentation gas or biogas plants

- Made from 1.4404 stainless steel

- Optional equipment available

GAS CHILLER GC

-

Biogas, sewage gas and landfill gas always contain water vapour in an unsaturated state. During combustion, the water vapour results in considerable corrosion damages to the gas engines and turbines. Malfunctions caused by these damages lead to significant downtimes and high repair costs. The use of a gas dehumidification system can considerably extend the engines’ service life and notably reduce the maintenance costs. The condensation of the water vapour in the gas is caused by temperature reduction which in turn results in a dehumidification. The con-densate is separated out in a trap installed after the chiller and removed via a siphon. The de-humidification simultaneously results in an increased efficiency.

The EnvironTec gas de-humidification process presents a cost-effective solution in this context. The gas dehumidification modules are available in performance ranges offering gas flow rates from 100 to 6000 Nm³/h. Special designs are also available on request. Additional application examples are configurations in combination with a post-heating stage ahead of active carbon filters and feeding into a gas pipeline to prevent subsequent condensation. For additional energy savings the gas dehumidification can be enhanced with an extension module comprising an air cooler and a tubular heat exchanger.ATEX regulations.

APPLICATION AREAS

- Communal or industrial sewage treatment plants

- Chemical industry

- Paper industry

- Landfill sites

- Food industry

- Agriculture

CONDENSATE POT CP

-

Sewage gas / biogas is gas that is saturated with water vapour. In fermentation gas plants and their pipeline systems there typically is a build-up of condensed water caused by temperature effects. Condensate can lead to blockages at low points and deposits, corrosion, etc. in pipe sections.

The EnvironTec condensate separator for low-point water drainage effectively and safely collects and removes condensed water from the pipeline system. Condensate pots are usually installed directly in the pipeline but can also be flanged below low-lying points of the pipeline. The water condensed out accumulates on the container walls or the separation wall and is collected at the bottom of the container.

Removal is manual via a ball valve or automatic via a siphon or an automatic condensate separator. An optional fill level indicator or sight glass are also available. The system is available in different sizes and specifications (basic specification, semi and fully automatic). EnvironTec condensate separator pots are entirely made from 1.4404 stainless steel.

- Effective removal and collection of condensed water

- High storage capacity

- Low pressure loss

- Optional automatic condensate separator

- Optional fill level indicator/sight glass

- Easy cleaning

- Condensate pot entirely made from 1.4404 stainless steel

- Made in Austria

APPLICATIONS AND SPECIFICATIONS

- Condensate collection/removal in pipeline systems of fermentation gas plants

- Body made from stainless steel 1.4404

- Condensate drainage manual or via siphon or separator pot

GAS STORAGE

-

We offer a wide range of gas storage variants, such as double membrane gasholder and pressureless gas holder.

As an international player in the field of environmental technology with worldwide export activities, our company has a range of different gas storage variants in its program in order to be able to supply a tailor-made solution for every order.

Double membrane gasholder DM

-

A storage tank is used to store biogas and sewage gas. This container consists of two membranes. The outer membrane is a protective structure and is always under an overpressure required for structural integrity. The processes inside the storage tank can be observed at all times through a inspection glass built into the outer membrane.

The actually usable storage tank is the inner membrane. This membrane move up or down depending on the filling level. In gas storage tanks with a foundation plate, the bottom membrane seals the storage space from the concrete foundation. The membranes are attached to the foundation using the anchor ring. An individual calculation is made for each storage tank (internal pressure, wind and snow loads). As a result, we select membranes with high or low tear resistance. The PVC-coated membranes are flame-resistant in accordance with DIN 4102 B1, fungicide treated and fitted with extended UV protection.

To protect the membranes from the substances contained in the biogas (CH4, CO2, H2S etc.), the inner and bottom membranes have a special coating .

As a safety measure, a pressure control valve, which regulates the operating pressure and closes automatically in the event of a minimum required overpressure (static stability, failure of the fan) in the outer membranes, is installed in the air system. This device ensures that the storage tank remains stable during gas production. The fill level gauging enables optimum utilisation of the storage volume and the control of the subsequent devices (e.g.: flare, motor, burner, etc.).

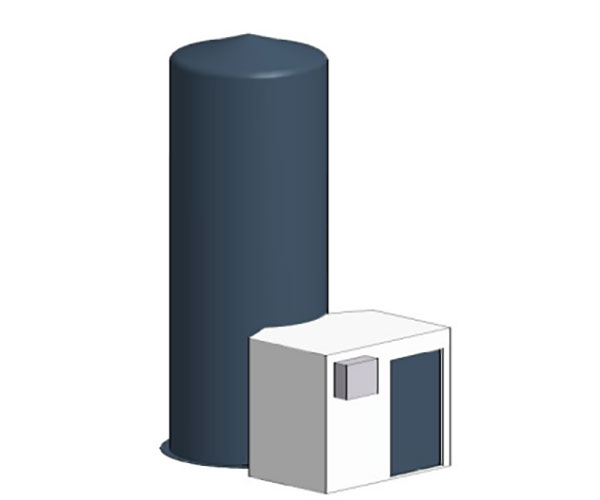

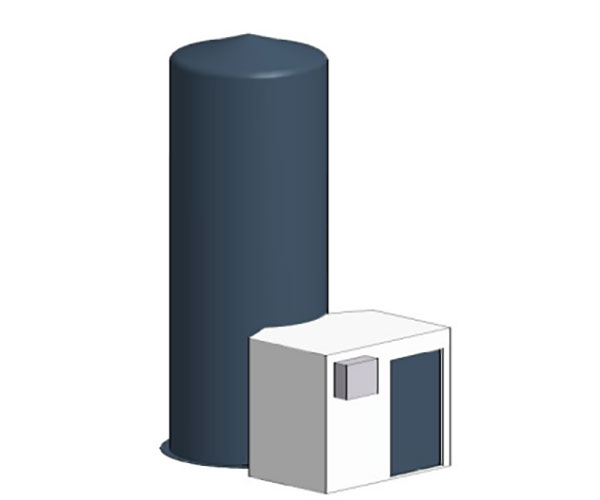

Pressureless gasholder TG/TGZ

-

EnvironTec has 2 non-pressurized gas storage systems, which differ in principle in the type of housing construction.

