- Offer Profile

-

Turck – Your Global Automation Partner

Turck is your global partner for factory, process and logistics automation in numerous industries. With its digitally networkable solutions for efficient automation systems, the family- owned company supports the digital transformation and is one of the pioneers of Industry 4.0 and IIoT. Automation solutions from Turck support the profitability, efficiency and sustainability of machines and plants. As a specialist in smart sensor technology and decentralized automation, Turck brings intelligence to machines and ensures reliable detection, transmission and processing of relevant production data – from sensor to cloud – not only with robust I/O solutions in IP67, but also with user-friendly software and services.

Industries & Solutions

- Automation solutions and products by TURCK increase the availability and efficiency of your machines and systems in numereous industries

Automotive

-

The automotive industry demands robust products that can survive the toughest of conditions regardless if its during the body and assembly, body in white, stamping or powertrain sector of the automotive manufacturing process.

TURCK partners with customers to provide a wide array of solutions to respond and solve our automotive customers automation needs. With an unmatched range of automation solutions including a specially developed sensing line for welding, TURCK has been the go to partner for automotive automation solutions for years.

Click on our success stories below for more examples on how TURCK works to solve your automation challenges.

Chemical

-

Working with chemicals is no easy task, thankfully TURCK robust automation solutions are more then up to the test. We know sealing and corrosion resistance is critical to your applications success and we have solutions specially designed withstand the challenge.

TURCK partners with customers to provide a wide array of solutions to respond and solve our customers automation demands. With an unmatched range of automation solutions including corrosion resistant sensors, overmolded cordsets, distributed I/O products and RFID, TURCK is ready to tackle whatever automation challenges you are facing.

Click on our success stories below for more examples on how TURCK works to solve your automation challenges.

Energy

-

Few other industries endure the challenges that energy applications must persevere through on a daily basis. Extreme temperature, rain and moisture, and even the exposure to the sun can wreak havoc on sustainable energy applications. TURCK provides robust solutions focused on keeping your systems running and letting you collect and produce energy quickly, efficiently, and with minimized downtime.

Click on a success stories below for more examples on how TURCK works to solve your automation challenges.

Food and Beverage

-

When your application demands the highest standards of cleanliness while still providing protection against constant washdowns we provide IP rated hygenic automation solutions you can be confident in.

TURCK partners with customers to provide a wide array of solutions to respond and solve our customers automation demands. With an unmatched range of automation solutions including corrosion resistant sensors, industrial cordsets, distributed I/O products and RFID, TURCK is ready to tackle whatever automation challenges you are facing.

Click on our success stories below for more examples on how TURCK works to solve your automation challenges.

Mobile Equipment

-

Extreme temperatures and the shock and vibration of the road are just the beginning of what mobile equipment applications face everyday. TURCK rises to the challenge, offering solutions that thrive when put to the test of the most extreme environments.

TURCK partners with customers to provide a wide array of solutions to respond and solve our customers automation needs. With an unmatched range of automation solutions including sensors, industrial cordsets, distributed I/O products and RFID, TURCK is ready to tackle whatever automation challenges you are facing.

Click on our success stories below for more examples on how TURCK works to solve your automation challenges.

Oil and Gas

-

Rugged work requires rugged equipment. When you need to be able to rely on your automation solution, TURCK answers that call letting you focus on what you need to, your work.

TURCK partners with customers to provide a wide array of solutions to respond and solve our customers automation needs. With an unmatched range of automation solutions including sensors, industrial cordsets, distributed I/O products and RFID, TURCK is ready to tackle whatever automation challenges you are facing.

Click on our success stories below for more examples on how TURCK works to solve your automation challenges.

Packaging

-

Precision and innovation are key to the packaging industry and TURCK provides innovative automation solutions to match.

TURCK partners with customers to provide a wide array of solutions to respond and solve our customers automation needs. With an unmatched range of automation solutions including sensors, cordsets, distributed I/O products and RFID, TURCK is ready to tackle whatever automation challenges you are facing.

Click on our success stories below for more examples on how TURCK works to solve your automation challenges.

Semiconductor

-

TURCK answers the demands of the semiconductor industry by providing the most precise and reliable automation products to ensure solutions for your application.

TURCK partners with customers to provide a wide array of solutions to respond and solve our customers automation needs. With an unmatched range of automation solutions including corrosion resistant sensors, overmolded cordsets, distributed I/O products and RFID, TURCK is ready to tackle whatever automation challenges you are facing.

Click on our success stories below for more examples on how TURCK works to solve your automation challenges.

Pharma

- The pharmaceutical industry is characterized by strict hygiene requirements, aggressive cleaning processes and short cycle times. As a specialist in plant and process automation, Turck can offer you an optimum solution for any automation task in the pharmaceutical industry — from production and packaging to logistics. Whether a pharmaceutical manufacturer, a top-level engineering firm and super skid supplier or a systems integrator — customers around the world are already benefitting from Turck's sensor, field bus and connection technology as well as our I/O and identification solutions.

Product groups

Sensors

- Sensors provide important information for almost all areas of industrial automation, such as digital and analog position signals, currents, flow rates, temperatures, paths, and angle. As a co-founder and pioneer of modern sensor technology, TURCK offers the appropriate range of products. You can choose from more than 5,000 proximity switches, photoelectric, flow and position sensors to implement your made-to-measure solutions

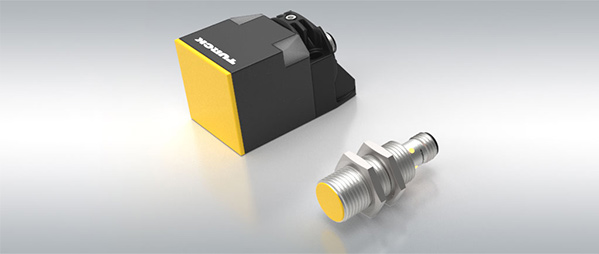

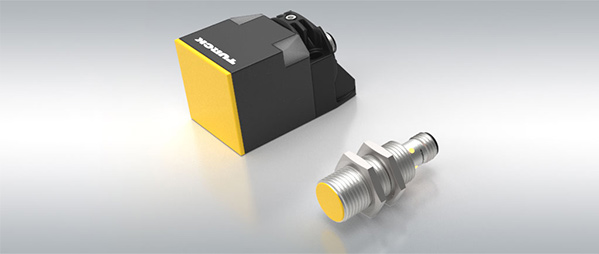

Inductive sensors

-

Inductive sensors detect metallic objects without making physical contact. The wear-free operating principle ensures maximum operational safety and guarantees that the resistant initiators have a long useful lifetime.

Thanks to their extraordinary coil concept, uprox sensors from Turck also offer the largest switching distance, Factor 1 for all metals and unique installation freedoms. Proximity switches can be flexibly installed.

