SGS Tool

Videos

Loading the player ...

- Offer Profile

- Specialized Facilities,

Global Coverage - We are a privately-held, ISO-certified leader of round

solid carbide cutting tool technology for the aerospace, metalworking,

and automotive industries with manufacturing sites in the United States and United Kingdom.

Our global network of Sales Representatives, Industrial Distributors, and Agents blanket the world selling into more than 60 countries.

Product Portfolio

End Mills

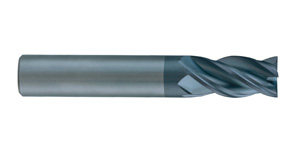

HIGH PERFORMANCE

Z-Carb-AP Patented Variable Rake Carbide End Mill

- The Z-Carb-AP Patented Variable Rake Carbide End Mill offers performance so advanced, it goes way beyond typical “high performance” end mills. Superior chatter suppression through an unequal helix design and patented variable rake angle. Achieve incredible accuracy and improved shearing capabilities with enhanced corner geometry and tight-tolerance corner radius. The Z-Carb-AP comes with Ti-NAMITE-X® coating for extremely long life

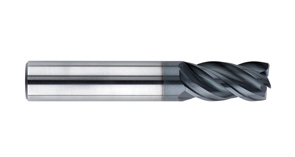

Z-Carb Unequal Helix End Mills

- Maximize stock removal and improve productivity with the original unequal helix end mill. The Z-Carb reduces chatter, increases tool life, and optimizes performance, even in aggressive milling applications.

Z-Carb MD End Mills for Mold & Die Applications

- Get all the benefits of SGS' best selling Z-Carb unequal helix end mills with geometric enhancements specifically for high speed mold and die applications.

Z-Carb HTA End Mills for High Temperature Applications

- Z-Carb-HTA solid carbide end mills are designed specifically for use with difficult-to-machine materials. Z-Carb-HTA for high temperature alloys maximizes stock removal and improves productivity by reducing chatter, increasing tool life, and optimizing performance.

Multi-Carb High Performance Finishing End Mills

- The Multi-Carb High Performance Finishing End Mill incorporates a large number of flutes for stability and high feed finishing capabilities in applications where surface finish and tolerance are critical factors. The large flute count design allows smoother cutting performance and increased tool life, positively impacting productivity and quality levels. Available with 7, 9, or 11 flutes.

V-Carb Five Flute Finishing End Mills

- V-Carb 5-flute solid carbide end mills for finishing and semi-finishing produce an exceptional finish while tackling heavy milling tasks, including roughing and slotting. V-Carb can be run at higher production rates, is coated with Ti-NAMITE-A® (AlTiN) tool coating, and is available in stub, regular, and long flute lengths for any finishing application.

S-Carb 3 Flute End Mills for Aluminum & Non Ferrous

- The S-Carb end mills are a high performance family of end mills designed for Non-Ferrous materials. Available in a 2 flute and 3 flute version, the tools are engineered with a specialized flute to effectively manage the large size and volume of chips produced during the aggressive machining of Non-Ferrous materials. A circular land stabilizes the tool while cutting and produces an excellent surface finish. With long reach neck options from inventory, there is an S-Carb option for just about every application.

Ski-Carb End Mills for Aluminum

- Ski-Carb solid carbide end mills for aluminum & non-ferrous applications come with patented design features that allow for corner milling without chatter, greater shearing ability, increased rigidity, and additional protection against chipping. Primary and secondary flute wall construction avoids chip interference.

Power-Carb End Mills for Mold Grade Steels

- Power-Carb solid carbide end mills for mold grade steels up to 65 HRc feature eccentric relief and an extreme negative radial rake for increased edge strength, a high helix/multi-edge design for increased rigidity and feed rates, and extra long shanks for extended reach capabilities. Ideal for high feed/speed rates and wet or dry machining.

Turbo-Carb End Mills for Complex Shapes in Hardened Steels

- Turbo-Carb solid carbide end mills are ideal for machining complex, contour shapes in tough and hardened mold & die steels up to 60 Rc. Coated with Ti-NAMITE-A® (AlTiN) tool coating for maximum heat and wear resistance.

