- Offer Profile

-

Today’s HARTMANN VALVES GmbH belongs to the leading manufacturers in the areas of ball valves, pigging valves, and well flanges. A worldwide presence in the crude oil, natural gas, petrochemical industry, power plant technology as well as geothermal and other renewable energies is our reference.

BALL VALVES

-

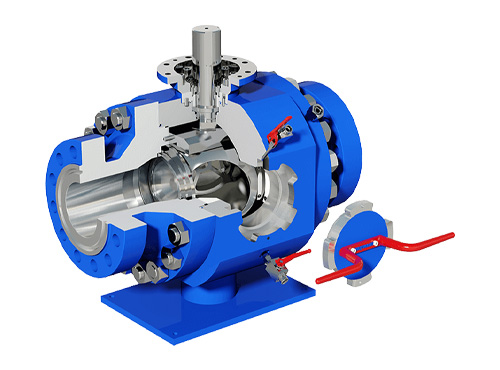

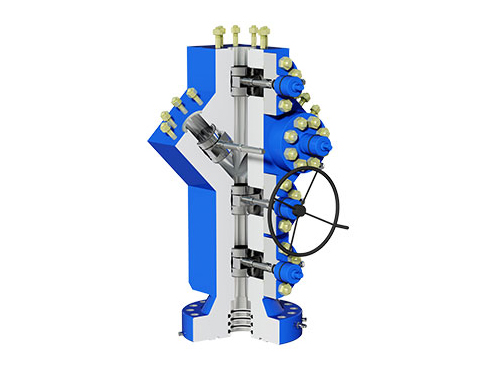

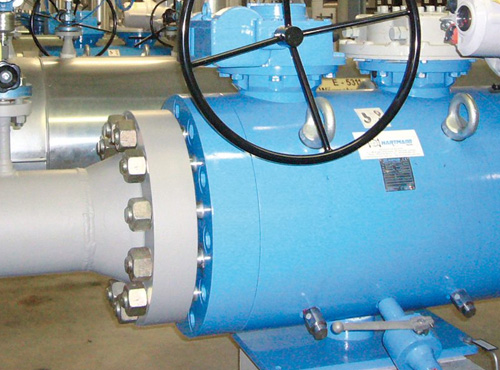

High-Performance metallic sealing gastight ball valves for severe service applications

Designed to individual customer requirements, Hartmann ball valves guarantee the highest levels of safety and availability – even under extreme operating conditions. As a reliable shut-off valve, they resist aggressive media, extreme pressures and temperatures or frequent actuating operations. The metal-to-metal sealing between ball and seat rings with high quality hardfacing provides an especially long service life and minimises maintenance requirements.

The ball valves are equipped with hand lever or gearbox for manual operation. Automatic operation by means of electric, pneumatic or hydraulic actuators. Configuration variants e.g. rapid close, fail-safe-open, fail-safe close and high cycle with ≥200,000 actuations per year. We develop tailor made solutions for special process requirements.

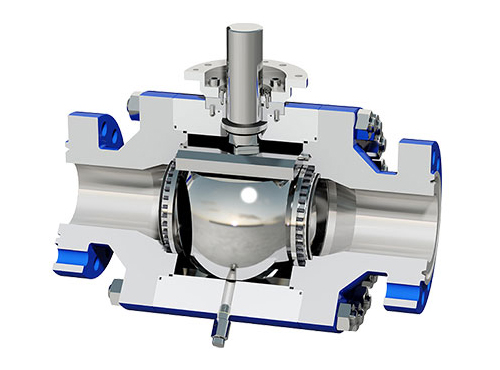

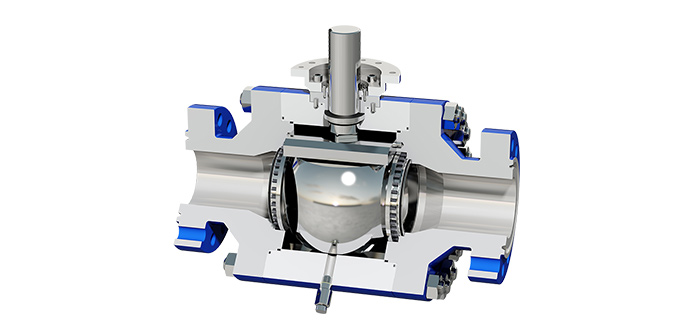

BALL VALVE TYPE AST

-

HARTMANN VALVES valves of the AST series are designed for use as high-pressure valves. With our unique and entirely metallic sealing systems they are equally suitable as reliably sealing shut-off valves for liquid as well as gaseous media with solid particle components.

TECHNICAL CHARACTERISTICS

- Design according to DGRL 97/23/EG, API 6D or API 6A

- Entirely metallic sealing

- O-bubble leak rate

- Two- and three part housings (split body) made of forged material

- Trunnion-mounted ball

- Blowout-safe operating spindle

- Float-mounted, self-centering seat rings with pre-tensioned spring elements

- Automatic housing pressure relief

- Sealing force dependent on line pressure

- Double Block and Bleed (DBB)

- Exchangeability of upper operating spindle seal at full line pressure

- No electrostatic charge-up

- Fire safe according to API 6 FA and BS 6755/2

- Maintenance free

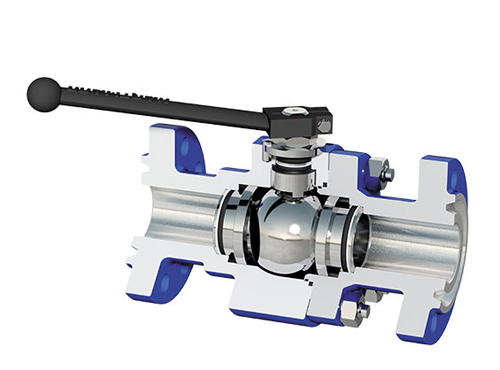

BALL VALVE TYPE ASF

-

HARTMANN VALVES ball valves of the ASF series – for reliable sealing function, even under more challenging operating conditions These HARTMANN VALVES ball valves with metallic sealing systems are suitable for gaseous and liquid media with solid particle components.