The complete range of inductive sensors includes, among other things, the following product series:

- Factor 1 sensors

- Rectangular, threaded and smooth barrel sensors

- Explosion-proof sensors

- Sensors with a cable connection, connector or terminal chamber

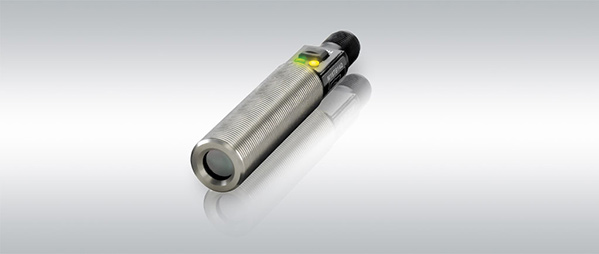

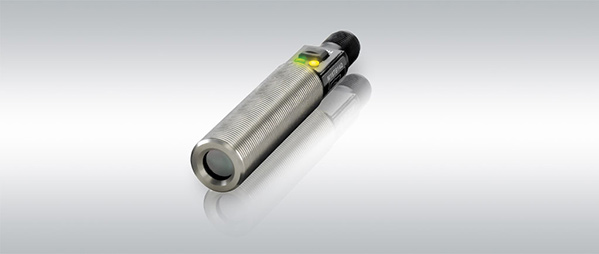

Photoelectric sensors

-

Photoelectric sensors are used in numerous industries such as material transport, packaging, food and beverage or pharmaceutical industries. Even in the high ranges, they detect almost all materials with no physical contact and do so with particularly fast response times. Thus, the sensors are ideal for applications with large numbers and frequencies.

Turck has one of the world's largest ranges of photoelectric sensors – whether in a compact miniature form, with a high range or especially resistant for use in extreme environments.

Capacitive sensors

-

Whether in the plastics, chemicals or packaging industry – capacitive sensors reliably detect all solids, bulk goods, liquids, metals and non-metals. As they are non-contact, reaction-free and work through container walls, there is no wear. Only limit level sensors from the NCLS product series, which can also be used in the food industry thanks to the hygienic design, come into direct contact with media.

The potential uses of sensors are as diverse as the available designs (threaded barrel, smooth barrel or rectangular). The limit level measurement of liquids is an important application area in addition to object detection and many other applications.

Magnetic Field Sensors

-

Magnetic field sensors are used, in particular, for the contactless detection of the piston position in pneumatic cylinders. We also offer application-specific sensor types for use in welding or Ex-areas as well as for analog position measuring.

Magnetically actuated proximity sensors in cylindrical form enable large detection ranges of up to 90 mm such as for pig detection in pipelines. Thanks to maximum EMC immunity and protection class IP67, the sensors support high system availability.

Ultrasonic sensors

-

By their nature, many media and objects make detection and distance measurement by sensors more difficult. However, metals or non-metals, transparent, liquid or powdery surfaces are usually well suited to be reliably detected by ultrasonic sensors.

To ensure ideal adaptation to the respective application, there are many variants of Turck ultrasonic sensor that feature temperature compensation, interference suppression for external noises and other options.

Radar sensors

-

Radar sensors are ideal solutions outdoors, because wind, rain or fog cannot harm them. Regardless of external influences, the sensors can prevent port machine or forklift collisions, for example.

With the help of the FMCW technology (Frequency Modulated Continuous Wave) radar sensors such as the QT50R, Q120R or Q240R reliably detect moving and static objects.

Linear position sensors

-

Position measurement tasks can be solved with a number of Turck sensors tailored to the requirements of each application. The portfolio comprises, on the one hand, inductive linear position sensors with a wear-free measuring principle. Furthermore, various draw-wire sensors and magnetostrictive linear position sensors are available for position detection in hydraulic cylinders and linear position sensors for the tracking of floats for level measurement.

Dynamic and highly precise: Inductive, magnetic, magnetostrictive or draw-wire can transmit path information of up to 40 meters measuring length to the higher-level control. High sampling rates and precise measurement signals are necessary for demanding motion control.

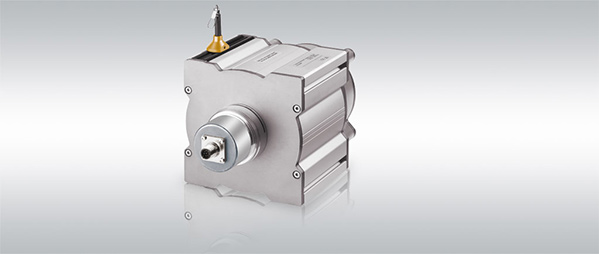

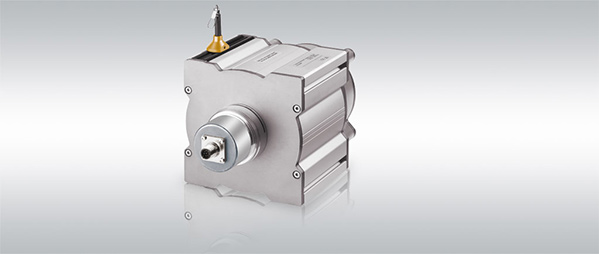

Encoders

- The contactless encoder Ri360P-QR24 makes no compromises in terms of ruggedness and resolution and is suited for all those applications where rotation speeds, sense, position, angle and lengths have to be captured. The TURCK portfolio also provides encoders in a wide variety of designs, graduated in a range of sizes from 24 up to 102 mm diameter, as versions for incremental or absolute position detection, as hollow or solid shaft variants. They fulfill different positioning tasks with a resolution of up to 18 bits (absolute encoders) and of up to 36,000 pulses per revolution (incremental encoders).

Inclinometers

-

Encoders are used for any application where rotation speed, sense, position, angle and length are monitored. The Turck range comprises contactless and conventional encoders in various designs, graduated in a range of sizes from 24 up to 102 mm diameter, as versions for incremental or absolute position detection, as hollow or solid shaft variants. Vibration resistance and robustness without compromise are prerequisites for reliable operation of the devices, even in demanding environments.

Innovative technology: Contactless encoders QR24 and QR20 are based on the inductive measuring principle. Users benefit from the wear-free design and interference immunity.

Pressure sensors

-

Whether on presses, cooling circuits or storage tanks – pressure that needs to be monitored and measured can be found everywhere. With an extensive range of pressure sensors, Turck offers tailor-made solutions for industrial applications and mobile equipment.

There is also a huge range of different sensor types, process connections and output signals available to users. The sensors are robust even under extreme conditions to ensure long-lasting, reliable operation. With smart IO-Link functions, the PS510 and PS310 series also support the requirements of Industry 4.0.

Temperature sensors

-

Turck's product portfolio provides users with flexibility for temperature measurement: Temperature sensors from the TS product series enable quick commissioning and offer a high level of convenience during operation. The TTM/TTMS product series includes a number of compact sensors – with integrated probe or with M12 connector for separate probes. T-Gage infrared sensors measure temperatures from 0 to 300 °C without making physical contact, which can prove to be a distinct cost advantage.

The range is supplemented by quick temperature measuring amplifiers (IMX12, IM34), including particularly narrow interface devices – for more space in a switch cabinet with peak performance at the same time.

Flow sensors/Flow meters

-

Flow monitoring

Flow monitoring is a procedure that demands a reliable and reproducible surveillance of limit values and flow patterns. Flow sensors detect critical deviations of the flow rate of liquid and gaseous media. Typical areas of application are the monitoring of cooling circuits in welding applications for example, protection against dry running of pumps, as well as the flow monitoring in air ducts and air conditioning equipment. Because of the calorimetric mode the media temperature is also monitored.Flow rate measurement

In addition to reproducibility, flow-rate measurement demands a defined degree of accuracy. The flow meters continuously and accurately measure a defined volume of a fluid per unit of time and are suitable for applications where qualitatively consistent process results and a steady supply of fluids is essential. We offer flow meters with calorimetric, magnetic-inductive and Vortex measurement principle for various areas of application.

Level sensors

-

Users can utilize the respective advantages of different measuring principles for limit level detection or continuous level measurement. This depends on factors such as whether granular media or liquids where foam forms on the surface are used. Similarly, special solutions are required for mounting in confined spaces, in areas with explosion protection and in particularly deep containers.