The TG model consists of a galvanized sectional steel construction which is clad with trapezoidal sheet metal.The TGZ model consists of a prefabricated metal silo made of galvanized corrugated steel sheet segments with laterally attached stiffening profiles and a conical roof. The storage membrane is made of high-quality, leak-tested, UV-resistant PES with a PVC coating, which is fungicide-inhibiting and flame-retardant in accordance with DIN 4102 B1. The membrane is completely self-contained and is mounted free-standing in the tank.

It is attached to the conical tip of the housing and to the base of the gas bags with a stainless steel connection flange (material no. 1.4571).

A protective floor mat is applied to the concrete foundation to protect the storage membrane.

The gasholders are equipped with hydraulic overpressure/underpressure protection, a mechanical pressure relief valve, as well as an optical fill level indicator and an underpressure monitor.

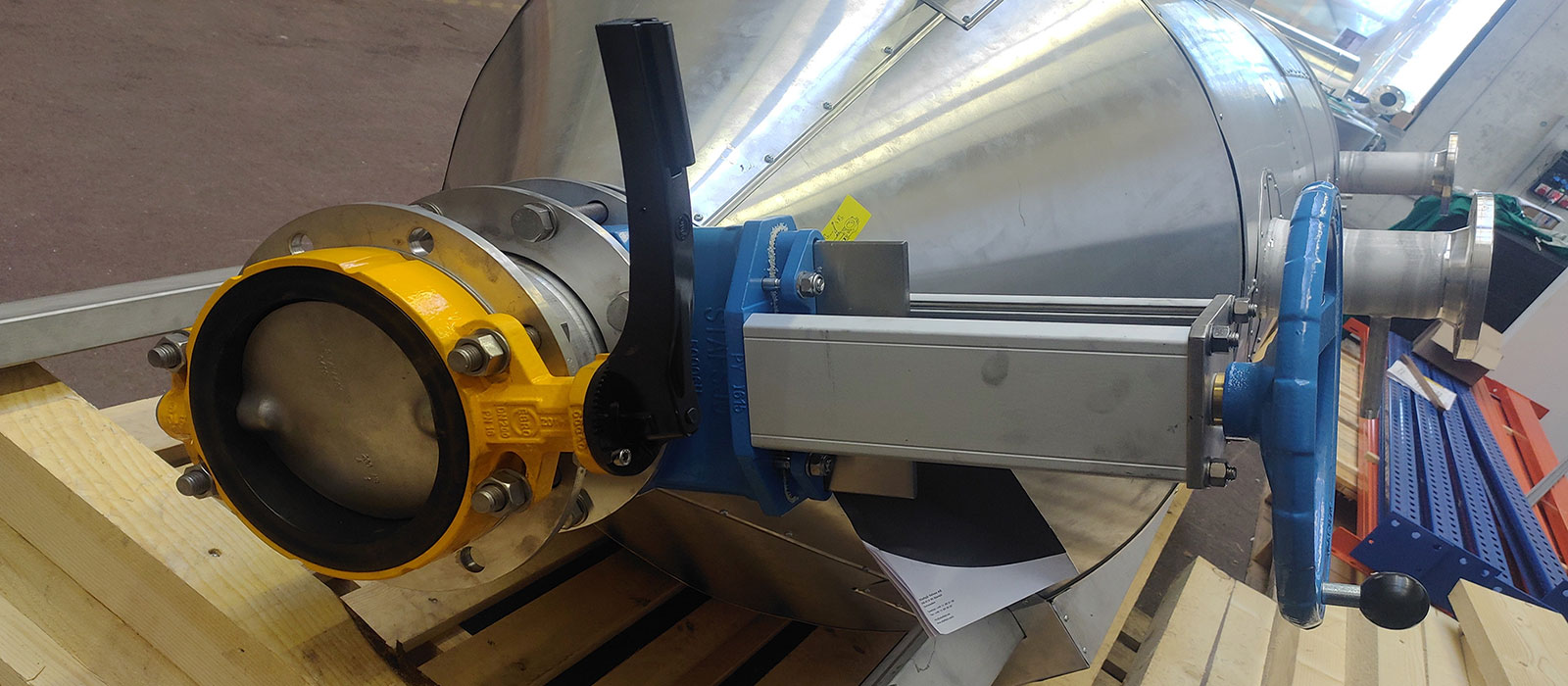

Gas compression

-

EnvironTec provides you with single or replacement units from leading international manufacturers for a capacity of 50 to 5000m³/h or pressures from a few millibars to 0.5 bar generation.

EnvironTec not only provides individual units, but also delivers complete plug-and-play manufactured container compression systems, which are used in biogas/biomethane and/or landfill applications.