- Offer Profile

- PCB Piezotronics was founded in 1967 as a manufacturer of piezoelectric quartz sensors, accelerometers, and associated electronics for the measurement of dynamic pressure, force, and vibration. The unique expertise of the company was the incorporation of microelectronic signal conditioning circuitry within these sensors to make them easier to use and more environmentally compatible. These ICP® sensors gained wide popularity and became the foundation for the company's success.

Accelerometers

Accelerometers/Vibration Sensors

-

PCB Piezotronics manufactures precision accelerometers to measure vibration, shock, acceleration, and motion for monitoring, control, and testing applications. ICP®, PE, MEMS and Capacitance sensing technologies are used to fulfill a wide assortment of measurement requirements. Accelerometers are used by field test, in factory production and design as well as Research and Development organizations to acquire critical data. In addition to our precision miniature units, rugged accelerometers and vibration sensors for industrial machinery vibration monitoring are offered by our IMI Sensors division.

PCB's single axis and three axis (triaxial) accelerometer configuration parameters include sensitivity, temperature, frequency response, amplitude response, form factor and lead wire grounding. Accelerometers are critical for evaluating proper performance of equipment or structures. Such applications usually require proof of calibration of the entire measurement system from the sensor through to the final output. PCB calibrates all products traceable to NIST and includes a calibration certificate with each sensor shipped.

The most commonly used technology is ICP® accelerometers. These sensors require ICP® Power supplied. Most modern data acquisition, digital control, and portable data systems provide ICP sensor power. ICP Sensors can be referred to as Voltage Mode output sensors. Our PE sensors can be referred to as Charge Mode output sensors. Each directional axis measured requires one channel of the data system or signal conditioner.

Accelerometers can be referred to as accelerometer, accelerometers, accels or accel or the industrial community may refer to them as vib sensor or vib probe. Lifetime Warranty is standard with our Platinum Products offerings.

Accelerometer Highlights::

- Rugged and durable

- High stiffness

- Very repeatable

- Wide dynamic range

- Fast rise time

- High useable frequency range

High Temperature ICP® Accelerometers (+325 ºF/+163 ºC)

-

Conventional accelerometers are designed to withstand moderate upper ambient temperature conditions. These are designed for continuous operation up to 250 to 275 F. At higher temperatures the conventional construction may effect solders, epoxies, internal wiring insulation and reduce the sensor sensitivity from the desired value resulting in lower output. Thus,an error results.

PCB® offers specially designed and tested ICP® accelerometers for conducting vibration and shock measurements under the demanding environmental conditions. These sensors combine proven quartz, and ceramic shear sensing technology with specialized, built-in microelectronic signal conditioning circuitry to achieve dependable operation in extreme temperatures and through repetitive temperature cycling. Laser-welded, hermetically sealed, lightweight titanium or stainless steel housings offer further protection from the environment.

Applications:

- Quality Assurance (HALT, HASS, ESS)

- High Temperature

- Thermal Stress Screening

- Environmental Testing

- Combined Environmental Chambers

High Temp Accelerometers (> +500 ºF/+260 ºC)

-

Voltage mode (ICP type) sensors can only operate to a limited ambient temperature. The ICP sensors internal electronics is the limiting factor at high temperatures. Many test articles, such as gas turbines, steam turbines, jet engines, high power motors, exhaust systems and under the hood testing have high temperatures exceeding this types sensors temperature rating. In order to properly function at these higher temperatures a different sensor technology is needed. PCB®’s Charge Mode Output accelerometers utilize piezo-ceramic sensing elements to directly output an electrostatic charge signal that is proportional to applied acceleration. This type sensor is termed a PE style or charge mode style. These sensor can operate at extreme high temperatures.

Applications

- High Temperature Vibration Measurements

- Engine Compartment Studie

- Exhaust Component Vibration Tests

- Steam Turbine Testing

- Engine Vibration Analysis

Structural Test ICP® Accelerometers

-

Highlights:

- High output piezoceramic sensing element for strong output signal

- Lightweight casing materials to minimize mass loading effects

- Available in a variety of packages, mounting and cable options

Conventional structural test data systems use few to several hundred sensors. Cables bundles can be complex and confusing resulting in setup errors. Sensors with TEDS (Transducer Electronic Data Sheet) allow for an internal sensor digital chip to store sensor information. This information contains descriptive identifiers that when connected to a TEDS compatible signal conditioner or data system, reads the descriptive information and automatically aligns the data system.

