- Offer Profile

- Our product range

supplemented with agency products from other leading, world class

manufacturers – is completed by related services such as the design and

installation of pump plants, oil spill recovery and after sales service

through our network of service centers.

In order to meet future customer demands for more complete systems, including DESMI pumps, we are providing solutions and systems as well as single standard pumps or components. With focus on the individual needs from our customers we are providing solutions based on proven technology.

Marine and Offshore

-

DESMI is your preferred supplier of reliable and high-quality engine room pumps and pumping solutions.

Our pump range covers all marine applications and ensures a trouble-free operation with low energy consumption and high performance.

Engine Room Pumps

-

High-efficiency & Reliable Marine Pump Solutions Thousands of DESMI pumps are at work on the seven seas, and these pumping solutions are living proof that our customers are satisfied with the performance of our products.

For more than 50 years we have supplied marine pumps to the world's fleet - from the largest container ships to the smallest fishing vessels. Regardless of the size of the ship we know the owners' demands for many years of trouble-free operation.

Complete pump packages

The complete pump packages have been designed to meet the customer’s requirements regarding reliability and high system efficiency.

Ballast Water Management

-

DESMI OCEAN GUARD A/S

specialises in the development, manufacturing, sale and service of IMO and USCG certified Ballast Water Management Systems. The mission is to deliver systems that reliably meet the IMO and USCG discharge standards, with the lowest total cost of ownership.Since its establishment in 2009 DESMI Ocean Guard has developed three type approved Ballast Water Management Systems (BWMS), with the most recent one being the CompactClean BWMS.

Scrubber Pumps

-

Market Leader at both Sea and Land One component, in particular, needs to be carefully selected to ensure safe and efficient sulphur removal. The Pump!

DESMI has manufactured pumps and pumping solutions for more than a century and in recent years our expertise in pumps for scrubber solutions has increased significantly, which makes us a unique partner for delivery of pumps for scrubber systems for all types of vessels and landbased applications.

FineFog™ - Fire Fighting

-

DESMI has supplied water-based firefighting solutions to all kinds of vessels around the globe. Benefits of the Fixed Water-Based Fire-Fighting Systems:

- Up-to-date development ensures rule compliance and system reliability

- High-efficient fire extinguishing or suppression

- Quality components used through system design

- Easy service, maintenance and trouble shooting due to modular design

- Compact design, small pumps, pipes, tanks and etc.

- Low water flow rates/water consumption

- Low installation, operation and maintenance costs

- World-wide service and technical solution support

OptiSave™

-

Optimizing Pump and Fan Speed to Current Conditions and Saving Fuel

The benefits of DESMI OptiSave™

Easy and fully automatic operation

- Energy saving up to 90%

- Short return on investment

- Prolonged lifetime of pumps due to less wear and tear

- Minimum changes in existing electrical installations

- Proven savings from +575 systems in operation

- Reduced OPEX

- Worldwide service support

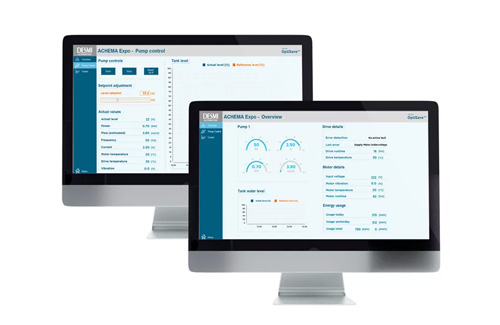

Automation

-

With DESMI Automation you get a solution that increases efficiency, competitiveness and enables you to meet future challenges with a green and sustainable profile.

With continuous development of our range of automation solutions, when installing pumps and pumping solutions around the world, we extend our optimization expertise to a range of other applications, where automation can make a difference.

Methanol Pumps

-

DESMI's high-efficient & reliable Methanol Pumps are revolutionising the safe handling of alternative fuels. Due to its seal-less design, the mag-drive pump is the perfect match when handling new marine fuels, as they can be environmentally sensitive.

The quest for greener alternatives to traditional fossil fuels is essential, yet it comes with its own set of challenges. New fuel types such as methanol are often toxic or hazardous, necessitating stringent isolation measures and double-walled piping systems.

Insulated composite cannister, designed to eliminate eddy loss, and ensure low power consumption. High-quality material and optimal structure secure the pump maximum working pressure up to 16 bar. With its compact design and small footprint this pump offers convenient and flexible installation, particularly in enclosed spaces. Built-in PT100 allows for monitoring of coupling temperature risk. Leakage probe option can be used to detect any leaks from the cannister.

