- Offer Profile

- Yamazaki Mazak was established in 1919 and has been contributing to the development of the machine tool industry as a leading global company. Yamazaki Mazak manufactures not only advanced machine tools such as multi-tasking centers, CNC turning centers, machining centers and laser processing machines but also automation systems with the concept of DONE IN ONE to support global manufacturing by providing exceptional productivity and versatility. We will continue to develop advanced machine tools for progress in manufacturing as well as society.

Automation

-

Mazak is the largest manufacturer of Flexible Manufacturing Systems, with a production history of more than 27 years.

The PALLETECH SYSTEM is designed with the flexibility required for shorter product life cycles, minimum in-process inventory, just-in-time production and other demands of today’s manufacturing environment.

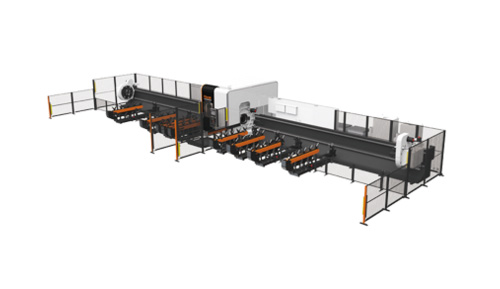

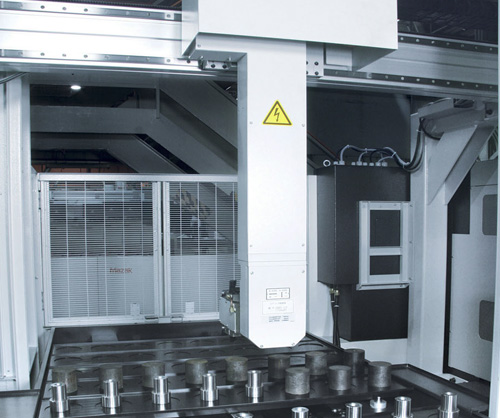

PALLETECH MANUFACTURING CELL

-

We offer the PALLETECH Manufacturing Cell (1 level) and PALLETECH High Rise System (2, 3 levels) according to your production volume and budget.

Furthermore, the PALLETECH System is designed for convenient system expansion after the initial installation to easily respond to increased production requirements in the future.

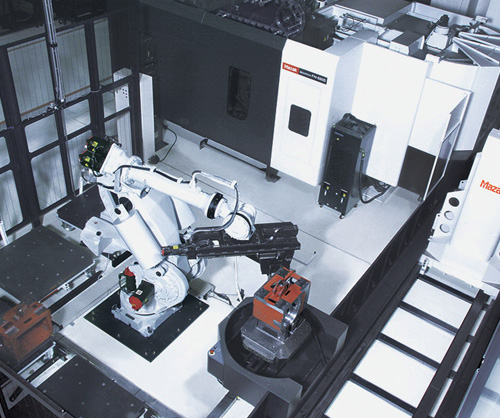

E-BOT CELL

- The e-BOT Cell 720 is designed to realize up to 720 hours of unmanned operation per month in the machining of a wide variety of workpieces. Even for changes in production lot sizes, labor requirements are minimal.

GANTRY LOADER (GL)

-

A gantry robot with separate loading and unloading hands to enable end-users to achieve the fast takt times demanded by mass production. What’s more, with a width of just 1750mm, the GL automation system is ideal for small floor spaces.

Gantry robots are a very effective system to automatically load material and unload workpieces for unmanned operation over extended periods of time

AUTO FLEX CELL

-

Frequent changes to production variables have the potential to massively impact productivity and profitability. The AUTO FLEX CELL is a unique automation solution for the INTEGREX i-series, developed for highly flexible manufacturing environments.

Designed to increase the profitability of jobs requiring frequent changes of tooling, chuck jaws or workpiece, the cell maximises machining hours by reducing product turnaround time – in turn delivering a lower component cost price and increased profitability.

AUTO WORK CHANGER

-

The VARIAXIS i-300 AWC (Auto Work Changer) looks and performs like no other 5-axis automation solution. It is designed to deliver a lower cost price per component, faster return-on-investment and improved profitability.

The AWC is ideal for manufacturers requiring increased flexibility to meet the challenges of machining complex components, with a high product mix in small batch sizes. When paired with the AWC, VARIAXIS’ outstanding productivity is enhanced further by fast product changeovers from its 32 stockers to provide continuous machining and reduced non-cutting time.

LASER FMS

-

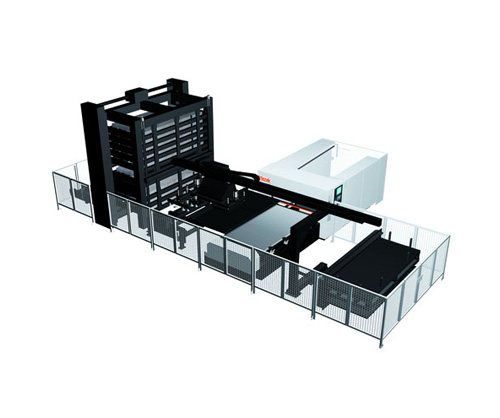

Extensible Manufacturing Cell

Flexible system expansion by adding material stockers, additional laser machines and finished workpiece stockers in response to increased production requirements.Shown with SUPER TURBO-X 510 Mk lll G + Extensible Manufacturing Cell

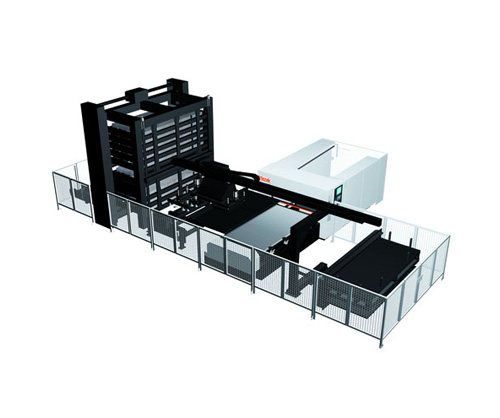

Compact Manufacturing Cell

10 pallets with the material and finished worksheets can be stored in the shelves. Number of micro joins can be minimized since the finished worksheet is unloaded to the stocker with the pallet.Shown with OPTIPLEX 3015 II

MULTI PALLET POOL (MPP)

- The Multi Pallet Pool (MPP) offers high-speed pallet transfer and further extended unmanned running, compared to twin or six pallet automation systems. Specifically designed for unmanned lights out running, the configuration on display at EMO will feature a 16 station MPP, but a smaller 10 pallet version is also available. The MPP has an economic footprint – up to 40% smaller than a comparable PALLETECH system – and is controlled using the Smooth CNC, which is equipped with Mazak’s SMOOTH MPP software application. Smooth MPP facilitates advanced scheduling functions, faster analysis of production results and more efficient system utilisation and can be accessed remotely on PCs and smart phones.

TA-12

- Easy-to-programme robot cell integrated with Mazak’s Smooth CNC, ideal for small to medium lots sizes. Automated robot arm for loading and unloading of workpieces. Ideal for applications that require lights-out unmanned running overnight or at weekends, both the machine tool and the robot are controlled from the Mazak Smooth CNC, which provides a seamless interface and extremely fast set-up.