Applications- Structural Vibration Testing

- Multi-channel Modal Analysi

- Analytical Model Correlation

- Design Studies

- Force Response Simulation

General Purpose Single Axis Accelerometers

-

Motion of a rigid body can be characterized within six degrees of freedom. Providing mechanical excitation to simulate this motion as may be encountered in the real world can entail a variety of test machines. There are various pound/force vibration shakers for structural testing. Regardless of the apparatus, the goal is always to ensure that the product under test can adequately perform, and reliably survive, in the environment in which it will be deployed, or to which it will be exposed during transport. PCB® accelerometers provide the measurement signals needed to control the vibratory input and to analyze the product’s reaction to such testing. Did the test achieve the acceleration amplitudes and frequencies desired? Did the product react in a consistent manner? Did any components or mounting techniques become altered? These are just a few of the questions that can be verified by analyzing the signals generated by PCB®accelerometers.

Applications:

- Routine Vibration Testing

- Product Testing

- Structural Testing

- Vibration Control

- Package Drop Testing

High Sensitivity ICP® Accelerometers

-

High sensitivity ICP® accelerometers are specifically designed to enable the detection of ultra-low-level, low-frequency vibrations associated with very large structures, foundations, and earth tremors. These sensors typically possess exceptional measurement resolution as the result of its comparatively larger size, which furnishes a stronger output signal and a lower noise floor.

Both ceramic and quartz sensing elements are utilized in seismic accelerometer designs. Model 393C, with a quartz sensing element, offers the best low-frequency response in this series. Ceramic element styles with built-in, low-noise, signal conditioning circuitry offer the greatest measurement resolution. The model 393B31 leads the way, providing 1 µg rms broadband resolution.

Applications:

- Building Vibration Monitoring

- Earthquake Detection

- Structural Testing of Bridges

- Floor Vibration Monitoring

- Geological Formation Studies

- Foundation Vibration Monitoring

Miniature Piezoelectric Accelerometers

-

Structured with highly sensitive piezoceramic sensing elements, miniature Ceramic Shear ICP® Accelerometers have an excellent signal-to-noise ratio, high measurement resolution, and are ideal for conducting low-level vibration measurements. Due to their inherent higher sensitivity, a ceramic ICP® accelerometer can be assembled with a smaller mass than comparable quartz units, resulting in a sensor that is lighter in weight, has a higher frequency response, and has a lower noise floor.

Highlights:

- No moving parts provides durability

- Rigidity imparts high frequency range

- Lightweight construction minimizes mass loading

- Numerous configuration options

- Mount by screw, stud, or adhesive

- Available with both Quartz elements (for thermal stability) or Ceramic elements (for high measurement resolution)

Applications:

- Drop Testing & Package Testing

- Small Component Qualification Testing

- Low Amplitude Vibration Measurements

- High Frequency Applications

- Space Restricted Installations

MEMS DC Response Accelerometers

-

Highlights:

- True DC measurement capability

- Simple, DC-power excitation schemes

- Gas-damped, silicon MEMS sensing elements offer high frequency overload protection

PCB® series 3711E, 3713E and 3741E MEMS DC response sensors are used to measure low frequency motion down to zero hertz. These accelerometers are used in applications such as structural monitoring, aerospace vibration testing, driveability and gravitational force measurements. Each series includes a full scale measurement range from ± 2g to ± 200g and features low spectral noise with high resolution.

Automotive Crash Accelerometer For High-G Impact Events

-

PCB Piezotronics is introducing a new automotive crash accelerometer for high-G impact events. The new PCB® Series 3641 and 3651 sensors are a rugged and reliable drop-in replacement for other models on the market. PCB® offers high-quality crash sensors with a low cost-to-own and exceptional customer support. Our Models 3641 and 3651 Piezoresistive MEMS crash accelerometers are offered in both damped and undamped versions for High-G impact events. These models are designed for crash testing, anthropomorphic testing, sled testing and similar applications that take advantage of its low 1-gram mass, standard low transverse sensitivity and standard low zero G offset.

Highlights:

- Drop-in replacement for competitive models

- Robust design

- Rugged aluminum housing

- Performance

- Precise measurement signal

- Fully active bridge

Industrial Accelerometers

- Also known as seismic vibration pickups, industrial accelerometers are rugged, stainless steel vibration monitoring sensors for predictive maintenance applications. All IMI sensors are hermetically sealed and case isolated. Our integral cable units are submersible and IMIÂs vast product line includes high temperature models (both charge mode and ICP®) and dual output temperature and vibration sensors. IMI sensors interface directly with handheld data collectors for both permanent mount and route based applications.