Turck offers a comprehensive portfolio featuring sensors for various media and environments and both medium-contacting and contactless detection. These include capacitive and magnetostrictive sensors, fiber optic, ultrasonic and radar sensors, and devices with a guided microwave.

Condition monitoring sensors

-

Condition monitoring sensors are specially designed to record environmental and system variables that allow conclusions to be drawn about the condition of a machine or system. With the help of this information, critical conditions or anomalies can be detected early in order to plan maintenance in advance and increase system availability.

Turck offers condition monitoring sensors for the detection of vibration, temperature and humidity. IO-Link interfaces facilitate system integration and information transfer. Modbus wireless interfaces enable connection to wireless systems, which simplifies retrofitting of the condition monitoring sensors as well as our mounting accessories.

Identification

-

The compact or modular RFID systems from Turck can use proven HF technology and long-range UHF technology in parallel in one identification solution. The Turck RFID system offers data carriers, read/write devices, connectivity solutions and the corresponding interfaces, which can be flexibly combined depending on requirements. Interfaces are available for OPC UA, PROFINET, EtherNet/IP, Modbus TCP, TCP/IP, PROFIBUS-DP, DeviceNet, CANopen and EtherCAT.

Read/Write Head HF/UHF

- Application optimized read/write heads in the industry-standard design (up to IP69K with HF), allow for optimal integration into your application. Depending on the environmental conditions, read-write ranges of up to 1 m (HF) or several meters (UHF) are possible. The radio interface for read/write heads and data carriers is internationally standardized (ISO 15693 and ISO 18000-6c with HF at UHF).

Tags HF/UHF

-

The rugged tags (data carriers) with high protection class are insensitive to dirt and liquids and are available with a max. memory size of 8 kB.

They are passively powered via the read/write head and are maintenance free.

Tags for high temperatures and direct mounting on metal allow flexible use under extreme conditions. Tags for use in hazardous areas and autoclavs complete the product portfolio.

Interfaces HF/UHF

- RFID interfaces from Turck connect the read/write heads to the OPC UA, PROFINET, EtherNet/IP, Modbus TCP, TCP/IP, PROFIBUS-DP, DeviceNet, CANopen and EtherCAT networks. The fully encapsulated TBEN multiprotocol modules with RFID and I/Os (IP67/IP69K), as well as the modular BL67 system (IP67), are ideal for direct use in harsh environments. Users are thus saved the task of setting up protective boxes in the field. Customers use Turck's BL20 modular system for mounting on a DIN rail in the switch cabinet. The programmable variants of the RFID interfaces perform preprocessing steps and control actions directly on the module.

Handheld HF/UHF/Barcode

- With its mobile RFID handhelds for RF or UHF applications, Turck offers simple solutions for the efficient optimization of your identification processes � from improving inventory management to simply rewriting tags. Whether you are using the robust IP67 complete solution or the smartphone version in IP20, the functionality of the RFID devices will win you over.

Barcode Readers

- Our barcode readers are camera-based reading devices in a compact and robust housing. During product identification in production and logistics areas, the most widely used 1D and 2D codes are captured and evaluated. The data recorded is transferred via an RS232 or Ethernet interface, depending on requirements, to facilitate the further exchange of information to a controller. The setup is carried out quickly without need for a PC and takes place directly on a touchscreen connected to the device. To offer customers flexibility in selecting the right barcode reader, a range of models with different lenses and internal lighting are available.

Accessories

- The BL ident� connectivity portfolio offers field-wireable extension cables in various versions (Standard, Economy and Food & Beverage) for the secure communication between interface and read/write head as well as field-wireable bus and supply lines. The accessories include mounting adapters for read/write heads and tags, as well as protective frames for read/write heads. In addition, the portfolio also includes handheld readers for mobile reading and writing of tags.

Connectivity

- For use in rough industrial environments, TURCK offers standardized and customized components for all requirements. The portfolio of connectivity products comprises male and female connectors, flanges and cable bushings, connection and extension cables, fieldbus lines and junction boxes in many designs and variants. Field-wireable types complement the product range, allowing you to use them with your own cables.

Cables

- We offer round connector systems in M8 × 1/Ø 8 mm and M12 × 1 acc. to IEC 61076-2-101 as connection and extension cables. The 1/2" and 7/8" round connector systems are particularly suitable for applications with increased power requirements. The M16 and M23 × 0.75 × 1 round connector systems are used for connecting multiple junction systems. A, B, C, or I-type valve connectors acc. to EN 175301-803, are available with and without protective circuit for the connection of various different valves.

Receptacles

- A mounting flange is available for all common connector systems with front and rear wall mounting and printed or soldered contacts, as well as with stranded wires. They transform any switch cabinet or switch box as well as various end devices into a plug-and-play device or act as a circuit board connection.

2-Way Splitters

- 2-way splitters, such as Y-, T- and H-splitters, combine two signals or data or distribute the power to the required actuators. This can significantly reduce the number of cables to be laid. The 2-way splitters are available in the designs M8 × 1, M12 × 1 and 7/8

Passive Junction Boxes

- Passive 4-, 6- and 8-way junction boxes combine input signals or distribute output signals. This means up to 16 I/O signals can be transmitted via a single multicore cable. The multi-junction-box systems are available in M8 and M12 designs.

Field-wireable Connectors

- Field-wireable connectors are available in sizes M8 × 1/Ø 8 mm, M12 × 1, 1/2", 7/8", M16 × 0.75, M23 × 1 and also as valve plug. The connectors make installation easier in applications in which it is difficult to estimate the needed cable length.

Bulk Cables

- We offer cables in different qualities, perfectly tailored to the respective application. The products range from simple PVC up to PUR and PP cable types for food and beverage applications. All cables are available as yard goods or with injection-moulded connectors.

Inductive Couplings

- The inductive coupler of the NIC series is designed for contactless bidirectional transmission of power and data. The devices consist of two components, the primary part NICP and the secondary part NICS. The primary part supplies the secondary part with power via the air interface. In return the secondary part provides data to the connected sensors and actuators.

Lighting and Indication

- We have a huge range of LED displays and lights for industrial applications for you to choose from: work lights to directly illuminate workstations and machines, signal lights and display lights to show process and machine statuses and Pick-to-Light versions for order-picking processes. The tower lights and indicator lights provide visual as well as acoustic status messages. Versions of the work lights for challenging working conditions—such as high temperatures, aggressive media or a dirty environment—are also available. All devices are characterized by low power consumption. Thanks to their long lifetime, the LEDs need not be replaced.

Industrial LED Task Lighting

- The LED work lights are high-quality, energy-efficient products with high illuminance for a service life of over 50,000 hours. The rugged, vibration-resistant housing and the elegant design make this product series ideal for a wide range of industrial and mobile applications, including machine lights, housing lights, work lights, lights for visual inspection and room lights. The low nominal voltage allows a light control via a PLC or other control system for additional energy savings.

Tower Lights

- The LED tower lights are clearly visible within the entire plant. They are composed of differently colored LEDs and are available with or without beeper. They can be mounted directly on machines, in the cabinet or in places within the production lines that need to be monitored.

LED Indicators

- Our indicators provide numerous types of bright, well visible models, from daylight-bright up to several colors in one device. These indicators have a rugged design for long-term use and require no additional protective housing. The flexibility in design, size and mounting provides a unique solution for many applications.

Touch Buttons

- Touch buttons are suitable for a range of applications that require a visual display for employees and feedback to the controller. Unlike in conventional pick-to-light systems, inputs and outputs are actuated individually and are independent from each other. The input signals control only the display; pressing the button creates only an output signal.

