- Offer Profile

-

Statiflo International is a world leader in the development and application of static mixers and associated technologies with thousands of customers in every process industry in over 80 countries.

Our headquarters are located in Macclesfield in the north west of England.

We also service industries throughout the world from offices strategically situated in the USA, Germany and Canada, as well as through our globally distributed network of agents.

Pipe Static Mixers

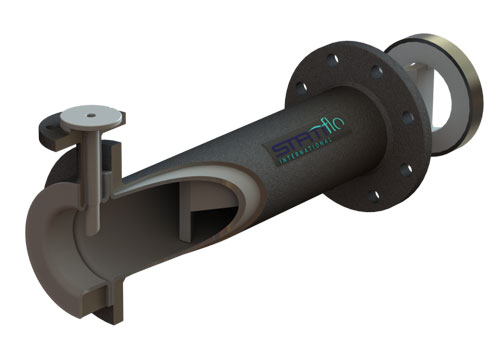

General Industrial Static Mixer: Series 100/150

- Statiflo General Industrial Inline Static Mixers suitable for all process industries supplied with fixed or removable mixing elements.

Usually supplied with SO or WN flanged end connections, but could equally be supplied with plain or weld prepared ends. Screwed/threaded end connections available for smaller sizes.

Optional flanged or threaded injectors and sampling points. Optional heating/cooling jackets.

Hygienic/Sanitary Static Mixer: Series 200

- Sanitary and hygienic design Inline Static Mixers with removable elements suitable for use in food & drink, brewery and pharmaceutical applications as well as CIP (cleaning in place) systems.

Complete with specialist sanitary surface finishes depending on your requirements.

Supplied as standard with IDF, RJT, DIN, tri-clamp ferrule – or any other standard sanitary – end connections but flanged or plain ended options are also available.

Can be supplied be injection/sample branches and heating/cooling jackets

PTFE Corrosion Resistant Static Mixer: Series 300

- Static Inline Mixers with solid PTFE removable mixing elements and PTFE lined carbon steel housing for corrosive duties in all industries. Also available with optional separate PTFE/PFA injection or sample tees.

Can be supplied with a choice of different PTFE-lined housings including painted carbon steel, stainless steel or others.

Plastic Static Mixer: Series 400

- Statiflo Series 400 Pipe Mixers: Plastic construction for cost effective general purpose and corrosion resistant duties.

Fixed mixing elements housings with flanged/threaded ends or with coupling connections.

Optional injectors and sample points. Our Series 400 Pipe Mixers are also available in other plastics such as PP, PE, PVDF or cPVC.

GRP/FRP Static Mixer: Series 500/550

- Corrosion resistant GRP/FRP, large diameter (+250mm) mixers with fixed elements for corrosive applications in the water, wastewater, desalination and pulp & paper industries. Flanges supplied as standard and available with optional injectors and sample points.

Water Treatment Static Mixer: Series 600/650

- Statiflo Inline Static Mixers suitable for the water and wastewater treatment industries supplied with fixed mixing elements.

Flanged or plain ended for VJ couplings with screwed end connections available for smaller sizes.

Optional injectors and sampling points.

Generally supplied in all stainless steel but for large diameters epoxy coated carbon steel is available for increased cost effectiveness.

High Viscosity Static Mixer: Series 700

- Precision machined mixers with high surface finish and edge sealed elements for high temperatures and pressures, polymer processing, thermal homogenisation and melt extrusion. Available in carbon steel, stainless steels and exotic alloys if required.

Steam Heater/Direct Steam Injection Static Mixer: Series 800/850

- Direct steam heaters in steel and exotic alloys for all industries. Fixed elements with integral steam injector or injector jacket.

The body of the actual mixer housing would be drilled with a series of steam injection holes to ensure that steam is injected radially around the mixer zone, to enable rapid and uniform dispersion of steam throughout water, resulting in rapid and efficient thermal heating.

S-Type Static Mixer

- Statiflo Inline Static Mixers suitable for all process industries. Pre-fabricated and packed – meaning you can have rapid delivery of the items you require.

Supplied in a standard construction with EN1092 PN16 flanges and a 1″ injection boss.