Series 33 End Mills for Stainless Steel, Nickel & Titanium

- Series 33 High Performance End Mills handle slotting of

difficult materials such as Stainless Steel,

Titanium, and Inconel. Ideal for applications struggling with chip evacuation, this 3-Flute

design offers increased chip clearance and a reduction in harmonics.

Series 7 End Mills

- Series 7 solid carbide end mills provide precision performance and high production rates without chatter. This is the tool that can deliver it all: improved chatter suppression, longer tool life, better surface finishes, reduced harmonics, and improved side-wall straightness.

Series 27 Slow Helix End Mill

- Series 27 slow helix design adds strength to the edge

making the tool more capable of milling of

highly abrasive materials. The stable configuration and full cutting edge leads to improved surface finishes.

GENERAL PURPOSE

4 Flute General Purpose End Mill

- Square, ball, and corner radius end solid carbide end mills with 30° right hand spiral. Available in stub, regular, long, and extra long lengths with a variety of coatings to enhance tool life.

3 Flute General Purpose End Mill

- Square and ball end solid carbide end mills with 30° right hand spiral. Available in regular and extra long lengths with a variety of coatings to enhance tool life.

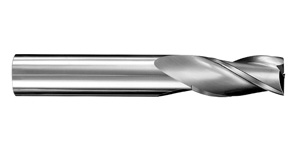

2 Flute General Purpose End Mill

- Square, ball, and corner radius end solid carbide end mills with 30° right hand spiral. Available in stub, regular, long, and extra long lengths with a variety of coatings to enhance tool life.

4 Flute Double End End Mills

- Square and ball end carbide end mills with 30° right hand spiral available with flat and a variety of coatings to enhance tool life.

2 Flute Double End End Mills

- Square and ball end carbide end mills with 30° right hand spiral available with flat and a variety of coatings to enhance tool life.

3 Flute Tapered End Mills

- Square end solid carbide end mills with taper spiral and straight shank. Available with a variety of coatings to enhance tool life.

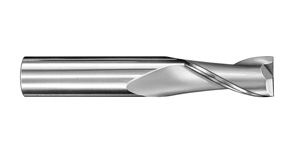

2 Flute Non-Ferrous End Mill

- Square end solid carbide end mills for aluminum.

4 Flute Non-Ferrous End Mill

- Square end solid carbide end mills for aluminum.

Miniature End Mill

- Solid carbide miniature end mills with 30° right hand spiral.

Roughing End Mills

- Corner radius end solid carbide end mills for roughing mild steel, steel alloys, stainless steel, cast iron, space age exotics including titanium, inconel, rene, and waspaloy, as well as aluminum, brass, and copper.

End Mill Sets

- Square and ball solid carbide end mill sets with selections of 4-flute, 3-flute, and 2-flute end mills.

Drill

HIGH PERFORMANCE

Hi-PerCarb High Performance Double Margin Drills

- Hi-PerCarb Double Margin Carbide Drills increase production rates up to 12 times over conventional carbide drills. Double margin construction provides greater stability & point cooling, improved surface finishes and increased tool life. Available in 3x and 5x diameter lengths, comes standard with Ti-NAMITE-A® (AlTiN) Tool Coating.

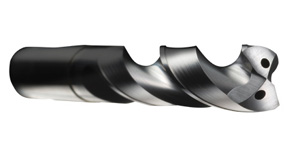

ICe-Carb Internal Coolant Drills for Depths up to 8XD

- ICe-Carb Internal Coolant Drills for depths up to 8xD eliminate the need for pecking in most applications. Unique through coolant design carbide drill achieves higher cutting parameters and greater chip control. A 140° self-centering point angle and unique geometry enhance coolant flow and chip removal. Comes standard with Ti-NAMITE-A® (AlTiN) Tool Coating.

Series 120 Composite Drill

- This all new 8 Facet Double Angle Hi-Per Carb series drill offers application benefits beyond that of other high performance drills in its category. Each feature of this 8 facet design was engineered as a solution towards addressing the issues commonly encountered during Composite drilling. This unique High Performance drill design successfully creates an accurate hole without splintering or delamination, ultimately optimizing the Composite drilling process. It is available exclusively with the Di-NAMITE coating, specifically formulated for SGS Composite solutions.

