- Offer Profile

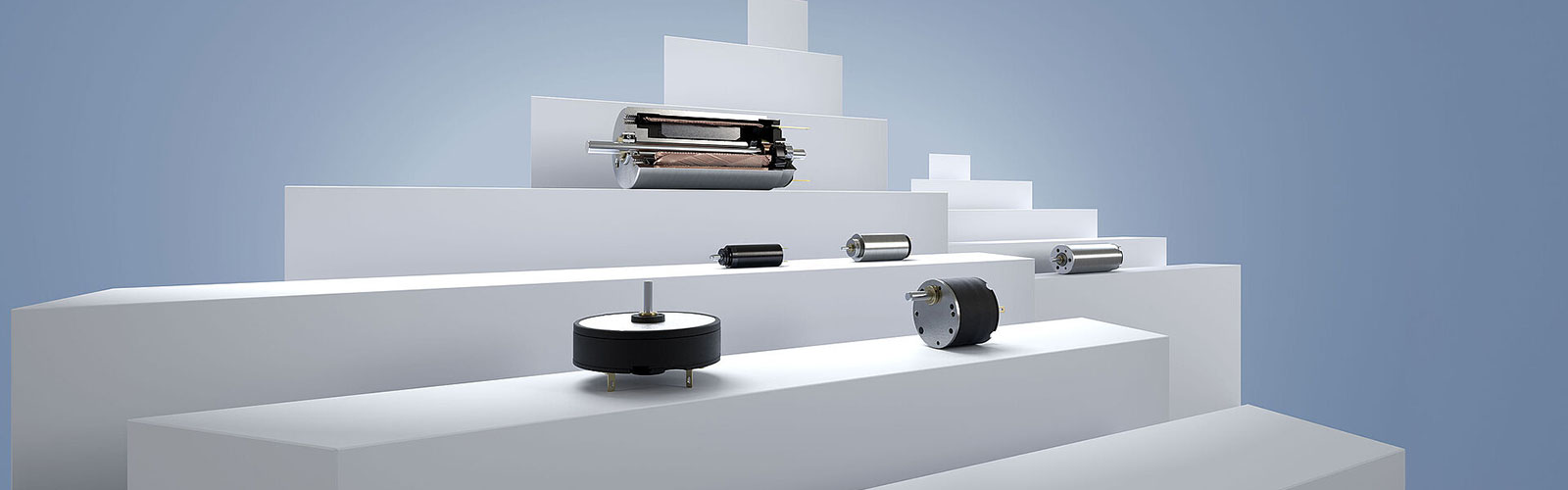

- FAULHABER is a leading supplier in the area of high precision miniature and micro drive systems. FAULHABER offers the most extensive range of miniature and micro drive technologies available from a single source worldwide. From high performance DC Motors, BLDC Motors, to Linear Motors, and Stepper Motors, each drive is designed to achieve maximum performance in minimum dimensions and weight. Matching precision gearheads, encoders, linear components and drive electronics are available to complete the system.

Micro motors fromFAULHABER

- Electric motors convert electric current into mechanical power – they are therefore also referred to as electromechanical transducers. As a specialist for small and miniature drive systems, FAULHABER offers a broad range of micro motors. This type of motor allows a particularly high power density with low weight and minimal installation size.

DC-Motors

- Cogging-free use: DC motors fromFAULHABER

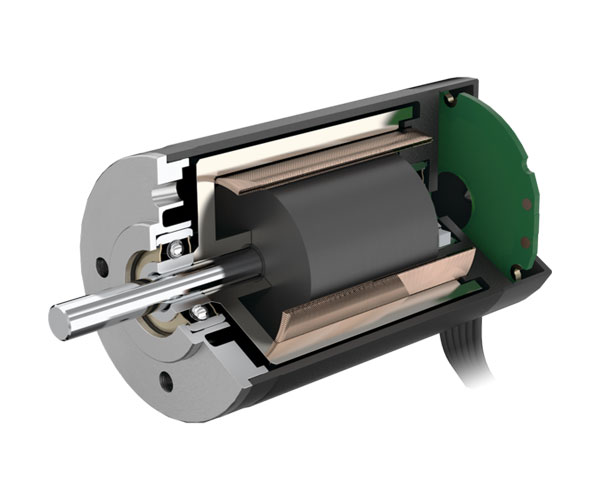

Unlike conventional DC motors with iron armatures, brushed DC motors from FAULHABER have a self-supporting skew-wound copper coil. This design not only minimizes the moment of inertia of the rotor, but also gives the drives maximum dynamics and precise, cogging-free running. The technology was developed by Dr. Fritz Faulhaber Sr. With maximum performance in minimum space, it has created new drive options for numerous application areas.