Pick-to-Light

- Pick-to-light systems control and monitor commissioning, configuration and installation processes. For example, the light screen located in front of a picking bin captures the hand of the operator and reports removal back to the control. Then work lights indicate in which bin the operator has to reach next. Pick-to-light solutions are available in various versions, also for direct mounting on picking bins.

Fieldbus Technology

-

The fieldbus product portfolio includes I/O modules and I/O systems for applications in the Ex and non-Ex area. The modules and systems are available in protection class IP67 for installation in the field as well as in protection class IP20 for cabinet mounting. You have the choice between PROFIBUS-DP, PROFIBUS-PA, Foundation fieldbus, DeviceNet, CANopen and Modbus RTU/ASCII as well as the Ethernet protocols PROFINET, Ethernet/IP, Modbus TCP and EtherCAT.

Das Feldbusprogramm umfasst I/O-Module und I/O-Systeme f�r Anwendungen im Ex- und Nicht-Ex-Bereich. Die Module und Systeme sind sowohl in Schutzart IP67 f�r die Feldmontage als auch in Schutzart IP20 f�r die Schaltschrankmontage verf�gbar. Bei den Feldbussen besteht die Auswahl zwischen PROFIBUS-DP, PROFIBUS-PA, FOUNDATION fieldbus, DeviceNet, CANopen und Modbus RTU/ASCII sowie den Ethernet-Protokollen PROFINET, EtherNet/IP, Modbus TCP und EtherCAT.

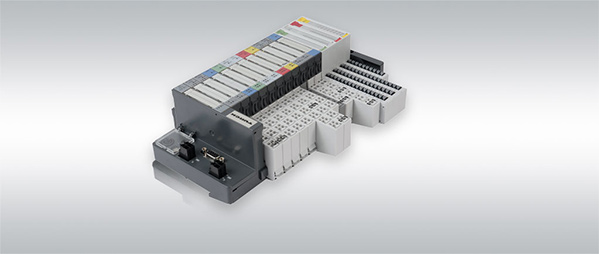

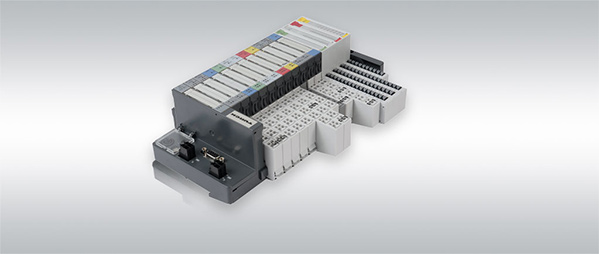

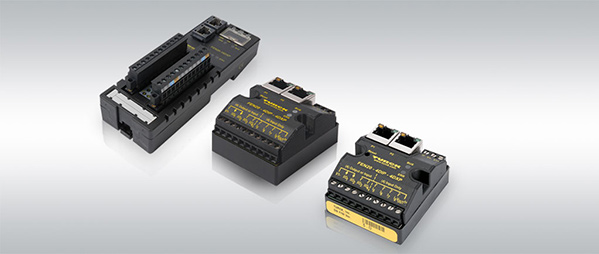

I/O Systems

-

Modular fieldbus I/O systems map the signal requirements of each application precisely and highly efficiently thanks to the individual composition of the electronic modules. They offer the advantages of a high level of intelligence, individualization and flexibility. In addition, modular systems shorten planning and commissioning times in project work and allow parallel connection to OT and IT networks.

The Turck BL20 I/O system is optimized for use in the control cabinet. BL67 is the equivalent of decentralized automation directly in the field. The highly available I/O system excom is designed and certified to meet the highest requirements in terms of availability and explosion protection in process automation, especially in the pharmaceutical, chemical, oil or gas industries.

I/O Modules

-

The strength of block I/O modules lies in their simple, distributed wiring. Thanks to Turck's multiprotocol standard, Turck's modules effectively reduce the number of device variants needing to be reserved: International machine and plant manufacturers use these modules in networks with PROFINET, Ethernet/IP or Modbus-TCP control, without modifying them. Their multilingual functionality not only reduces storage costs but also supports the digitization of your production: While the modules are communicating with the controller via PROFINET or Ethernet/IP, status data for preventive maintenance can be accessed via Modbus TCP.

PA Bus Components

-

The FOUNDATION fieldbus and PROFIBUS-PA fieldbus systems enable data communication directly between the field device and the control system in process automation settings. Their advantages compared to point-to-point technology are the flexible topology as well as genuine, highly accurate and reliable measured values.

Bidirectional communication with field devices also enables the exchange of diagnostic data for predictive maintenance or for communication with multivariable devices. Another advantage of PA fieldbuses is the interoperability of field devices from different manufacturers � both with each other and with external host systems. Turck products can therefore be combined with devices from other manufacturers without any problems. Turck offers a complete range of solutions for both systems from a single source - including customized solutions.

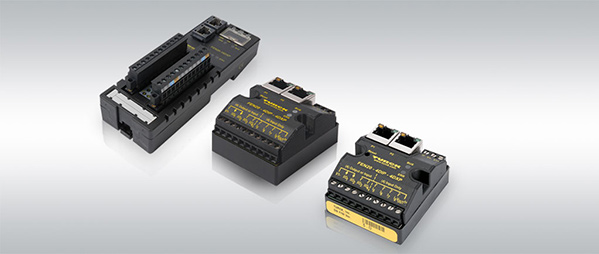

Interface Technology

- Take advantage of the flexibility and versatility of our interface product portfolio: Compact designs, a choice of different operating concepts and configurations, as well as a wide range of features for separating, conditioning, processing, converting and adapting digital and analog signals - available as 1 to 4-channel versions, for Ex and non-Ex applications. You get interface solutions in the required design and with the functionality you need for your application.

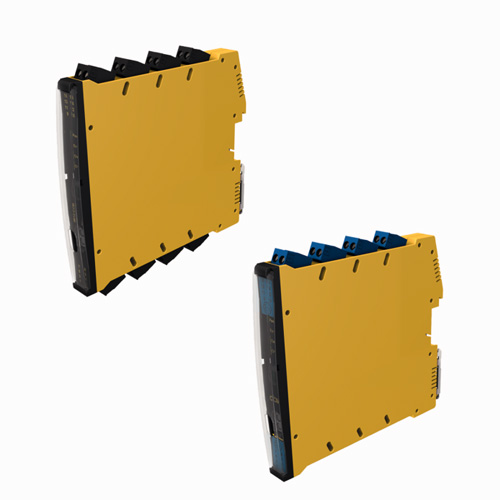

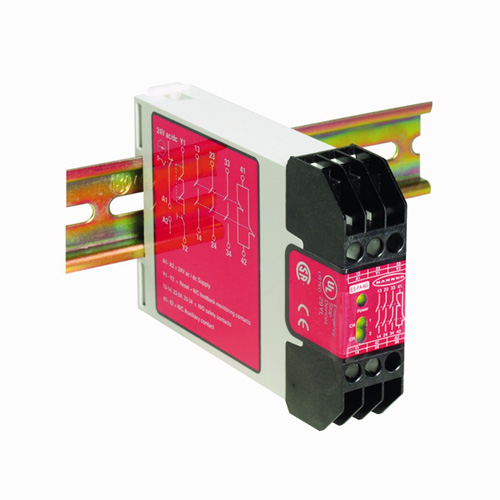

Safety Barriers

- Our interface devices are used everywhere digital signals must be galvanically isolated and processed or a current- and voltage-limited galvanically isolated power supply is needed, such as solenoid drivers, relay couplers, isolating switching amplifiers and rotation speed monitors. The interface devices are available in the IP20 modular housing for the DIN rail as well as in the compact IP67 housing for decentralized on-site use. The product portfolio also comprises solutions for the Ex area and SIL-certified devices.