TECHNICHAL CHARACTERISTICS

- Design according to DGRL 27/23/EG, API 6D or API 6A

- Entirely metallic sealing

- O-bubble leak rate

- Two part housings (split body) made of forged material

- Blowout-safe operating spindle

- Float-mounted, self-centering seat rings with pre-tensioned spring elements

- Sealing force dependent on line pressure

- Exchangeability of upper operating spindle seal at full line pressure

- No electrostatic charge-up

- Fire safe according to API 6 FA and BS 6755/2

- Maintenance free

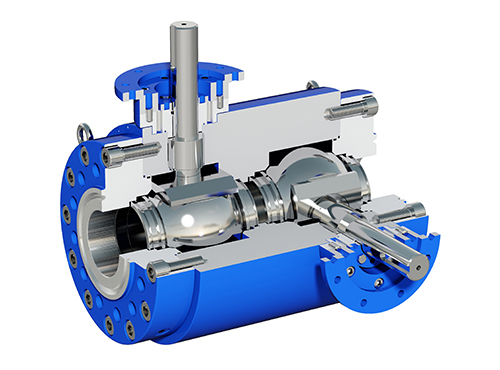

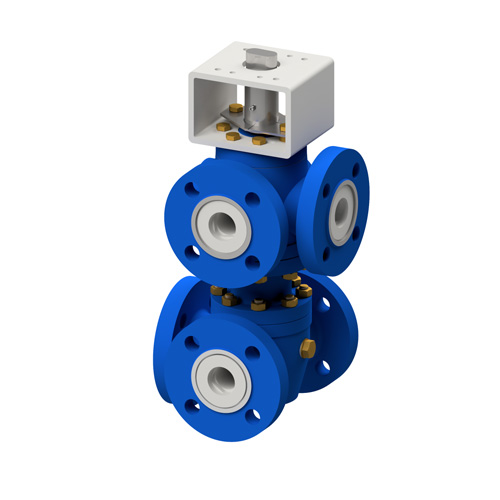

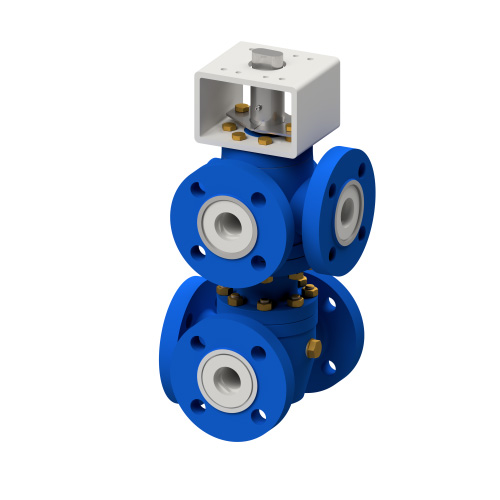

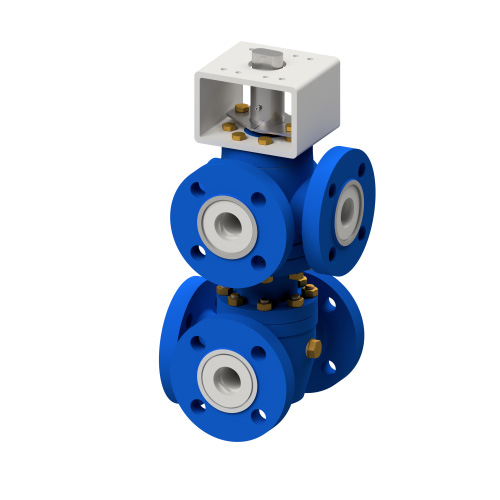

BALL VALVE TYPE TBV

-

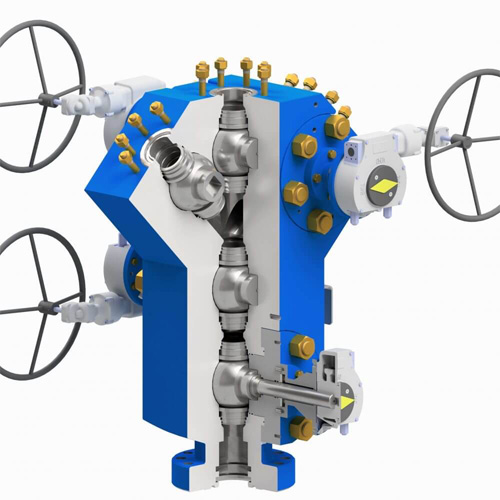

HARTMANN VALVES ball valves of the TBV series find use when strict safety regulations require a dual pipeline shut-off. Designed for these applications, the HARTMANN VALVES TBV series combines two complete and independent shut-off systems (“Twin Ball Valve“) in just one housing: 0-bubble seal tight, and testable between the shut-off systems. The compact design facilitates operational reliability, and furthermore helps in saving space and lowering costs due to lowered material demands.

TECHNICAL CHARACTERISTIC

- Design according to DGRL 97/23/EG, API 6D or API 6A

- Entirely metallic sealing systems

- O-bubble leak rate

- Three part housings (split body)pr block design made of forged material

- Depending on the nominal width with trunnion-mounted or float-mounted spheres

- Blowout-safe operating spindle

- Float-mounted, self-centering seat rings with pretensioned spring elements

- Automatic housing pressure relief (with trunnion-mounted spheres)

- Sealing force dependent on line pressure

- Double block and bleed (with trunnion-mounted spheres)

- Exchangeability of upper operating spindle seal at full line pressure

- No electrostatic charge-up

- Fire safe according to API 6 FA and BS 6755/2

- Maintenance free

SPECIAL BALL VALVES

-

Hartmann Valves ball valves are also used successfully, in a design modified by our engineers, in the most specialized application areas:

TECHNICAL CHARACTERISTICS

- Coupling valves with throttling option

- Shut-off ball valves with additionally integrated check valve

- “Slurry” ball valves in media with high content of coarse-grained contamination

- Tapping valves in piping

- Special shut-off valves on drilling ships

- Safety shut-off valves with response times of down to

- Valves implemented for extreme switching frequencies

- Special high-pressure valves in Top-Entry-Design

- Valves in filling plants

- Valves with special design lengths and ports

- Valves for the shut-off of measurement sections

- Valves with TA-air implementation

- and many others

GATE VALVE

-

Hartmann Valves of the Gate Valve series, type HGV, complement our ball valves. Solid shut-off slider, made of a single forged steel body from European forges and equipped with a full-gate, two seating rings, as well as the use of proven seal technology provide the guarantee for secure deployment and a long service life.

TECHNICAL CHARACTERISTICS

- Nominal bore: DN8 up to DN1000 (¼“ up to 40“)

- Pressures: Vacuum up to 1035 bar (15.000 psi)

- Temperatures: -200 °C (-328 °F) to + 550 °C (1022 °F)

- Design: 2-way, 3-way, 4-way ball valves, floating or trunnion-mounted ball design

- Sealing system: Metallic sealing with 0-bubble leakage rate (A)

- Connections: flange, but weld, socket weld, threaded

- Body material: Carbon Steel, Stainless Steel, Duplex, Superduplex, Hastelloy,Incolloy, Inconel, Monel, Titanium and others

- Double Isolation and Bleed (DIB) – two barriers in one or both directions

- Double Block and Bleed (DBB) – valve can be tested while mounted in the pipeline