Brushless DC Motors

- Continuous maximum performance: Brushless motors fromFAULHABER

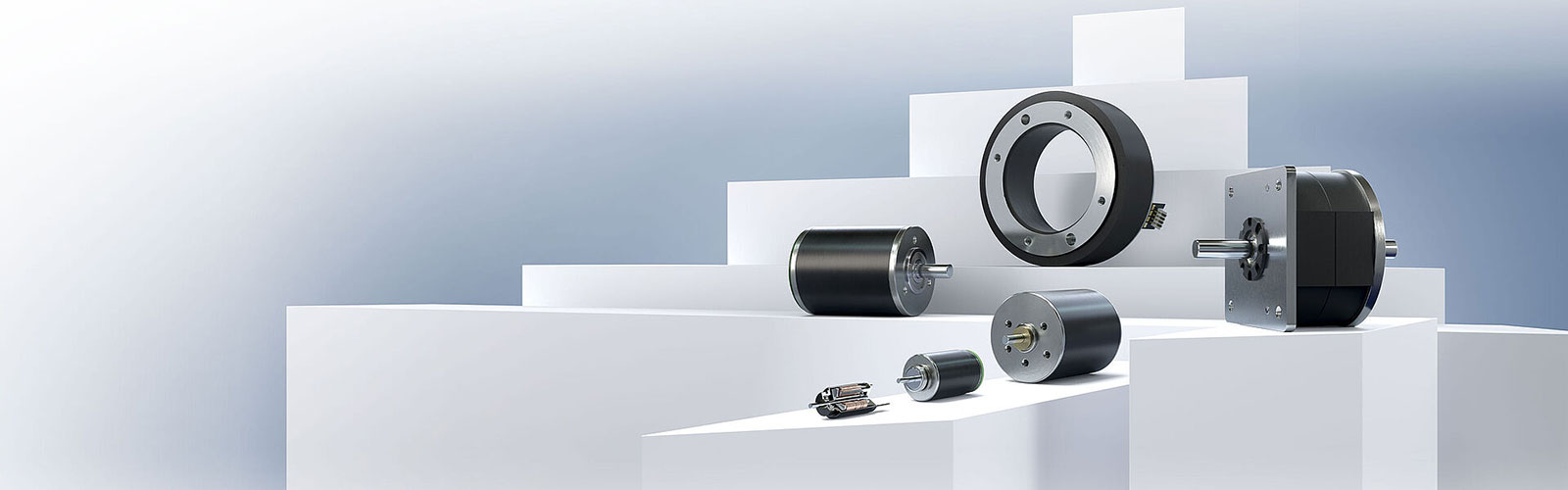

Brushless DC-motors from FAULHABER stand for maximum performance in the smallest space. They feature the highest values for speed, torque, and service life. They are very low in noise and vibration. They can even handle overload and continuous operation. The models range from the smallest micromotors to highly efficient flat servo motors and ultra-powerful motors with external rotor technology.

Motors with integrated Electronics

- Motors with integrated Electronics

FAULHABER offers a broad selection of motors with integrated electronics. Our Speed Control Systems are suitable for drive systems with speed control, and our Motion Control Systems are the ideal solution for precise rotational speed control or positioning tasks. All in all, our range of motors with integrated electronics includes motors for an extremely wide variety of application scenarios in the smallest of spaces.

Linear motors

- Linear motors fromFAULHABER- Force with direction

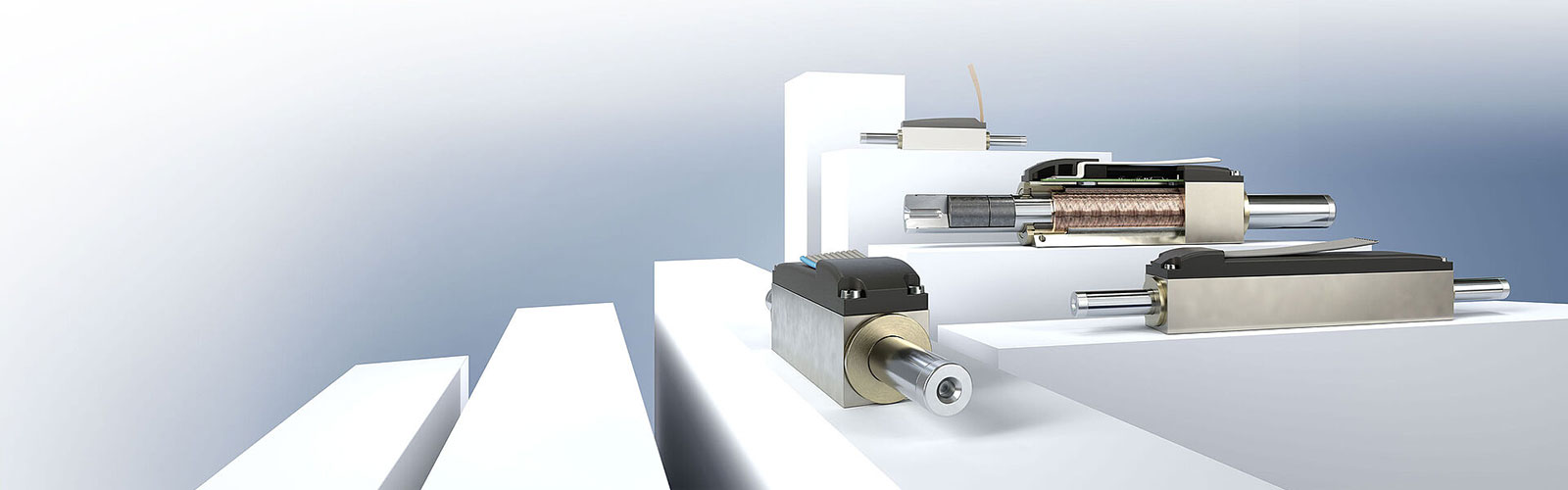

A linear motor produces a translational motion, meaning it deploys its force in a straight line. Small linear motors from FAULHABER do this particularly quickly, efficiently and flexibly. They are also characterized by their very high repeatability. This makes them ideal for tasks where components are continuously moved at high speed on a straight axis or where a defined pressure is exerted.

Stepper Motors

- for demanding positioning tasks

For demanding positioning tasks that require a high level of accuracy, stepper motors are generally used. The name comes from the operating principle, as the stepper motors are driven by an electromagnetic field. This turns the rotor a small angle – a step – or a multiple thereof.

Robust assembly, high speed range, and exceptional performance in even the harshest environments make FAULHABER drive systems the perfect solution for demanding positioning applications. The stepper motors from FAULHABER are also characterised by a long service life and high reliability hanks to their electronic commutation (motor without brush).