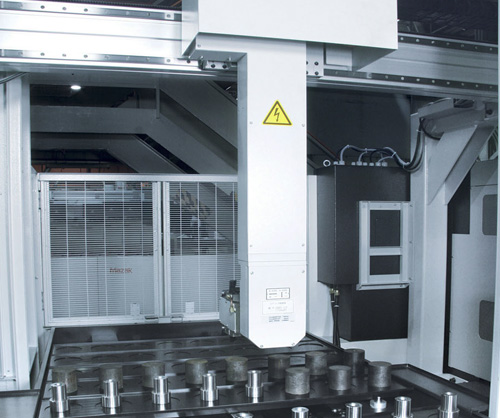

TOOL TRANSPORT SYSTEM

- In order to realise unmanned operation over extended periods of time, tools required for machining must be in the machine magazines. By the use of the TOOL TRANSPORT SYSTEM, multiple machines can share and manage tools according to the machining schedule.

Mazak Laser Technology

-

High-speed, high-accuracy laser cutting with unsurpassed productivity

Yamazaki Mazak started the production of laser processing machines in the 1980's.

Ever since, we have concentrated on producing the most advanced machines available, capable of cutting thin to thick flat workpieces, cubic workpieces and pipe and structural materials – all with high-speed and high-accuracy. This is made possible by using the latest machine tool and CNC technology and CAD/CAM software while focusing on overall ergonomic machine design. Our extensive laser product range incorporating the most advanced technology is designed to meet virtually any production requirement. 2D LASER PROCESSING MACHINES

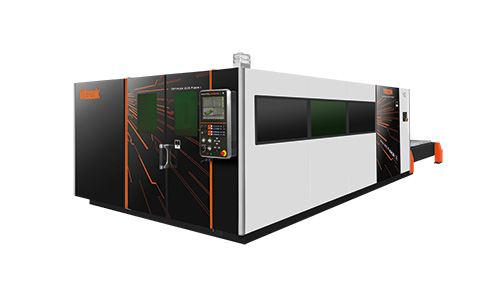

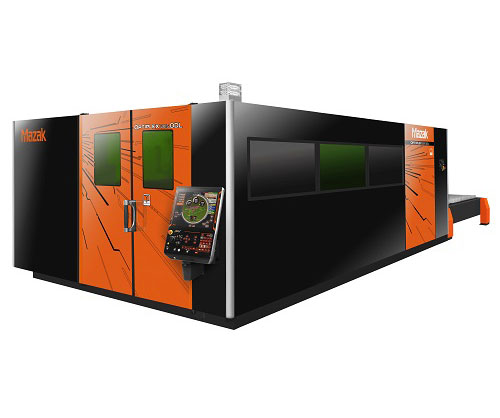

OPTIPLEX FIBER III

-

Fiber Laser processing machine

Intelligent performance for maximum productivity

- Utilizes high dynamics configuration, 2 pallet changer design with a helical rack and pinion positioning system that features high cutting speeds, maximum throughput and rugged construction.

- Equipped with Intelligent Multi-Function Torch and Nozzle Changer technology directly increases the productivity by allowing the machine to optimize the torch setup automatically per program.

- Fiber technology for ultra high-speed cutting and lower running costs

- Fiber laser for cutting thick material, such as stainless steel and aluminum.

OPTIPLEX DDL 3015/4020

-

Direct Diode Laser combines high performance with cutting-edge laser technology

- Productivity is increased by 15% in workpiece high-speed cutting thanks to the DDL Resonator

- The Multi-Control Torch and a variety of Intelligent Functions provide incomparable operator support for exceptional ease of operation and optimum machine efficiency

- Wide range of cutting parameters for high quality cutting–stable cutting over extended periods of operation

- DDL shorter wavelength than a fiber laser improves high speed cutting of thin to mid worksheets including highly reflective materials such as aluminium, brass and copper

- The DDL is capable of rapid traverse rates of 120 m/min in the X- and Y-axes, and 60m/min in the Z-axis.

OPTIPLEX NEXUS FIBER

- Fiber laser processing machine designed to provide you the maximum value

SUPER TURBO-X series

-

High-precision, CO2 laser processing machine

Advanced MAZATROL PREVIEW 3 CNC

SUPER TURBO-X unique features:- Table Feed System Designed for excellent table access, ease of operations and convenient processing of a wide variety of workpieces in small size lots.

- Constant beam length for stable cutting performance

- A wide variety of automatic operation systems are available

- The SUPER TURBO-X can be easily integrated into an Extensible Manufacturing Cell

2D/3D

SPACE GEAR 510 MK II

-

SPACE GEAR 510 MK II delivers full size machine performance with the flexibility of 2D/3D features. Tubes, pipes and structural shapes can all be processed by adding a CNC rotary chuck and supports for long workpieces.

- All –in-one 2D/3D Laser processing machine for maximum flexibility

- 6-Axis with integrated chuck, ±360° A-axis and ±135° B-axis

- 2D flat worksheets, 3D workpieces and pipe processing all cut by one machine

- Constant –beam length system provides stable cutting performance

SPACE GEAR –U 44

-

2D/3D laser Processing machine

Laser processing machine that cuts 2D flat sheet and plate with high speed and high accuracy as well as 3D formed shapes and 3D 6-axis-rotary fabrication of pipe, tube and structural steel and bevel cutting of plate.

3D TUBE CUTTING MACHINES

3D FABRI GEAR II series

-

3D Laser Processing Machine

Automatic and continuous 3D laser cutting of long structural material

Key Features and Benefits:- 3D laser cutting of long round/ square / rectangular pipe, as well as H, I and L beams

- Complete all cutting processes from 3D cutting to tapping in just one machine when equipped with the optional tapping unit [Max. M12]

- Just load long material in the loading station, 3D cutting performed automatically as well as transfer of finished parts to the unloading station

- Reduced running cost, thanks to the new laser oscillator

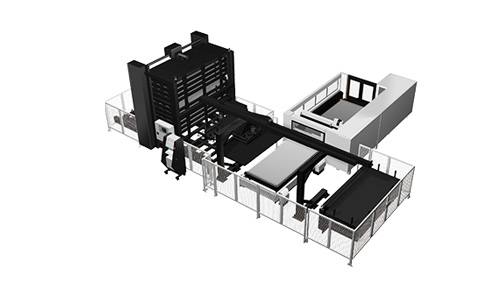

AUTOMATION

EXTENSIBLE MANUFACTURING CEL

-

Variety of automation systems available to meet a wide range of production requirements

- Flexible system expansion by adding material scockers, additional laser machines and finished workpieces stockers.

- Designed for continuous unmanned operation 24hours/day

- Production schedule management, on-line operation and managemenet of material stocker are performed by system controller

- Thin to thick worksheet, up to 25mm are automatically loaded and unloader

- System expansion up to 4 machines

- Customer’s rack system can be integrated in the EMC.

COMPACT MANUFACTURING CELL

-

- Compact 10 pallet stocker for OPTIPLEX Series

- 25 mm thick material capacity

- 1000 Kg plate capacity

- Optional sorting station also available.

FMS OPTOPATH 7200

-

- From raw material to cut parts sorted from scrap.

- FMS OPTOPATH 7200, high adding value thanks to unmanned operations

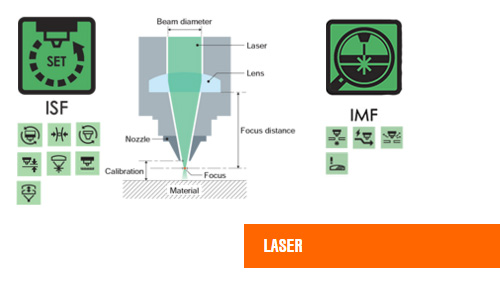

INTELLIGENT FUNCTIONS

Intelligent Technology

-

The Multi-Control Torch and the variety of Intelligent Functions provide incomparable operator support for exceptional ease of operation and the optimum machine efficiency.