Low-cost for Permanent Installation

- Cost-effective accelerometers recommended for vibration trending applications.

Precision

- Industrial accelerometers for route-based condition monitoring and predictive maintenance.

Multi-axis

- Accelerometers that measure vibration in two or three planes of motion.

High Temperature (to 1200 ºF / 650 ºC)

- Accelerometers for installations at elevated temperatures

Hazardous Area Approved

- Accelerometers approved for use in hazardous areas are certified by ATEX, CSA and GOST-R to be spark proof. It is common to require these certifications when installing sensors in a potentially explosive area. Some installations may require an additional energy limiting barrier depending upon the classification of the hazardous area.

High Frequency

- Accelerometers for monitoring high-speed rotating equipmen

Low Frequency

- Accelerometers for monitoring slow speed machinery.

Embeddable

- Embeddable accelerometers for building in to machinery.

Handheld Vibration Meter

- Simple vibration meter kit for route-based applications includes accelerometer, cable, magnet, headphones and meter.

Impact Hammers

-

Each PCB® Modally Tuned®, ICP® instrumented impact hammer features a rugged, force sensor that is integrated into the hammer’s striking surface.

“Modal Tuning” is a feature that ensures the structural characteristics of the hammer do not affect measurement results. This is accomplished by eliminating hammer resonances in the frequency range of interest from corrupting the test data, resulting in more accurate and consistent measurements.

The force sensor serves to provide a measurement of the amplitude and frequency content of the energy stimulus that is imparted to a test object. Accelerometers are used in conjunction with the hammer to provide a measurement of the object’s structural response due to the hammer blow. A variety of tips supplied with each hammer permit the energy content of the force impulse to be tailored to suit the requirements of the item under test.

Using multi-channel data acquisition and analysis software, the test engineer is able to ascertain a variety of mechanical properties leading to an understanding of an object’s structural behavioral characteristics. Items analyzed can include resonance detection, mode shapes, transfer characteristics, and structural health – such as crack and fatigue detection. Impact Hammers

-

Highlights:

- Modally Tuned® to provide more consistent results

- Variety of hammers to suit any size test objec

- Assortment of tips offer frequency tailored impulse

Applications

- Structure Health Testing

- Resonance Determination

- Modal Analysis

Acoustic Condenser Microphones

-

Precision Microphones with the performance you demand, unbeatable prices,

24/7 support, best warranty, and fast shipment

When you need a microphone for product tests such as sound power, sound quality, noise source location, there's no need to compromise quality and performance for a great price.

With 100% of its microphone manufacturing in-house, PCB Piezotronics provides condenser, modern prepolarized, traditional externally polarized, array, probe, low-profile surface and other specialty purpose microphones, preamplifiers and accessories. Prepolarized Microphones

-

Modern prepolarized microphones are designed with newer technology than traditional externally polarized microphones. Prepolarized microphones have many advantages over the externally polarized models. They use ICP® power circuitry invented for sensors by PCB®. By applying a polymer coating to the top of the backplate and embedding a charge on it, expensive 200V power supplies can be eliminated and 2-20 mA constant current supplies or signal conditioners can be used as the power source.

Prepolarized models are better suited for portable applications or those in high humidity environments. An added benefit is the interchangeability with other test equipment such as accelerometers or piezoelectric pressure sensors. This lets you use low cost coaxial cables with 10-32, SMB or BNC connectors. With a multiple channel power supply, you can perform your vibration and acoustic tests within the same set-up, saving both time and money.

Highlights:- Modern design

- Operate from ICP® sensor power

- Low cost per channel

- Uses coaxial cables with BNC or 10-32 connections

- Interchangeable with ICP® style accelerometers and pressure sensors

- IEC Type 1 compliant

1/4" Prepolarized Microphone & Preamplifier Systems

- All PCB condenser microphone systems come standard with TEDS IEEEP1451.4 (version 0.9) ex. 378B02. If IEEE1451.4 (version 1.0) is needed, include the TLD prefix in the model number.

1/2" Prepolarized Microphone & Preamplifier Systems

-

All PCB condenser microphone systems come standard with TEDS IEEEP1451.4 (version 0.9) If IEEE1451.4 (version 1.0) is needed, include the TLD prefix in the model number.

1/4" ICP® Preamplifiers for Prepolarized Microphones

- These low-noise, general purpose, prepolarized microphone preamplifiers are powered by any constant current (2-20 mA) ICP® sensor power supply. All models are supplied with TEDS capability and are designed to be used with prepolarized microphones.