They are available with a wide variety of modular servo components such as encoders, zero backlash gearheads or integrated lead screws.

DC-Motors

-

DC motors from FAULHABER - Cogging-free use

Unlike conventional DC motors with iron armatures, brushed DC motors from FAULHABER have a self-supporting skew-wound copper coil. This design not only minimizes the moment of inertia of the rotor, but also gives the drives maximum dynamics and precise, cogging-free running. The technology was developed by Dr. Fritz Faulhaber Sr. With maximum performance in minimum space, it has created new drive options for numerous application areas.

Faulhaber S/G

-

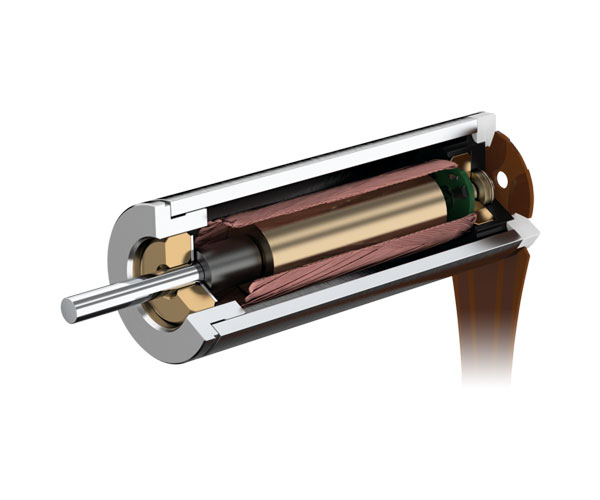

DC-Micromotors with precious metal commutation

Originally invented by Dr. Fritz Faulhaber Sr. and patented in 1958, the System FAULHABER coreless (or ironless) progressive, self-supporting, skew wound rotor winding is at the heart of every System FAULHABER DC Motor. This revolutionary technology changed the industry and created new possibilities for customer application of DC Motors where the highest power, best dynamic performance, in the smallest possible size and weight are required.

The main benefits of this technology include no cogging torque resulting in smooth positioning and speed control, higher overall efficiency than other DC Motor types, extremely high torque and power in relation to motor size and weight, and a linear relationship between load to speed, current to torque, and voltage to speed. The very low rotor inertia results in superior dynamic characteristics for starting and stopping and the motors exhibit extremely low torque ripple and EMI.

Key Features:- Diameter: 6 ... 22 mm

- Length: 15 ... 32.6 mm

- Nominal voltage: 1.5 ... 40 V

- Speed up to: 24,000 min⁻¹

- Torque up to: 5.39 mNm

- Continuous output up to: 8.39 W

Faulhaber SXR

-

DC-micromotors with innovative winding for higher performance as standard

The motors of the FAULHABER SXR product family set new standards in the areas of performance and versatility. Equipped with an innovative, hexagonal winding technology with high copper filling factor and high proportion of straight lines, they achieve significantly increased performance and efficiency. The DC microdrives are available in flexible voltage variants from 3 to 18 V as well as in various bearing configurations. The optimized rotor balancing ensures smooth speed control and thereby contributes to the durability of the motors.

The SXR family can be combined with a number of FAULHABER products to form a compact, diameter-compliant drive solution. Individual configuration options ranging from front and rear shaft adaptation to options for vacuum and temperature environments ensure high flexibility and suitability for use in a wide range of applications.

Key Features- Diameter: 12 ... 16 mm

- Length: 18.3 ... 28.3 mm

- Nominal voltage: 3 ... 24 V

- Speed up to: 15,000 min⁻¹

- Torque up to: 5.03 mNm

- Continuous output up to: 9.76 W

Faulhaber SR

-

DC-Micromotors with precious metal commutation

These ironless DC motors are the most compact in the industry today and most types feature integrated high resolution encoders for use in highly precise positioning and speed control applications. The commutation system is characterized by its small size, low contact resistance and clean low noise commutation signal. It is ideal for use in battery operated applications where current is at a premium. Combinations with a wide variety of precicion gearheads and DC motor controllers make it possible to create the best system solution for even the most challenging applications. Product catalogue Technical information Start Drive Calculator Powerful rare-earth magnet

Key Features- Diameter: 8 ... 22 mm

- Length: 15.8 ... 32.2 mm

- Nominal voltage: 3 ... 36 V

- Speed up to: 17,000 min⁻¹

- Torque up to: 10 mNm

- Continuous output up to: 8.37 W

Faulhaber GXR

-

Powerful DC-motors with graphite commutation

The motors of the GXR family offer outstanding robustness, durability and performance. Unlike the structurally identical SXR family, the GXR motors are graphite-commutated and therefore suitable for applications that require particularly high current and performance. They offer flexible voltage variants from 4.5 V to 24 V and are available in various bearing configurations. Thanks to the hexagonal winding with high copper filling factor and optimized straight section, the DC-motors are temperature-stable and thus ensure increased efficiency.

The GXR drives are also characterized by a high degree of flexibility due to their customizability – from modifications to the front and rear shafts to options for use in vacuum or high-temperature environments. They can be combined with many different products from the FAULHABER range, including diameter compliant gearheads or encoders with and without line driver.

Key Features:- Diameter: 16 mm

- Length: 27 mm

- Nominal voltage: 4.5 ... 24 V

- Speed up to: 15,000 min⁻¹

- Torque up to: 5.71 mNm

- Continuous output up to: 9.31 W

Faulhaber CXR

-

DC-Micromotors with graphite commutation

The CXR series combines power, robustness and control in a compact form. This is ensured by graphite commutation, highquality neodymium magnets and the tried-and-tested winding of the FAULHABER rotor.