Available in uPVC or stainless steel materials from DN25 (1″) to DN100 (4″). We also have a variety of other static mixer types available.

Other Products

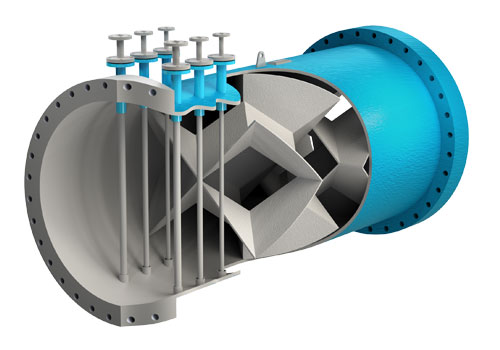

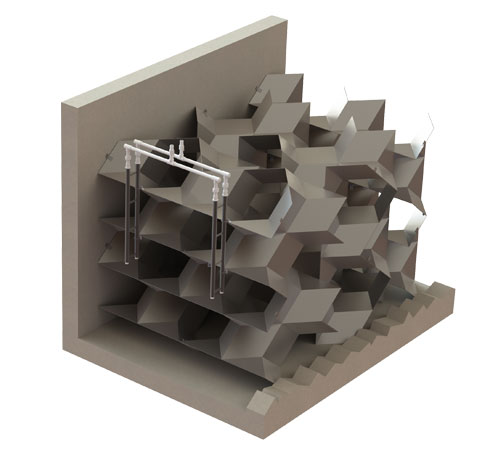

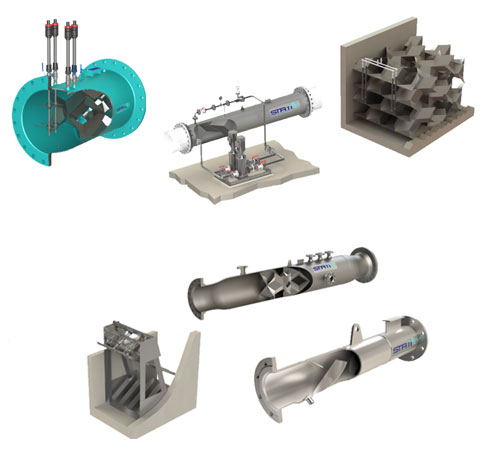

Channel and Duct Static Mixers

-

Statiflo's Channel Mixers are revolutionising the design and operation of water and waste water treatment plants.

Statiflo Series 900 Channel Mixers rapidly achieve a high degree of mix with extremely low headloss in very short lengths.

Complete mixing in the channel is possible, achieving a low CoV, over a wide range of flowrates. With headlosses of just a few millimetres feasible, gravity flow is an option, eliminating the expense of pumping, saving not just capital costs, but ongoing maintenance and energy costs too.

Statiflo Channel Mixers can be installed in new treatment works or easily retrofitted into existing installations, even when flooded and live. The modular design concept, based on the STMC mixing elements, allows wide variations in aspect ratio (height/width) suitable for square or nearly square channel sections, narrow deep channels and wide shallow channels. Independent trials have established that the STMC concept is the most efficient of all known commercially available static mixers.

Open channels can develop unusual velocity profiles not found in conventional piping systems. Statiflo has invested considerably in developing a procedure to ensure that the correct amount of additive is injected proportional to the local mainstream flowrate.

Applications include:

- Raw water blending

- pH control

- Rapid coagulant addition

- Polyelectrolyte dosing

- Residence time control

The high efficiencies and benefits of the channel static mixer apply to any scale, the largest installed to date is 7m wide x 5m deep, handling 7 tonnes/sec of water.