Signal Conditioners

- We offer the appropriate interface device for separating, forming, processing, converting and conditioning analog signals. The product portfolio comprises analog signal isolators, isolating transducers, temperature measuring amplifiers, potentiometer amplifiers, trip amplifiers and level monitors - for simple and complex requirements, for Ex- and non-Ex applications, available in the IP20 housing for DIN rail as well as in the compact IP67 housing for decentralized on-site remote control.

Control Cabinet Monitoring

- The IM(X) 12-CCM (Cabinet Condition Monitoring) can be installed and even retrofitted in virtually any cabinet or any protective enclosure to continuously check the current protection degree offered. The DIN rail device uses a switching signal to report improperly closed doors, as well as exceedances of temperature and interior humidity, to the control system.

Machine Safety

- The degree of automation is very advanced in today's manufacturing technology. At the same time, machine and system hazards have been reduced considerably. This is, in particular, owed to the high demands on the safety technology and the skilled handling of safety functions. For security solutions in mechanical and plant engineering, we offer a choice of powerful, certified components and systems.

Safety Light Curtains

-

Safety light curtains protect personnel from injury and machines from damage by creating a sensing screen that guards machine access points and perimeters.

We offer intuitive, easy-to-use safety light curtains for a wide variety of safety applications. Type 4 safety light curtains protect personnel from injury and machines from damage by guarding points of operation, access, areas and perimeters.

Safety Grid System

- Multi-beam safety light curtains are cost-effective protective devices that prevent access and offer wide-range protection. They are available as emitter/receiver models that provide protection over very long distances, and as easy-to-install active/passive models that enable additional cost savings.

Safety Laser Scanners

- Safety laser scanners provide a laser safety solution for safeguarding mobile vehicles and stationary applications, such as the interior of robotic work cells that cannot be solved by other safeguarding solutions.

Emergency Stop and Stop Controls

- Emergency stop devices provide workers with a means of stopping a device during an emergency by pushing a button or pulling a rope in order to prevent injury to personnel and material loss.

Two-Hand Controls

- Modules monitor the output of each mechanical switch button and deenergize when the machine operator removes one or both hands from the buttons, providing protection for the worker actuating the hand controls.

Safety I/O Modules

- For safety-related applications, we offer IP67 block I/O modules with safe digital inputs and universal digital channels that can be used as inputs or outputs. The modules also feature non-secure universal digital channels and IO-Link master ports. This allows connection of standard I/Os and IO-Link devices to an IP67 fieldbus module - in addition to the safety inputs and outputs. Via the IO-Link IO hubs, up to 32 more universal digital signals can be connected. Information about the Turck Safety Configurator can be found under www.turck.de/tsc.

Safety Controllers

- Industrial safety controllers provide an interface between safety devices and the machines and processes those devices monitor for an easy-to-use safety control solution.

Safety Relays

- Industrial safety relays provide an interface between safety devices and the machines and processes those devices monitor for an easy-to-use safety control solution.

Safety Switches

- Available with a wide range of functions and different designs, Turck's safety switches are suitable for dimensionally accurate monitoring of protective doors or positions. The product range includes everything from reliable mechanical safety switches (e.g. for use on door hinges) to safety sensors with contactless detection. Inductive sensors detect different metals without wear and represent a robust solution for users who wish to dispense with magnetic or mechanical counterparts. By contrast, contactless RFID safety switches offer specific tamper resistance with three selectable coding types, they allow cascading of up to 32 sensors and they are resistant to vibration.

Industrial Controls

- Control and monitor your production seamlessly and comfortable. We have the right automation solution for you - such as programmable gateways, as well as HMI operator panels and controls.

Programmable HMI

-

Industrial HMI touch screens from Turck represent a contemporary and robust solution for your visualization and control tasks. HMI and PLC versions are available in addition to simple HMI models. The all-in-one devices reduce costs, complexity and space requirements compared to the use of a PLC with a separate HMI. Various screen sizes, processors and extension modules are available, including versions with conventional I/Os or a connection to a mobile network. Turck also offers configurations for use in Ex areas, outdoors, in the food and beverage industry and with all-round IP67 protection. Most models have an integrated Ethernet switch that is compatible with Ethernet multi-protocol technology and IIoT, with OPC-UA and MQTT communication, and that has serial interfaces and an SD card slot for maximum flexibility.

Control

- The TBEN-PLC is a robust and compact IP67 control for cabinet-free automation concepts. With the modern CODESYS 3 programming environment object-oriented programming in the following IEC 61131 languages is possible: Instruction List, Ladder Diagram, Function Block Diagram, Sequential Function Chart and Structured Text. In addition to the 8 universal digital I/O channels the PLC supports various Ethernet and fieldbus protocols as master and slave. These include PROFINET, EtherNet/IP, Modbus TCP, CANopen, SAE J1939 and Modbus RTU.

Programmable Gateway

- The programmable gateways of the BL20 (IP20) and BL67 (IP67) I/O systems can be used as autonomous PLCs for control tasks or as network devices for fast signal preprocessing in the periphery. For this, the gateways have a fieldbus interface for PROFINET, Modbus TCP, Ethernet/IP or PROFIBUS-DP; in addition the gateways support standard Ethernet and serial communication. The extension modules communicate via the internal module bus with the gateway and can be configured independently of the fieldbus protocol.

Power Supplies

- Thanks to their universal voltage input, our power supplies can be used worldwide in numerous networks. Whether for mounting directly in the field or for mounting on DIN rail, power supplies of the series PSU67 and iIM82-24 supply 24 V voltage where it is needed most - with a high degree of operational reliability, wide temperature range and good energy balance.

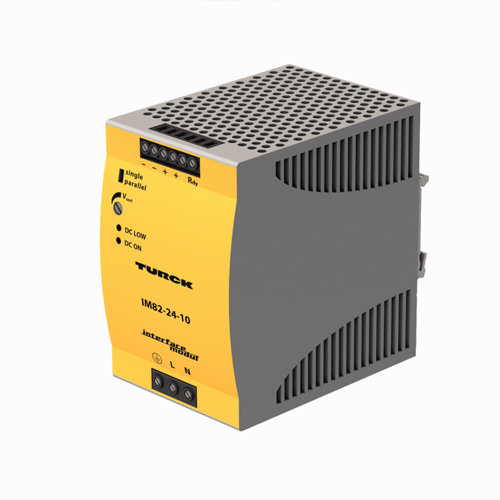

Power Supplies DIN Rail IP20

- The power supply modules of the IM82-24 series feed DC consumers and especially our IM, IMS and IMC interface modules with 24 V. The devices are mounted on DIN rail and meet protection class IP20. The output current is - depending on the type - 2.5 A, 5 A, 10 A or 20 A. Thanks to their universal AC/DC input, the power supplies can be used worldwide in numerous networks. Other features include high efficiency, as well as temperature resistance and dynamic overload capability.

Power Supplies for the Field IP67

- The power supply units of the PSU67 series are IP67 rated and can be mounted in the field. Short power drops of maximally 50 ms are bypassed independently by the devices. Failsafe operation is enhanced through no-load and short-circuit protection as well as passive air cooling. The output current is - depending on the type - 2 A, 4 A or 8A. Thanks to their universal AC/DC input, the power supplies can be used worldwide in numerous networks. The high efficiency of up to 90% provides a good energy balance.