The powerful neodymium magnet gives the motors a high power density with a continuous torque ranging from 3.6 to 40 mNm. The impressive performance data and the compact size open up a wide spectrum of possible applications at an optimised price/performance ratio. The standard drive can be combined with high-resolution optical or magnetic encoders for applications with precise speed control or positioning tasks. A broad and optimally matched selection of gearheads is available to extend the range of requirements that this series is able to fulfil.

Key Features:- Diameter: 13 ... 26 mm

- Length: 27.2 ... 57 mm

- Nominal voltage: 6 ... 48 V

- Speed up to: 10,000 min⁻¹

- Torque up to: 42.3 mNm

- Continuous output up to: 35.8 W

Faulhaber CR

-

DC-Micromotors with graphite commutation

Highly stable and low-wear graphite commutation, extremely powerful neodymium magnets and a particularly high copper content in the winding of the FAULHABER rotor give the CR series its enormous power. The impressive power range of 19 to 224 mNm is ideal for high-performance applications with fast start/stop operation or periodic overload conditions.

Thanks to the extremely high power density as well as the outstanding dynamics with minimal rotor inertia, the CR family is the most powerful product family of the entire FAULHABER DC range. The standard drive can be combined with highresolution optical or magnetic encoders for applications with precise speed control or positioning tasks. A broad and optimally matched selection of precision gearheads is available to extend the range of requirements that this series is able to fulfil.

Key Features:- Diameter: 23 ... 38 mm

- Length: 42 ... 90 mm

- Nominal voltage: 6 ... 48 V

- Speed up to: 11,000 min⁻¹

- Torque up to: 222 mNm

- Continuous output up to: 138 W

Faulhaber SR-Flat

-

Flat DC-Micromotors and DC-Gearmotors

Precious-metal commutated DC-Micromotors with uniquely flat coil technology with three flat, self-supporting copper windings used in the SR-Flat series form the basis for drive systems in applications where space is extremely limited.

With their powerful rare-earth magnets, the motors deliver a continuous output of 0.8 W to 4 W and at the same time have only minimal inertia. The motors are available with integrated gearheads and optical encoders – both with an extremely flat design matched to the motors. When combined with integrated gearheads and encoders, flat DC-motors provide a very compact drive system with increased output torque.

Key Features:- Diameter: 15 ... 26 mm

- Length: 5.5 ... 21.5 mm

- Nominal voltage: 3 ... 24 V

- Speed up to: 16,000 min⁻¹

- Torque up to: 100 mNm

- Continuous output up to: 4 W

Brushless Motors

-

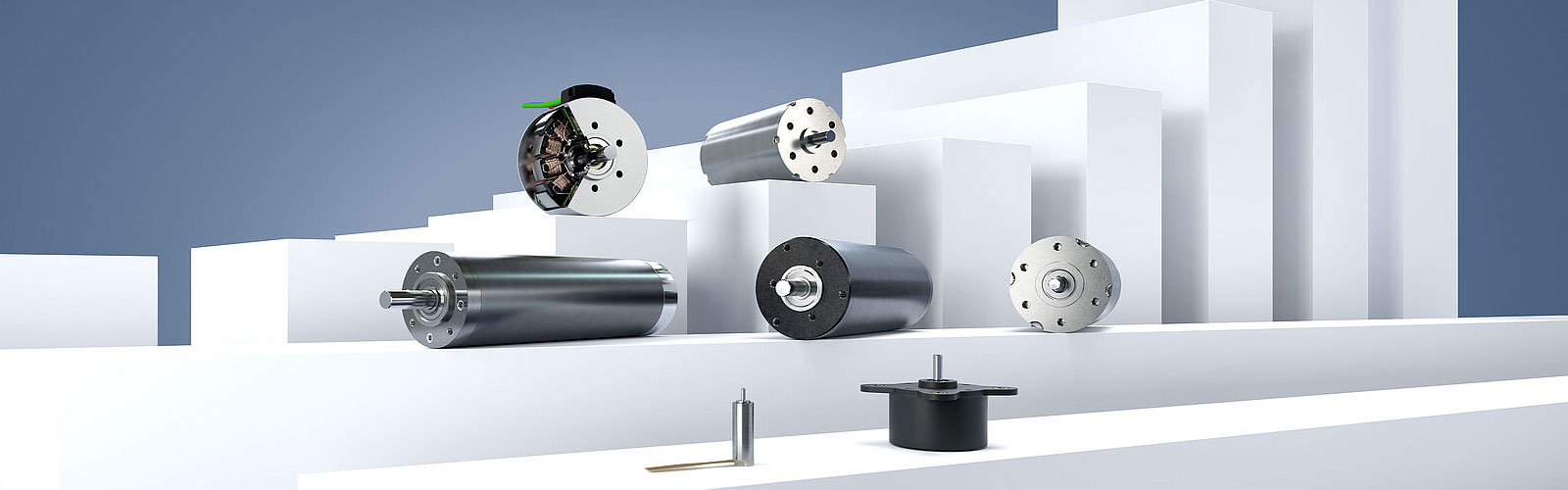

Continuous maximum performance: Brushless motors from FAULHABER

Brushless DC-motors from FAULHABER stand for maximum performance in the smallest space. They feature the highest values for speed, torque, and service life. They are very low in noise and vibration. They can even handle overload and continuous operation. The models range from the smallest micromotors to highly efficient flat servo motors and ultra-powerful motors with external rotor technology.

