- Offer Profile

- The future of product

marking - Made in Germany

cab is setting new technological benchmarks in developing and manufacturing devices and systems for product labeling and product marking. Barcode printers are as much part of our delivery program as label printers, print and apply and marking laser systems. Customers from the manufacturing, service industries and trade rely on our high quality standards.

Marking

-

Products need labeling

cab sets technological milestones in the development and manufacturing of devices and systems for product marking. Barcode printers are as much part of our delivery program as label printers, print and apply and marking laser systems. Customers in industry, services and trading rely on cab’s high quality standards. Product marking - Made in Germany.

A visit to the world’s market leader for breast prostheses

-

What do you expect from your printers?

Dinzenhofer (Amoena): First of all we expect precise marking and that the imprints are of good quality and sustainability. A good contrast of the barcodes assures quick and easy scanning both in our house and at the customer. When using new ribbons we first print labels with different print parameters and then check the abrasion with a pull-off test. An error-free print image is the first condition. We furthermore differentiate between the applications. The product labeling must be of a higher quality than the labeling on packaging for logistic purposes.

So what is your conclusion?

Dinzenhofer (Amoena): The cab printers enable us to realize everything that is needed. Thereby, we achieve very good results.

Manufacturer of electrical components

First of all more flexibility in the marking of flow-wrap pouches

„Standard product, not a custom design“

A manufacturer of stamped metal electrical components located in the Northeastern U.S. was looking printer/applicators to replace obsolete custom-built machines used to apply 1.63” x 1” UPC-A barcode labels.

The labels are applied to the pouches as they exit the flow-wrap packaging machine at a rate of 40-100 parts/minute. Experience with their obsolete machines made the requirements for the new machines obvious and clear.

Working together with our local cab distributor, we developed a solution that met and exceeded the customer’s requirements using standard components from cab’s extensive line of modular printers and printer/applicators .

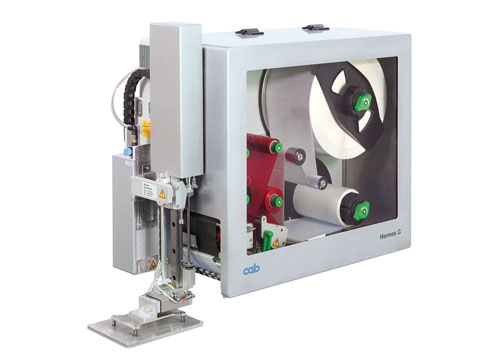

At TFL various chemical containers are labeled with Hermes C systems

-

Labeling on barrels

At a filling line 200 liter plastic barrels are passing by on a conveyor belt. The labels on the barrels display Borron® LB, a complexing agent used in the wet process in a beamhouse. Each barrel that arrives at the labeling station has already been automatically filled in the line, provided with a lid and screwed.

Labeling on barrels requires different demands on Hermes C. Each barrel needs to be marked with two labels, not from top but from the side. Hence, Hermes C has been horizontally mounted. A roll-on pad has been chosen as transfer module, because the barrels to be marked are round objects. The roll-on pad sets the left margin of the label to the barrel. At the same time the rotary table, on which the barrel stands on the conveyor belt at this moment, starts to rotate. During the rotational movement, the label is completely rolled on the barrel.

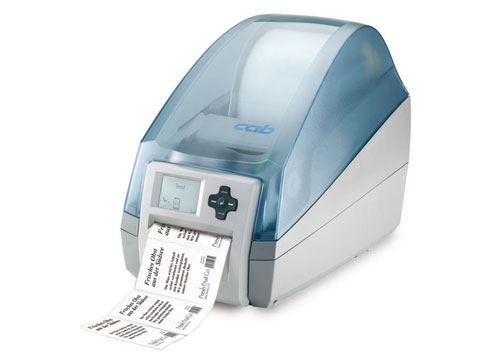

Label printers

MACH1/MACH2 - for small to medium-volume printing

- The low-budget desktop printers

Reliable 4“ desktop printers in proven technology. MACH1 with control buttons and LED display, MACH2 with colored LCD display and navigator pad.