1/2" ICP® Preamplifiers for Prepolarized Microphones

- These low-noise, general purpose, prepolarized microphone preamplifiers are powered by any constant current (2-20 mA) ICP® sensor power supply. All models are supplied with TEDS capability and are designed to be used with prepolarized microphones.

1/4" Prepolarized Microphone & Preamplifier Systems

- These low-noise, general purpose, prepolarized microphone preamplifiers are powered by any constant current (2-20 mA) ICP® sensor power supply. All models are supplied with TEDS capability and are designed to be used with prepolarized microphones.

1/2" Prepolarized Microphone & Preamplifier Systems

- These low-noise, general purpose, prepolarized microphone preamplifiers are powered by any constant current (2-20 mA) ICP® sensor power supply. All models are supplied with TEDS capability and are designed to be used with prepolarized microphones.

Prepolarized ICP®Array Microphones

-

Prepolarized ICP® Array microphones are a cost-effective alternative to the higher end, class 1 test and measurement microphones. These value-priced array microphones are an excellent choice for large channel count applications and are suitable for sound measurements within the normal human hearing range.

Externally Polarized Precision Condenser Microphones & Preamplifiers

-

Externally polarized microphones were the original standard for all test and measurement acoustic applications. This design utilizes a separate 200V power supply and special cables with 7 pin LEMO® connectors. Their simple design enables a large product offering. These microphones are commonly used to replace existing externally polarized microphones, or in cases where a prepolarized alternative is not available.

Highlights:- Operates from 200V power

- Large assortment of sizes and models

- Interchangeable with other manufacturers' externally polarized models

- IEC type 1 compliant models

1/4" Externally Polarized (200V) Precision Microphone

1/2" Externally Polarized (200V) Condenser Microphones

1" Externally Polarized (200V) Condenser Microphone

Preamplifiers for Externally Polarized Microphones

Specialty Microphones

- When acoustic measurements need to be made in demanding environments and applications, a variety of PCB® specialty microphones are available.

Water & Dust Resistant Prepolarized Array Microphone and Preamplifier

-

Model 130A24 is a 1/2” (12mm) prepolarized microphone and preamplifier system with a replaceable water and dust resistant cover. This acoustically transparent cover provides an unobtrusive alternative to windscreens and a more consistent response than rubber protective covers.This array microphone is equipped with a rugged stainless steel grid cap similar to our high end condenser microphones.The 130A24 is an excellent choice for large channel array microphone applications, outdoor measurements, high humidity applications or harsh industrial settings where dust or oil splash is a concern.

Highlights:

- Water and dust resistant

- Max Amplitude: 143 dB (150 dB Clip)

- Cartridge Noise: 35 dBA

- Sensitivity: 1.0 mV/Pa

- Temperature: -10 to +50°C

- Polarization: Prepolarized (0V)

Applications:

- Brake noise testing

- Acoustic holography

- Beamforming

- Noise source identification

- Non-contact defect detection

- Research and development

- Acoustic tests where oil splash, high humidity or dust is a concern

Prepolarized High Temperature Microphones

-

These microphones are used to make measurements in environments where operating temperatures can reach +250 ºF (+120 ºC). Typical high temperature applications include engine, manifold, exhaust, transfer path, and HVAC testing.

Highlights:

- Operating temperature to +120 ºC (+250 ºF)

- Operates from ICP® sensor power

- Low noise floor

- Wide frequency range

- System sensitivity guaranteed within +/- 1.7 dB

- Temperature range eliminates the need for high-priced probe microphones

- ½ package with BNC connectors

- Competitively priced, best value on the market

Applications:

- Engine analysis

- Manifold testing

- Transfer path analysis

- Exhaust pipes

- HVAC tests

- General acoustic testing in high temperature applications

Surface Microphone for Product Testing

-

These low profile microphones are used for measuring true surface pressure and noise. Its footprint allows noise measurements to be taken where traditional microphones will not fit. A water and dust resistant grid cap is ideal for dirty and rough environments. Typical applications include wind tunnel noise measurements, brake noise, acoustic fatigue analysis, and clear air turbulence (CAT) testing.