Mazak laser processing machines feature advanced functions, optimum lens and nozzle can automatically be selected and changed for each material and thickness. Even unskilled or inexperienced operators can now easily perform high quality cutting. Quality of machined components is improved with reduced machining time and running cost.

CNC SYSTEM

Mazak laser processing machine CNC systems

-

The revolutionary MAZATROL CNC, developed exclusively by Mazak, was first used on metal cutting machine tools in 1981.

This unique system also has been used on Mazak lasers for almost 30 years.By incorporating the most advanced technology possible, these systems provide unsurpassed ease of operation and high performance.

INTEGREX - Multi-Tasking

-

The complete Fusion of a CNC Turning Center and Machining Center

Complete every one of your machining operations from raw material to finished component in one hit, in one setup with the ultimate DONE-IN-ONE machine from Mazak.

Ergonomic, environmentally efficient and excellent value, the all new Integrex i-series incorporates the very latest technologies, Mazak quality and total support.

INTEGREX e-H

-

Done-in-one processing for the machining of large workpieces.

Large swing and Y-axis stroke for large workpieces

Roller guides on all linear axes for increased rigidity

Wide variety of optional equipment to reduce machining processes and improve machining capability

Key Features and Benefits:- Done-in-One performance

- Y-Axis, off-center machining

- 240-degree B-Axis milling spindle positioning

- Single-setup machining

- Second turning spindles

- Lower turret rotary tool spindles

- Large capacity tool magazine

INTEGREX e-RAMTEC

-

The INTEGREX e-RAMTEC series is equipped with a ram spindle for deep ID turning/machining in addition to the machining capabilities of the INTEGREX e-V II series.

Key Features and Benefits:- High-accuracy positioning of B and C-axis

- Ram spindle for deep inner diameter turning and milling

- 2 pallet changer and large-capacity tool magazine for reduced setup time

- Convenient operation and maintenance thanks to the ergonomic machine design

- Factory automation – convenient system expansion to meet changes in production requirements

INTEGREX e-V

-

The INTEGREX e-V II series is complete fusions of CNC machining centers and vertical turning centers. These combinations of machining centers/turning centers are by far the most advanced Multi-Tasking machines in the industry. Complete all operations in a single setup – turning, milling, drilling and more with Mazak's Done-in-One machining concept that can be applied to small to large very complex parts. Machines include B-axis tilt milling spindles and C-axis turning spindle tables. Machine configurations are two pallet or single table (S) versions.

Key Features and Benefits:- Done-in-One performance

- 150-degree B-axis tilt milling spindles

- Powerful turning/C-axis spindles

- Single-setup machining for large parts

- Large capacity tool magazine

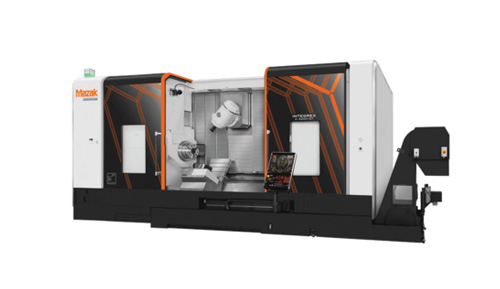

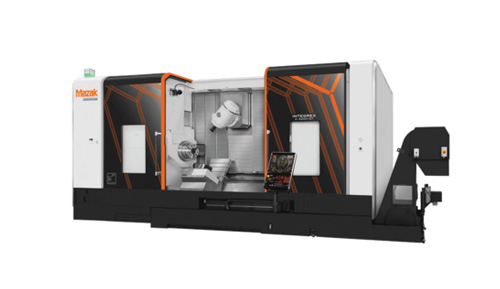

INTEGREX i

-

The INTEGREX i series, the fifth generation Mazak multi-tasking machine, features a large machining area and high accuracy plus ease of operation and convenient maintenance thanks to the ergonomic machine design.

Key Features and Benefits:- Long strokes for large workpiece capacity

- 5-axis simultaneous machining for complex workpieces

- Processing from raw material to finish workpiece in a single setup

- High-power spindle for heavy-duty cutting

INTEGREX i-V

-

The INTEGREX i-V series is the productive fusion of the performance of turning centers and machining centers incorporating of tilting B-axis for 5-axis machining.

Key Features and Benefits:- 5-axis simultaneous machining for complex workpieces

- Processing from raw material to finish workpiece in a single setup

- High-power spindle for heavy-duty cutting

INTEGREX j

-

The INTEGREX j-series, your new portal for multi-tasking, is designed to provide you the maximum value as the newest member of the INTEGREX series and will define a new standard for multi-tasking machines.

Key Features and Benefits:- Compact machine design with a large machining area

- Large true Y-axis design

- Mill Spindle indexing (B-axis) for versatility

- High-speed, high-torque milling spindle

- matrix nexus 2 CNC controller

- 20-tool magazine (standard), 36 and 72 tool magazine optional

5-Axis

-

What is 5-Axis Machining?

5-axis machining provides infinite possibilities as to the part sizes and shapes you can effectively process. The term “5-axis” refers to the number of directions in which the cutting tool can move. On a 5-axis machining center, the cutting tool moves across the X, Y and Z linear axes as well as rotates on the A and B axes to approach the workpiece from any direction. In other words, you can process five sides of a part in a single setup.

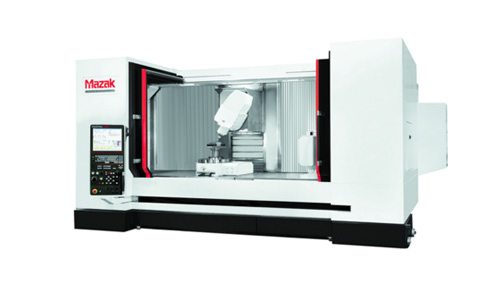

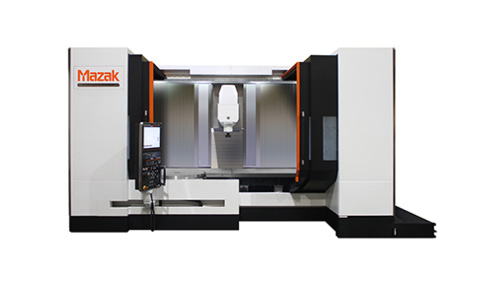

VARIAXIS i

-

Multiple-Surface / Simultaneous 5-axis Machining Center

5-axis simultaneous machining centers designed for exceptional versatility, now available with turning capability.

The VARIAXIS i series features high-speed, high-accuracy performance.Largest machining envelope for this class machining center.

Additionally, turning capability, 2 pallet changer systems and FMS are available to meet a large variety of production requirements.

Key Features and Benefits:- Done-In-One capability streamlines production and improves overall management

- Intelligent Functions provide ease of operation and optimum efficiency

- Wide range of spindle speeds available for exceptional versatility

- Reliable cam-driven tool changer offers higher productivity

Various tool magazine capacities provide part-processing flexibility - High-rigidity table with roller gear cams eliminate backlash to ensure accuracy

- MATRIX 2 CNC control provides unbeatable accuracy and increased productivity

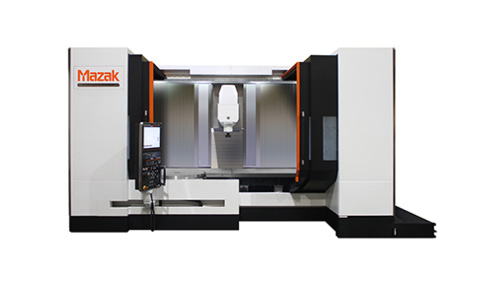

VARIAXIS j

-

The high-accuracy, high-value VARIAXIS j-Series provides multiple surface and simultaneous 5-axis machining center options for handling a wide variety of applications within industries that include aerospace, automotive and general machinery.