EOS series - one concept, two sizes

- The low-budget desktop printers

The new EOS series combines all functions of a solid industrial printer with highest ease of operation. EOS1 for label rolls up to 155 mm diameter. EOS4 for label rolls up to 210 mm diameter.

MACH4 - for small footprint and medium runs

- The low-budget desktop printers

MACH4 has the same performance data as the established industrial printer A4+. Labels and transfer ribbons are feed from the front. Therefore it needs only a small work space. RFID optional.

SQUIX - designed for industrial application

- The new label printers designed for industrial application

The focus of SQUIX development was on an easy, intuitive operation, reliability and speed when printing and high printing accuracy. SQUIX are the further development of the successful A+ printers.

SQUIX applicators

-

Real-time labeling

The applicator S1000 combined with a SQUIX is a cost-effective solution for all dispensing printers in semi-automatic operation or when vertically integrated in a production line. The label is placed on the product with a stroke cylinder.

A+ series - for industrial demands

- The industrial printers with extensive accessories

During development, we focused first and foremost on simple and convenient operation coupled with high reliability. Extensive peripherals and software enable customized solutions – any time.

A+ series applicators

- The industrial printers with extensive accessories

The A1000 and A3200 represent in combination with the thermal printers A2+, A4+ and A6+ the inexpensive solution both for semi-automatic labeling and for the integration into automated production lines.

SQUIX 4 M - particularly for very small labels and slim continuous materials

- For printing on all materials that are wound on rolls or reels resp. fanfold. Especially for very small labels and slim continuous materials such as pressed tubes.

SQUIX 4 MT - particularly for textile materials

- Because of high heat energy while printing and the electrostatic charge of the materials the ribbon may stick with the textile tape. A separator guarantees reliable separation.

XD4T - for double-sided printing of textile materials

- Label printers for textile materials

For simultaneous front and rear printing of textile materials. The additionally installed drive roller after the printhead enables the textile material to be reliably separated from the transfer ribbon.

XC-series - for two-tone printing

- The specific for two-color printing

Two in-line arranged thermal transfer print units for simultaneous two-color printing in one label. The XC meets the conditions for the Classification and Labeling Inventory according to GHS.

Print and apply

- Experience and technical know-how from more than 30 years of product development are combined in our cab print and label systems.

Hermes+ print and apply

- The Hermes+ is designed for fully-automated print and apply processes in production lines. Precise label positioning and a robust design make the Hermes+ the choice for industrial labeling applications.

Hermes+ applicators

- For the precise applying in real time. The precision guide enables the labels to be applied or blown on the product with great accuracy.

A+ series applicators

- The A1000 and A3200 represent in combination with the thermal printers A2+, A4+ and A6+ the inexpensive solution both for semi-automatic labeling and for the integration into automated production lines.

PX print module - for industrial environments

- The PX series has been designed for fully automatic print and apply in technically demanding environment. PX enables printing /applying in any position and can be integrated in every production line.

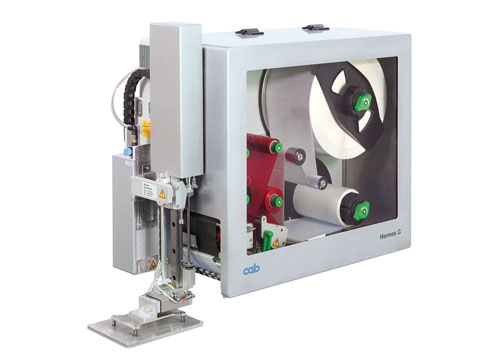

Hermes C - two-color print and apply

-

Two-color printing and dispensing

The new Hermes C is worldwide the first system for real-time printing and applying of individual two-color labels.

- For marking of chemicals and hazardous substances

- On drums, buckets, boxes and palettes according to GHS

- Designed for industrial application in production linesNominated for German Packaging Award 2015cab wins German Packaging Award 2015 in category "Labels, seals and other packaging aids" with Hermes C. The award was presented on FachPack in Nuremberg in September.