Applications:

- Environmental testing

- Wind tunnel noise measurements

- Acoustic fatigue analysis

- Clear Air Turbulence (CAT) testing

- Flush mount applications

Highlights:

- Height: 1/8Â (3mm) low profile

- Measurement range: 32 dBA to 150 dB

- Flexible mounting methods

- Water and dust resistant grid cap

- Built in preamplifier

- TEDS IEEE 1451.4 compliant

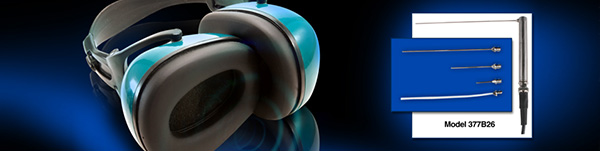

Probe Microphone & Preamplifier

-

For small, hard-to-reach areas and high temperature environments

The small profile Probe Microphone (Model 377B26) is used for acoustic measurements in small, hard-to-reach places and where precise placement is required in near-field testing within confined areas. This probe microphone is used in extremely high temperatures environments 1740?F (800?C).

Features

Low profile 0.050Â diameter probe tip 164 dB maximum amplitude (3% distortion)

45 dBA Noise Floor

2 Hz to 20 kHz frequency range

0V Prepolarized design

5 probe tips

-40 to 800°C operating temperature range

Applications:

Sound pressure distribution for cell phones

Headphone testing

Music equipment sound distribution

Acoustic impedance measurements

Leak detection

General noise test in high temperatures

General purpose sound analysis in confined areas

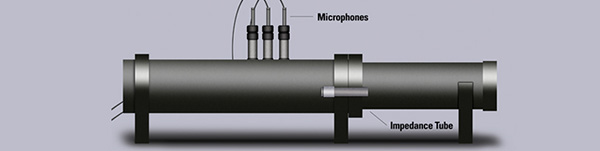

Side Vented, Prepolarized Pressure Field Microphone

-

These microphones can be flush mounted in a cavity, tube, wall or panel. This design allows for equalization of atmospheric pressure between the inside of the microphone and the outside of the structure. They are recommended for applications such as impedance tube testing, HVAC testing, and where high sound pressure levels or high frequency measurements are required.

Highlights:

Sensitivity: 1.0 mV/Pa

Frequency: 3 HzÂ100 kHz (+/- 3dB)

Cartridge Noise: 35 dBA

Max Amplitude: 174 dB

Temperature: -40 to +120°C

Polarization: Prepolarized (0V)

Applications:

Impedance tube

Panel testing

Flush mounting applications

Closed couplers

Gunshot analysis

Research and development

Hearing preservation and safety

Prepolarized 1/4" High Amplitude Pressure Microphones

-

High amplitude applications such as airbag testing, gunshot analysis, blast detection, and hearing preservation/safety require microphones that accurately measure high sound pressure levels.

Highlights:

Sensitivity: 0.25 mV/Pa

Frequency: 4 Hz  20 kHz

Max Amplitude: 187dB

Temperature: -40 to +120°C

Polarization: Prepolarized (0V)

Applications:

Precision sound level measurements

Research and development

Hearing preservation and safety

Airbag testing

Gunshot analysis

Blast detection

Force Sensors

-

PCB®’s quartz, piezoelectric force and strain sensors are durable measurement devices which possess exceptional characteristics for the measurement of high frequency dynamic force and strain events. Typical measurements include dynamic and quasi-static forces as encountered during actuation, compression, impact, impulse, reaction, and tension.

Since the measurement signal generated by a quartz sensor will decay over time, long-term, static force measurements are not feasible. However shorter-term, or “quasi-static”, measurements are possible within certain time limits, depending upon the sensor and signal conditioning used.

Due to this limitation, it is not practical to use quartz force sensors in weighing applications where strain gage type load cell is best suited. For dynamic force applications; however, quartz force sensors offer many advantages and several unique characteristics that make them ideal choice for many dynamic force measurement requirements.Highlights:

- Rugged and durable

- High stiffness

- Very repeatable

- Wide dynamic range

- Fast rise time

- High useable frequency range

Applications:

- Crash Testing

- Drop Testing

- FatigueTesting

- Fracture Testing

- Press Monitoring

General Purpose Quartz Force Sensors

-

General purpose force sensors are offered in either stud or axial mounted configurations. They are internally pre-loaded and can be used for dynamic compression, tension, and impact force measurements. Tapped mountÂing holes on both ends of the radial connector style support link, platform, integrated link, and free-standing installations. The axial mounted type offers protection of the electrical connector and sensor cable from potential damage during drop testing and in free-standing installations. Supplied impact caps facilitate impact and drop force measurements.