The series handles all processes from raw material input through final machining to provide dramatic reductions in lead times and improve workpiece accuracy through the elimination of multiple setups.

Key Features and Benefits:- j-500 and j-600 provide high-accuracy multi-surface machining

- j-500 5X and j-600 5X offer high-accuracy simultaneous 5-axis machining

- Done-in-One operations reduce total production time

- Rotary/tilt table on j-500 and j-600 provides simultaneous 4-axis capabilities and A-axis indexing

- Rotary/tilt table on the j-500 5X and j-600 5X enables simultaneous 5-axis machining

- High-rigidity tables provide precision machining

- 12,000 and 18,000 spindle speeds provide exceptional versatility

- 18-tool and 30-tool magazines offer long, continuous operation

- Automatic tool changers reduce machining cycle times

- Linear roller guide on X-, Y- and Z-axes provide high accuracy positioning

- Easy conversational programming for multi-surface and simultaneous 5-axis machining

VERSATECH

-

The VERSATECH Series of multiple-surface 5-axis double-column machining centers is designed to provide unsurpassed productivity in the machining of very large workpieces thanks to spindle heads that can position to the vertical and horizontal positions and any angle in between. The machining time for cast iron and non-ferrous material workpieces can be considerably reduced thanks to the fastest cutting feedrate and spindle speed in this machining center class. In addition, since multiple-surface machining can be realized by just changing the position of the spindle head by program command, non-cutting time is considerably reduced.

Key Features and Benefits:- Multi-Face Machining

- C-Axis Rotation Continuous for full 5-Axis Machining

- Expansive tool-storage capacities

- High Speed, High Accuracy, High Rigidity

- Mazatrol Matrix 2 - Standard Equipment

VERTICAL CENTER NEXUS

-

The Vertical Center Nexus Series combines advanced technology, productivity and value for a wide variety of machining applications. This makes them an incredible value for shops large and small. Equipped with the Mazatrol Matrix Nexus CNC, this control provides conversational or EIA programming, giving the capability and productivity necessary for today's technology driven shops.

Key Features and Benefits:- Standard, high-speed (HS) or high-torque spindles available

- Rotary/tilt tables on for 4 and 5-axis models

- Various capacity tool magazines

- Large machining envelopes

- Two-pallet changers and Twin-Table changing with front loading stations

- Easy integration of articulated robots for process automation

VORTEX HORIZONTAL PROFILER

- 5-Axis Simultaneous Horizontal Machining Center

VORTEX i-V

-

5-axis Vertical Machining Center

High productivity with integration of latest MAZATROL SmoothX CNC.

- Ensure high-efficiency machining of complex workpieces thanks to the

VORTEX II

-

The VORTEX Series of 5-axis Vertical Machining Centers delivers high productivity through full simultaneous 5-axis machining as well as multiple surface machining capabilities. The Series features larger sized machines for processing big complex workpieces such as those often found in the aerospace industry. Tilt/rotary spindles as well as pallet changing highlight the series of machines.

Key Features and Benefits:- High speed, simultaneous 5-axis and multiple surface machining

- Tilting and tilt-rotary spindles

- Large table sizes

- CAT 50-taper 10,000 rpm / 50 hp spindles and available high-torque spindles

- Tool storage capacities from 30 to 348 tools availableTwo-pallet changin

- PALLETECH automation is available with certain machine models

VTC

-

Mazak’s Vertical Travelling Column (VTC) range of machining centres has been designed to meet the needs for today’s challenging and diverse range of manufacturing applications where performance, flexibility and precision are key product attributes. The flexible configuration of the VTC provides the capability to process an extensive range of components from medium to large across industries including aerospace, power generation, industrial equipment and general subcontract.

The VTC range of products is available in either 3, 4, 5 and 6 axis configurations, which in conjunction with an extensive range of customer defined options and accessories delivers the ultimate platform for your application needs.

Key Features and Benefits- Integrated Mazak Technology delivers class leading accuracy and repeatability.

- Reduced load and unload time for maximum spindle utilisation.

- Flexibility to meet changing application needs.

- Enhanced productivity through easy to program Mazatrol CNC.

- Superior Operator Ergonomics

CNC Turning Centers

-

Delivering outstanding productivity and performance

Mazak offers world-class CNC turning centres that combine advanced technology, productivity, and value. A wide variety of machine specifications - from 2-axis models to turning centres with rotary tool spindle, Y-axis and second spindle - are available to meet your production requirements.

QUICK TURN PRIMOS series, a compact & high-performance CNC turning centre equipped with integral spindle motor providing unsurpassed productivity with minimum floor space requirements.

QT COMPACT series, entry-level models boasting Mazak’s integrated spindle technology for the main spindle and Tool Eye as standard, together offer both improved performance and accuracy. An extensive range offering a compact and cost-effective solution for turning, milling, Y-axis, and second spindle capability.

QUICK TURN series, high performance turning centres that make complex parts accurately and with reduced set up time. Equipped with the new Smooth Mill Drive turret with BMT or VDI tooling interface and 5000 or 10000rpm capability.

New MULTIPLEX W series is ideally suited to high-volume applications and features a slant bed for improved chip management. The machine employs two Smooth Mill Drive turrets to perform continuous and simultaneous machining.

HQR series, 2 turret, 2 spindle machines offering optimised cycle times for higher volume parts, by enabling tandem turning or milling by means of the upper and lower turrets working concurrently. Y-axis functionality on both the upper and lower turrets also increases the flexibility for more complex components.

CYBERTECH TURN

-

Powerful, Heavy-duty CNC Turning Centers

This powerful turning centre is equipped with a rotary tool spindle, lower turret and many new features to deliver higher productivity.

A wide variety of optional specifications are available, including an automatic long boring bar stocker and advanced threading software that re-cuts threads, making CyberTech Turn especially suitable for oil industry components and other industries that machine long, large diameter workpieces.Key Features and Benefits:

- 12-position upper turret with turning and/or rotary tool abilities

- Various bed lengths for long shaft applications

- Deep hole boring with automatic changer

- Fully Programmable servo tailstock

- Mazatrol matrix 2 and matrix nexus 2 conversational programming

DUAL TURN

-

2-spindle CNC Turning Centres

For high-efficiency, high production chuck work. Twice the machining capability on single machine platforms for saving valuable manufacturing floor space. The machines provide twice the tool capacity with two 12-position turrets.

HQR

-

- 2 turret/2 spindle construction delivers unsurpassed productivity

- High productivity with integration of latest MAZATROL SmoothG CNC

- Both main and second spindles have 22kW (30min) 5000rpm giving high performance cutting

IVS-II

-

The unique IVS Inverted Vertical Spindle Series of machines provides maximum stability and high accuracy positioning for high volume production applications. Machine automation can be custom configured to specific application requirements, and two machines can be joined to complete first and second processes. For the IVS Series, Mazak can supply the automation, material handling, tooling and gauging for complete turnkey systems. All this combined in a compact footprint with maximum accessibility for part and tool setups.

Key Features and Benefits:

- Inverted spindle designs

- Available rotary tool milling (M) capability

- High accuracy positioning and performance stability

- Accepts parts in any orientation

- Easily configured into two-machine turnkey setups

- Rotary tooling for more complete processing

- Gantry loader automation

MTV

-

The MTV Series of Column-feed Vertical Machining Centers designed for enhanced ease of operation and productivity. The machines provide ample table sizes for long part or multiple smaller-part setups.