The Innovative Gas Dispersion System: Custom Designed, Engineered and Built

-

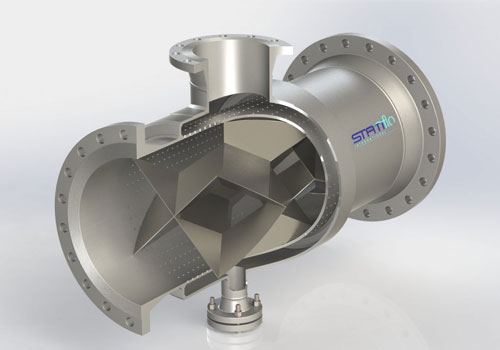

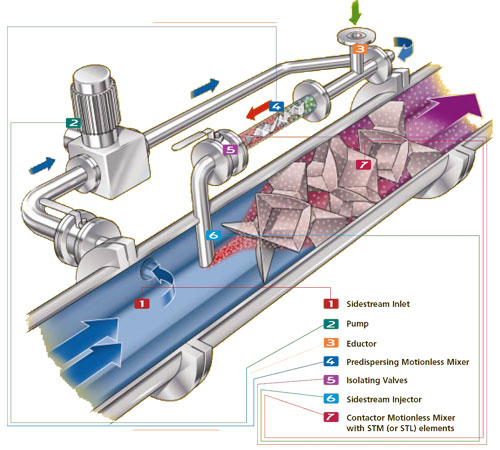

The Statiflo Gas Dispersion System (GDS) is a totally new concept for simultaneous mixing and mass transfer.

The Statiflo GDS is designed to overcome the difficulties associated with the use of a single static mixer. The system uses two different mixers, the first, in a sidestream, to form small gas bubbles and the second, in the main line to provide contact time and efficient mass transfer. As the gas bubbles are formed in a constant velocity sidestream, the gas bubble size is constant and independent of any variations in the main liquid flow.

Typical applications:

- Aeration of drinking water for iron, manganese and carbon dioxide removal

- Ozonation for disinfection of drinking water and waste water

- Ozonation for treatment of cooling tower water to disinfect and reduce scaling thereby offering better heat transfer efficiencies, lower blowdown volumes and decreased chemical usage.

- Ozonation for removal of disinfection byproducts (DBPs)

- Ozonation for removal of micro-pollutants such as pesticides

- Ozonation for odour and taste elimination

- Carbonation of mineral water

- BOD and COD reduction

The Statiflo GDS consists of:- Main line mixer/contactor

- Sidestream equipment, including:

- Pre-disperser static mixer

- Gas eductor (if gas at low pressure) Centrifugal pump ( operating at constant flow rate)

- Sample point, valves, instrumentation, interconnecting pipework and stand-by equipment as required. The sidestream gas/liquid dispersing equipment can be compactly side mounted directly on the contactor mixer or alternatively floor/skid mounted.

The sidestream gas/liquid dispersing equipment can be compactly side mounted directly on the contactor mixer or alternatively floor/skid mounted.

Key benefits include:- High mass transfer efficiency which does not decrease over time

- Low capital cost

- Low pressure drop

- Gas bubbles generated indepedently of liquid velocity in contactor

- Low energy consumption

- High turndown capability

- Compact design

- No moving parts except for centrifugal pump

- Minimal maintenance requirements

- Simple to operate with no special training required.

Wastewater Mixers

-

Statiflo Non-Ragging Pipe Mixer (NR)

The Statiflo NR Mixer has been specifically designed for sludge mixing or wastewater applications with high fibre content.

In full-scale trials with a major UK water utility the Statiflo NR Mixer outperformed all competitor's designs including a static mixer, an orifice plate and sludge valves.

These pictures and graphs illustrate the superior performance of the Statiflo NR Mixer compared with a competitor's mixer. The graph shows the typical effects of ragging with increasing headloss and reduced flow until the competitor's mixer ceased to operate in less than four hours.

Statiflo Non-Ragging Channel Mixer (NRC)

A non-ragging static mixer for dosing additives into wastewater including raw sewage. The Statiflo NRC Mixer has been designed specifically for P removal applications but can equally be used on any chemical dosing service on raw sewage where non-ragging properties are essential. It has a unique variable geometry custom designed for the widest range of wastewater velocities and channel depths found on a typical wastewater treatment plant.

Statiflo NRC Mixers have been installed since 2008 and have consistently remained rag free and have required no maintenance.