Scrubber Pumps

-

Today DESMI is working together with the world's biggest suppliers of scrubber solutions and some of the reasons why they prefer DESMI are:

- Highest efficiency in class

- Reliable stainless steel pumps

- Installations worldwide

- Short delivery time

Harbour Pumps

-

Enhance port operations with DESMI's HT Harbour Pumps, ensuring optimal heating for main engine during port stays and effectively reducing power consumption.

Save energy with a dedicated harbour pump for heating

• Reduce yearly operating hours on main circulating pumps

• Endorsed by engine builders for reliability and efficiency

• Lower power consumption in port for cost savings and reduced CO2 emissions

DESMI marine pumps

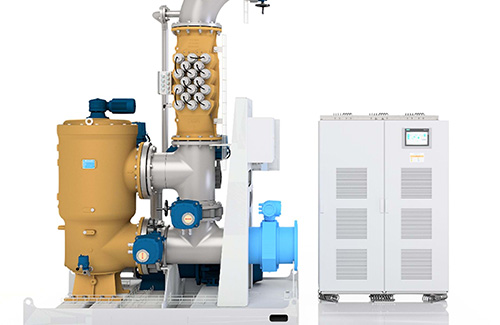

OptiSave™ - Energy Saving System

- Intelligent control of your cooling water system

With DESMI OptiSaveTM Energy Saving System it is simple - save 80,000 USD by having an intelligent control of your cooling water system

The cooling water system on-board vessels is designed for operation in 32°C seawater and 100% engine load and the auxiliary equipment runs as if this condition is permanent.

However, the seawater temperatures of the oceans are not 32°C all over the world. Actually, there are only few hotspots where these conditions are present. This means that the cooling system in 95% of operatio- Energy saving up to 90%

- Short return on investment

- Prolonged lifetime of pumps due to less wear and tear

- Minimum changes in existing electrical installations

- Proven technology

- Reduced OPEX

- Worldwide service support

n time are absorbing too much energy.

CompactClean - Ballast Water Management System

- Compact Ballast Water Management System

Looking for a ballast water management system that can be installed easily and without relocating other equipment? CompactClean is the answer.

- Only system in the world with integrated stripping solution

- Filter and UV unit in seawater resistant Nickel-Alu-Bronze

- Automatic flow control and lamp dimming

- Worldwide service network

- Fully automated operation

- Graphic HMI touchscreen interface

- Automatic generation of PDF reports to authorities

- Short delivery time

- Easy maintenance

- No salinity or temperature limitations

- Down to UV Transmission of just 42% - Also in US Territory!

- 100% chemical free treatment

NSLV-R & NSLH-R Centrifugal Pump with Inducer

-

End suction centrifugal pump with inducer.

Up to 6,200 m³/h (27,300 US gpm)The DESMI NSLV-R & NSLH-R pumps are designed for vertical and horizontal mount and meets the special marine and industrial market requirements.

Marine & Offshore:

- Condensate & Drain Transfer

- Seawater Supply & Cooling

- Bilge & Ballast

- Main & Emergency Firefighting

- Water Spray & Deluge Firefighting

- Foam Firefighting

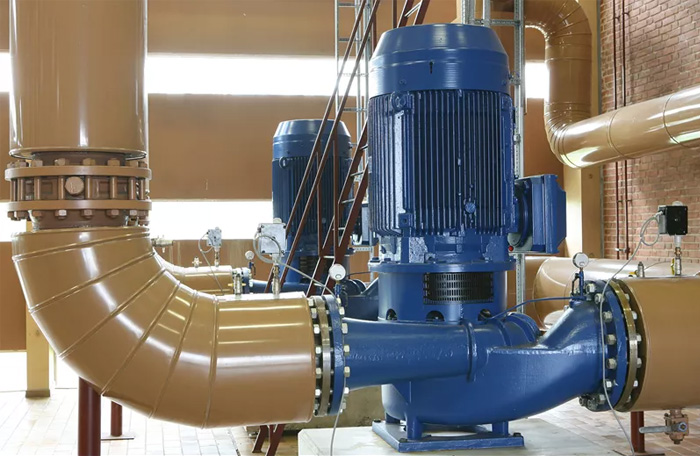

NSL Centrifugal Pump

-

Vertical In-line Centrifugal Pump Up to 1800 m³/h (7900 US gpm)

The NSL range of pumps represents high efficiency, low NPSH values, easy to installation and low maintenance. The NSL series is widely used within different applications and markets.