- Regulations and Standards: API 6A, API 6D, ASME, PED, DGRL, DIN ISO

- Certified for: Fire-safe, TA Luft, SIL and more

SCRAPER VALVES

-

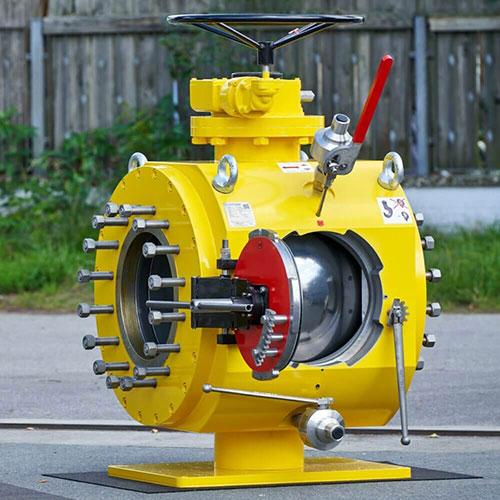

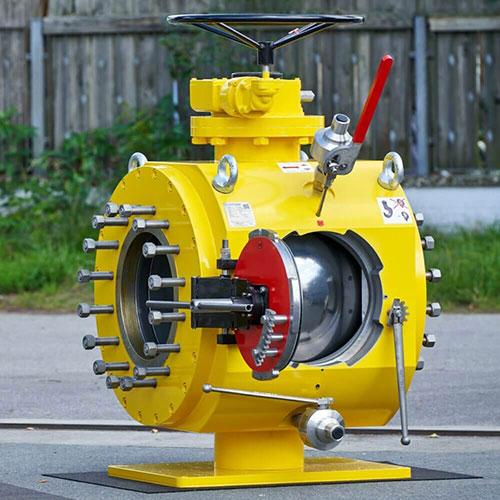

Hartmann Valves pigging ball valves combine the advantages of the metallic sealing ball valve and in addition to classic applications function as shut-off valves for pigging insertion or removal valves.

The advantages at a glance:- Shut-off valve and pigging/scraper station in one

- Pigging station for launch and receiving

- Space- and cost-saving substitution for expensive pig trap systems

Hartmann pig valves offer a space- and cost-saving substitution for expensive pig trap systems. In addition to the classic application as a shut-off valve, the pig ball valve functions as a pig launcher and receiver.

A laterally integrated lock gate, which is locked and secured by a bayonet system, allows pigs to be inserted and removed easily, quickly and safely.

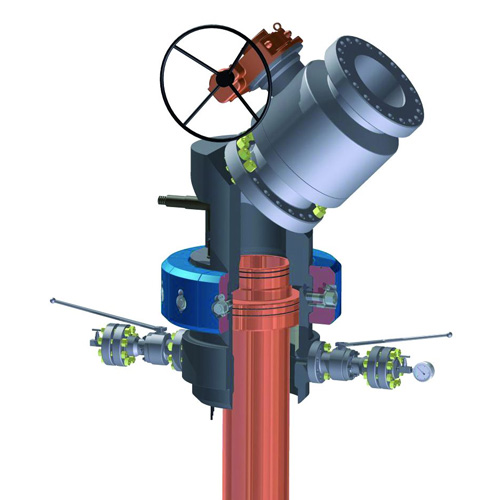

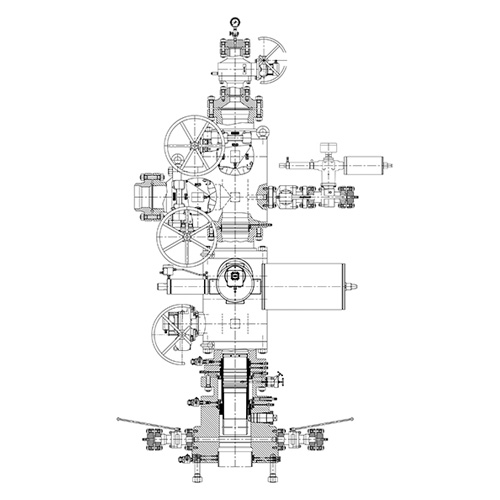

WELLHEADS

-

Durability and long service life characterize our equipment.

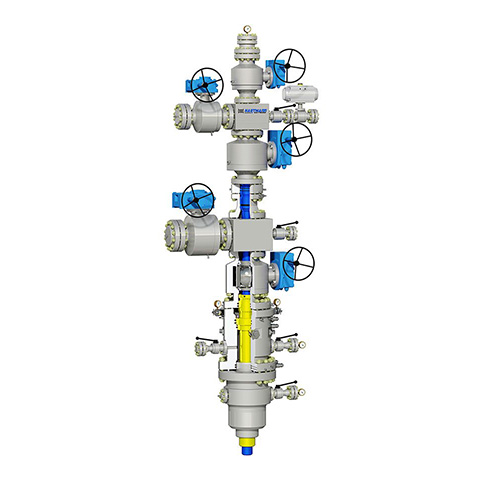

Our API 6A-compliant wellheads are designed to meet the highest standards and have been used for decades in oil and gas production, storage technology and deep geothermal applications. Made of high-quality materials, they are equipped as standard with gas-tight, purely metallic sealing ball valves. An integrated design not only minimizes height and weight, but also saves a lot of money by saving on flange connections. For the assembly service, repairs and maintenance an experienced service team is available around the clock.

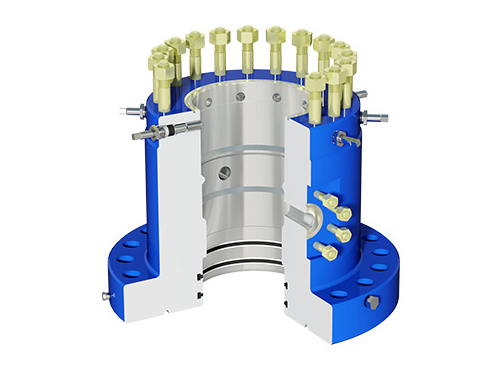

BASE FLANGE

-

Available in all sizes and implementations common to the industry, as well as in accordance with the customer specifications. The lower armature pipe connector can be equipped with API and other threads, as well with a weld-on variation. Another option commonly provided by HARTMANN VALVES is the implementation of the Body Flange with a matching pipe provided by the customer, fully welded and tested. The side outlets are of course available in the standard version, displaced by 180° in different API 6A variants. Upon customer request we also manufacture different outlet variants with a flexible arrangement of 90°.

MANUFACTURING PROGRAM- Lower connections: Welded with o-ring seal, bolted together with o-ring seal, wedge connection system

- API head flange sizes 21.1/4″, 20.3/4″, 18.5/8″, 16.3/4″, 13.5/8″, 11″, 9.5/8″, 7.1/16″ quick connects

- API pressure stages: 2.000 PSI, 3.000 PSI, 5.000 PSI, 10.000 PSI

- API temperature classes: L, N, P, R, S, T, U

- API material classes: AA, BB, CC, DD, EE, FF, HH

- API PSL test classes: PSL 1, PSL 2, PSL 3, PSL 3 G

- additional nominal sizes and pressure levels upon request!