Key Features and Benefits- High efficiency, high-horsepower 50 taper spindles

- Fast rapid traverse speeds

- Standard 30-tool storage capacity, 60-tool optional

- Long X-axis travels

MEGATURN

-

Versatile vertical turning centers designed to provide exceptional value

Key Features and Benefits- Powerful cutting capability for high productivity

- 12 position drum turret for heavy-duty machining

- Automatic tool changer for turning tools (Option)

- MAZATROL SmoothC control system

- Ergonomic design for convenient operation

- Designed for machining large workpieces found in the construction machinery, aerospace and energy industries

MULTIPLEX II

-

The MULTIPLEX Series of CNC Turning Centers with dual-spindle/dual-turret machine configurations for mid-sized lot production. Both spindles can be used to efficiently machine the front and back sides of parts, including milling, single-setup production. Both turning spindles are identical in performance and can also be used to simultaneously cut two parts at one time. Their synchronized rotation delivers high-accuracy for operations like shaft work.

Key Features and Benefits:

- Center partition allows use as two separate machines

- High accuracy shaft machining

- High accuracy and high speed workpiece transfer

- Large window for excellent visibility of both spindles

- Moveable CNC operation panel for operator ease of use

- Ease of programming with ability to use both conversational and EIA ISO programming format as standard

MULTIPLEX W

-

Innovative design for higher productivity

The MULTIPLEX W-200 series of CNC Turning Centers with dual-spindle/dual-turret machine configurations, is ideally utilised to high volume applications.

Key Features and Benefits:- Symmetrically designed machine platform with 2-spindle and 2-turret configuration increases machining productivity

- Employs two high power SMOOTH Mill Drive turrets to perform continuous and simultaneous machining, and is also equipped with a 5,000rpm main spindle

- New smaller SmoothG operator panel solely for MULTIPLEX W-200 series

- Slant bed design for improved chip flow and operator accessibility

- New gantry loader system for improved efficiency

QT-COMPACT

-

Compact, high-performance CNC turning center

- QT-COMPACT M- turning center with rotary tools

- QT-COMPACT MS- rotary tools and second spindle

- QT-COMPACT MY- rotary tools with Y-axis

- QT-COMPACT MSY- rotary tools, second spindle with Y-axis

- Equipped with high rigidity integral spindle / motor for unsurpassed machining performance – no gears or belts are used that can generate vibration during machining

- C-axis indexing in 0.001° increments plus rotary tools mounted on turret provide exceptional versatility

- High accuracy positioning is ensured by the high rigidity linear roller guides and direct coupled servo motors on all linear axes

- Advanced features of the Mazak SmoothC CNC

QUICK TURN

-

Specifications designed to meet your production requirements from small batch to high volume applications

Key Features and Benefits:

- Equipped with Advanced features of the Mazak SmoothG CNC

- Powerful, high-rigidity machines for a wide range of demanding workpiece applications

- Wide variety of available integral / spindle motor specifications, from standard spindle to high torque spindle for heavy duty machining

- Thanks to its design, vibration is minimised during high-speed operation to ensure exceptional surface finishes and maximum tool life.

- Mazak's standard positioning accuracy is 2 times better than the ISO standard

- High speed clamping / unclamping can be performed without interference

- Advanced automation technology such as gantry loader systems are available.

QUICK TURN NEXUS

-

New generation world-class CNC turning centers that combine Advanced Technology, Productivity, and Value. A wide variety of machine specifications - from 2-axis models to turning centers with rotary tool spindle and second spindle - is available to meet your production requirements.

Key Features and Benefits:

- Powerful main turning spindles with integral motors

- Full C-axis contouring available on machines with rotary tool milling spindles

- CNC programmable tailstocks

- Through-hole chuck packages

- Fast indexing turrets for maximum efficiency

- Automatic tool eye

- Easy integration of bar feeders and robotic loading for unmanned operation

QUICK TURN PRIMOS

-

Compact, high-performance CNC turning center

Floor space requirement is 20% smaller than comparable machines

QUICK TURN SMART

-

The QUICK TURN SMART Series of CNC Turning Centers combines productivity, high-accuracy, and high-reliability, while providing high performance and unsurpassed production value for small to medium-sized parts. Also available with rotary tool milling spindles, (M) machine configurations provide milling, drilling and tapping capabilities in addtion to turning operations.

This series offers Mazak's entry-level SMART control with a user-friendly interface that provides just the right amount of technology needed to quickly and accurately produce simple workpieces.Key Features and Benefits:

- Powerful main turning spindles with integral motors

- Full C-axis contouring available on machines with rotary tool milling spindles

- CNC programmable tailstocks

- Through-hole chuck packages

- Fast indexing turrets for maximum efficiency

- Automatic tool eye

- Easy integration of bar feeders and robotic loading for unmanned operation

SLANT TURN NEXUS

-

Heavy-duty CNC Turning Centres

High efficiency machining of long shaft workpiecesKey Features and Benefits

- Designed to efficiently machine long shaft workpiece by powerful 45 kW (60 HP) [30 min. rating] spindle motor with maximum torque of 7000 Nm ( 713.8 kgf.m)

- Available with an optional NC steady rest with a maximum gripping range of à 410mm.

- Provides ease of operation thanks to the MAZATROL Nexus 2 CNC which also controls the tailstock and optional NC steady reast

SQR

-

- Faster shaft workpiece cycle times by simultaneous turning with upper / lower turrets

- High efficiency machining of shaft work workpieces for large volume/mass production applications

SUPER QUADREX

-

The Super Quadrex 4 axis Series of single spindle, two-turret CNC Turning Centers offers Multi-tasking machining. Faster cycle times by simultaneously cutting with upper and lower turrets –such as O.D. and I.D, O.D. and drilling for balanced cutting. These high production machines also increase throughput for mass production applications of longer shaft work, or for chucked work. Super Quadrex (M) configuration machines also offer live spindles for secondary drilling and milling operations on the centerline.

Key Features and Benefits:

- Two 45 degree opposed wedge style turrets for combined operations

- Balanced cutting capability using both turrets

- Steady rest applications capability

- Fast setup using standard tool eye feature

- Integral spindle technology

- Easy integration of bar feeders and gantry robots for automated operations

Vertical Machining Centers

-

Mazak's Vertical Machining Centres serve the full spectrum of industries, from subcontract to aerospace.

With the VTC series there is so much flexibility for 3, 4 and 5-axis machining, that you will be able to access almost any industry sector and deliver high quality precision parts quickly, reliably and competitively.

FJV

-

High-rigidity, double column vertical machining center

Equipped with an automatic tool changer for angle tools. Simplified conversational programming of multi- surface machining thanks to the MAZATROL CNC. By performing multiple surface machining in a single workpiece setup, in-process time is considerably reduced when compared to conventional processing.Key Features and Benefits:

- FJV 5 Face II series

- Newest member of the FJV series which has the capability of machining 5-faces of a workpiece in a single setup.

- Multi-surface attachment (option) for increased productivity.

- Ergonomic machine design provides unsurpassed ease of operation in the machining area.

MAZATECH

-

The MAZATECH Series of Column-feed Vertical Machining Centers designed for enhanced ease of operation and productivity. The machines provide ample table sizes for long part or multiple smaller-part setups.