Within the marine industry the pumps are suitable as:

- Fresh and seawater cooling pumps

- Bilge and ballast pumps

- Fire-fighting

- General service pumps

- Transport of slightly aggressive liquids with low viscosity such

as diesel and lubricating oils.

NSLV Centrifugal Pump

-

End suction centrifugal pump with horizontal inlet Up to 1800 m³/h (7900 US gpm)

The DESMI NSLH pumps are designed for horizontal mount and meets the special marine and industrial market requirements.

Applications:

- District heating/cooling

- Sea water

- Water circulation

- Cooling towers distribution

- Chiller distribution

- Diesel transfer up to 500 cSt.

- Scrubber (flue gas cleaning).

NSLH Centrifugal Pump

-

End suction centrifugal pump with horizontal inlet Up to 1800 m³/h (7900 US gpm)

The DESMI NSLH pumps are designed for horizontal mount and meets the special marine and industrial market requirements.

Applications:

- District heating/cooling

- Sea water

- Water circulation

- Cooling towers distribution

- Chiller distribution

- Diesel transfer up to 500 cSt.

- Scrubber (flue gas cleaning).

DSL Centrifugal Pump

-

The in-line DSL double suction centrifugal pump Up to 5400 m³/h (23800 US gpm)

The DSL pumps are single-stage, double-suction, vertical, centrifugal pumps. The design of the suction side provides for a perfect flow, and the inlet is placed in line with the outlet.

Applications:- District heating/cooling

- Seawater

- Water transport or circulation

- Cooling towers distribution

- Chiller distribution

- Scrubber (flue gas cleaning).

ESL Centrifugal Pump

-

High-Efficiency Vertical in-line centrifugal pumps

The ESL Centrifugal Pump is designed for high efficiency, low NPSH and is installation and service friendly. The ESL is widely used within different applications and markets.

Application:- Hot water circulation

- Fresh water circulation

- Refrigeration

- HVAC

- Hydrophore pump

- Cooling water

- The pump can be equipped with an air-driven or electrically driven priming device.

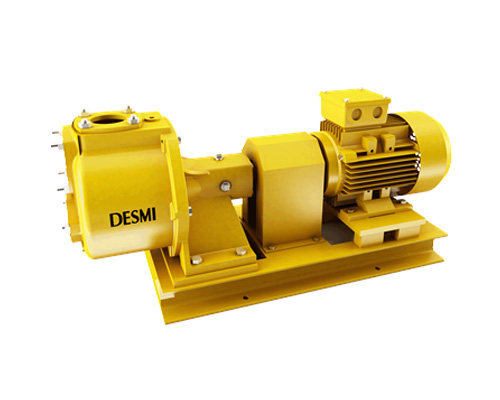

Modular S Centrifugal Pump

-

Self-priming Centrifugal Pump Up to 400 m3/h (1760 US gpm)

The Modular S Centrifugal Pump represents one of the most distinctive products of self-priming pumps. On the basis of 50 years of experience in the production of self-priming pumps we produce a pump series that meets the future demands for economical and reliable pumps. The Modular S is widely used within different applications and markets.

Marine pumps- Bilge pump

- Ballast pump

- Fire pump

- Cooling-water pump

- Wash-deck pump

- General service pump

VAC Centrifugal Pump

-

A new generation of dirty water vacuum pumps

A new generation of dirty water vacuum pumps, based on the principle of the liquid ring system. This compact pump combines all performances of diaphragm, piston and centrifugal pumps and will pump continuously, by means of the specially developed rotor, on liquids, air or gasses in any mixture.

Applications:- (Emergency) bilge pump

- Bilge-ballast pump

- General service pump

- Vacuum pump

- Gland-leaking water pump

- For chemical industries

- Draining holds

- Emptying vessels

- Well point systems

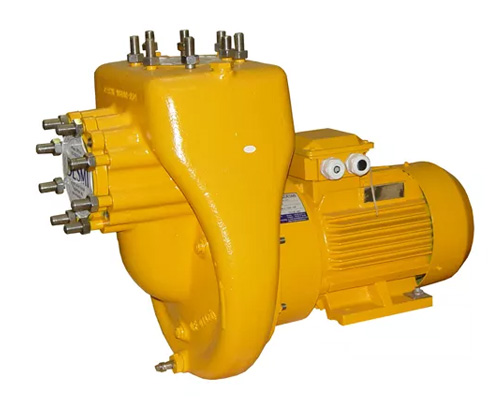

NSA Centrifugal Pump

-

Close coupled self-priming centrifugal pump

is a totally renewed design based on the original “K&R” models. However fully 10141able with former types, in dimensions as well as capacities.