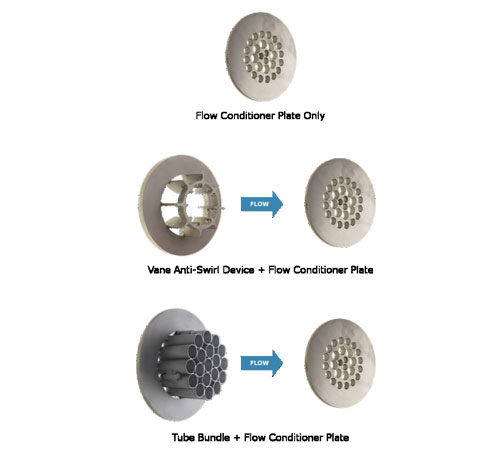

Flow Conditioners

- The new range of Statiflo Flow Conditioners for a variety of applications including oil and gas fiscal measurement and municipal metering.

Flow Conditioning is an extremely important factor to consider when undertaking flow measurement. The use of a flow conditioner helps to create a pseudo-fully formed flow profile, thereby optimising the performance of flow meters. This leads to increased predictability and reliability, with the ultimate goal of increasing your process efficiency, accuracy and repeatability.

Just like Statiflo Static Mixers, the Statiflo Flow Conditioners have no moving parts which means no maintenance requirements.

Available in a wide range of sizes and materials to suit your requirements. Enquire Now!

Features and benefits:- Optimise flowmeter performance (Bias, Linearity and Repeatability)

- Reduce uncertainty

- Eliminate piping disturbances by creating a pseudo-fully formed flow profile

- Minimal pressure drops with k-value = 1.2

- Not sensitive to Reynolds number

- Variety of models to fit any type of applications

- AGA, API & ISO approved

- Independently tested and verified by 11 international laboratories

- Available in a wide range of sizes and materials

- Custom engineered for your requirements

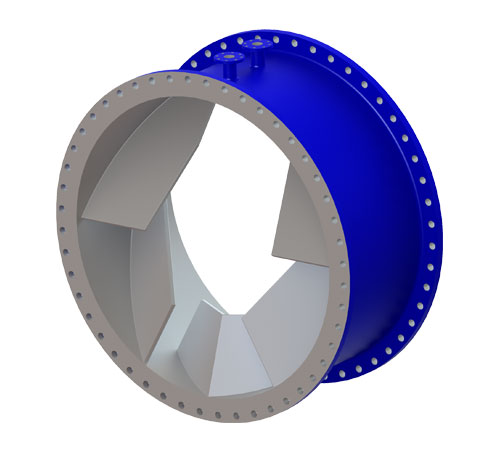

Custody Transfer (CT) Mixers

- Statiflo Series 100/150CT Custody Transfer Motionless Mixers are designed to be versatile enough to cover all your custody transfer applications including transfer stations, LACT skids, etc.

It is of the utmost importance that seller and customer both know exactly the water content of the oil they are purchasing or selling. This can often be very difficult because even the best sampling systems in the world can only provide accurate data if they are taking a representative sample.

Statiflo’s market-leading dual leading edge designs can consistently achieve a C1/C2 ratio above 0.9, in accordance with ISO3171 and API 8.2 standards, therefore meaning that the water is adequately dispersed within the oil and that a representative sample can be taken at the mixer discharge for water in oil analysis. Return on investment is typically measured in months, not years.

Remember – Statiflo Custody Transfer Mixers have no direct power consumption and since there are no moving parts that means there is no maintenance requirements and no expensive spare parts.

Don’t continue to pay for water at crude oil prices, contact Statiflo today for a quotation to fit your custody transfer requirements.

Wafer-style / Short Length Static Mixers (DSM Series)

- A range of Inline Wafer-Style Static Mixers originally developed to meet the special requirements of the global desalination industry, but now expanded across almost all process industries where a short length mixer is required.

The Statiflo DSM compact static mixer provides the highest mixture quality with minimum dosing of additive(s), eliminating overdosing to enhance downstream separation efficiencies and membrane lifespan. The requirement for dosing lances with small additive release holes, aided by internal baffles, has been eliminated.

The very latest techniques for design and modelling have been used to develop the Statiflo DesalMixer (DSM) for turbulent flow dosing and blending applications in the pre-treatment and post-treatment stages of desalination processes.

The Statiflo DSM has also been independently tested for pressure drop and mixture quality (variation coefficient, CoV) by BHR Group, world leaders in fluid engineering, research & consultancy. Mixers have been tested at industry realistic fluid velocities and additive ratios and demonstrated to achieve better than industry standard mixture quality.