Faulhaber B-Micro

-

Brushless micro DC servo motors 2 Pole Technology, sensorless

The brushless, sensorless DC servo motors can be used even in the most challenging applications where space is extremely limited. After many years of development and experience in microsystem technology, FAULHABER has succeeded in reducing the size of all components and modules to a minimum in order to provide reliable drive functions even with the smallest of dimensions. The micro DC servo motors are sensorless and available with matching, highly compact gearheads for increasing the output torque, and speed controllers. They provide a technology basis that can be modified for projects according to the requirements of the individual customer.

Key Features:- Diameter: 3 ... 5 mm

- Length: 8.4 ... 14.6 mm

- Nominal voltage: 3 ... 6 V

- Speed up to: 96,000 min⁻¹

- Torque up to: 18 µNm

- Continuous output up to: 0.44 W

Faulhaber B

-

Brushless DC servo motors 2 Pole Technology

These ironless slotless motors are built for use in highly challenging areas of application and environmental conditions from the vacuum of space to medical device technology. They are precise, have extremely long operational lifetimes, and are highly reliable. The DC servo motors are available with a wide variety of complementary products such as high resolution encoders and precision gearheads. For maximum integration and reduction of size the standard digital hall sensors in the motors can be replaced with optional analog (linear) hall sensors which can eliminate the need for an encoder in most applications.

Key Features:- Diameter: 6 ... 44 mm

- Length: 18 ... 90 mm

- Nominal voltage: 6 ... 48 V

- Speed up to: 100,000 min⁻¹

- Torque up to: 217 mNm

- Continuous output up to: 282 W

Faulhaber BHx

-

Brushless DC-Servomotors 2 Pole Technology

The BHx series uses 2-pole brushless technology based on an innovative and robust design to deliver high power in a compact size. These motors come in 2 distinct versions to support a wide variety of different application needs: the BHT variant is dedicated to high torque for large impulsive cycles, and the BHS model is focused on very high speed for continuous use. BHx series is capable of driving variable load with minimum speed fluctuation to guarantee smooth behavior at constant speed.

Furthermore their low inertia and short response time provide also high dynamics. Those characteristics make BHx series ideal for both-high speed operation and fast accurate positioning, especially in intermittent operation when combined with integrated high resolution encoder. BHx series exhibits low vibration level and low noise to reduce human fatigue and stress inside application environment. Their high efficiency minimizes heat generation and helps to increase comfort when used as handtools.

Key Features:- Diameter: 16 mm

- Length: 45 ... 60 mm

- Nominal voltage: 24 ... 48 V

- Speed up to: 100,000 min⁻¹

- Torque up to: 18.7 mNm

- Continuous output up to: 96 W

Faulhaber BX4

-

Brushless DC-Servomotors 4 Pole Technology

From dynamic start/stop operation to speed control and highprecision, integrated position control in confined installation spaces – the flexible BX4 modular system can be combined with a wide variety of gearhead and lead screw attachments and offers customised solutions for a broad range of different applications.

The long service life, high torque and an innovative as well as compact design are further outstanding features of this 4-pole product family. Smooth running, low vibration and low noise mean that these motors can be used in sensitive markets, e.g. medical technology, in addition to market sectors such as automation technology, robotics and machine construction.

Key Features:- Diameter: 22 ... 32 mm

- Length: 33.8 ... 70.2 mm

- Nominal voltage: 6 ... 48 V

- Speed up to: 29,000 min⁻¹

- Torque up to: 96 mNm

- Continuous output up to: 62 W

Faulhaber BP4

-

High torque brushless DC-motors 4 Pole Technology

The four-pole brushless DC-Servomotors of the BP4 series are characterised by their extremely high torques, despite the compact 22 mm and 32 mm diameter design and low weight. At the heart of the motors lies innovative winding technology that not only allows a very high copper content in the stator, but also has a high electrical and geometric winding symmetry.

This minimises losses and maximises efficiency. The BP4 series is overload-resistant and suitable for applications involving high power where the lowest possible total weight and smallest possible installation space are required, and also for dynamic start/stop operation.

Key Features:- Diameter: 22 ... 32 mm

- Length: 64 ... 74 mm

- Nominal voltage: 12 ... 48 V

- Speed up to: 34,500 min⁻¹

- Torque up to: 158 mNm

- Continuous output up to: 152 W

Faulhaber B-Flat

-

Brushless DC gear motors and flat DC-Micromotors

The four-pole brushless DC-Servomotors, which have uniquely flat coil technology with three flat, self-supporting copper windings and are used in the B-Flat series, form the basis for drive systems in applications where space is extremely limited. With their powerful rare-earth magnets, the motors deliver a continuous output of 1.5 W to 9 W and at the same time have only minimal inertia. In combination with the integrated gearheads in extremely flat design, the BLDC gear motors provide a very compact drive system with increased output torque. Due to the electronic commutation of the drives, the service life is many times longer compared to mechanically commutated motors.

Key Features:- Diameter: 15 ... 26 mm

- Length: 8.8 ... 22 mm

- Nominal voltage: 6 ... 12 V

- Speed up to: 40,000 min⁻¹

- Torque up to: 100 mNm

- Continuous output up to: 9 W

Faulhaber BXT

-

Flat brushless motors with external rotor technology

The external rotor motors of the BXT series set new standards: thanks to innovative winding technology and optimum design, the flat BLDC motors deliver a torque of up to 134 mNm. The ratio of torque to weight and size is unmatched. The iron-core motors with 14 high-performance rare earth magnets on the rotor and 12 teeth on the stator are just 14 mm, 16 mm and 21 mm long, making them suitable for applications that require a short drive solution with high torque. Combined with optical and magnetic encoders, precision gearheads and DC motor controllers, the result is a compact drive system.