Applications:- Bilge pump

- Ballast Pump

- General service pump

- Emergency fire pump

- Cooling water pump

SA

-

The DESMI SA self-priming centrifugal pump Up to 650 m3/h (2900 US gpm)

The diffuser principle in the self-priming DESMI SA centrifugal pump means that the priming capacity is not dependent on valves or other mechanical elements since it is the liquid flow which carries the air.

Within the marine industry the pumps are suitable as:- Bilge pumps

- Ballast pumps

- Fire pumps

- Cooling water pumps

- Wash-deck pumps

- Fuel pumps

- Wellpoint pumps

- Irrigation pumps

- Circulation pumps

ESLH Centrifugal Pump

-

End suction centrifugal pump with horizontal inlet DN 25-100, Up to 200 m³/h

High-Efficiency Vertical In-line and End-suction Single-stage Centrifugal Pumps

Applications:- Hot water circulation

- Fresh water circulation

- HVAC

- Hydrophore pump

- Cooling water

and water, water with additives, seawater and oils up to 500 cSt

Cargo Pumps

-

Deepwell Cargo Pumps for LPG, LEG, Chemical and CO2 Tankers

The NDW pumps from DESMI are energy efficient and well proven for pumping every media from LPG, to LEG over a wide range of chemicals, through to CO2. The pump consists of three main components: base arrangement, pipe and pump cylinder. The cylinder is designed with a variable number of impellers and casings to meet the required head and capacity.

The pipe stack consists of a number of intermediate pipes in which the cargo is transported to the outlet flange of the base arrangement. The intermediate shaft, which drives the impellers, is placed in the centre of the pipe stack. The shaft is supported by guide bearings for each 1.2 metres / 4 ft, which is also the length of the intermediate pipes in the pipe stack. The bearings are made of carbon and are lubricated by the cargo.

ROTAN® GP Internal Gear Pump

-

Simple and compact construction for non-abrasive liquids

General Purpose Internal gear pumps in cast iron, for clean, non-abrasive liquids. The simple and compact construction makes it a low-cost pump, often used in modified versions by OEM customers.

Pumping of:- Clean oil

- Glycol

- Vegetable oil

- Solvents

DESLUBE Lubrication Oil Pump

-

Submerged lubrication oil pump

The DESLUBE series is a submerged deep well pump designed for Main Engine Lubrication oil supply for especially large two-stroke engines. The design is based on our long time experience of manufacturing deep-well pumps as well as the design features from our in-line centrifugal series

Advantages:- Low NPSH

- Low noice or vibrations

- Low maintenance costs

- High reliability

- High flexibility

Mobile Fire & Emergency Pumps

-

Mobile Fire & Emergency Pumps Mobile and stationary diesel-driven bilge pump units

These pump units are made to comply with the demands of the marine industry as regards materials, design, and ease of handling.

All DESMI's mobile pumps are in compliance with the Danish Maritime Authority's requirements for portable emergency fire pumps in fishing and cargo vessels together with P-vessels.

NSL Stainless Steel

-

Vertical In-line Centrifugal Pump in stainless steel DN 65 to 400, Up to 1800 m3/h

Market Leader at both Sea and Land

The DESMI NSL stainless steel pump meets the special marine and industrial market requirements:

DESMI has manufactured pumps and pumping solutions for more than a century and in recent years our expertise in pumps for scrubber solutions has increased significantly, which makes us a unique partner for delivery of pumps for scrubber systems for all types of vessels and landbased applications.- Aggressive fluids

- Sturdy design

- Low NPSH values

- Easy installation/service

DESMI Priming Ejector

-

Designed for mounting on non-selfpriming centrifugal pumps

The DESMI priming ejector is designed for mounting on non-selfpriming centrifugal pumps thus making the pump unit self-priming. In order to make the unit work, the delivery pipe has to be shut off, e.g. by means of a non-return valve

Compressed air will flow through the ejector and create a vacuum in the pump casing and suction line. After priming, the pumps will build up pressure in the discharge line which will activate the presure switch. The presssure switch then disconnect the power to the solenoid valves and the priming stops automatically.

At a fluid pressure of e.g. 10 m / 33 ft total head the unit will disconnect automatically (adjustable from 3 - 100 m / 10 ft - 328 ft total head). If the pressure drops to less than 10 m / 33 ft total head, the unit will automatically start functioning until a counter pressure has been reestablished.