Hermes C applicators

-

For real-time labeling on packaging or products

According to the type of pad the product is either in motion or not. Labels may be applied on the product from all sides.

The pad is positioned above the peel-off plate. The label is held by the applicator during the printing process. A short stroke cylinder turns the tamp pad horizontally to the labeling position and places the label on the product. The cylinder stroke defines the maximum distance from the peel-off plate to the product.

Marking lasers

- cab marking lasers are economical, precise, fast and ideal for marking many different materials such as aluminum, various plastics and many further materials

Marking lasers FL+

-

Precise, fast, economic – cab fiber lasers

Performance and quality of a marking mainly relies on the output power and the laser beam‘s focusing. cab marking lasers FL+ are diode-pumped, air-cooled and offer highest beam quality and pulse peak power. An output power of the laser source of 10 up to 50 Watt is available.

Different plano-spherical lenses allow the lasers to mark in a field of 69x69 up to 290x290 mm. The lasers are used to mark on plastic, metal and color-coated surfaces.

The marking lasers FL+ consist of two fiber coupled functional modules: The scan head and the control unit with integrated laser source. The scan head may be assembled in each installation position. Control unit with integrated laser source is available in two different designs.

Marking software cabLase

-

Design- control - monitor

All FL+ marking lasers have installed the marking software cabLase Editor 5. Key features are:Graphic design of layouts

Control of marking

Monitoring marking process

Stand-alone mode

cabLase supports marking without the need of a PC. Marking layouts and associated fonts are downloaded and then transferred to the laser control for further management. Allows process control and monitoring by digital signals.Remote host mode

cabLase allows to be remote controlled via serial, Ethernet or ProfiBus connection by a host control e.g. PC, PLC. Programming commands are available to select layouts, to change marking data, for process control and monitoring.Remote API interface

Specially designed to be integrated into demanding manufacturing environments. Allows to generate objects, its parameter setting, management and processing of associated layouts and variable contents.COM Automation Server vergrößern

COM Automation Server

For individual, customizable marking applications. Offers a command library with all functions of the marking software cabLase.

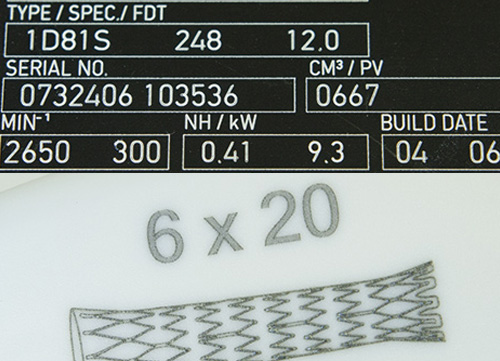

Laser label marker LM+

-

Mark and cut labels in different sizes out of continuous material

The laser label marker LM+ allows to precisely mark and cut labels in different sizes out of continuous material without the need of additional tools.The labels can then be separated via cutter or rewound by using an external rewinder.

Laser safety housing LSG+65

-

Easy and fast marking of single workpieces and small series

The laser safety housing LSG+65 offers a professional solution that allows an easy and fast marking of single workpieces and small series. The desktop version provides enough working space even for larger workpieces.

The manual operation door is balanced. Keyboard and monitor may, as an option, be installed in an ergonomic way on a pivot arm.

Accessories

- 6.2 Pivot arm for monitor with keyboard tray

- 6.3 Rotary axis

- 6.6 Suction hose

- 6.7 Mobile cart

Laser safety housing LSG+100

-

Industrial solution that allows the marking of parts in series with the FL+ marking laser

The laser safety housing LSG+100 offers the industrial solution that allows the marking of parts in series with the FL+ marking laser. The robust metal design provides a large working area and enough space for the integration of laser source and industrial PC into 19“ rack mounts.

Keyboard and monitor are installed in an ergonomic way on a pivot arm. The operation door opens and closes pneumatic driven.