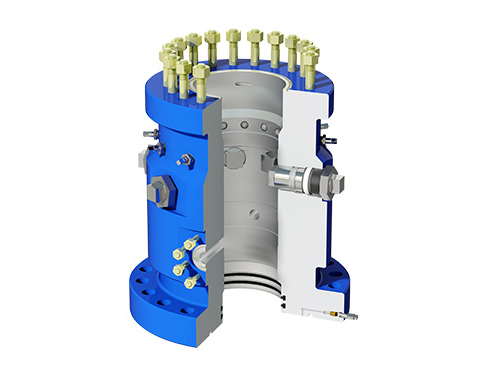

CASING DOUBLE FLANGE

-

Available in all sizes and implementations common to the industry, as well as in accordance with the customer specifications. The lower pipe seals are now equipped as a standard feature with testable and proven double sealing systems. Metallic sealing systems, as well as also the arrangement and implementation of the side outlets according to customer requests are a matter of course for us.

MANUFACTURING PROGRAM- API bottom flange sizes 21 1/4″, 20 3/4″, 18 5/8″, 16 3/4″, 13 5/8″, 11″ quick connects

- API head flange sizes 16 3/4″, 13 5/8″, 11″, 9″, 7 1/16″ quick connects

- API pressure stages: 2.000 PSI, 3.000 PSI, 5.000 PSI, 10.000 PSI

- Sealing systems: Single-P, double-P, T-sealing system, N-sealing system, NX-sealing system, metallic sealing systems

- API temperature classes: L, N, P, R, S, T, U

- API material classes: AA, BB, CC, DD, EE, FF, HH

- API PSL test classes: PSL 1, PSL 2, PSL 3, PSL 3 G

- additional nominal sizes and pressure levels upon request!

HEAD SPOOL TENSION TYPE

-

Designed to suspend casing/tubing in a pre-tensioned state. Allows to run the pipe below landing level, than pool to required tension and suspend. Depending on the casing string and the production casing string, a defined or an infinite underpinning is possible.

TECHNICAL CHARACTERISTICS

- Design according to API 6A

- Sealing toward the casing in the lower flange, with P-Seal, FS-Seal , elastomers or metallic sealing systems

- Suspension via segments, bolts, or jaw with suspension loads>350 to.

- Lower and upper connection as flange, quick- or clamp connect

SHAPE AND CLAMP HANGERS

-

Hangers of mandrel or slip type are designed for suspension of the pipe strings in the wellhead systems. With shape hangers the connection is established through external – internal threads, or through a welded connection, in the case of clamp hangers by means of wedge segments.

TECHNICAL CHARACTERISTICS

- Design according to API 6A

- Sealing of the casing head with weight-activated packing or elastomers

- Sealing of the hanger neck with P-Seal, FS-Seal , elastomers or metallic sealing systems

- The sealing of the wedge hangers is accomplished via separate packing systems.

- All threaded connection possible according to customer specification

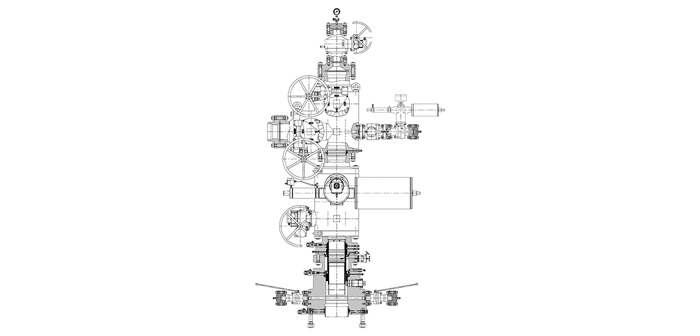

SOLIDBLOCKS

-

Block type x-mas tree designed for two or more x-mass tree valves in same body block. Can be implemented correspondingly in the most different configurations, according to customer specifications. Besides compact design and the use of forged steels, combinations of proven ball valves and gate valves are possible, or can be equipped completely with ball valves and gate valves. In order to facilitate operability of manual valves, drives, if used, can also be mounted on the backside.

MANUFACTURING PROGRAM

- Christmas tree combination “Solid Block” construction

- Design: T and Y design

- Valves: Ball valves and shut-off sliders, as well as combined

- Activation: Hand wheel, transmission, or drive combined

- Through bore hole: 2 1/16“ – 6 3/8“ ( DN 52 – DN 162 )

- Pressure level: up to API 10.000 ( 690 Bar )

- Connector flange bottom: to 13 5/8“ ( additional sizes upon request )

- Connector flange top: to 7 1/16“

- Connector flange to side: to 7 1/16“

- MC: AA, BB, CC, DD, EE, FF, HH

- TC: K – Y ( -46 °C bis +345 °C )

SPECIAL COMPONENTS

-

Gear of the Special components series are tailored specifically to your requirements, and designed with API 6A or other valid norms in mind. Acceptance after “third party inspection” is of course also possible for these components.

- Wellheads according to API 6A for cavern storage, porous resevoirs, aquifer storages, for gas and oil production, geothermal trees and injection trees up to +350°C (+662°F)

- Equipment with maintenance-free, true metal to metal seated valves - manually or automatically operated

- Central control unit

- Solid block design

- Additional equipment including plugs, back-pressure-valves and two-way check valves

- API 6 A valves 1 13/16“ – 13 5/8“ API 10,000 PSI WP

- Oil field equipment including rod rotator, lubricator and polished rods

- Gate valves

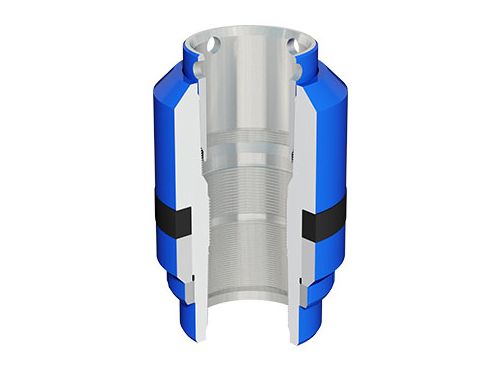

KELLY VALVES

-

Our Hartmann Kelly Valve enables a safe drilling and production operation.

KELLY VALVES

-

Our Hartmann Kelly Valves are manufactured and tested to API specification 7-1 and in compliance with IS0 9001:2015.

Kelly valves are used as a safety valve in drilling rigs. The use of the kelly valve enables an interruption of the media flow inside the drill string. Depending on the conditions, we supply our kelly valves with different overall lengths, external and internal diameters as well as thread types. Manufacturing is done according to API specifications 7-1 and in compliance with IS0 9001:2015. Certification (Type Approval) by ABS and DNV is possible.

Industries

- Challenging Applications – We support our customers with industry specific expertise, innovative solution concepts and reliable products.

RENEWABLE ENERGIES

- High performance valves for power to gas and wellheads for large-volume underground energy storage provide the highest levels of safety and set new standards.