Key Features and Benefits

- High efficiency, high-horsepower 50 taper spindles

- Fast rapid traverse speeds

- Standard 30-tool storage capacity, 60-tool optional

- Long X-axis travels

MTV

-

The MTV Series of Column-feed Vertical Machining Centers designed for enhanced ease of operation and productivity. The machines provide ample table sizes for long part or multiple smaller-part setups.

Key Features and Benefits- High efficiency, high-horsepower 50 taper spindles

- Fast rapid traverse speeds

- Standard 30-tool storage capacity, 60-tool optional

- Long X-axis travels

SUPER VELOCITY CENTER

-

The SUPER VELOCITY CENTER 2000L II Series of traveling column Vertical Machining Centers deliver high speed and efficient machining of extremely long workpieces. Linear motors provide high-speed super-fast X-axis rapid traverse speeds to reduce non-cut times. These machines are especially well suited for long aerospace parts.

Key Features and Benefits:

- Long beds accommodate extremely long workpieces

- Fast high-accuracy positioning and cutting rates

SVC

-

The SVC-2000L series of traveling column Vertical Machining Centers deliver high speed and efficient machining of extremely long workpieces. Linear motors provide high-speed super-fast X-axis rapid traverse speeds to reduce non-cut times. These machines are especially well suited for long aerospace parts.

Key Features and Benefits:- Long beds accommodate extremely long workpieces

- Fast high-accuracy positioning and cutting rates

VCN

-

Highest productivity in this class of vertical machining centers

Reduced cycle times thanks to high speed feedrate, acceleration / deceleration and tool change

Key Features and Benefits:- High accuracy machining and high productivity are realised thanks to the unique MAZAK mechanical and machine control technologies

- A variety of Intelligent+ Functions provides incomparable operator support for exceptional ease of operation and the optimum machine efficiency

- MAZATROL SmoothG - 4 axes simultaneous CNC

VERTICAL CENTER NEXUS

-

The Vertical Center Nexus Series combines advanced technology, productivity and value for a wide variety of machining applications. This makes them an incredible value for shops large and small. Equipped with the Mazatrol Matrix Nexus CNC, this control provides conversational or EIA programming, giving the capability and productivity necessary for today's technology driven shops.

Key Features and Benefits:

- Standard, high-speed (HS) or high-torque spindles available

- Rotary/tilt tables on for 4 and 5-axis models

- Various capacity tool magazines

- Large machining envelopes

- Two-pallet changers and Twin-Table changing with front loading stations

- Easy integration of articulated robots for process automation

VERTICAL CENTER PRIMOS

-

Compact & High Performance

Newly-designed spindle ensures stable machining performance. Overall productivity is increased, thanks to high acceleration rate on spindle and 60m/min rapid traverse rate.

VERTICAL CENTER SMART

-

The VERTICAL CENTER SMART Series is a world-class line of Vertical Machining Centers that combine advanced technology, productivity and value for a wide variety of machining applications. Grease-packed ceramic spindle bearings increase machine rigidity, reduce heat and help to reduce maintenance. The series offers Mazak's entry-level SMART control, with a user-friendly interface that provides the most current technology needed to quickly and accurately produce work pieces in Mazatrol Conversational or EIA formats.

Key Features and Benefits:

- Compact footprint to maximize floor space

- Robust 40-taper grease-packed spindles with ceramic bearings metal

- SMART CNC control simplifies machine set up and increases operator efficiency

- Performance enhancing Intelligent Machine features

- Ergonomic control swings for easy operator viewing

- High accuracy and productivity for a variety of industry applications

- Easy integration of articulated robot for process automation

VTC

-

Mazak’s Vertical Travelling Column (VTC) range of machining centres has been designed to meet the needs for today’s challenging and diverse range of manufacturing applications where performance, flexibility and precision are key product attributes. The flexible configuration of the VTC provides the capability to process an extensive range of components from medium to large across industries including aerospace, power generation, industrial equipment and general subcontract.

The VTC range of products is available in either 3, 4, 5 and 6 axis configurations, which in conjunction with an extensive range of customer defined options and accessories delivers the ultimate platform for your application needs.

Key Features and Benefits

- Integrated Mazak Technology delivers class leading accuracy and repeatability.

- Reduced load and unload time for maximum spindle utilisation.

- Flexibility to meet changing application needs.

- Enhanced productivity through easy to program Mazatrol CNC.

- Superior Operator Ergonomics

Horizontal Machining Centers

-

Designed to provide unsurpassed performance, productivity and reliability

Increased cutting performance thanks to high-rigidity bed and column

The increased number of available spindle specifications provides efficient machining for a wide variety of workpiece material

Longer Y-axis stroke and larger maximum tool diameter for increased productivity

µ-Series

- The µ-Series is a high-performance small machining center for pallets up to 1000x1000 mm. It is equipped with a variety of countermeasures for heat displacement to ensure stable accuracy over long periods of operation, providing the same machining accuracy as a Jig-borer.

FF

- Compact high speed horizontal machining center for mass production

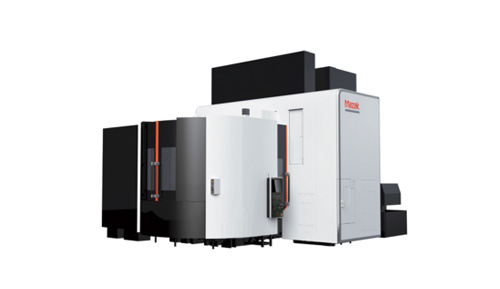

HCN

-

Powerful 10000rpm, 50 taper 37kW spindle for machining a wide range of workpieces and materials

2 Pallet Changer as standard equipment for higher efficiency

60m/min high speed rapid traverse reduces non cutting time to increase productivity

HCN-Q

-

Faster machining cycle times with spindle quill

The quill makes it possible to perform deep boring without any interference with the headstock for improved productivity

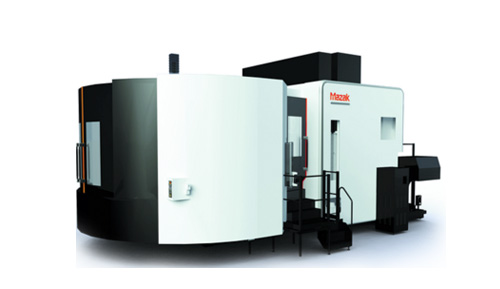

MEGA

-

The MEGA Series Super High-Torque Horizontal Machining Centers are highly rigid machines that make the heavy-duty machining of tough materials from steel and cast iron to Inconel and titanium extremely efficient, accurate and productive. The machines feature wide machining areas for accommodating large, heavy workpieces.

Key Features and Benefits:

- High-horsepower, high-torque integral spindle/motors

- High-rigidity bed and column ensure high-performance, high-accuracy

- Linear-roller guides on all axes for speed and accuracy

- Cam-driven tool changing ensures reliable high-speed tool change cycles

- 60-tool storage capacity and 80, 120, 160, 180, 240 and 348 capacities optional

- Standard two-pallet changers

- Easy interface with Mazak's PALLETECH System for automated operation

ORBITEC

-

The ORBITEC large part machining centers provide the capability to create true turned surfaces on parts that difficult, or too large, to rotate. The machines greatly reduce setup times and improve throughput for large, heavy and awkward workpieces such those often found in the energy industry. As a cost-effective, innovative valve body production center ORBITEC machines can complete more than 75% of valve applications in one setup while maintaining high tolerances.

