DVS Technology

- Offer Profile

-

TURNING / GEAR HOBBING / GRINDING

All DVS know-how under one roof

At DVS Technology we provide services for our customers with the intention of establishing a long term relationship distinguished by mutual trust.

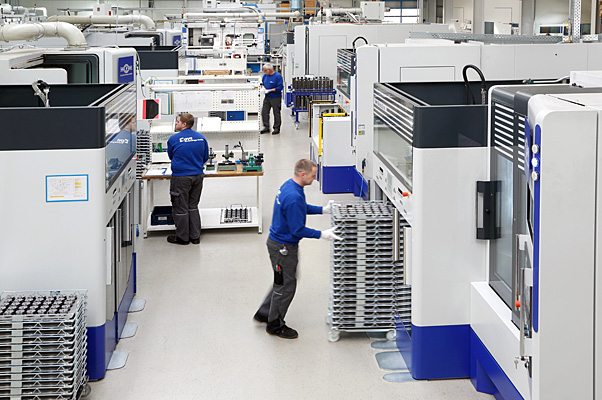

DVS Technology offers job order production including everything to go with large scale production. The quality of our products is the focal point of our work. Our production equipment consists of the latest generation of machines from the DVS group.

Product Portfolio

PRODUCTS and SERVICES

-

We machine different types of parts on highly automated single spindle and double spindle machines.

We use the DVS Group technology practically to ensure you a competitive advantage. This means the entire range of DVS know-how is at your disposal.

TURNING

- We provide precision machining work on hardened materials on single and double spindle vertical lathes. Our work processes are supported by automation and interlinkage systems matched to our customer's parts. We place particular value on the possibility of operating the machines flexibly as interlinked or single units.

HIGH PERFORMANCE GEAR HONING

-

Our high performance gear honing machines offer numerous advantages for improved product quality and efficiency.

Regardless of whether unit costs, geometrical and surface accuracy or gear noise in the transmission.

CHAMFER AND LOCKING GROOVE MILLING

-

Hypo-cycloid milling is a process patented by Präwema for efficient machining of chamfers and locking grooves on gears with internal or external teeth.

The major advantage of this process is, on the one hand, the high machining accuracy as well as minimization of the machinery chain.

The combination tool for the chamfer and locking groove as well as the integrated calibration device for deburring allows the work sequence to be carried out by one machine: Machining the chamfer, milling the locking groove and final broaching of the internal teeth.

QUALITY

-

We have state-of-the-art measuring equipment to monitor our processes continuously. Continuous measurement and use of SPC (Statistical Process Control) guarantees perfectly mastered mass production.

Our clear job handling process, defined in our DIN EN ISO 9001:2008 manual, guarantees optimum quality and our capability of meeting production deadlines.

Our Capabilities > Machining Large Parts

- We manufacture a wide range of cast-iron and steel brake discs for the railway and commercial vehicle industries. The machining is done on a PITTLER-CNC vertical lathe with a slide unit, which carries out the turning either on one or the other spindle. There is a single-tool holder constructed on the slide, which is supplied with tools from a common tool magazine.