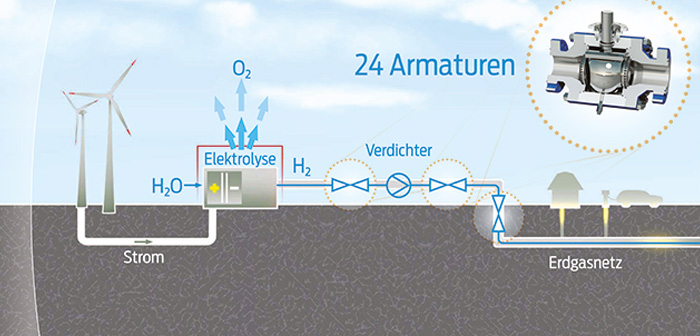

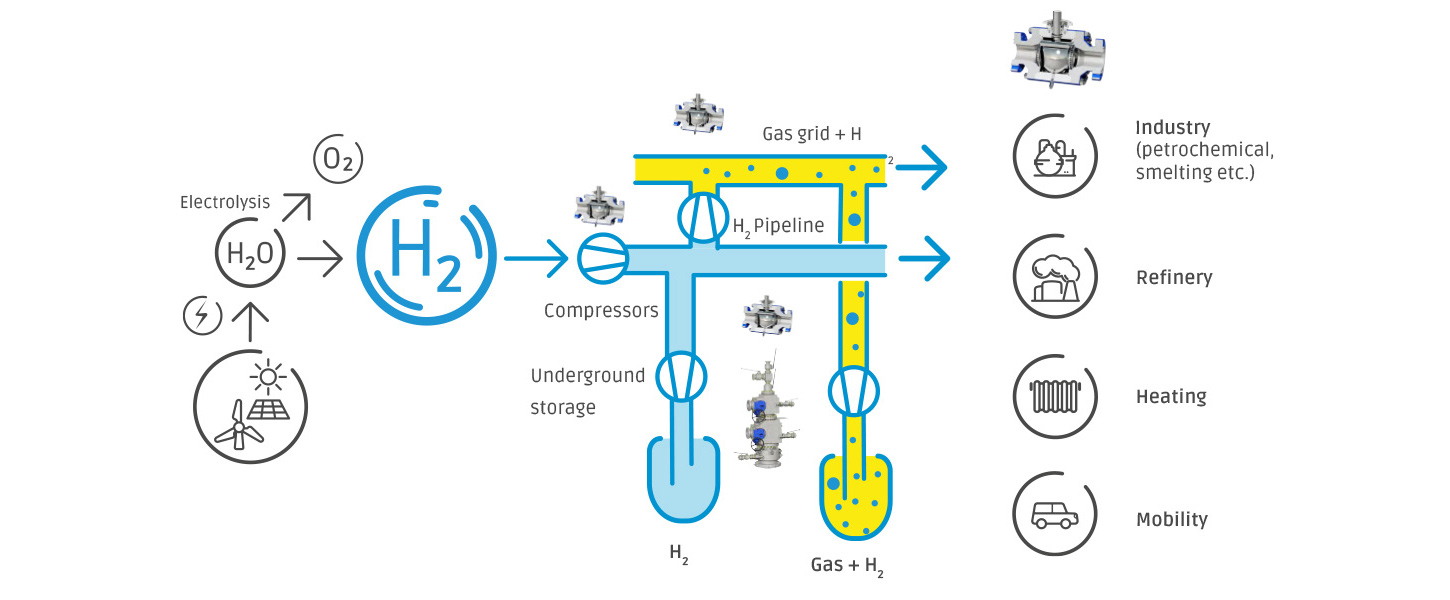

POWER TO GAS

-

Innovative energy concept: deployment of hydrogen ball valves in the "WindGas Falkenhagen" power to gas plant.

For the safe storage of renewable energy in the natural gas network, gas-tight hydrogen ball valves by Hartmann Valves are deployed.

The power to gas process enables electrical power from regenerative energies to be made storable in the form of chemical energy. In various pilot plants wind energy, for example, is converted into hydrogen by means of electrolysis. Particularly high demands are placed on the shut-off valves by the medium hydrogen when feeding into the gas grid. Hartmann Valves, supplier of ball valves and wellheads for more than 70 years, has the appropriate expertise in the area of gas storage engineering and valves for extreme conditions, for example in hydrogen applications. Absolute gas-tight ball valves which have a pure metallic sealing system are already in use in several power to gas plants. Produced from high grade materials and designed for the special requirements of hydrogen, they guarantee extreme reliability and a long service life.

ENERGY STORAGE IN CAVERNS

-

With customer-specific designs, Hartmann wellheads are available for the safe storage of large quantities of energy.

Hartmann wellheads and valves provide the highest levels of safety with demanding media and innovative processes.

In order to store future large quantities of energy for balancing production and consumption, various concepts are being pursued. In so doing, different media such as compressed air energy storage (CAES), hydrogen or synthetic natural gas are stored underground. Decades of experience from the crude oil, natural gas and chemical industries as well as collaboration in the first pilot projects makes Hartmann Valves a sought-after partner for the expansion of renewable energies and provides safe and controlled handling of the vast quantities of energy.

Based on the newest technical standards, adapted to the special requirements and in close coordination with the customers, the Hartmann wellheads are designed for this. Metal-to-metal sealing ball valves thereby guarantee a gas-tight and especially low maintenance shut-off.

Hydrogen

- Hydrogen offers the opportunity to store, transport and utilise renewable energy for further applications.

In three minutes the video explains Hartmann’s hydrogen solutions.

Areas of application

-

Special valves, which have evolved for the demanding hydrogen medium, have been used in the petrochemical industry for many decades. With energy transition, hydrogen will be found increasingly in other fields of application – from electricity generation (such as power-to-gas), through transport (in natural gas grids or hydrogen pipelines), to processing and mobility.

The underground storage of hydrogen in salt caverns constitutes an environmentally friendly and safe solution for storing large amounts of energy to balance between power generation and demand.

BALL VALVE

-

Durable special valves provide a reliable shut-off

- True metal-to-metal seal between ball and seat ring

- Gas-tight, even at high pressures up to 690 bar

- Special design for temperatures up to 550°C

- High cycles up to 200,000 per year

- Two independent barriers – Double Isolation and Bleed (DIB)

- Test in the pipeline – Double Block and Bleed (DBB)

- Triple sealing technology

WELLHEAD

-

Secure interface with underground storages

- Ball valves acc. to API 6A with DIB in large diameters up to 13-5/8“

- Doubled sealing at the flange connection

- Integration of several components in one block

(fewer flange connections) - Metallic seals at the wellhead

- Special designs for:

- Control lines

- Load measurement using strain gauges

- Electric pumps

GEOTHERMAL ENERGY

- Decades-long expertise and durable wellheads make Hartmann Valves one of the sought-after partners in the field of deep geothermal energy.

WELLHEADS WITH INTEGRATED BALL VALVES

-

The use of metallic sealing ball valves on the wellheads ensures superior leak-tightness, a long service life and low maintenance requirements.

Our API 6A wellhead equipment guarantees safe borehole closure – even with demanding conditions and scaling formation.

More than 30 reference projects since 1978 speak for themselves: as interface between the borehole underground and the above-ground geothermal plants, Hartmann wellheads have been in maintenance-free deployment for years in the Munich Molasse basin, the Rhine graben as well as in France, Belgium, the Netherlands and Turkey, amongst others. Adapted to project-specific requirements and designed for the highest flow rates and temperatures, they provide maximum operational safety and plant availability.