The patented head-design technology in ORBITEC machines allow them to perform a variety of operations, including the facing of flange surfaces, conical boring of taper holes, face milling and endmilling, in a single part setups. The machine's head allows the centerline of rotation to be moved for positioning the turning centerline where needed.Key Features and Benefits:

- Unique headstock design

- High-precision large-component machining

- Heavy duty integrated spindle motor

- Large-diameter turning capability

- Optional two-pallet changer and integration into PALLETECH system for linking with other Mazak machining centers in atutomated production cells

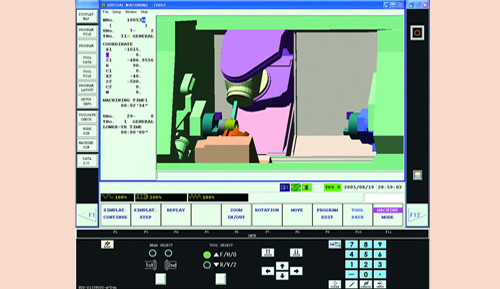

Machine Tool CADCAM System

-

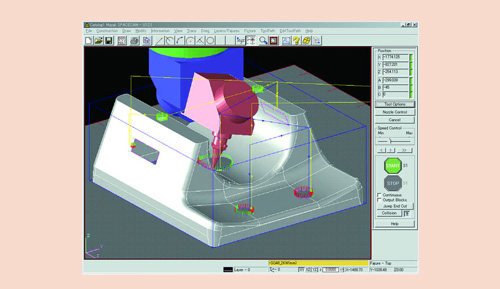

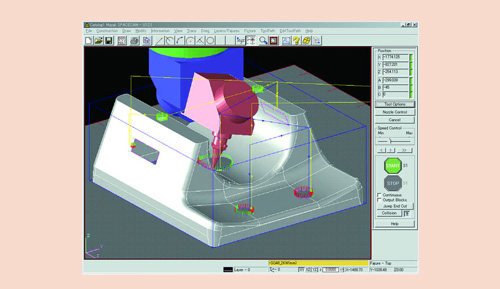

MAZATROL CAM – Programs can be made, edited and checked anytime in the office

A machine operator can easily use the MAZATROL CAM since the operation method is the same as the CNC mounted on a machine

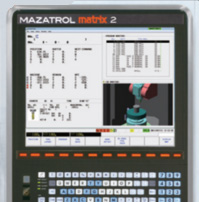

MAZATROL SMOOTH

- SMOOTH TECHNOLOGY incorporates the new MAZATROL SMOOTHX CNC alongside new machine hardware and servo systems to deliver an improved operator experience, faster machining times and further integrate CNC into the overall factory management system. The result is a breakthrough in CNC which uses intuitive operations in a similar manner to smartphones and tablets.

MAZATROL Matrix CAM 2

- Machine programs can be made and then checked for machine interference in the office using the Matrix CAM 2

MAZATROL CAM Smart 2

- Programming and program checking can be done in the office.

Laser CADCAM System

-

Mazak CADCAM Systems – Indispensable tools to enhance laser machine productivity

- Mazak software provides the optimum processing conditions in order to maximize productivity

- CADCAM Fabrication System

SMART System

Innovative CADCAM system that uses 3D solid models. Even an inexperienced operator can easily make NC programs for complex shapes from 3D models to considerably increase laser machine utilization.SPACE CAM

3D CAD files can be imported and used to make cutting programs in the minimum time. The same data can be used to automatically make the cutting programs used to produce fixture components for the workpiece.

Mazak Cyber Production Center

-

Comprehensive Factory Management Software

By using a network, this software can manage your factory in real-time by providing accessibility to machine data, machining programs, fixture data, tool data, production schedules and other data

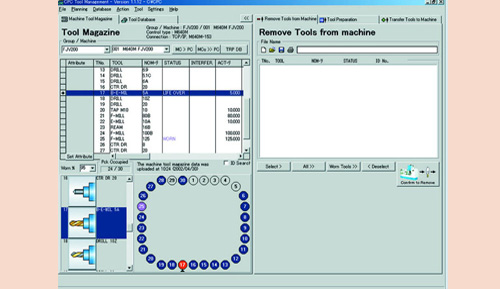

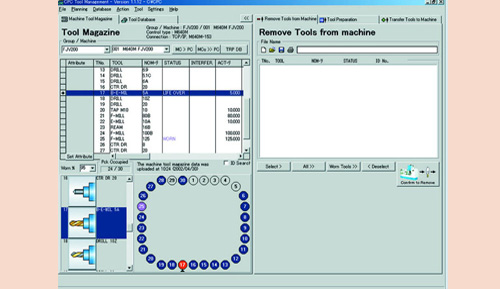

Cyber Tool Management

Comprehensive control of all tool data over a network minimizes machine non-cutting time due to tool setups

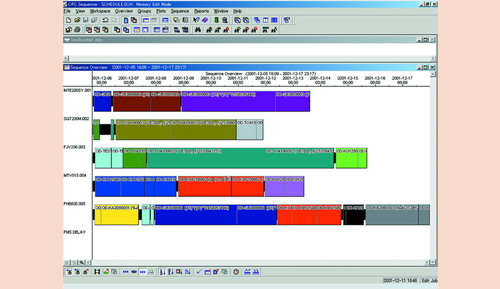

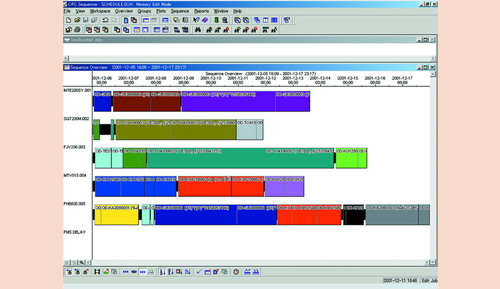

Cyber Scheduler

Easily displays current workloads on all machines and estimated completion time when new jobs are added.

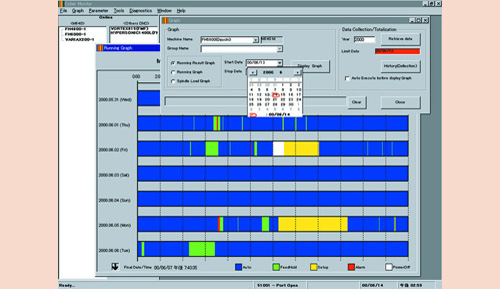

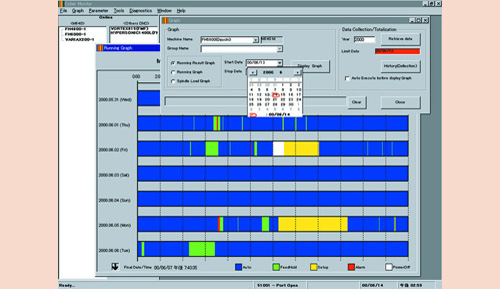

Cyber Monitor

Conveniently check machine operation and job process status in office or off-site location.

Siemens Technology

-

The class leading Mazak machines

- VTC-800/30SR

- VTC-800/20SR

- VTC-800/30SDR

- VARIAXIS i-500

- VARIAXIS i-600

- INTEGREX e-500H II

- INTEGREX e-670H II

Are now available with the latest SINUMERIK 840D sl CNC technology.

SINUMERIK is simple to operate and offers many innovative functions and technology cycles for cost-efficient manufacturing. The programming method is always the right one for your requirements – be it for small or large batch production, for simple or complex workpieces. SINUMERIK is a productive CNC system for every technology application.