Key Features:- Diameter: 22 ... 42 mm

- Length: 14 ... 22 mm

- Nominal voltage: 6 ... 48 V

- Speed up to: 10,000 min⁻¹

- Torque up to: 134 mNm

- Continuous output up to: 100 W

Motors with integrated Electronics

-

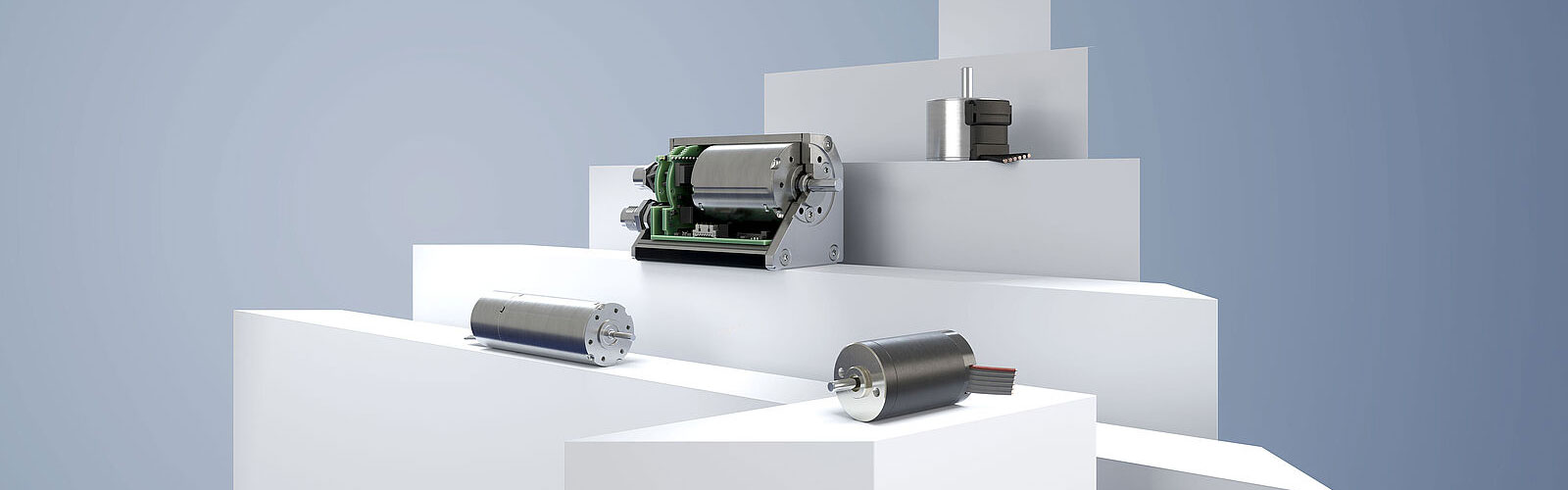

Motors with integrated Electronics

FAULHABER offers a broad selection of motors with integrated electronics. Our Speed Control Systems are suitable for drive systems with speed control, and our Motion Control Systems are the ideal solution for precise rotational speed control or positioning tasks. All in all, our range of motors with integrated electronics includes motors for an extremely wide variety of application scenarios in the smallest of spaces.

Faulhaber BRC

-

Brushless DC-Motors with integrated Speed Controller

The efficient motor series with continuously smooth running impresses with an extraordinarily long service life. In optimised continuous operation, the motors of the BRC family convince with their high-performance bearings and cogging-free running in the linear speed and torque range. The brushless motors with integrated speed controller operate with precise speed control.

This allows the operating point and the operating behaviour to be precisely controlled by means of corresponding software. Measuring 15 to 31 mm in diameter, these motors are suitable for installation in extremely confined spaces and – thanks to their robust design – also for applications with high loads. The motors can be operated reversibly in a clockwise or anti-clockwise direction, depending on the required control mode. The frequency output of these motors enables precise reproduction and determination of the speed of the motor.

Key Features:- Diameter: 15 ... 31 mm

- Length: 25.4 ... 53 mm

- Nominal voltage: 6 ... 24 V

- Torque up to: 36.5 mNm

- Continuous output up to: 17.5 W

Faulhaber BX4 SC

-

Brushless DC-Servomotors with integrated Speed Controller

When it comes to speed control in a DC-motor, the drives with integrated speed controller combine the advantages of brushless DC-Servomotors with diametercompliant control electronics installed in the mounted motor unit measuring just 18mm in length.

Combinable with various precision gearheads, they can be used in a wide variety of market sectors such as laboratory technology, equipment manufacturing, automation technology or machine construction. The default factory preconfiguration in combination with the Motion Manager allows quick and easy commissioning of the system. The selectable Hall sensor type (digital/analogue) ensures optimum coverage over a wide speed range. The integrated current limitation matched to the respective type protects the motor against overloading and therefore against potential destruction. The two-wire version SCDC allows brushed DC-Motors to be replaced easily in certain applications.

Key Features- Diameter: 22 ... 32 mm

- Length: 49.6 ... 85.4 mm

- Nominal voltage: 12 ... 24 V

- Torque up to: 99 mNm

- Continuous output up to: 53 W

Faulhaber BXT SC

-

Brushless DC-Servomotors with integrated Speed Controller

The drives with integrated speed controller combine the advantages of brushless DC-servomotors with diameter-compliant control electronics which, fully integrated, extend the motor by only 6.2 mm. Combinable with various precision gearheads, they can be used in a wide variety of market sectors such as pumps, handheld devices, equipment manufacturing or laboratory and industrial automation.