Cloud Solutions

- Turck Cloud Solutions offers you easily and flexibly scalable software solutions. Whether you require hosted or on-premises cloud solutions, thanks to the holistic concept combining hardware and software, Turck Cloud Solutions can offer you the ideal solution from a single source.

Hardware

-

Turck Cloud Solutions offers you the appropriate hardware for your application. In addition to devices with an automatically built-in cloud connection, you have a choice of either EDGE devices in IP20 for installation in a control cabinet or IP67 variants in fully encapsulated housings for mounting directly on the machine.

EDGE gateways either with cable-bound or wireless connection with WLAN or mobile radio offer you a flexible connection from anywhere, independent of existing Internet connections.

Software

- Turck Cloud Solutions offers you flexibly scalable software solutions. Whether as "Infrastructure as a Service" (IaaS), hosted by Turck or as an on-premise installation, in your own computer center or on Turck's cloud servers, you can choose from all possible solutions to meet your requirements.

Accessories

-

Turck offers the right Cloud Gateway accessories for your application. Connectors and antennas are available in a variety of designs and with a range of installation options. This allows you to remain flexible and find the optimum solution for all installation scenarios.

You can choose between the following mounting options:

- Mounted directly on the device

- Screwed into the control cabinet wall

- Mounted using adhesive

- Screwed onto the wall

Industrial Wireless

-

In the industrial sector, modern radio systems connect the field level with the control level in a cost-effective and efficient way. They can be used and extended flexibly and as a result are suited for a variety of applications. They are highly robust and reliable, making them fit for use in difficult environments. They also form a key part of Industry 4.0.

In the wireless I/O version, sensor and actuator signals are exchanged bidirectionally between the participating communication levels. Wireless Serial allows RS485-based bus telegrams to be transmitted. In both cases, the devices are used in lieu of cables. Matching accessories such as antennas, cables, add-on modules, etc. complete the portfolio.

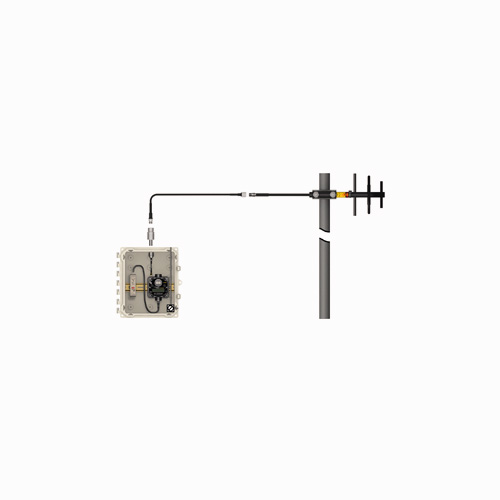

Industrial Wireless Radios

- The DX80 wireless system enables simple and fast transmission of process data from the field to higher level control systems. In both versions, DX80-PM for simple cable replacement as well as in DX80 star topology for a complex network, gateways communicate via radio signals with the nodes in the field and transfer the signals from the field devices to the controller. Nodes to be used directly in hazardous areas are available in metal housing in the DX99 series.

Data radios from the DX80DR series transmit serial data such as Modbus RTU telegrams. They form a self-organizing tree topology, which is extended via repeaters. Sensors and actuators can also be directly connected to the device, whose signal can then be processed via a register access.

Wireless Controllers

- DXM series wireless controllers combine the features of a gateway or a master in the radio network with those of a PLC. They are ideal for logic functions, mathematical operations, register manipulation, data logging, connecting to the cloud and notifying the operator via email or text message. They provide a platform for the Industrial Internet of Things (IIoT).

Wireless Sensors, Lighting and Indicators

- A large variety of sensors and displays are especially suited for connecting to the DX80 wireless system and can either be integrated directly into the network or connected with the gateway via a special node. Some series are characterized by serial interfaces, which communicate directly with a node or with the Modbus RTU network via RS485. This allows preventative maintenance, status monitoring or mobile applications to be implemented.

Wireless Accessories

- The available accessories include antennas for various applications, antenna cables in different lengths and designs, battery cases for supplying power, signal convertors and expansion modules for radio networks.

Vision

-

Image sensors and smart cameras combine high-performing image processing tools with intelligent features and intuitive user interfaces. Image sensors, like the iVu series, have a reduced resolution and a limited processing algorithm. These are exclusively parameterized directly with a touchscreen and they perform simple applications.

On the other hand, smart cameras, like the VE series, are equipped with high-resolution optics and an almost complete image processing set and are intended for more complex inspection tasks.

These are cost-effective systems that are easy to implement. From a simple feature verification to complex inspection tasks, image sensors and smart cameras offer a user-friendly solution.

Vision Sensors

- Our iVu vision sensors combine the simplicity of an optoelectronic sensor with the intelligence of an image processing system in a single compact and robust housing. This design creates new application options that could previously be realized only by using high-grade, high-cost image processing systems. User-friendly parameterization is carried out directly via a touchscreen connected to the device, rather than via a PC. The vision sensors are designed for simple applications due to their reduced resolution and limited processing algorithms.

Smart Cameras

- Image processing systems are easy to operate and offer high-performance image processing tools for a wide range of applications. Complex algorithms can be used to carry out sophisticated camera-based inspection tasks by means of high-resolution vision sensors. Countless image processing tools for various applications, such as positioning, measuring and analysis, give the user the freedom to choose the right image processing solution for their requirements. Software and firmware updates for image processing systems are always available free of charge.

Vision Lighting

- The light source is a critical component of any image processing system. It is the most effective means to produce contrast. Relevant characteristics of the examined object can thus be intensified and other characteristics toned down. The selection of the optimum light source depends on form, texture, color, and light transmittance of the object. To achieve the best contrast for your application, we offer a wide range of different LED lights.

Vision Controllers

- Image processing systems are easy to operate and offer high-performance image processing tools for a wide range of applications. Complex algorithms can be used to carry out sophisticated camera-based inspection tasks by means of high-resolution vision sensors. Countless image processing tools for various applications, such as positioning, measuring and analysis, give the user the freedom to choose the right image processing solution for their requirements. Software and firmware updates for image processing systems are always available free of charge.

Vision Accessories

- Adapt image processing systems for use with your existing systems by adding the relevant accessories. Protective housings shield the sensitive lenses from mechanical stress and dirt. Some protective housings provide a higher protection class. We offer a large selection of lenses with focus and iris lock. Turck also offers corresponding spectral filters to enable particular features to be suppressed or allowed within an application.

Topics & Technologies

IO-Link

-

What is IO-Link?

Most sensors and actuators today are already equipped with microprocessors, which can be used for parameterization, storing configuration data, and controlling indication. The obvious next step is to overcome the bottleneck of the binary standard interface and make additional functions centrally accessible for the automation system.

For this reason a lot of well-known manufacturers from the field of automation have come together and developed a fieldbus independent communication interface for sensors and actuators: IO-Link. Compatibility with existing technologies was the primary objective during development in order to guarantee investment protection.

Technology

IO-Link is based on a point-to-point connection between the sensor/actuator and an interface module. Up to now, the binary connection was only designed for transferring switching information, but IO-Link now allows two bytes to be transferred normally in a 2 ms cycle via a combined switching status and data channel. Other information can be exchanged in addition to the process values, such as parameters or diagnostics messages. This enables communication with sensors and actuators down to the �last meter� to be established for universal communication.