Technology

High Speed, High Accuracy

High Speed, High Accuracy

- Yamazaki Mazak has always focused on developing innovative machine tools and has designed machines to meet today’s as well as tomorrow’s requirements. Mazak machines not only incorporate multi-tasking technologies, they also utilize the most advanced technologies such as automation, direct drive motors, roller guides and conversationally programmed CNC systems to provide you with the ability to effectively machine a wide variety of workpieces in small size lots. Our goal is to develop machines that provide customers unsurpassed productivity and ease of operation.

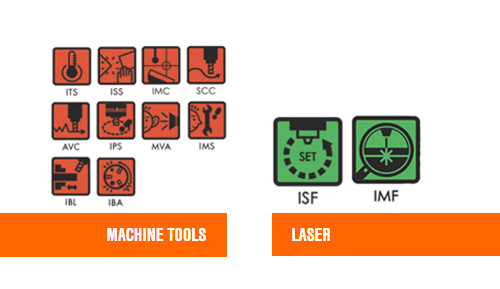

Intelligent Technology

-

The MAZATROL, the first conversationally programmed CNC system in the world, was introduced in 1981. In 1998, the MAZATROL was fused with a personal computer that incorporated our extensive expertise for unsurpassed operating efficiency. Today,There are 10 INTELLIGENT functions for the machines tools and 2 for laser processing machine – all incorporate the latest technology in order to provide higher productivity.

A variety of Intelligent Functions provides incomparable operator support for exceptional ease of operation and the optimum machine efficiency.

Machine tools

-

- Intelligent Thermal Shield

- Intelligent Safety Shield

- Intelligent Mazacheck

- Smooth Corner Control

- Active Vibration Control

- Intelligent Performance Spindle

- Mazak Voice Adviser

- Intelligent Maintenance Support

- Intelligent Balance Analyzer

- Intelligent Bar Loader System

Laser

-

Intelligent Set-Up Functions:

- Auto Torch Changing

- Auto Nozzle Changing

- Focus Detection

- Auto Focus Positioning

- Beam Diameter Control

- Auto Profiler Calibration

- Auto Nozzle Cleaning

Intelligent Monitoring Functions:

- Piercing Detection

- Plasma Detection

- Burning Detection

- Lens Monitoring

Ergonomic

- Yamazaki Mazak has always focused on not only improved machine performance but also machine ergonomics in order to realize unsurpassed ease of operation.

Excellent accessibility to the machining area

Efficient setup

Ease of operation

Large CNC display

Centralized maintenence

Door handle

Visibility of machining aarea

Orange line

Done-in-One

Done-in-One

-

Another important target is the ability to efficiently machine a wide variety of parts in small size lots. One of the most effective approaches for this is DONE-IN-ONE processing.

The “DONE-IN-ONE” concept incorporates all machining processes from raw material input through final machining – in just one machine. It provides the ability to reduce production lead time, improve machining accuracy, reduce floor space and initial cost, lower operating expenses, reduce operator requirements and to improve the work environment. As a result, the concept not only streamlines production, it also improves overall management.

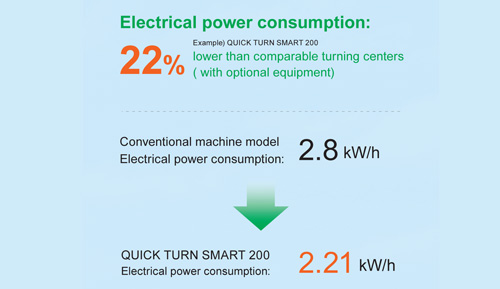

Advanced Technology & Environmentally Friendly

-

The environment and our impact on our natural surroundings have always been important concerns of Yamazaki Mazak.

This is shown by the fact that all factories in Japan where Mazak machine tools are produced are ISO 14001 certified, an international standard confirming that the operation of our production facilities does not adversely affect air, water or land.

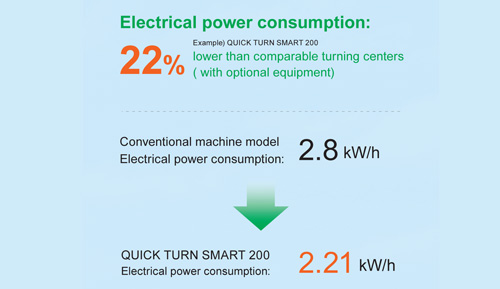

High efficiency LED and low power consumption

-

High efficiency LED work lights are used for illumination of the machining area.

These lights, the CNC display and the optional chip conveyor are automatically shut off after a predetermined period for lower power consumption when the machine is in the stand-by state. Additionally, the optional high efficiency hydraulic system lowers overall electrical power consumption.

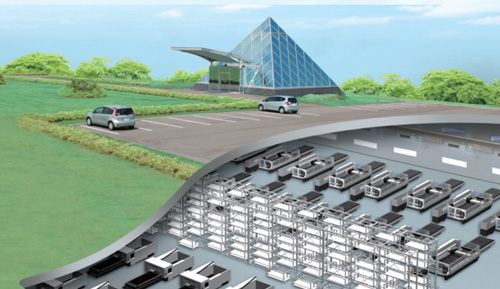

Earth-friendly manufacturing plant and laboratories

-

World R&D Center (World Research and Development Center)

Yamayaki Mazak Optonics Corporation

Smooth Technology

-

Yamazaki Mazak is set to revolutionise the world of CNC and deliver a step-change in machine control and performance with the launch of its SMOOTH TECHNOLOGY.

SMOOTH TECHNOLOGY incorporates the new MAZATROL SMOOTHX CNC alongside new machine hardware and servo systems to deliver an improved operator experience, faster machining times and further integrate CNC into the overall factory management system. The result is a breakthrough in CNC that uses intuitive operations in a similar manner to smartphones and tablets.

Productivity

-

PROGRAMMING

- New ‘Quick MAZATROL’ interface reduces the number of keystrokes to write a conversational program by 38% compared to its predecessor.

- Windows 8 gestures for moving, zooming, scaling and rotating the 3D display.

- Block processing speed for handling fine segment programs is four times faster than its predecessor

- New ‘3D Assist function’ provides directly import of 3D CAD to the CNC reducing programming time eliminating errors from manual input

- Five new process home screens to present critical data in a single view, simplifying the key operational stages from part programming, management of tool data and set-up, through to the actual machining cycle.

- New ‘Quick EIA’ interface includes a high speed display of tool paths and an analysis function to determine errors in the program that could cause surface defects.

Connectivity

-

Factory management integration

- Various interfaces (EtherNet I/P, Profibus and C-Clink) enable flexible and fast connection to peripheral devices such as automated robotic loading and measuring systems

- Supports the MTConnect open-source, royalty-free manufacturing protocol

- Smooth Process Support (SPS) is the name for Mazak’s brand new range of shop management software for a PC

- Operation status and maintenance information can be managed and analysed by desktop and mobile devices with Smooth Monitor software

- Allows for centralised management and sharing of production data and system management

- Operation status and maintenance information, including mean time between failure analysis, are co-managed to improve productivity

- Potential fault cautions can be directly emailed to office devices

New key Functions

-

- New Intelligent Pocket Milling (IPM)

- Seamless Corner Control (SCC)

- Variable Acceleration Control (VAC)

- Smooth Machining Configuration (SMC)

Ease of Operation

-

- New touch-screen Graphical User Interface (GUI) panel with intelligent keyboard to offer intuitive operation similar to a smart phone or tablet

- The operating panel boasts a 19” control panel yet is 36% smaller than its predecessor

- Control panel angle is easily adjusted to suit the varying height and posture of the operator

- Control panel has been designed in collaboration with world-renowned industrial designer Ken Okuyama