Typical Applications

Pre-treatment applications for minimising biofouling, sealing and membrane plugging:-- Inlet blending

- pH control

- Disinfection

- Anti – scalant

- Coagulation

- Flocculation

3 versions are available, ultra short length (0.25D), standard length (0.5D) and extended length (1.0D) – allowing ‘tuned’ mixer selection for both rapid (highest headloss) and slow mixing (lowest headloss) duties (e.g. coagulation and disinfection). Custom length versions also available.

Single and multiple injection options can be provided and the internal configuration diverts and swirls the mainstream into the additive release zone for efficient mixing without the need for internal spargers or baffles.

Chemical Dosing Lances / Injection Lances

-

Statiflo Chemical Dosing Lances / Injection Lances are specifically designed to meet the needs of industry and maximise the mixing potential of Statiflo Inline Static Mixers. They are available to purchase with our Static Mixers or as a standalone product.

Being withdrawable under pressure means that the main line doesn’t have to be completely depressurised in order to remove the dosing lance for maintenance.

Various designs are available including the new XHP (Extra High Pressure) dosing lance which in addition to working with higher pressures than the rest of the Statiflo Chemical Dosing Lance range, uses a threaded wind-out design – as is now required by some sites – to be suitable for the most stringest of health & safety requirements.

Industries

Water Treatment

- Inline Static Mixers are used in the Municipal and Industrial Water Treatment Process

The demands for precise and responsive chemical dosing in the treatment of drinking water is growing. Applications such as disinfection, flocculation, fluoridation, plumbosolvency, control of taste and odour, ph correction, turbidity, ozonation to name but a few require precise metering of chemicals.

Not only does this require the precise metering of chemicals to meet process demands, stringent levels of residuals, but also to perform when operating in a variety of flow conditions. Therefore there is a need to shorten process times and to ensure that any analysers/sample probes are measuring a representative sample after chemical dosing.

To assist in this process Statiflo inline mixers for water treatment can be supplied complete with chemical injection lances which direct the chemical into the heart of the mixer for optimum performance of the mixer.

The mixing and correct dosage of these chemicals has a fundamental influence on each stage of the treatment process and ultimately the complete process itself. So often site conditions do not provide the high level of mixing and process times to meet the prerequisite conditions. The use of in pipe or channel static mixers provides the required level of mixing so that optimum chemical dosing is achieved. Thereby saving chemical, improving the performance of the treatment process as well being able to operate in a variety of conditions and flows encountered in todays treatment processes

With modern advances in water treatment the use of powerful oxidants such as ozone and AOP processes (Advanced Oxidation Process) are not uncommon. Ozone is a strong oxidising compound which rapidly oxidises organic materials, iron, manganese and other substances when it is added to drinking water. In addition, it is an extremely effective disinfectant against bacteria and viruses. Ozone is very unstable and therefore has a short life. It is therefore essential that the ozone is mixed and dispersed into the water as soon as possible. Statiflo static mixers and gas dispersion systems are ideally suited for this application and there are many installations worldwide.

Static mixers have gained in popularity, as unlike stirred tanks the complete water flow and chemicals are subject to complete and thorough mixing in a relatively short period of time. The required energy for mixing is taken from the main water flow. The resulting headloss is very low and will depend upon the operating conditions and the design of the chosen mixer. Statiflo have considerable experience in designing and selecting the right mixers for the acceptable and calculated head loss.

Wastewater Treatment

- Pipe and Channel Static Mixers used in the Wastewater Treatment Process

Just like Municipal drinking water treatment, Municipal wastewater and Industrial wastewater treatment requires chemical dosing for precipitation and flocculation, using organic coagulants or polyelectrolytes.

In the above applications, it is a requirement of the process to mix the chemicals effectively with a large body of water in a very short length of pipe or channel. This can be difficult as turbulence could be low in some designs of wastewater treatment works. They are designed for settlement and hence the possibility for low turbulence. In these applications the installation of inline or channel mixers is essential for the thorough mixing and process control.