B114N DESMI priming pump

-

The DESMI B114 priming pump is driven by its own electric motor

The DESMI priming pump is designed for mounting on non-selfpriming centrifugal pumps thus making the pump unit self-priming. In order to make the unit work, the delivery pipe has to be shut off, e.g. by means of a non-return valve.

The filter prevents solids from penetrating the priming pump, and the non-return valve (H) secures that back flow is avoided when the priming pump is stopped.

If the main pump has positive suction head the solenoid valve stops water from running through the priming pump unexpected when the pump and priming pump are stopped.

The priming pump is provided with a supplementary tank at the discharge side of the priming pump which has to be filled with water prior to starting the system. During priming, the air escapes while the water circulates in the pump procuring sealing and cooling.

DESMI Vertical Pumps DP

-

Vertical Mulitstage Centrifugal Pumps

The art of transporting water is finding the right solution, with maximum efficiency, for each situation. The DPV series of vertical, multistage, centrifugal pumps is the result of 55 years of experience and the pumps can be used for numerous applications.

Applications:- Domestic water supply

- Utility

- Cooling water transport

- Hot water applications

- Fire fighting

- Food, chemical and process industry

- Irrigation

Applications

-

The natural choice for high-quality pumps and pumping solutions

Thousands of DESMI marine pumps at work on the seven seas have proved our customers' satisfaction with the performance of our pumps.

Having supplied marine pumps for decades we know the owners' demands for many years of trouble-free operation.

Ballast Pumps

- Ballast pumps are crucial for the operation of most vessels. They pump water in and out of the ballast water tanks during loading, off-loading and trim of the vessel. The pumps often require low NPSHr and high flow. Pressure can be increased if a Ballast Water Treatment System is installed.

Ballast Stripping Pumps

- In most cases ballast pumps will not be able to completely empty the ballast water tanks. In order to do this a ballast stripping unit is required. This unit should have good priming capabilities and low NPSHr.

Base Oil Pumps

- Base oil is a thin oil used in the offshore industry to mix with drilling mud. The application is only used on offshore vessels like rigs and offshore supply vessels.

Bilge Pumps

- Bilge pumps play a vital role in the operation of vessels - both in the daily use and in case of emergency. After cleaning or repairwork inside the engine room, some water or other liquids will run into the bilge wells. These wells are then emptied by means of a bilge pump. As the water may contain oil it needs to be cleaned before pumping overboard. For daily use a small pump will handle the task, however, when an emergency arise it may be necessary to use an emergency bilge pump. In such cases one of the SW cooling pumps, a ballast pump, a fire pump or a general service pump can be used and thus serve a dual purpose.

Boiler Feed Pumps

- Most vessels have one or more boilers onboard for different applications such as exhaust gas or oil fired boilers. If the boiler is filled with water it is recessary to re-fill it with water when steam is leaving the boiler. For this purpose a boiler feed water pump is needed.

Brine Pumps

- Brine pumps are used to pump cold brine in a closed circuit from the evaporator that creates the cold to the cooling surfaces where the cold is needed. This could be in a HVAC system or a fish freezing system. The brine is often filled with e.g. salt which allows the brine to be cooled down to below the normal freezing point of water. This high content of salt gives the brine a very high density which can be as much as 2.5 kg/litre.

Drill Water Pumps

- Drill water pumps are only applied by the offshore industry. Drill water is used during the drilling of the oil well. The liquid can be both seawater as well as fresh water dependent on the rig arrangement.

Emergency Fire Pumps

- The worst thing that can happen to a vessel - besides going down - is fire. In the event of fire it is crucial that sufficient water is available at sufficient pressure in order to be able to extinguish the fire. For this purpose several fire pumps are required.

Fresh Water Cooling Pumps

- A lot of equipment onboard a vessel generates heat which needs to be removed, and a good way to do this is to cool it with water. This could be the case for thruster units, hydraulic units, cooling units and many other types of equipment. Fresh water is used to remove this surplus heat.

Inert Gas Cooling / Scrubber Pumps

- Inert gas is used onboard tankers with flamable cargo. It is pumped into the tank to 10141 the atmospheric air as this contains oxygen which can make the cargo ignite. Inert gas can be nitrogen from a nitrogen generator or exhaust gas from a inert gas generator where fuel has been burned using the oxygen. However, after the burning the inert gas needs to be cooled.

Lubrication Oil Pump

- The main engine needs a continuous flow of lubrication oil to lubricate all parts inside the engine and to cool the lower side of the pistons. Without these pumps the main engine cannot operate.