Pick-to-Light

-

What is Pick-to-Light?

Turck Pick-to-Light solutions provide operators with a visual indication of the required part in an assembly sequence. Actions (correct or false) are indicated by means of lights and optional audible signals. Completed operations can either be automatically or manually acknowledged.

All components in Turck Pick-to-Light systems are perfectly matched ensuring quick and reliable installation and maintenance.

Profinet

-

What is PROFINET?

The Profinet protocol is based on Industrial Ethernet and is a communication standard for factory automation. It describes the entire data exchange between so-called slaves such as Turck's multiprotocol I/O modules and a controller, the Profinet master. In this function Profinet is considered the successor to the Profibus fieldbus protocol.

Profinet was optimized in the area of cyclical data exchange and offers several new functions and extensions compared to conventional fieldbuses, particularly in relation to parameterization and diagnostics. Profinet offers users flexibility in the design of their network structures and enables them to transfer both process data in real-time (RT) as well as additional IT data via a single cable.

The system overview provides an initial impression of the network architecture and the different I/O and network components. Connections can be implemented via linear, star and tree structures, or also via a redundant ring topology (MRP).

Multiprotocol Ethernet

-

What is Multiprotocol?

Turck offers a complete line of industrial Ethernet products, including on-machine, in-cabinet, block, and modular I/O. The multiprotocol technology by Turck is an innovative new approach to Ethernet distributed I/O; multiprotocol I/O devices automatically self-configure to the active fieldbus protocol on each power-up. Supported protocols include Modbus TCP, EtherNet/IP and PROFINET.

What are the benefits of Industrial Ethernet?

Industrial Ethernet benefits users by utilizing tools and techniques familiar to traditional office communication systems, and extending them to industrial applications. This facilitates data transfer across the entire plant floor - as well as plant-to-plant and globally - via secure network connections.

With Industrial Ethernet remote maintenance can be established easily. Like this on-site service can be reduces to a minimum, what is good for you and your customer.

Multiprotocol: The Easy Way to Industrial Ethernet

Multiprotocol products are simple and intuitive, allowing easy transition between multiple common industrial Ethernet protocols without the need to physically switch parts. An advanced webserver integrated in all Turck multiprotocol devices facilitates simple device configuration and troubleshooting via web-browser. Furthermore, an impressive array of advanced features for each supported protocol has been incorporated into the devices to meet many unique application requirements.

Turck�s multiprotocol technology makes moving from one industrial Ethernet protocol to another plug-in simple. Turck�s multiprotocol products offer a seamless transition to industrial Ethernet, whichever industrial Ethernet protocol that may be.

Industry 4.0

-

What is Industry 4.0?

The term "Industry 4.0" describes the fourth industrial revolution. In practice it is more of an evolution than a revolution. Business and value creation processes are becoming ever more closely linked and increasingly automated. Industry 4.0 resolves the dichotomy between customized products and mass production. For this to happen, commercial, logistics, and production processes have to be closely interlinked.

Although Industry 4.0 is often portrayed as a blueprint for factories of the future, intelligent applications which allow for customizable, highly flexible production have long since been a reality.

Turck will support you on the path to Industry 4.0 with innovative solutions to acquire, condition and transfer relevant production data.

Key Technology

Whether RFID, IO-link, OPC-UA or Ethernet � as a specialist in the key technologies of industry 4.0 Turck paves the way to the intelligent future factory for you.

RFID

With the RFID system BL ident Turck has implemented solutions for flexible control of production processes, but also for the spare parts/service business, piracy protection or serialization. Together with the IP67 I/O PLC modules from Turck you have available robust solutions with distributed intelligence for data processing or for control tasks.

IO-Link

Turck offers one of the most comprehensive portfolios of IO-Link solutions - ranging from numerous sensors and connection technology to fieldbus and Ethernet I/O systems with IO-Link masters in the protection classes IP20 and I67. How to benefit from intelligent data acquisition and communication solutions from a single source.

Ethernet

Ethernet is the standard for communication, not only in the IT world, but also in the industrial environment. Turck offers especially user-friendly solutions such as the multiprotocol technology that supports the automatic use of I/O systems in the Ethernet protocols PROFINET, Modbus TCP or EtherNet/IP.

OPC-UA

OPC-UA is the world's next standard for integrative communication across all levels of the automation pyramid. In close cooperation with science and industry, Turck participated in the development of the standard and has already implemented it in the first products

Field Logic Controller

-

Let us be so bold to predict the death of PLCs as we know them

Demonstrating our commitment to flexible, custom solutions, Turck has developed the next big thing for control: the field logic controller (FLC). Turck's FLC solutions are made possible by ARGEE (A Really Great Engineering Environment), a revolutionary web-based programming environment that allows users to set conditions and actions directly at the field level. By utilizing HTML5, Turck provides a complete engineering environment for users to write, run, simulate, debug, and monitor code, all without requiring the use of a PLC.

Using FLCs, Turck's multiprotocol block I/O products can act as simple I/O devices or as standalone logic controllers. While ARGEE programming is not designed to replace a PLC outright, it can be used to change the way we think about control, allowing FLC devices to:

- Be used without a PLC in standalone applications

- Perform arithmetic functions, use timers, counters, and even toggle bits

- Share data with a PLC via assigned I/O variables

Technology

Using a simple "Condition" and "Action" principle that is integrated into a flow chart user interface, ARGEE allows users with little or no programming experience to easily configure and program their Turck FLC devices.

ARGEE challenges what an I/O device can do by creating a hybrid between simple block I/O and higher level PLCs. The result - Turck's FLC.

Codesys

-

Open system

Unlike the programming environments of major control manufacturers, the software is independent of the more than 400 hardware manufacturers that use the automation platform. Openness and interoperability of devices and systems from different manufacturers are therefore a fundamental feature of the program. More and more users worldwide appreciate this approach and are reinforcing the system as a whole with their solutions.

IEC 61131-3 ensures interoperability

The software follows the international standard for PLC programming IEC 61131-3, which in turn guarantees interoperability of Codesys programs with other standardized devices. Programming in Codesys is based on programming languages such as AWL, ST, FUP and others, which ensures smooth communication with other devices and systems.

Limitless

Codesys allows the use of different fieldbuses/Ethernet protocols in an automation system. When users create applications in combination with Profinet and EtherNet/IP or EtherCAT, they benefit in turn from the openness of the software.

Condition Monitoring

-

Condition Monitoring of Machines and Systems

The term condition monitoring refers to the process of monitoring a parameter of conditions in machines and systems. Nowadays, "listening" to motors, electronic devices or areas of a system to check for faults goes far beyond on-site inspections by workers.

Thanks to state-of-the-art sensor technology, intelligent field devices and wireless transmission, condition monitoring can be carried out not just continuously but from absolutely anywhere. On the basis of the collected data, systems can indicate an imminent failure at an early stage. Reliable condition monitoring is therefore essential for predictive maintenance.

Simplify condition monitoring of your plant using products from Turck � from sturdy sensors to system solutions with flexible cloud monitoring. Whether the system is in a new build or you want to retrofit the solutions you have in an existing environment � all devices can be easily integrated into your existing automation system. Alternatively, decentralized standalone systems can monitor key condition data without affecting the main control unit.

Ethernet in Hazardous Locations

-

Ethernet in the Process Industry

Industrial Ethernet has been a vital networking and communication solution in factory automation for decades. Today, it is quite widespread. The process automation industry presents special challenges due to potentially explosive atmospheres, which have so far not allowed the use of Ethernet. These requirements include intrinsic safety, configuration in run, redundancies for maximum availability and a long cable length, which is limited to 100 meters for industrial Ethernet. When using Ethernet solutions in the process industry, it is important to distinguish applications where they will be used by their respective Zones.