The default factory preconfiguration in combination with the Motion Manager allows quick and easy commissioning of the system. The high number of poles of the motors ensures optimum coverage of a wide speed range, also with digital Hall sensors. The integrated current limitation matched to the respective type protects the motor against overloading and therefore against potential destruction. The combination of the BXT H motors with the integrated Speed Controller is the ideal solution if speeds need to be controlled precisely in the smallest of spaces and high torques are also required. Product catalogue Technical information Support High torque and speed rigidity thanks to 14-pole technology

Key Features- Diameter: 22 ... 42 mm

- Length: 21 ... 28 mm

- Nominal voltage: 12 ... 24 V

- Torque up to: 92 mNm

- Continuous output up to: 60 W

Faulhaber B-Flat SC

-

Brushless Flat DC-Micromotors and DC-Gearmotors with integrated Speed Controller

The brushless DC-Servomotors with integrated electronics are based on the motors of the B-Flat series. In the case of the B-Flat series, the four-pole brushless DC-Servomotors with their uniquely flat coil technology with three flat, selfsupporting copper windings form the basis for drive systems in applications where installation space is extremely limited.

As an integrated electronic actuation unit, a speed controller is already available for these motors. What makes this speed controller so special is that it is fully integrated on the motor circuit board and does not increase the length of the motor in any way. In combination with the extremely flat, integrated gearheads, these motors provide an extremely compact drive system with increased output torque.

Key Features- Diameter: 26 mm

- Length: 10.4 ... 22 mm

- Nominal voltage: 6 ... 12 V

- Torque up to: 100 mNm

- Continuous output up to: 1.6 W

Faulhaber MSC

-

Brushless DC-Servomotor with integrated Motion Controller

The motion control systems of the most recent generation V3.0 are available in three performance classes with a continuous torque of 76 to 160 mNm. The drives comprise a brushless DC-Servomotor, a high-resolution actual value encoder and a Motion Controller in a complete, compact drive unit. The large number of different communication interfaces, the highly dynamic controllability, the robust design with protection class IP 54 as well as the industry standard connection concept via M12 connectors enable use in industrial environments ranging from automation technology and industrial special machinery construction to robotics and aerospace.

In combination with precision gearheads or high-quality lead screw systems, this results in complete system solutions for a wide variety of different applications. The systems can be used with any of the interface variants, both as stand-alone axes or in slave mode at various master controls. Furthermore, flexible usage possibilities are supported by various libraries and application notes that are available for download on the home page. All features of the drives are available here without restriction via all of the standard interfaces.

Key Features- Length: 75 ... 110 mm

- Nominal voltage: 12 ... 24 V

- Speed up to: 12,300 min⁻¹

- Torque up to: 160 mNm

- Continuous output up to: 140 W

Faulhaber BX4 IMC

-

Compact brushless DC-motors with integrated Motion Controller

The IMC product family adds the Integrated Motion Controller, a servo controller based on the FAULHABER Motion Controller 3.0 family, to the 22mm BX4 Servo family in various executions. Inheriting the muscle of the BX4 servo motor family and the brains of the Motion Controllers V3.0, these are likely the most compact Motion Control System on the market. The drives are available in two lengths and are characterized by a first-class volume-to-performance ratio. The diameter-compliant design optimizes space and resources providing an efficient and highly dynamic complete solution.

Using the version RS with the RS232 interface, the drive with integrated Motion Controller can easily be controlled either from a PC as well as via an embedded master. Supporting libraries are available for donload.

Key Features- Diameter: 22 mm

- Length: 49.6 ... 67.6 mm

- Nominal voltage: 12 ... 24 V

- Speed up to: 13,000 min⁻¹

- Torque up to: 27 mNm

- Continuous output up to: 15.1 W

Stepper Motors

-

Clear positioning: Stepper motors from FAULHABER

Stepper motors can perform demanding positioning tasks with particularly high accuracy. They accelerate very quickly and reach their full power almost without delay. In addition, they hold their position even when the power supply is switched off and can be controlled precisely without an encoder. FAULHABER offers a uniquely broad range of different stepper motors in numerous sizes.

FAULHABER AM

-

Two phase stepper motors with single magnets

The stepper motors of the FAULHABER AM family are ideal for positioning tasks that require high accuracy. They are characterized by a high holding torque and power density while keeping power consumption low. Even without power supply, they are able to hold their positions, which makes them the ideal choice of miniature stepper motors for battery-operated applications. Being available in various sizes and diameters and offering 20, 24 or 48 steps per revolution, the AM motors are very versatile and applicable to a vast variety of application areas.

The FAULHABER AM series can be combined with a wide selection of fitting controllers, encoders, gearheads and linear actuators, creating a powerful drive system for a broad range of positioning tasks. In laboratory automation, the miniature stepper motors are applied for moving and orientating samples during pipetting tasks, while in optics applications, they can be used, for example, for the positioning of moving stages in microscopes or scanning. Within satellites, the AM motor series can perform the precise positioning of antennas or solar panels.

Key Features- Diameter: 8 ... 32 mm

- Length: 13.8 ... 42 mm

- Step angle (full step): 7.5 ... 18°

- Static torque rating: 0.65 ... 85 mNm

FAULHABER DM-MICRO

-

Two phase micro stepper motors with a magnetic disc

The FAULHABER DM-Micro stepper motor family is the ideal choice for microstepping applications, due to its ability to position with an extremely high accuracy. With no additional encoder necessary, the two phase motors provide a cost effective solution for positioning tasks. They are made up of a magnetic disc and four coils and can deliver a total of 20 steps per revolution.

The stepper motors of the FAULHABER DM-Micro series run very smoothly with a low cogging torque, which makes them an optimal choice for applications in optics, for example when it comes to the positioning of lenses in an infrared or thermal camera. They are equally well suited for the use in inspection robots or semiconductor handling. If required, the motors can be delivered in special executions with redundant windings and can be combined with a selection of fitting controllers, gearheads and linear actuators.