Main Engine Preheating Pumps

- Main engine preheating pumps are only in operation when the main engine is not running. The purpose of this system is to keep a constant, high temperature in the main engine in order to avoid unnecessary heat and cold contractions and thus keep the engine ready to run at all times.

Sludge/Dirty Oil Pumps

- Sludge is residue from purifiers after the lube and fuel oil have been purified. The sludge or dirty oil is stored in a tank from where it is being removed when the tank is full. The pump has a low amount of running hours.

Seawater Cooling Pumps

-

A seawater cooling pump takes suction from the sea chest, pumps the seawater through the central FW cooler(s) and then overboard.

The system can be designed with two or three pumps. The pumps are crucial for the operation of the vessel and they are always running.

Sewage Pumps

- Sewage from the accommodation is handled by a special system where the sewage pump is a important part.

New Green Solutions

-

With over a century of expertise in pumping solutions, DESMI's New Green Solutions are committed to leading the journey towards a sustainable future. While we recognize that the path to complete green solutions is a continuous process, we are dedicated to making significant strides in this direction.

Our advanced pumping solutions for green fuel ships, such as those powered by methanol, and our innovations in Power-to-X applications are the first steps in our broader vision for a greener planet.

These solutions are examples of our commitment to achieving this vision:

- GREEN FUEL PUMPS

- LIQUIFIED GAS CARGO PUMPS

- BALANCE-OF-PLANT PUMPS

AquaCulture - AquaCulture and Fish Farming

-

AquaCulture, commonly known as fish farming, is a pivotal industry for meeting global seafood demand, involving the breeding and harvesting of aquatic organisms. DESMI provides AquaCulture solutions, specialising in high-quality recirculation AquaCulture pumps integral to Recirculation AquaCulture Systems (RAS).

To support the fish farmers in achieving this goal, DESMI offers a One Stop Shop for AquaCulture and offers highly energy-efficient and reliable pumping solutions, including UV Treatment System for the vessel and land-based fish farming markets.

Explore the world of DESMI’s AquaCulture pumps and solutions and discover how our expertise can elevate your fish farming operations to new sustainable heights. Dive into our range of products, learn more about our innovative approaches, and connect with us to tailor the perfect solutions for your AquaCulture needs.

Defence

- DESMI Miltary Pumping Systems used by military forces and navies around the globe & Navy Ships providing pumping solutions for military applications

Products

-

Military off the shelf pumps

The extensive range of DESMI standard pump models can be quickly adapted to meet military specifications especially in the marine sector.

DESMI is a major force in the development of new products and systems meeting the latest civilian standards in a military environment

Shock Rated Pumps

-

Pumps for installation in a shock rated environment

All DESMI centrifugal pumps are available in shock rated design. The pumps are made to survive and it is crucial that these pumps are working in order to bring the sailors back home safely. They are made to withstand shock and remain in operation both before, under, and after a shock impact.

Ship Based Helicopter Refueling Systems

-

Refueling & Transfer Systems - Complete System Provider. The DESMI systems are intended for use in both the military and commercial sectors.

We are a preferred supplier of systems for fixed and rotary wing aircrafts as well as for ground vehicles and static equipment.

Each system is specifically designed for pumping, filtering and dispensing of fuel for military and naval use. The ship based helicopter refueling system is used for pressure and gravity fueling of aircrafts on board Naval Vessels, and the system is also fitted with a facility to defuel the aircrafts.

Emergency Fire Pumps

-

Engine driven pumps comes in a broad range of different executions suitable for a diverse range of special applications for both ship based operations or as transfer capacity on ground.

Shock Rated Diesel-driven Emergency Fire Pump

These pump units are designed to withstand the rough life at sea and to be ready for action at all times. Even after the ship has been exposed to shock. Capacity is 100 m3/h at 7 bar

Fuel Transfer System

-

Our extensive pump range in either stainless steel or cast iron material is the preferred solution for land based fuel handling applications.

Pumps for example for air field installations can be temporary installed with a diesel driven self-priming standalone unit, or a more permanent installation with an electrical driven vertical execution for high efficiency.

Industry

-

DESMI offers customised pumping solutions for challenging media in the process industry.

