WMZ

- Offer Profile

- Our company Werkzeugmaschinenbau Ziegenhain GmbH (WMZ) stands for high-quality motor spindles as workpieces or as drive spindles for the processes of turning, milling, drilling, grinding and honing. A second area of business is the construction and manufacturing of complete tool machines. Next to the spindles, all-round and multi-functional heads and welding assemblies like i.e. highly complex machine beds are manufactured. Furthermore, our program offers automations like loader axis and pivoting modules. Finally we offer services in the area of job order production and –assembly as well as customer service.

Product Portfolio

Lathes and Center Driving Lathes

C700/ CM700

-

Technologies:

- Centering

- Curling

- Drilling

- Milling

- Trimming

- Turning

- Winding

Highlights

- Modular machine concept in inclined bed design

- Standarized modular system

- Simultaneous machining of the right and left side of the workpiece (CM700)

- Up to 22 NC-controlled axis

- Shortest processing times for workpiece of up to 4500 mm length

Machine description

„C“ stands for Lathes and the additional „M“ for Center Driving Lathes. Both concepts are based on the same platform. Where workpieces can be tensed in the middle, center drive lathes are convincing with the simultaneous machining of both ends of the workpiece in a single setting.

Individuality in an new DimensionOur „Premier Class“, the lathe of the 700 series stands for an elaborate, customized complete solution for many rotating tasks, which demand shortest piece/cycle times. Center drive lathes technology or standard collection technology between tops, chuck or collet, we are offering our Know-How to you in form of a modular designed machine.This customized machinery is in best use whenever there are large and very long workpieces to be processed.

Technical Data

Control Siemens Sinumerik 840D Driving Power Up to 45 kW Speed Range Up to 2.500 min -1 Workpiece Diameter Up to 280 mm (CM700), Up to 315 mm (C700) Workpiece Length Up to 4.500 mm (C700/ CM700) Rapid Traverse Rate Up to 20 m/min Machine Installation dimension

Basic MachineLength Up to appr. 8000 mm according to nominal length

Width appr. 2500 mm

Height appr. 3000 mmWeight appr. 38 t, depending on machine model

CV300/ CMV300

-

Technologies:

- Centering

- Curling

- Drilling

- Milling

- Trimming

- Turning

- Winding

Highlights

- High flexibility through modular constructions = custom-made solutions

- Different automation systems = Reduction of idle times

- Up to 12 NC-controllen axis

- Simultaneous machining of the right and left side of the workpiece (CMV300)

- No more changeover errors while using center drive lathe technology = high workpiece and concentricity

- No telescoping covering for guideways

= lower service costs by reducing movable parts

Machine description

„C“ stands for Lathes, and the additional „M“ for Center Drive Lathes.

Both concepts are build using the same vertical „V“- platform in different nominal lengths. Where workpieces can be tensed in the middle, center drive lathes are convincing with the simultaneous machining of both ends of the workpiece in a single setting. Through simultaneous processing of both ends of the workpiece, a second setting is no longer needed, therefore a high concentricity and running precision is guaranteed. The increase of production quality goes hand in hand with shortest processing times.

A new definition of efficiency and precision: The center drive

By using the center drive technology it is possible to process workpieces simultaneously at both ends with two tool systems - and all of this, without the need to re-chuck.

The machine can be equipped and operated with one (short workpieces), or two center drive headstocks (longer workpieces).

The modular construction starts with the vertically arranged machine bed, which is manufactured in different bed lengths. Three construction sizes of center drive headstocks round up the the construction set.

Technical Data

Control Siemens Sinumerik 840D Driving Power Up to 37 kW Speed Range Up to 3.000 min ¹ Workpiece Diameter Up to 100 mm (CMV300),

Up to 250 mm (CV300)Workpiece Length Up to 1.200 mm (CMV300),

up to 2.200 mm (CV300)Rapid Traverse Rate 20 m/min Machine Installation dimension

Basic MachineLength appr. 2400 mm up to 4200 mm according the nominal length

Width appr. 2200 mm

Height appr. 2400 mmWeight appr. 12 t, depending on machine model

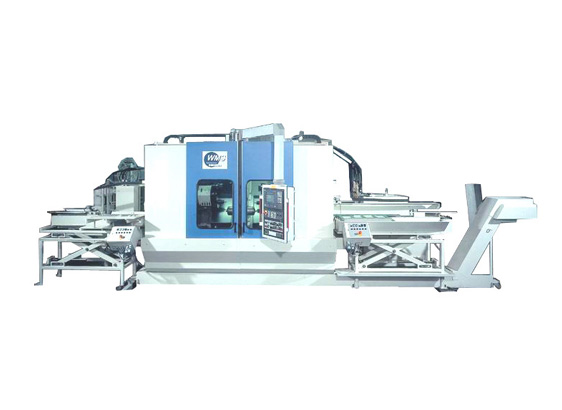

C500/ CM500

-

Technologies:

- Centering

- Curling

- Drilling

- Milling

- Trimming

- Turning

- Winding

Highlights

- Modular machine concept in inclined bed design

- Standarized modular system

- Up to 12 NC-controlled axis

- Simultaneous machining of the right and left side of the workpiece (CM500)

- Shortest processing times

Machine description

„C“ stands for Lathes and the additional „M“ for Center Driving Lathes. Both concepts are based on the same platform.