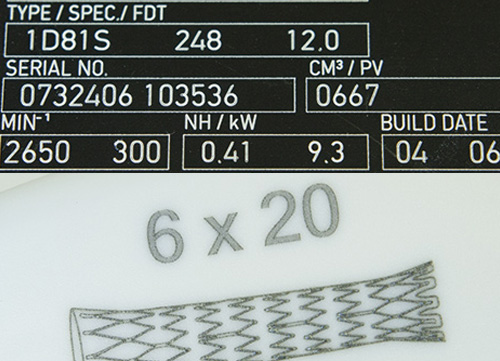

Laser typeplate handling THS+

-

Durably mark flat parts as e.g. typeplates or marker sheets made of plastics or metal

The laser typeplate handling THS+ allows to durably mark flat parts as e.g. typeplates or marker sheets made of plastics or metal.

Designed for the processing of nameplates for motors, pumps, control cabinets, and others it is used for applications in demanding industrial environments where the contents needs to be clearly legible even after years.

Two different designs are available

Type 1 “THS+Basic”

Plates or other flat parts up to a thickness of 4 mm are individually inserted into a jig, fed after start, marked and then automatically rejected.Type 2 “THS+M”

The plates are stacked in a magazine. The upper one of a stack is marked and then automatically rejected.

Extraction and filter device AF1

-

Protects the operator’s health and prevents the working area and lens from being contaminated

Material processing with lasers produces toxic dust and gaseous contaminants. The extraction system protects the operator’s health and prevents the working area and lens from being contaminated, thus providing a constant laser output power.

The contaminated air of the working area is extracted by a high-power turbine and transported to the filter unit via a flexible hose. Contaminant particles, respectively dust are filtered out in the pre-filter and filter for suspended particles. Gaseous contaminants are absorbed by the activated carbon filter. The cleaned air is then diverted into the environment.

The extraction and filter device AF1 features

- compact design,

- small footprint,

- simple and fast change of filter,

- low sound level due to extract air silencer,

- monitoring of filter saturation and motor.Consumables

- 10.5 Pre-filter box

- 10.6 Filter

- 10.7 Filter for supended particles

- 10.8 Active carbon filter

Labels and ribbons

- No matter what your requirements, we have the right label with full adhesive strength and flawless surfaces. cab labels and ribbons are available in all popular qualities and dimensions. They are also available in small quantities and at very low cost direct from stock. cab also caters to other requirements, such as customized labels with a company logo, etc.

Labels

- Stock items are available in small quantities at a low cost. The core diameter and winding are suited to the cab printers. Specific labels are produced with high quality and in a timely manner.

Ribbons

- For small or wide labels, for product marking or type

plates, cab offers you, with more than 20 types for every application, the

right ribbon. They are siuted for cab printers and ensures a constant

quality.

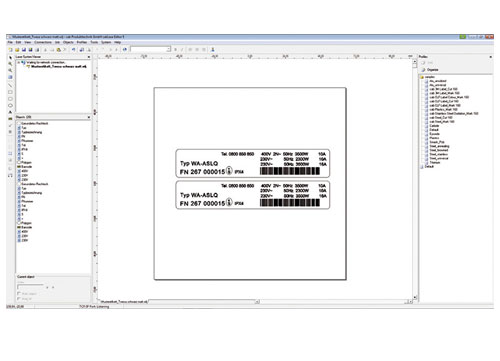

Label software

- The right software for every solution – for seamless

operation. cablabel S3 Lite is a comprehensive standard label software –

free with purchase of printer. Firmware and drivers you can download in

support area.

For more information on connecting databases, monitoring printers and administration of cab label printers please go to:

cab software tools

Integration in SAP R/3*

SAP and cab have jointly developed a method to control the cab printers easily with SAPScript from SAP R/3. cab is a silver level partner of the SAP Printer Vendor program and thus has access to the SAP development environments to provide high quality printer support* * SAP and R/3 are registered trademarks of SAP AG.

cablabel S3

- The software, which was developed by cab, opens the full potential of cab devices during label design.