The industrial pumping solutions is covered by both ROTAN® internal gear pumps and energy efficient DESMI Centrifugal pumps.- PUMPS FOR ASPHALT & BITUMEN

- CHOCOLATE PUMPS

- AQUACULTURE & FISH FARMING SOLUTIONS

- PUMPS FOR DESALINATION

- FIRE FIGHTING SPRINKLER SYSTEMS

- PUMPS FOR OIL BLENDING, ISOCYANATE, PAINT, SOAP & SUGAR

ROTAN® – Internal Gear Pumps

-

The ROTAN® internal gear pump provides favourable flow conditions, as the direction of the liquid flow is only changed slightly through the pump.

The internal gear pump principle was developed in 1915 by a Danish American. In 1921, he licensed a Danish company to manufacture the pumps, which have been continuously marketed worldwide under the ROTAN® name.

Geared to individual solutions

The ROTAN® internal gear pump provides favourable flow conditions, as the direction of the liquid flow is only changed slightly through the pump.

Industry and Utility

-

The business areas covered within the utility segment include energy efficient pumps and pump solutions for:

- District Heating

- Combined Heat & Power Plants, Cogeneration/Tri-generation, Biomass Plants. Waste-to-Energy Plants etc.

- District Cooling

- Medium/Larger HVAC – chiller & cooling tower applications etc. (Airports, Datacenters, Skyscrapers, Hotels, Shopping Malls etc.)

- Power Generation (various types of power plant applications)

- Leisure Industry (larger municipal/private pools, aqua parks)

- Waste Water

PRODUCTS & SOLUTIONS

PRODUCTS & SOLUTIONS

- Energy efficient and reliable pump solutions for Leisure Industry and district central heating/cooling. In brief DESMI's pump competences include pump solutions for CHP Plants, Transmission & Distribution Networks, Substations etc.

Applications

-

The business areas covered within the utility segment include energy efficient pumps and pump solutions for:

- District Heating

- Combined Heat & Power Plants, Tri-generation etc.

- District Cooling

- Medium/Larger HVAC – chiller & cooling tower applications etc.

- Power Generation (various types of power plant applications)

- Leisure Industry (larger municipal/private pools, aqua parks)

- Waste Water

District Heating

-

District Heating is an energy distribution network

- that transports heated water generated in a centralised utility through piping to residential homes and commercial buildings primarily in urban areas. District Heating is clean, efficient and cost-effective due to its flexibility, scale of production and optimal heat generation conditions. DESMI provides energy efficient pump solutions both for applications in the heat production plants as well as for the transmission and distribution network.

District Cooling

-

District Cooling is an efficient and environmentally friendly utility service

- which provides chilled water from a centralised cooling plant (or cold water from the sea) through a network of pipes to multiple residential, industrial and commercial buildings for air conditioning purposes. District Cooling is 40% - 60% more energy efficient than conventional systems - and reduces CO2 emissions.

DESMI provides energy efficient pumping solutions for water intake (e.g. seawater) and centralized cooling plants (condenser pumps, chilled water pumps as well as pumps related to cooling tower applications). The DESMI pump solutions are recognized as being highly energy efficient with low NSPH values. The pumps have a long life cycle and are very maintenance friendly

Sprinkler Systems

-

DESMI offers dimensioning and guidance when complete units for fire protection, including electronic control, are supplied.

All solutions are in accordance with national as well as international fire-fighting regulations.

The units can be supplied as a permanent containerized solution or as a transportable unit and are proven according to the following standards:

- DBI 25 I / 400 I

- EN12845

- CEA 4001

- NFPA20

- FM

- VdS

Waste Water

-

Transport and treatment of waste water are important tasks in a modern society

The waste water must be transported from residential areas and industrial companies to the waste water treatment plant, that need to optimise the way it treats wastewater with the least possible impact on people and nature.

Transportation of waste water is full of challenges. Energy optimisation, design, installation and maintenance are just some of the issues that must be addressed when establishing such systems. The waste water must be transported from residential areas and industrial companies to the waste water treatment plant, that need to optimise the way it treats wastewater with the least possible impact on people and nature.

Leisure Industry

-

DESMI has many years of experience in the swimming pool/public baths (aqua parks) industry.

To ensure low energy consumption and pumps with high efficiency levels, we have developed new, highly effective, all bronze swimming pool pumps at reasonable prices.

Bronze is the best material

The choice of all bronze is very deliberate. Bronze is definitely the best material when it comes to pumping chlorinated water. The efficiency remains virtually unchanged throughout the pump's lifetime, and since it is substantially higher for the new pumps, in many cases, a smaller pump can be utilised, which gives additional savings.

Power generation

-

DESMI's experience with power plants is partly connected to Denmark's leading position with Combined Heat & Power Plants (Co-generation) as well as Waste-to-Energy Plants, Biomass Plants etc.