Versions offering full-scale measurement ranges of 10 lb to 5000 lb compression (45 to 22k N) and 500 lb (2200 N) tension are available. For higher ranges, consider the dedicated ring, link, or impact-style sensor configurations. Applications include matrix print-head studies, drop testing, machinery studies, punching and forming operations, impact testing, fatigue testing, fracture analysis, and materials testing.

Applications:- Dynamic Tension & Compression

- Impact & Repetitive Applications

- Drop Testing

- Materials Testing

Quartz ICP® Force Rings

-

Ring-style sensor configurations measure dynamic compression. Tension measurements are also possible if the unit has been installed with proper pre-load. The through-hole mounting supports platform, integrated link, and support style installations using either a through-bolt or the supplied stud.

Versions offering full-scale measurements of 10 lb to 100k lb (45 to 450k N) compression are available. Tension range is dependent upon the amount of applied pre-load and strength of mounting stud used. Applications include tablet presses, stamping, punching and forming operations, balancing, machinery studies, and force-controlled vibration testing.

Highlights:- Capacities from 10 lbs to 100k lbs

- Stainless Steel Construction

- Hermetically Sealed

- -65 °F to +250 °F Operation Range

- Wide Temperature Operating Range

(-100 to +400 °F/-73 to 204 °C) - Scaling & DTC?User Settable Via Charge Amplifier

- Stainless Steel Construction

Applications:

- Crimping, Stamping, & Press Monitoring

- Machinery Mount Forces

- Mechanical Impedance Testing

- Material Testing

- Tablet & Punch Presses

- Roll Nip Profile

- Balancing

- Machinery Process Monitoring

- Stamping & Forming

- Force Limited Vibration Testing

3-Component Quartz Force Rings and Links 260 & 261 Series

-

Three-component quartz force ring sensors are capable of simultaneously measuring dynamic force in three orthogonal directions (X, Y, and Z). They contain three sets of quartz plates that are stacked in a preloaded arrangement. Each set responds to the vector component of an applied force acting along its sensitive axis. 3-component ring force sensors must be statically preloaded for optimum performance. Preloading provides the sensing elements with the compressive loading required to allow the proper transmission of shear forces. Versions are available with ranges up to 10k lb (45k N) in the z-axis (perpendicular to the top surface), and up to 4000 lb (18k N) in the x-and y (shear) axes. Both ICP® and charge output styles are available.

Highlights:

- Measure 3-Orthogonal Forces

- Simultaneously

- Stainless Steel Construction

- Hermetically Sealed

- Choice of ICP® or Charge Versions

Quartz ICP® Impact Force Sensors

-

mpact-style sensors are specifically designed for impact force measurements. The sensor is typically mounted in a free-standing manner with the installed impact cap directed toward the oncoming object with which it will collide.

Applications:- Impact Testing

- Stamping Presses

- Crash Testing

- Punch & Tablet Presses

- Package Drop Testing

- Shock Testing

- Repetitive Impacts

- Wire Crimping

- Metal Forming

Miniature Quartz Force Sensors

-

Often the test engineer will try to take low level measurements with a sensors not rated for these low levels. Due to insufficient sensitivity the resulting data may be noisy, hard to analyze or unusable.

Using the appropriately sized and ranged PCB Miniature Quartz Force Sensor solves the problem and gives reliable data at a Low Amplitude level. The miniature sensor configuration permits low-amplitude, dynamic compression, tension, and impact force measurements.

Highlights:- High sensitivity

- Tension/compression models

- High resonant frequency

Strain Sensors

-

Conventional strain sensors are based on strain gage technology. In order to effectively measure the strain values in a force or load measurement application, a full, 4 element strain gage bridge circuit is utilized. The configuration is known as a Wheatstone Bridge Circuit. A Wheatstone Bridge has a very linear output in it’s midrange. That being considered +100% to -100% of range. Unfortunately, a Wheatstone Bridge becomes non-linear above the upper and lower extremes of range. Therefore, significant errors can result above the end points when attempting to take precision measurements. It is particularly important to take accurate measurements in some R&D or control applications. To avoid the mentioned error issues, PCB manufactures quartz and piezoelectric strain sensors that output the same mV/microstrain sensitivity throughout the entire useful range. Thus, accuracy is improved and control requirements are enhanced that may occur at positive extremes of the measurement range. The models RHM240 and model 740B02 series sensors are the strain sensors for these applications.