The wellheads are, by default, fitted with gas-tight ball valves which have a metallic sealing between ball and seat ring thus guaranteeing extreme reliability and long service life. In contrast to gate valves, ball valves have the advantage that even with scaling deposits in the pipe they close securely and require significantly less maintenance. With high safety factor levels Hartmann ball valves are true workhorse valves which if required are provided with flushing connections, e.g. for acidification.

ADAPTED GEOMETRY AND LONG-TERM PARTNERSHIP

- As a leading wellhead supplier in the German deep geothermal energy field, Hartmann Valves is assisting the Stadtwerke München (SWM) with the implementation of their district heating vision: by 2040 Munich will be the first large German city in which district heating will be extracted 100 % from renewable energies, above all geothermal. There are already two Hartmann wellheads being deployed in Freiham with six planned for the future in the Schäftlarnstraße which have been developed for the special project circumstances. Based on a framework contract, Hartmann Service is assisting with maintenance work such as the regular exchanging of pumps.

In Freiham the two boreholes have been drilled down to a true vertical depth (TVD) of approx. 2,500 metres. Producing around 90 litres per second at a temperature of 90 degrees Celsius, the district heating station is achieving a thermal capacity of up to 20 MW. The two boreholes were fitted with API 6A wellheads, pressure class 5000 psi and equipped with highly resistant metallic sealing ball valves. These have been prepared for retrofitting with an actuator where necessary. By means of the adapted design of an eccentric suspension for the 8 5/8 inch (approx. 220 mm) production casing string, enough space could be created for two cable penetrations for the pump. At the same time three further penetrations are made for the retrospective insertion of lines, e.g. for introducing inhibitors. The use of identical components in the production as well as the injection bores makes subsequent replacement between the two possible at any time, if necessary.

OIL / GAS PRODUCTION

- Harsh operating conditions and aggressive media call for especially durable wellhead equipment and reliable shut-off valves.

DEMANDING MEDIA

-

Hartmann wellheads with integrated ball valves are distinguished by their special robustness and long service life.

In the extraction of oil and gas a multitude of particles and concomitant materials are entrained in the medium flow. This places high demands on the shut-off valves. For more than 70 years Hartmann products, with their robust and individually tailored design, have provided the highest level of safety – even with dangerous and corrosive media such as sour gas, sour oil (H2S) and CO2. An experienced service team is available around the clock for assembly service, repairs and maintenance work.

RELIABLE COMBINATION

-

In both conventional wellhead design and in solid block design, metal-to-metal sealing ball valves provide the highest level of safety.

Wellheads with gas-tight ball valves have proven themselves to be very successful on the market.

Our API 6A conformant wellheads are fitted as standard with metal-to-metal sealing ball valves which are also gas-tight. In comparison to gate valves they offer a very high level of safety as they have a lower tendency towards blocking, are subject to less wear and don’t have to be filled with grease which can contaminate downstream plant parts. Thanks to the metallic sealing between ball and seat ring, Hartmann ball valves fulfil a leak rate of A or 0 and are especially robust and require only little maintenance. Additional safety is provided by a second barrier (DIB 2). Decisive for the long service life is an appropriate material selection as well as surface treatments and special coatings – against corrosion, for example. Hartmann wellheads are adapted to individual customer requirements as conventional or integrated designs.

INTEGRATED DESIGN AND SPECIAL SOLUTIONS

-

This wellhead for sour gas production is equipped with a quick-closing valve with the appropriate actuator.

With the integral design the functions of several valves and wellhead components are brought together in one component. By this means, not only is the installed height minimised but by saving on flanged connections, safety is increased above all. Added to that, the installation time is reduced, corrosion-prone nuts and bolts are dispensed with and an absolutely perpendicular installation with uninterrupted diameter is a given. In the area of oil extraction, Hartmann ball valves are also suitable at high temperatures in the steam applications used to fluidise the oil. In this regard the viscosity is lowered by steam injection at high temperatures.

PIG VALVES

-

Clever concept: the Hartmann pig valve replaces complex launching and receiving stations.

Scrapers lend themselves to the cleaning of paraffin deposits or water condensate. Hartmann pig valves offer a space and cost saving alternative to complex pig launching stations. In addition to the conventional application as a shut-off valve, the pigging valve functions as a sending or receiving valve for pigs.The pig valve can furthermore be deployed for separating various products in a pipeline. This concept has two independent safety barriers when opening and requires no special tools. Hartmann pigging valves are deployed, amongst others, by well-known oil concerns as a global standard solution.

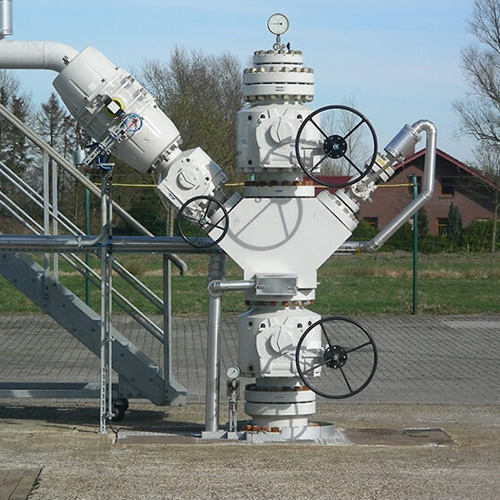

STORAGE TECHNOLOGY

- Hartmann wellheads and valves with their gas-tight components and their long service lives are ideally suited for the equipping of underground storages.

SAFE STORAGE OF CRUDE OIL AND NATURAL GAS

-

As a system supplier to the storage industry, Hartmann is involved in virtually all German oil and gas storage projects.

As early as the 70’s the underground storage capacity in Germany was massively extended for the national oil reserves. In oil storage, oil and saturated salt solution (brine) are alternated. With its high salt content, the brine is very corrosive and thus places high demands on wellhead materials.

Akin to crude oil storage, gas is also stored in subterranean reservoirs. These can be previously depleted reservoirs, aquifers or artificially produced cavities (caverns). Gas storage serves fundamentally to compensate for the varying seasonal demands. Cavern reservoirs in particular have large access cross sections and are stringently reliant on gas-tight components. Due to these demands, Hartmann has been able to assert itself as market leader for the equipping of gas reservoirs. Originating in Germany, the wellheads are also being deployed in many international projects in England, Denmark, the Netherlands, Portugal, Turkey and China.

Hartmann ball valves are integrated into the wellheads as a reliable shut-off or are deployed as high-performance valves in brine plants, compressor stations and gas refinement plants.

RELIABLE COMBINATION

-

Hartmann wellheads with integrated ball valves are characterized by their special resistance and longevity.

Wellheads with gas-tight ball valves have proven to be very successful in the market.