We have energy efficient pump solutions available for almost all hot water and cooling applications in such plants. In conventional power plants, primary system applications include boiler feed pumps, condensate pumps, cooling water circulation pumps, loop systems pumps and wide range of utility applications.

HVAC

-

Energy Efficient Pumps and Pump Solutions for HVAC (heating, ventilation and air conditioning)

The HVAC/Cooling arena include cooling applications to buildings such as: Scyscrapers, datacenters, hotels, shopping malls, airports, convention centres but also more industrial applications with cooling towers etc. The pump solutions from DESMI mainly cover the medium and larger pump sizes.

EnviRo-Clean

-

Proven Technology for Oil Spill, Seaweed & Clean Waterways

Whether the requirement is for offshore, or nearshore, the Arctic or Equatorial environment, we continue to deliver proven solutions for all spill conditions including marine debris and seaweed.

- OIL SPILL EQUIPMENT

- OIL CONTAINMENT BOOMS

- OIL SKIMMERS

- WASTE COLLECTION & MARINE DEBRIS MANAGEMENT

- SEAWEED SOLUTIONS

- WORKBOATS

- AND MUCH MORE

ENVIRO-CARE

-

Combating Marine Pollution & Protecting Waters!

DESMI is a world leader in solutions for combating marine pollution in the oceans and environmental solutions around the globe.

Marine & Aquatic debris, garbage and trash is one of the most widespread solvable pollution problems plaguing the world's oceans, rivers and lakes. Successful waste management, floating garbage collection and debris removal requires a comprehensive understanding of marine and aquatic environments together with the necessary experience with debris equipment like trash barriers and booms.

SEAWEED

-

The Eco-Friendly seaweed handling solution from DESMI is keeping sandy beaches free of sargassum and at the same time removing free-of sand Sargassum for future utilization as base for paper, medicine, fertilizer etc.

The DESMI Sea Turtle Sargassum Project was born in 2015 when a massive amount of Sargassum (Pelagic Sargassum Seaweed) arrived in the Caribbean. Initially it was an investigation and research project developed to find an ecological and cost-effective solution and today it is a complete response system ready for Sargassum abatement.

Oil Spill Response

-

We are the world's most experienced manufacturers of oil spill response systems and have helped to clean most of the world's oil catastrophes to date.

Proven Oil Spill Technology is our promise as a complete oil spill response supplier.

- OIL CONTAINMENT BOOMS

- OIL SKIMMERS

- SWEEP SYSTEMS

- LAUNCH & RECOVERY SYSTEMS

- DOP PUMPS

- POWER PACKS

- STORAGE TANKS

- WORK BOATS

- TRAINING & COMMISSIONING

- AND MUCH MORE

CONTAINMENT BOOMS

- DESMI Booms set the standard for containment in the challenging offshore environments.

OIL SKIMMERS

- High capacity oil skimmers with a proven track record

WORKBOATS

- We have a range of Oil Spill Recovery Vessels such as the Pollcat and Pollkitten.

EnviRo-Clean Applications

- The oil spill response solutions from DESMI are trusted in the industry. Whether your requirement is for the offshore or the shoreline area; the Arctic or Equatorial environment, we continue to deliver proven solutions for all spill conditions – and we offer the very best life cycle costs.

OFFSHORE

- In the rugged and harsh offshore environments, DESMI is the market leader for booms, recovery systems, burn kits and storage systems for oil spill response.

COASTAL & NEAR-SHORE

- For coastal and near-shore use DESMI provides the well known Ro-Boom but in smaller sizes whilst maintaining the integrity of the larger product offerings.

Beach & Shoreline

- For oil spill response in beach and shoreline environments DESMI offers a whole range of equipment to handle any eventuality.

PORTS, HARBOURS & TERMINALS

- For oil spill response in beach and shoreline environments DESMI offers a whole range of equipment to handle any eventuality.

Fast Water, Rivers & Lakes

- Oil spill response operations are notably difficult in rivers with strong currents. Proven oil spill technology is your answer.

Sea Water Intakes & Outfalls

- The DESMI Oil Spill Response segment has many years' experience in the manufacture, and installation of permanent oil boom solutions for a vast range of sea water intake systems.

Arctic

- DESMI develops oil spill recovery systems to operate in the most difficult and harsh environments known to man. This equipment is known as the ARCTIC range.

Industrial

- The removal of oil and chemicals from water within the industrial environment is a key requirement.