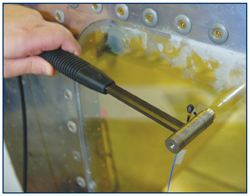

ICP® Strain Sensors For Process Monitoring/Quality Control

The Series M240 Industrial ICP® Strain Sensors incorporate piezoelectric quartz sensing crystals that respond to a longitudinal change in distance. The resultant strain measurand is an indirect measurement of stress forces acting along the structure to which the sensor is mounted. As such, these devices can provide insight into the behavior of mechanical systems or processes that generate an associated machinery reaction.

Monitoring such measurement signals can provide the necessary indication for process interrupt and pass/fail decisions or for determining wear and degradation of equipment and tooling. The sensors are used for controlling processes in plastic injection molding, spot welding, stamping, and pressing, as well as monitoring processes and final product quality. These devices are easy to install and can be powered by any ICP® sensor signal conditioner such as our DIN rail module 410B01.

In additional to providing ICP® power, the 410B01 serves as an interface between sensor and machine control. Features such as independent peak and continuous outputs, gain, and selection of AC/DC coupling make integration straight forward. Strain Sensors

-

Highlights:

- Measure longitudinal strain on machinery

- structures

- Control press forces and other processes

- Monitor quality, safety, and reliability

- Robust construction endures harsh, industrial environments

- Simple installation is noninvasive to process

- Single bolt screw or adhesive mount screw

Applications:

- Process monitoring

- Control press forces & other processes

- Monitor quality, safety, & relibility

- Composite material Testing

Pressure Transducers

-

The full line of PCB® of piezoelectric pressure sensors are used for a variety of dynamic pressure measurements.

The ability to measure small pressure fluctuations at high static pressure levels is a unique characteristic of piezoelectric pressure sensors. With ICP® amplified output, the transducers are well-suited for continuous operation in “dirty” environments, underwater, and in field test applications across long cables. Special low-noise cable and charge amplifiers are not required. These sensors are ideal for virtually all dynamic pressure applications where sensor temperatures range from -320 to +275 °F (-196 to +135 °C). For higher temperature applications, charge output sensors are available for use up to +750 °F (+399 °C).

Although piezoelectric pressure sensors are primarily recommended for dynamic pressure measurements, some quartz pressure sensors have long discharge time constants that extend low-frequency capability to permit static calibration and measurement of quasi-static pressures over a period of a few seconds.

Solid state construction of a piezoelectric pressure transducer provides a wide linear measuring range such that PCB® confidently provides calibrations at 100% and 10% of full scale output for most models.

To discuss specific applications, or if a special pressure sensor or adapto is required, please contact PCB® for assistance.Highlights:

- Fast, micro-second response time

- Resonant frequency to =500 kHz

- Measure small pressure changes at high static pressure levels

- Rugged solid state construction

- Applications

- Hydraulic & pneumatic systems

- Blast and ballistics

- Fluid borne noise

General Purpose Pressure Sensors for High Frequency

-

PCB® dynamic pressure sensors set the standard for extremely fast, micro-second response with a wide amplitude and frequency range. These characteristics allow them to excel in high-frequency applications, where minimum sensor diameter is required.

Tips from Techs:

When calibrating in air or other gas, apply grease to the diaphragm to avoid false data caused by thermal shock.Highlights:

- Fast rise time = 1 µsec from quartz element

- Ultra-high resonant frequency of = 500 kHz

- Frequency-tailored output without the Âringing characteristic of most other sensors

- Internal acceleration compensation minimizes shock and vibration sensitivity

Applications:

- Combustion Studies

- Explosive Component Testing (e.g. detonators, explosive bolts)

- Airbag Testing

- Measurement of air blast shock waves

Sub-Miniature ICP® Pressure Sensors

-

PCB®Âs sub-miniature 105C dynamic pressure sensors are small enough to accommodate for installation where space is limited. These dynamic pressure sensors are designed specifically to fit into tight spaces where mounting space is at a premium.

These transducers are excellent for cavitation studies due to a robust, solid diaphragm design. Measurement ranges include 100 psi and 1000 psi.

Highlights:- Integral machined diaphragm for long life

- Fast rise time of = 2 µsec from quartz element

- High resonant frequency of = 250 kHz

High Sensitivity Pressure Sensors

-

High sensitivity ICP® pressure sensors are for low pressure measurements requiring excellent resolution and small size. PCB® Series 112A pressure sensors are used to measure small dynamic hydraulic and pneumatic pressures such as turbulence, noise, sound, and pulsations, especially in adverse environments. They are capable of measuring high-intensity sound pressures from 111 to 210 dB at any static pressure level from full vacuum to 1,000 psi (6,895 kPa).