Not only does this require the precise metering of chemicals to meet process demands, stringent consent thresholds or residuals level, but also to perform when operating in a variety of flow conditions. Therefore there is a need to shorten process times and to ensure that any analysers or sampling systems are measuring a representative sample after chemical dosing.

Along with the demands typically present in regular water treatment, wastewater treatment plants feeds will have a certain content of rags, fibrous or stringy materials and generally a high level of solids.

The classic style of static mixer would create issues with such contents and that is why Statiflo has developed the Non-Ragging Static Mixer (also known as the Non-Blocking or Non-Clogging Static Mixer) – a range of Static Mixers designed specifically for the requirements of the wastewater treatment process. The Statiflo Non-Ragging Static Mixer is available in pipe or channel form. We are proud to supply a range of quality wasterwater mixer products.

Channel mixing can be challenging, but Statiflo’s unique Non-Ragging Channel (NRC) mixer design makes for a simple installation which can be undertaken in a relatively short period of time and often in live conditions. With high mixing performance and consistent mixture quality, it is ideal for difficult raw waste water applications where there maybe a high content of rags and/or highly fibrous material.

Applications such as phosphate removal require that chemical dosing is a achieved at strategic points in the process in order to provide efficient treatment to comply with phosphate discharge limits but at the same time avoid overdosing of chemical. The use of static mixers also provides chemical savings and complements the combined use of biological control. The above is also applicable for industrial waste water treatment processes.

Oil, Gas & Petrochemical Industries

- The Petrochemical, oil and gas industries incorporate a number of processes where static mixers play an important part such as stream blending, additive mixing, liquid dispersion, emulsion formation, chemical reactors, laminar-flow heat transfer, mass transfer, and custody transfer/fiscal measurement.

The reason that static mixers are popular in these applications are that they provide highly efficient mixing with no moving parts and are therefore maintenance free, at the same time providing significant cost savings as no direct power is required. Minimal space is required, installation is quick and easy and they are available in a variety of materials to suit the application.

Providing mixing in a uniform volume, they are ideal for when reactions are taking place which are critical to product purity. For multiphase systems high energy dispersion rates and an even shear history help to improve mass transfer.

Typically these industries require a high level of QA/QC and as Statiflo operate with the latest ISO Quality Management Systems we can provide you with the documentation you need to meet your requirements. Example documentation in addition to the General Arrangement drawings supplied as standard with every order would include NDT procedures/reports, 3.1 or 3.2 material certificates, Quality Plan/Inspection Test Plan, Production Schedule, WPS/PQRs and a Certificate of Confirmity. Other documentation is avaialbale upon request.

Statiflo have a wide range of pipe and channel static mixer designs. Each mixer and the number of elements is carefully selected and designed by our engineers based upon proven design principles that have been independently tested and verified.

Statiflo is known throughout the world as a recognised supplier for the Oil, Gas and Petroleum industries.

Below you can find some breif details of applications whcih we have supplied static mixers for but to find out more about your application, contact us today.

Desalination

- Pipe Static Mixers used in the Desalination Process

With the growing demand for water, desalination is seen as one of the answers to meet the shortage of water. The desalination process includes chemical dosing as part of the pre and post treatment processes. Static mixers play an important part in ensuring thorough mixing of these chemicals and Statiflo has an extensive list of references in this industry having supplied Static Mixers to some of the world’s largest desalination plants.

Along with our world-renowned ‘classic’ static mixing element designs, Statiflo have used the latest design and modelling techniques to develop the short-length DesalMixer for turbulent flow dosing and blending applications in the pretreatment and post treatment stages of water treatment in the desalination process.

Like all of our mixer designs, the Statiflo DesalMixer has been independently wet tested for pressure drop and mixing quality (measured by coefficient of variation – CoV) by the BHR group who are world leaders in fluid engineering, research and consultancy. In accordance with Statiflo’s design policy the unit has been tested at industry realistic velocities and additive ratios. The DesalMixer has consistently demonstrated its ability to exceed mixing industry standards.

Food & Pharmaceutical

- The food & pharmaceutical industries strive to provide the highest quality products and achieve a high level of consistency. Statiflo Static Mixers play an important part in this process.