Database Connector

- In the stand-alone mode with additional network connection the Database Connector enables stand-alone printers to link up data from a SQL-compatible database and to print.

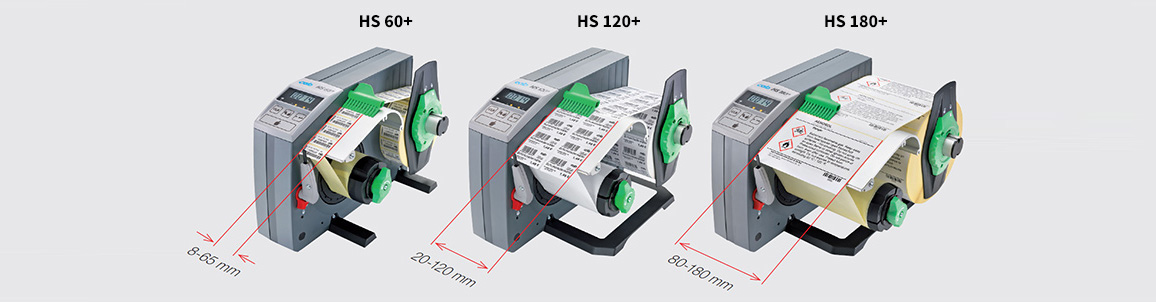

Label dispenser HS / VS

- Precise and simple label dispensing for a great price

The new label dispensers succeed through easy handling and affordability. cab offers two designs for dispensing in correct position:- the HS dispenses the label horizontal - bottom leading

- the VS dispenses the label vertical - top leading

- Dispensing label automatically or on demand

- Slow or fast feed rate

- Label counter from 1- 9,999

- Peripheral connection utilizing an external signal for "dispensing on demand"

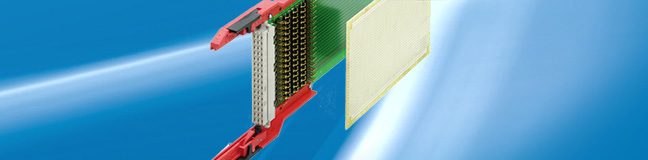

Electronics

PCB separators

Off-cut Remover Hektor 2

- Separates milled PCBs carefully and fast

PCB Separator MAESTRO 2 / 2M

- Compact, fast and economical PCB separator for PCBs with

pre-scored groove:

Separation type circular blade

Operation MAESTRO 2 by hand

Operation MAESTRO 2M motorized

Separation speed 2M 100/200/300 mm/s

Separation length 15 - 300 mm

PCB Separator MAESTRO 3E

- PCB Separator for small and large PCBs and for PCBs with

pre-scored groove:

Separation type circular blade/linear blade

Operation manual

Separation length up to 450 mm

PCB Separator MAESTRO 4S

- The MAESTRO 4S fulfills your expectations to variety for

the following requirements:

Delicate components are mounted directly next to the pre-scored groove

You separate PCBs with a thickness up to 3.2 mm

Aluminum PCBs have to be separated

Availablility on request.

PCB Separator MAESTRO 5L

- For automatic separation of PCBs with pre-sored groove

Separation type circular blades, max. 11 circular blades

Seapration motorized

Separation speed 100-220 mm/s. can be set in 10 steps

Separation length 100 - 570 mm when light barrier activated

Magazines / Universal cutter

PCB Magazines Series 600 / 700 / 800

- for automatic assembly lines

Series 600 - the cost-effective width adjustment with screws

Series 700 - widths adjustment whithin seconds with precision spindle

Series 800 - full automatic widths adjustment

PCB Magazines Series 100 / 180 / 300

- for manual assembly with 32 slots

Universal cutting machine FS 100

- With the Universal Cutting Machine, improve production

and lower costs

Resulting from the ease of use and low procurement cost the universal cutter is economicaly viable even for small quantities or samples.