Ethernet for Ex Zone 2

Turck offers its excom I/O system with Ethernet for installation in Zone 2. The system can pick up signals from Zone 1 or 0. To plug and unplug the Ethernet connectors at the gateway in run, users must ensure that the gateways are de-energized or work with a hot work permit. All other components such as power supply units, gateways or I/O modules can be exchanged during operation without a hot work permit

Ethernet for Ex Zone 1

Using Ethernet in Ex Zone 1 is technically more difficult. With interlinked devices, it must be ensured that power levels do not add up. Today, a consortium of companies is working to overcome these hurdles and develop a standard for a two-wire Intrinsically Safe (IS) Ethernet. Communication and power supply take place over the same line. The future standard is usually referred to as Advanced Physical Layer (APL). However, these developments are not yet suitable for broad industrial use in Zone 1 (status 03/2020). One day, APL should enable Ethernet connections up to the field devices. However, classic 4 to 20 mA technology and I/O systems will continue to exist in parallel for cost reasons alone, even after APL has been established.

Industrial Cloud

-

Cloud Solutions for Industrial Applications

Cloud solutions provide flexible access to storage, computing power or software. Data is not stored on the local IT hardware, but on servers. This allows users to access information or initiate actions from different web-enabled devices, regardless of location and time.

Unlike business or private clouds, industrial clouds are highly specialized. They need to address vertical integration within specific industries, support standardized communication protocols with bidirectional information flow and meet high security requirements.

Data preprocessing in edge controllers

In order to process data from machines and sensors specifically in the cloud, filtering in the edge, i.e. at the "outer edge" of a local network, is an important process. In edge controllers, users can define which information should be transferred to the cloud and which should remain in the OT environment instead. This reduces the data density on the servers.

Via cable, WLAN or mobile communication

Communication from field level to the cloud can take different paths. In addition to the option of connecting applications via mobile radio, existing Internet access points at the location can be used either wired or via WLAN. Future-proof standard protocols are OPC UA and MQTT, allowing components alongside Turck Cloud Solutions to be integrated into various clouds such as MS Azure, Alibaba or Amazon Web Services.

Machine Safety

-

Functional Safety for Machines and Processes

As part of Machinery Directive 2006/42/EC, all manufacturers must assess the risk posed by their products so that people who come into contact with the machine are protected. However, the Machinery Directive does not apply solely in the EU. It is also used in other countries in the European Single Market. Local standards often make reference to European safety standards, which are listed in the Machinery Directive as harmonized standards.

The risk posed by the machine must be reduced to a reasonable residual level. To this end, the manufacturer carries out a three-stage risk assessment. The risk must be reduced through design measures, by applying technical safeguards and by providing user information such as manuals.

Classifying risks into performance levels

In order to assess which technical safeguards are appropriate to the risk in question, manufacturers are guided by parameters that indicate the probability that safety-related components will fail. These parameters are called performance levels (PL). First, the manufacturer determines the required performance level (PLr) of a safety function. After designing a safety control to implement this function, the manufacturer determines the actual performance level. At the end of the process, PL and PLr must be the same. Broadly speaking, there are three types of safety controls.

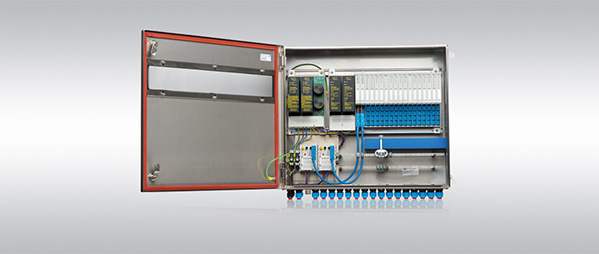

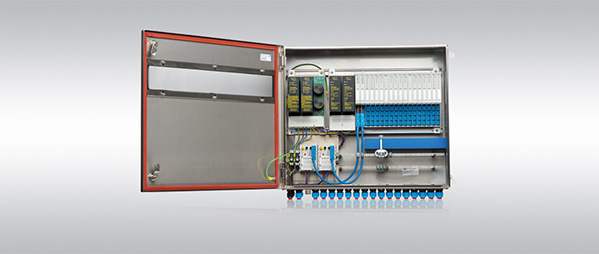

Modular Machines

-

Why Building Machines Modular?

The core idea of modularity in mechanical engineering is to divide complex machines into modules so that they can be individually assembled with an increasing number of identical parts. The combination of these modules covers the variance of machine types. Thanks to the economies of scale that this achieves, modular machines can be manufactured faster and more cost-effectively. In addition, they can be put into operation more quickly and expanded with greater flexibility.

Standardized interfaces are required to ensure the units can be combined easily and quickly. These include mechanical interfaces, but also those needed for power transmission, communication and, if necessary, compressed air. Modularity is not a characteristic that can be defined with a categorical yes or no. Instead, it ranges from low to absolute modularity.

Decentralized automation promotes modularization

Consistent modularization is not possible with point-to-point wiring in the central control cabinet. These central structures make it difficult to replace a module or expand a machine. Machine modules require autonomous structures. These can be implemented in small on-site control boxes on the module with IP20 components.

However, wiring and installation are usually more complex than for components with IP67 protection class, which can be mounted directly on the machine without any additional safeguards. However, if certain components are not IP67-rated or if special requirements apply in relation to hygienic design, food conformity or chemical resistance, IP20 solutions in the protective housing are often essential.

IP67 automation components facilitate the interconnectivity of modules. Decentralized I/O components for mounting directly in the field allow signals to be collected directly at the point of generation on the module and coupled from module to module via an Ethernet connection � and all without a control cabinet. This reduces installation costs and shortens commissioning times at the end customer's premises.

RFID

-

RFID Solutions for Production and Logistics

End-to-end tracking of incoming and outgoing goods, confirming automatically that the intended materials and tools are being used in production, or providing access points with increased security. For such industrial tasks, RFID has proven itself as a powerful Auto-ID technology for Industry 4.0, with contactless transmission of large amounts of information, even over long distances, and easy connection to higher-level systems from PLC to ERP.

Choosing the right frequency band

HF technology (13.56 MHz) is an important driver of digital production processes, it is based on magnetic near-field communication. However, if higher ranges or bulk readings of 200 data carriers and more are required, users should opt for UHF technology (865...928 MHz). Turck's modular RFID system BL ident enables the parallel operation of read/write heads in the HF and UHF range � and thanks to protection class IP67, this can also be done directly on site at the machine or plant. This allows consistently decentralized signal processing in the field.

Data transfer to higher-level systems

Communication in logistics and production plants today is divided into hierarchically structured levels. RFID readers with an Ethernet interface establish a direct exchange of information with higher-level systems, such as PLC, SCADA, MES and ERP or the cloud. Thus, goods movements are visible in real time, detected goods are matched with the database or, perhaps, automatic invoices are already created in the accounting software.

IIoT applications via OPC UA

The platform-independent communication standard OPC UA simplifies the integration of RFID solutions into PLC, MES, ERP or cloud systems. With the AutoID Companion Specification, it is also possible to exchange devices between Auto-Ident systems from different manufacturers. Turck played a significant role in the development of the standard and has an own RFID interface with OPC UA server in its portfolio. For secure communication, the interface offers mixed operation of HF and UHF read/write heads.