Due to their proven high level of performance they are used in a wide variety of food applications such as pasteurisation of raw cocoa mass, blending fruit pieces into yoghurt, live steam pasteurisation. Other typical applications include production of coffee, beer, molasses and chocolate.

In the pharmaceutical industry typical applications would include cooling and/or heating steps, drug trial productions and producing pharmaceutical intermediate products.

Whilst the Food and Pharmaceutical industries have clear differences in terms of requirements the inline static mixers supplied by Statiflo have many aspects in common.

Our Series 200 range for these industries would be supplied with removable mixing elements within metric or imperial tubing with a high level of surface finish – finishes up to 0.38 micron Ra are available. Specialist sanitary connections such as IDF, RJT,DIN or tri-clamp ferrules would come as standard, but flanged designs are also available. Integral injection or sample branches can be supplied in order to fine tune the mixing performance and achieve the best possible process control. Injectors and heating/cooling jackets are also available to complete the installation.

Cleaning in Place (CIP) is made easy with the crevice-free design which prevents unwanted build up of bacteria within the static mixer.

Continuous Process Industry

- Inline Static Mixers can be used in almost every Continuous Process Industry

Statiflo Static Mixers are used in almost all continuous processes throughout the world. By using the same concepts which are applied to other industries, Statiflo have developed an offering to improve almost any process.

At a time when increased efficiency of all process industries, both in an economical and environmental sense, is becoming an increasingly important issue, there is a high demand for technologies which can provide both cost savings and energy savings.

Applications such as general chemical production, polymer processing, metal smelting and the production of synthetic oils all use Statiflo Inline Static Mixers to improve their effiiciency, product purities and consistently produce on-spec products.

With environmental factors ever-more important in today’s industries, increased focus is being placed on DeNOx, DeSOx and other Selective Catalytic Reduction (SCR) and Selective Non-Catalytic Reduction (SNCR) processes. A Statiflo Static Mixer can be used for the makeup of treatment chemicals or within the gas scrubbing process itself.

Using a Statiflo Inline Mixer allows chemicals to be dosed effectively and efficiently – reducing the need to compensate for poor mixing by overdosing chemicals and therefore helping to minimise the quantities of chemical dosed.

Another added benefit is that, more often than not, representative sampling can be done immediately at the Static Mixer discharge which means the shortest possible control loop times and results in the very best control of your process.

Marine Industry

- Static Mixers for the Marine Industry

Statiflo supply Static Mixers and associated technologies to the marine sector globally.

Recent changes to legislation in the Marine sector by bodies such as the US Coast Guard (USCG) and the International Maritime Organisation are driving innovation in key areas where Static Mixing Techology can be applied.

Brewing Industry

- In an increasing cost conscious world, we are all striving to improve our effectiveness. Process equipment which has no moving parts, which is maintenance free, very energy efficient and which can improve plant performance will significantly contribute towards lower operating costs. It is proven that inline static mixing is now playing a significant role in the brewing industry.

Statiflo Motionless Mixers have many applications in all types of breweries and microbreweries, from simple blending operations to complex inline reactors involving heat exchange.

Below you can find some brief details of applications which we have supplied static mixers for but to find out more about how we can help with your specific application, contact us today.

Pulp and Paper

- Statiflo Supply Inline Static Mixers to the Pulp and Paper Industry

Statiflo are recognised as key suppliers to the Pulp & Paper Industry, supplying Static Mixers – sometimes known as Inline Static Mixers, Static Mixers or Motionless Mixers – to blue chip companies in this industry.

The Pulp and Paper industries require a high quality product in order to maximise time between shutdowns and prevent any risk of unscheduled dowtime.

Statiflo Static Mixers for the pulp and paper industries are energy saving compared to mechanical mixing equipment, provide chemical savings to meet strict environmental controls along with providing a continuous and constant mixture quality over a wide range of throughputs.

With a range of mixers manufactured in stainless steel, PTFE, Alloy 20, Hastelloys, Titanium and FRP/GRP. With this range of materials they are ideally suited to applications such as:-- Acid dilution, caustic dilution and pH control.

- Stock dilution.

- Stock blending, for both new and recycled products.

- Chemical, filler and additive blending Low consistency bleaching

- Green liquor coagulant addition.

- Stock bleaching.