GENERAL PURPOSE

2 Flute Single End General Purpose Drills

- Standard lengths, 118° four facet drill point, available with 20° spiral.

2 Flute Single End Short Length DIN 6539

- Short length carbide drills 145° four facet drill point and 27° spiral.

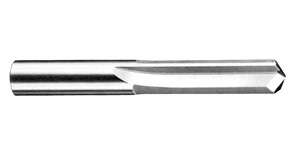

Straight Flute Single End General Purpose Drill

- Solid carbide straight flute drills for hardened materials have a 140° point angle.

3 Flute Single End General Purpose Drill

- 3-flute solid carbide drills for cast iron, high silicon aluminum, alloy steel, and nonferrous materials. 150° point angle and 30° spiral achieves greater hole dimensional accuracy at higher production rates. Also reduces drill deflection compared to HSS drills, cobalt drills and other carbide drills.

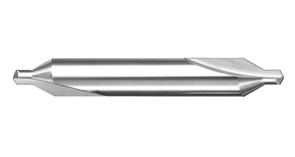

Double End General Purpose Drill Countersink

- Double end solid carbide combined drill and countersink with a 60° included angle.

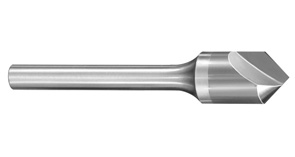

Single End General Purpose Drill Countersink

- 3-flute countersinks with eccentric relief design for use on soft materials, general purpose materials, and hardened steel.

Accu-Reamer Straight Flute Common Shank Short

- Straight flute, right hand cutting carbide reamers.

Double End Drill Countersink Set

- The combined drill and countersink is solid carbide and has a 60° Included Angle. The double ended tool is available coated and uncoated.

Router

HIGH PERFORMANCE

CCR Multi-Flute Carbon Fiber Composite Routers

- The Series 20 CCR Carbon Fiber Composite Router reduces fiber breakout in carbon-fiber reinforced polymer (CFRP) materials used in the manufacture of aerospace components. Reduce delamination, get longer tool life and use less cutting force.

Compression Router for Finish Milling of CFRP

- A major challenge in machining with Composite material is preventing separation of material layers during the machining process. By incorporating both a left and right hand helix, the cutting pressure to the center of the work piece is compressed, eliminating the fraying of the material.

GENERAL PURPOSE

2 Flute Single End Wood Routers

- Up cut and down cut 2-flute solid carbide wood routers for wood, plastic, and other non-ferrous materials.

Ti-NAMITE Tool Coatings

- Ti-NAMITE Tool Coatings are specifically engineered

for SGS solid carbiderotary tools. This proprietary

multi-layering process results in maximized tool life and increased speed and feed rates in any application. Titanium Nitride

(TiN)- A general purpose coating allowing higher speeds and longer tool life, Ti-NAMITE is effective in a wide variety of metal cutting operations. Recommended for general purpose and applications in: stainless steel, medium carbon steel, alloyed steel, copperalloys, brass and bronze

Aluminum Titanium Nitride (AlTiN)

- The most abrasion resistant and hardest coating, Ti-NAMITE-A is preferred for high speed and dry cutting and recommended for the machining of cast iron, hardened tool steels up to HRc 60 and other heat resistant alloys. Recommended for applications in cast iron, high temperature alloys, hardened steels, stainless steels.

Titanium DiBoride

(TiB2)- Our toughest coating ever, recommended for use with silicon aluminum alloys and titanium alloys. Recommended for applications in high silicon aluminum alloys and titanium alloys.

Titanium Carbonitride

(TiCN)- A harder, more lubricious coating offering better

performance in steels over HRc 40 and aluminum alloys, Ti-NAMITE-C is

violetbrown in color.

Recommended for applications in high silicon aluminum alloys, titanium alloys, low carbon steel, alloyed steels.

Ti-NAMITE X

(TX)- Ti-NAMITE X is our proprietary advanced coating using HPPMS coating process for increased hardness offering better resistance to abrasion wear. This ultra-tough coating provides superior adhesion that is critical in high performance applications that encounter a high level of mechanical stress. With a denser, more uniform coating structure, TX allows for improved performance at higher temperatures protecting tools for an even longer tool life.