In contrast to oil and gas extraction, storage necessitates considerably larger pipe cross sections. Conventional shut-off concepts such as gate valves are not up to these demands. Which is why our API 6A conformant wellheads are fitted as standard with metal-to-metal sealing ball valves which are also gas-tight. Compared to Gate Valves, they offer greater safety, as they are less prone to blocking, subject to less wear and need not be filled with grease, which could contaminate downstream equipment. Thanks to the purely metallic seal between ball and seat ring, the Hartmann ball valves fulfill a leak rate of A or 0 in all pressure stages and are particularly resistant and require little maintenance. Additional security is provided by a double barrier (DIB 2). Decisive for the long service life are an appropriate selection of materials as well as surface treatments and special coatings, for example against corrosion.

Adapted to individual customer requirements Wellheads are in classic design or available. In the latter case, the functions of several valves and wellhead components are combined in one component. This not only minimizes the height, but also increases safety by saving flange connections. In addition, the construction time is reduced, corrosion-prone bolts and nuts are eliminated and an absolutely vertical structure with undisturbed drift diameter is given.

EFFICIENCY BOOSTING OF EXISTING PLANTS

-

This x-mas treee in solid block design has the latest wellhead technology and offers increased safety due to the reduction of interfaces.

Many of the existing storage plants undergo a general overhaul after years of operation. The borehole completion is replaced and in the process, the wellheads are brought up to the latest state of technology. In collaboration with our customers we have, for example, been able to significantly increase the safety and integrity of the reservoirs in the past years. Hence strain gauges are used for monitoring the pipes and individual components are combined in blocks (block design) whereby interfaces are reduced. In addition to the metallic sealing he ball valves were also fitted with a second barrier (DIB 2). Remaining flange connections have also been given a second barrier and partial metallic sealing. With these innovative concepts, which the conventional oil and gas industries don’t offer, Hartmann Valves are making a sustainable contribution to long-term safety in reservoir storage. At the same time, professional consultation and support during all project phases are for us a given. The experienced Hartmann service team is available around the clock for installation and maintenance work.

STORAGE OF RENEWABLE ENERGIES AND SPECIAL MEDIA

-

In customized design Hartmann wellheads are available for the safe storage of large amounts of energy.

For the continued expansion of renewable energies a storage potential is necessary for enormously large quantities of energy. This energy can and is being stored in underground caverns. In this regard compressed air energy storage (CAES), with components from Hartmann, has been in existence for several decades and a further step (pilot projects have been or are already being implemented) is the storage of hydrogen and synthetic natural gas storage. In the area of hydrogen storage we are able to fall back on the many years of experience gathered from supplying to refineries all over the world. Flexibility and cross-industry experience has meant that the company Hartmann has also established itself as a good partner in the area of these special applications. Hence Hartmann has also equipped the first European storage cavern for helium.

CHEMICAL / PETROCHEMICAL

- Tailor-made Hartmann valves provide safe shut-off in the high performance area

BALL VALVES FOR EXTREME CONDITIONS

-

This FDA compliant hydrogen ball valve has a metal-to-metal sealing and guarantees a leak rate of A or 0

The metal-to-metal sealing ball valves are designed to individual customer requirements and are distinguished by their long service life and low maintenance.

The generation of products in chemical processes presents high level demands on the reliability of the plant components. The areas of application of high performance valves are varied: designed to individual customer requirements they are suitable for temperatures of -200 to +550 °C, pressure stages up to 700 bar and up to 200,000 cycles per year. Hartmann valves are already in successful deployment for the following, in part aggressive media: crude oil, natural gas, acid gas, syngas, oxygen, hydrogen, helium, steam, thermal water, coal dust, slurry, slag & ashes, polymers, cellulose as well as abrasive and degreasing media.

The valves can be flexibly combined with electric, pneumatic or hydraulic actuator technology.

MAXIMUM SAFETY AND DURABILITY

-

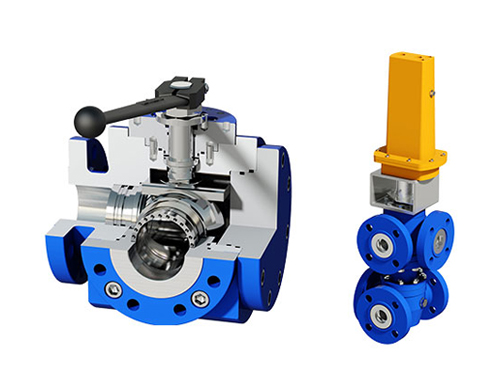

Double ball valve for double safety: with the twin ball valve the safety in the structural length of standard valvework is increased by a factor of 4.

The high leak-tightness and durability of the Hartmann special ball valves is achieved by means of a metallic sealing between ball and seat ring. This sealing system is gas-tight and also fulfils a leak rate of A or 0 even with high cycle operations. Even in the presence of contamination it is considerably more robust with low maintenance than soft sealing systems. A further decisive factor is the appropriate material selection as well as surface treatments and special coatings. Thanks to the longer maintenance intervals, substantial time and cost savings over the entire service life of a plant can be realised. Additional safety is provided by special design features and safety orientated functions such as double isolation and bleed (DIB), two additional independent barriers or double block and bleed (DBB), which enable testing in the pipeline. To increase the safety in existing plants with minimal outlay, the twin ball valve offers a compact and economical alternative to the deployment of multiple valves. These consist of two ball valves in one housing which can be equipped with two independent barriers if required.

MULTI-WAY VALVES AND SPECIAL DESIGNS

-

Our multi-way valves are also individually developed to customer requirements and are fitted with a metal-to-metal sealing system.

Multi-way valves lend themselves where switching over between different lines has to take place. An example of a typical application is the switching over between two filter systems. This makes continuous operation possible by which one filter remains in use while the second is cleaned, replaced or regenerated. The combination and mechanical coupling ensures that several valves are switched at precisely the same moment. The valves are furthermore used to switch over between different media, e.g. fuels on turbines. By means of the trunnion mounted design, the ball is centered in the middle of the valve even under asymmetric loads. The spring loaded sealing rings provide a reliable seal in all pressure situations. The different angle between the flanges and ball bores in L, T or X execution results in a variety of combinations.

POWER PLANT TECHNOLOGY

-

In power plants with particularly high demands, reliable high performance valves provide maximum safety.

Hartmann ball valves are deployed in many different power plants and thus also under the most varying conditions. Besides the applications listed below for hydropower, steam and gas turbines, ball valves for example are also being developed for the reverse transformation of electrical into chemically bonded energy in the form of hydrogen (see renewable energies).

HYDROPOWER

- In the area of hydropower, potential energy derived from the height differential is transformed into electrical energy. Because these are open systems the water has a high oxygen and solids fraction which results in considerable corrosive and erosive loads. Due to the metallic sealing system and the careful selection of materials, Hartmann ball valves are ideally matched to these conditions.

STEAM

- Steam turbines and the associated steam cycle are found in various types of power plants such as coal, nuclear or combined-cycle (GuD) plants. Steam, water and the intermediate form, saturated steam, place high demands on the material selection and design in terms of temperature and pressure loads. Even under these conditions the metal-to-metal sealing in combination with steam resistant seals has proven itself as a reliable system. With their experience of structural design for nuclear plants including earthquake calculations and the compilation of pre-test paperwork in the documentations department, Hartmann Valves is a reliable partner.