Key Features- Diameter: 6 ... 12 mm

- Length: 9.5 ... 17.6 mm

- Step angle (full step): 18°

- Static torque rating: 0.25 ... 2.4 mNm

FAULHABER DM-Dynamic

-

4-coil motor with low inertia disc magnet for very dynamic movement

The stepper motors of the FAULHABER DM-Dynamic series are especially equipped for tasks that involve highly dynamic movement. The low inertia of the disc magnet leads to an extremely high acceleration and deceleration and makes quick changes of direction possible. With doubled windings with separate connections, the FAULHABER DM-Dynamic motors are redundant drive systems by design. They require only minimal installation space thanks to their short length in addition to their low weight.

The DM-Dynamic stepper motors are ideally suited for applications with very dynamic movement, like in feeder devices or tooling selection wheels in the semiconductor industry. Thanks to their redundant windings, they can also be used in tasks where redundant motor phases are required, such as in the positioning of satellite elements like thruster arms or antennas. The DM-Dynamic series can be combined with fitting controllers, encoders, gearheads and linear actuators to form a complete drive solution.

Key Features- Diameter: 40 ... 52 mm

- Length: 20.3 ... 32.6 mm

- Step angle (full step): 3.6°

FAULHABER DM-Ring

-

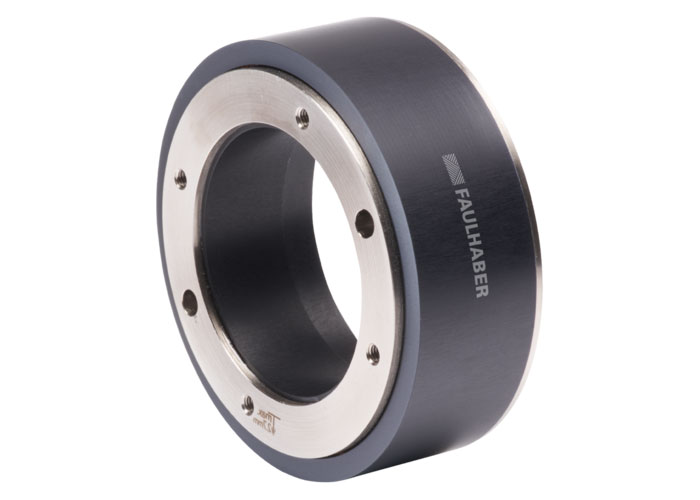

Ring stepper motor with very large aperture

The motors of the FAULHABER DM-Ring series are characterized by a special design: Similar to a hollow-shaft motor, the ring stepper motor offers a very large aperture of Ø 40 mm, which allows for laser or light signals, cables, gas or liquids to pass through the motor center, depending on the application. The direct drive consists of a magnetic disc with eight coils and runs without any backlash and with minimum friction. It supports very high loads due to big ball bearings and can operate with 200 steps per revolution.

Thanks to its very flat design and low weight, integration of the FAULHABER DM-Ring series into all kinds of applications is simple. The ring stepper motor is a great choice for highly demanding positioning tasks in areas like optics, aerospace or industry automation. It can be used for the precise rotation of lenses, while the light can be guided through the motor center. If the application requires electric cables routing in the motor center, they can be guided through the large aperture, while the motor drives antennas, turn tables or cameras.

Key Features- Diameter: 66 mm

- Length: 24 mm

- Step angle (full step): 1.8°

- Static torque rating: 307 mNm

Linear Motors

-

Linear motors from FAULHABER - Force with direction

A linear servo motor produces a translational motion, meaning it deploys its force in a straight line. Small linear motors from FAULHABER do this particularly quickly, efficiently and flexibly. They are also characterized by their very high repeatability. This makes them ideal for tasks where components are continuously moved at high speed on a straight axis or where a defined pressure is exerted.

Series LM 0830 ... 01

- Advantages

- High dynamics

- Excellent force to volume ratio

- No residual force present

- Non-magnetic metal housing

- Compact and robust construction

- No lubrication required

- Simple installation and configuration

Series LM 1247 ... 11

- Advantages

- High dynamics

- Excellent force to volume ratio

- No residual force present

- Non-magnetic metal housing

- Compact and robust construction

- No lubrication required

- Simple installation and configuration

Series LM 1247 ... 12

- Advantages

- High dynamics

- Excellent force to volume ratio

- No residual force present

- Non-magnetic metal housing

- Compact and robust construction

- No lubrication required

- Simple installation and configuration

Series LM 1483 ... 11

-

Key Features

- Continuous force up to: 6.2 N

- Stroke length: 20 ... 80 mm

- Width: 14 mm

- Height: 19.9 mm

- Length: 85.5 mm

- High dynamics

- Excellent force to volume ratio

- No residual force present

- Non-magnetic metal housing

- Compact and robust construction

- No lubrication required

- Simple installation and configuration

Series LM 1483 ... 12

- Key Features

- Continuous force up to: 6.2 N

- Stroke length: 20 ... 80 mm

- Width: 14 mm

- Height: 19.9 mm

- Length: 85.5 mm

- High dynamics

- Excellent force to volume ratio

- No residual force present

- Non-magnetic metal housing

- Compact and robust construction

- No lubrication required

- Simple installation and configuration

Series LM 2070 ... 11

- Key Features

- Continuous force up to: 9.2 N

- Stroke length: 40 ... 220 mm

- Width: 20 mm

- Height: 27.4 mm

- Length: 74 mm

- High dynamics

- Excellent force to volume ratio

- No residual force present

- Non-magnetic metal housing

- Compact and robust construction

- No lubrication required

- Simple installation and configuration