Where workpieces can be tensed in the middle, center drive lathes are convincing with the simultaneous machining of both ends of the workpiece in a single setting.

Design:- Inclined bed machine type

- Up to 3 NC-Supports

- 12-times discrevolver, also for driven tools and optional fpr Y-axis

- New, fixed cover systems

Where productivity gets it's name

The C500/CM500 series connects short processing and setup times with productivity, precision and efficiency.

The modular component system allows for a product-oriented machinery. Useful options take care of large rotary workpieces, those can be manufactured completely, using only one setting.

The 500 series regards itself as a customized complete solution.

Technical Data

Control Siemens Sinumerik 840D Driving Power Up to 37 kW Speed Range Up to 2.500 min ¹ Clamping Diameter Up to 1.500 mm (C500/ CM500) Rapid Traverse Rate Up to 20 m/min Machine Installation dimension

Basic MachineLength appr. 2400 mm up to 4700 mm according the nominal length

Width appr. 2200 mm

Height appr. 2400 mmWeight appr. 20 t, depending on machine model

C200/ CM200

-

Technologies:

- Centering

- Curling

- Drilling

- Milling

- Trimming

- Turning

- Winding

Highlights

- Modular machine concept

- Shortest processing times

- Integrated automation

- Simultaneous machining of the right and left side of the workpiece(CM200)

Machine description

„C“ stands for Lathes and the additional „M“ for Center Drives Lathes.

Both concepts are based on the same platform. Where workpieces can be tensed in the middle, center drive lathes are convincing with the simultaneous machining of both ends of the workpiece in a single setting.

Design:- 6-Pathbed machine in 2 nominal lenghts for workpiece lenghts up to 900mm

- As single spindle or counter spindle lathe series C200

- As center drive lathes with one or two drive headstocks series CM200

- Center drive headstocks are also NC - movable

- New, fixed cover systems

Use all possibilities of the 200 series

The center drive technology is especially suited for high demands to the concentricity of the left to the right workpiece side, in regards to the total concentricity, roundness, general concentricity and positional tolerances.

With the CM200 series it is possible to unite the centering, overtightening and the crosscutting of workpieces. During revs up to 5.000 min ־¹ four workpieces can be used simultaneously. The piece/cycle times can be reduced enormously - compared to common systems - by using the integrated loading and unloading system.

The C200/ CM200 series stands as a customized complete solution and convinces by minimal piece/cycle times.

Technical DataControl Siemens Sinumerik 840D Driving Power Up to 22 kW Speed Range Up to 5.000 min ¹ Clamping Diameter Up to 75 mm Rapid Traverse Rate Up to 30 m/min Machine Installation dimension

Basic MachineWidth appr. 2250 mm to 3300 mm according to nominal length

Depth ca. 1800 mm

Height ca. 2400 mmWeight appr. 10 t, depending on machine model

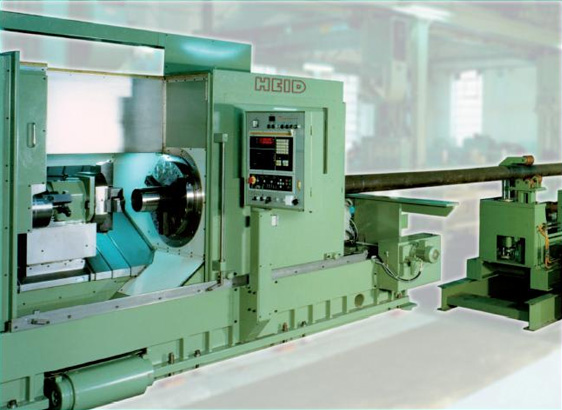

Heid-Driving Machines

PT

-

Technologies:

- Trimming

- Turning

- Winding

HEID-Lathes for the Oilfield-Industry

The machinery program of HEID FOR OILFIELD is offering any time – especially with the manufactering of threads in accordance with the demanded specifications i.e. API and GHOST, only the highest quality and a maximum of flexibility during the fully automated processing of:- Sleeves

- Pipes

- Tool Joints

The long-standing experience of HEID with the processing of components for the oil- and gas industry is proving itself through intelligent and efficient further development of our cooperation with WMZ and our customers.

CT/TJT

-

Technologies:

- Trimming

- Turning

- Winding

HEID-Lathes for the Oilfield-Industry

The machinery program of HEID FOR OILFIELD is offering any time – especially with the manufactering of threads in accordance with the demanded specifications i.e. API and GHOST, only the highest quality and a maximum of flexibility during the fully automated processing of:- Sleeves

- Pipes

- Tool Joints

The long-standing experience of HEID with the processing of components for the oil- and gas industry is proving itself through intelligent and efficient further development of our cooperation with WMZ and our customers.