GAS TURBINES

- With gas turbines, the safe infeed and, where applicable, shut-off is a deciding factor. Hartmann ball valves have proven themselves with their reliability in this area. Both standard ball valves and multi-way valves are deployed for operation with air, oil and gas. To increase the efficiency, the development is always towards higher input temperatures. Hartmann Valves is going down this route and offers special high temperature ball valves.

REFERENCES

- Quality since three generations – Long-lasting supplier relations and interesting application stories prove the satisfaction of our customers.

REFERENCE GAS STORAGE: EWE

-

Wellhead equipment for high demands

Durable wellheads with pure metallic sealing ball valves provide a high level of flexibility and availability in the Jemgum gas cavern storage.HIGH LEVEL OF FLEXIBILITY AND AVAILABILITY

With the new build of the storage plant in the Lower Saxony town of Jemgum, EWE Gasspeicher GmbH commissioned Hartmann Valves GmbH to supply all brine and gas wellheads, diverse special ball valves and the associated assembly and maintenance service. The „Hartmann concept“, i.e. the use of pure metallic sealing ball valves as wellhead shut-off valves which are absolutely gas-tight even in large nominal bores, had already proven itself in the equipping of other storage plants as highly durable and virtually maintenance-free.

REFERENCE GAS STORAGE WINTERSHALL DEA

-

Reliable isolation for Wolfersberg Gas Storage

Unique Twin Ball Valves designed for space limitation.MAXIMUM SAFETY FOR NATURAL GAS STORAGE

Reliable isolation for Wolfersberg Gas Storage – Unique Twin Ball Valves designed for space limitation

Since the upper Bavarian gas storage facility of DEA was established in 1973 about 800 Hartmann ball valves have been installed in the various operations. The depleted gas reservoir with depths of 2,900 to 3,000 metre located southeast of Munich is the deepest gas storage in Europe. Besides the 10 wells for injection and production, facilities are run for the compression, pressure reduction, drying and temperature control of the gas. A very high safety level as well as plant availability are critical. When old shut-off valves had to be replaced, Hartmann designed extra compact Twin Ball Valves, which are bubble-tight and solve problems of space limitation.

REFERENCE GAS PRODUCTION

-

Refit in record time

Optimal planned maintenance of safety ball valves enables recommissioning on scheduleREFIT IN RECORD TIME

Optimal planned maintenance of safety ball valves enables recommissioning on schedule

The natural gas field Völkersen located in the north-western part of Lower Saxony and operated by DEA is one of the most productive in Germany. When operating, as well as during service and preventative maintenance of the surface facilities and the production wells conducted by DEA Niedersachsen, safety has top priority. All components of the plant have to fulfill the highest technical requirements at any time.

In the course of regular 5 yearly maintenance of the Central Gas Drying Plant about 20 ball valves manufactured by Hartmann Valves were inspected and overhauled in September 2016. Thanks to early planning and close cooperation all valves could be reconditioned in a short period and taken back into operation right on schedule.

GAS TRANSPORT | NORD STREAM

-

With zero leakage, a 50 year lifetime and exceptional temperature and pressure ratings.

HIGH PERFORMANCE VALVES FOR LIFE

With zero leakage, a 50 year lifetime and exceptional temperature and pressure ratings, Hartmann ball valves have significantly reduced maintenance demands on the Nord Stream gas pipeline.

The Nord Stream pipeline transports natural gas from Russia to the EU internal market, with capacity to deliver up to 55 bcm per year, providing enough power for up to 26 million homes.

Nord Stream wanted to upgrade the pipeline’s valve system, to reduce maintenance demands and ensure reliable sealing on this important route.

Nord Stream selected Fahlke Control Systems and Hartmann Valves to deliver a new system, complete with actuator, control unit and ball valves, which could meet Nord Stream’s high safety, temperature, pressure and corrosion standards and deliver a 50+ year operational life.

REFERENCE CHEMISTRY | YARA GERMANY

-

Special ball valves for extreme conditions:

Innovative conversion of an ammonia factory.INNOVATIVE CONVERSION OF AN AMMONIA FACTORY

Special ball valves for extreme conditions ensure energy efficient and economical production

From 2012 to 2013 Yara Germany realized a comprehensive process optimization at the plant in Brunsbüttel. The ammonia factory is worldwide unique: both gasification lines can either be run on natural gas or oil. One component are the 5“ shut-off ball valves from Hartmann Valves. These are especially designed for the challenging combination of pure oxygen, steam and high temperatures. All customer demands have been fulfilled above-average. The energy efficient production secured the economic future of the facility.

POWER TO GAS: UNIPER ENERGY STORAGE

-

Metal to metal sealing ball valves for innovative hydrogen project.

VALVES FOR INNOVATIVE HYDROGEN PROJECT

Maximum operational safety and availability of Power-to-Gas-Plant: E.ON Gas Storage counts on true metal sealing ball valves

In 2013 Uniper Energy Storage GmbH (UST) brought the power-to-gas plant “WindGas Falkenhagen” successfully on stream. With this project Uniper has been demonstrating, as one of the first companies worldwide, a way how renewable energy can be stored in the natural gas grid in order to make production independent from consumption. For the pilot plant in Falkenhagen (Germany) Hartmann Valves supplied 24 true metal to metal sealing ball valves, designed to meet the excessive demands for service associated with pure hydrogen whilst ensuring maximum safety.

REFERENCE GEOTHERMAL: TRAUNREUT

-

Well completion for the deepest and most productive German well.

LEXIBLE IN DESIGN MODIFICATIONS, COMPRISING SERVICE

Consultant gec-co counts on Hartmann Valves & Wellheads for Well Completion

Geothermal energy is a perfect example for renewables. It is resource-saving, produces no pollution and the availability is almost unlimited. The city of Traunreut is an ideal location for geothermal energy since it is situated in the Bavarian Molasse Basin. With two wells drilled successful and the installation of the district heating transmission station, Traunreut feeds geothermal energy in the municipal network. 3000 housing units as well as industrial clients are supplied this way. The geothermal power plant will presumably produce climate-neutral electricity by 2016.

INNOVATIVE SOLID BLOCK DESIGN

-

Successful changeover: The Xmas tree with ball valves

SUCCESSFUL CHANGEOVER: THE XMAS TREE WITH BALL VALVES

Within the scope of overhauling several Xmas trees for gas production, a completely new design of construction was decided on: In the place of Xmas trees with gate valves, solid block Xmas trees with integrated ball valves have already been in operation at several North German locations since 2018. This concept unites the preferences for a compact design with the advantages of gas-tight ball valves over gate valves – at high and in particular also low pressures. Also decisive was the positive experiences with safety ball valves as complementing quick-closing valves in the above-ground installations. The innovative design, which was developed in close collaboration between Hartmann Valves and the operator, provides not only for increased safety and simple operability but also for significantly reduced maintenance requirements.