Highlights:- Fast rise time of = 2 µsec from quartz element

- High resonant frequency of = 250 kHz

- Contains a rigid, multi-plate quartz element for high output

- Internal acceleration compensation minimizes vibration sensitivity

Extreme Environment Dynamic Pressure Sensors

-

PCB® Cryogenic quartz dynamic pressure sensors are a high-resolution ICP® pressure sensor design, specially made for cryogenic environments. They consistently follow dynamic events found in cryogenic turbo pumps for liquid fuel handling systems or biomedical research.to avoid false data caused by thermal shock.

Highlights:- Fast rise time of = 2 µsec from quartz element, with high resonant frequency = 250 kHz

- Welded, hermetically sealed, stainless steel construction

- Electrically ground isolated, which helps prevent ground loop challenges

- Calibration supplied at room temperature with thermal coefficients at -320 °F (-196 °C)

Industrial Grade Pressure Sensors

-

One of the toughest applications for pressure sensors is measuring high pressure, repetitive pulses, such as those encountered in hydraulic applications. However, our Series 108 & 118 pressure sensors are designed to continuously measure repetitive pulses during applications such as hydraulic cylinder Âtorture testing or diesel fuel injection. Ordinary diaphragm-type sensors usually fatigue quickly in such applications.

Highlights:- Integral machined diaphragm, without use of thin diaphragms or flexures susceptible to fatigue failure

- Capable of continuously monitoring repetitive pulses

- Expected life is millions of cycles

High Frequency Pressure Sensors

-

High sensitivity micro-pressure sensors are well suited for short wavelength acoustic and shock wave measurements associated with high-frequency projectile detection systems. Incorporating a 1mm diameter sensing element and integral microelectronics in a 3mm housing, these sensors have very high sensitivity and microsecond response capable of identifying the bow and stern wave from a passing projectile. An internal 8 kHz high-pass filter eliminates low-frequency inputs. Series 132 Microsensors are available in five different physical configurations to accommodate a wide range of application requirements.

Highlights:

- Shock wave time-of-arrival ICP® microsensors

- 50 psi (344 kPa) range

- Rise time <3 µsec

- Resonant frequency >1M Hz

- Diaphragm diameter of 0.124 in (3.15 mm)

4-20mA Transmitters

- Looking for an overall vibration measurement on your most critical machinery? Our line of 4-20 mA vibration transmitters will interface directly to your PLC, DCS or SCADA control system. Scaled in inches per second velocity or gÂs acceleration, these sensors provide 24/7online protection for key plant machines, reducing downtime. Finally our impact detection products offer the ultimate machine protection. IMIÂs Bearing Fault Detector provides early warning of impending bearing failure from cracks and spalls developing in the bearing race. The Reciprocating Machinery Protector is an impact detector and overall vibration monitor in one 4-20 mA signal.

Reciprocating Machinery Protector

- Both an impact and overall vibration transmitter the RMP is designed to capture mechanical looseness and cracked rods in reciprocating machinery.

DIN Rail Mount Modules

- 4-20 mA signal conditioners and displays

Displays And Alarms

- The model 683A panel meter can be used with either ICP sensors or 4-20 mA vibration transmitters depending on the options selected. Each display also features two programmable relays with time delays and optional 4-20 mA re-transmit. Below are some of our more popular models but for a full ordering guide click on the pdf brochure at the bottom of the page.

Bearing Fault Detectors

- Provides early warning of bearing and gear faults, detects impacting associated with spalling, cracking, and lubrication problems, outputs 4-20 mA signals for overall vibration along with various filtered and normalized outputs for more efficient high frequency fault detection.

Vibration Transmitters

- 20 mA sensors for permanent installation that interface directly to a PLC.

2-Pin MIL Connector Vibration Transmitters

Integral Cable Vibration Transmitters

Integral Armored Cable Vibration Transmitters

Terminal Block Connection Vibration Transmitters

Explosion Proof Conduit Fitting Vibration Transmitters

Dual Temp and Vibration Output Vibration Transmitters

Vibration Switches

- IMIÂs new line of electronic vibration switches provides the total vibration monitoring package. Each model 685B vibration switch features 4-20 mA output, analog vibration analysis signal and dual relays with time delays standard. Our model 686B is simple and inexpensive two-wire USB programmable electronic vibration switch. The 686B vibration switch's programmable time delay eliminates false trips, making it a technically superior option to traditional mechanical shock switches. Electronic vibration switches are a great way to get your plant started towards a predictive maintenance program and provide protection for your most critical equipment. Around the world the IMI team is available for demos of their USB programable vibration switch as well as 685B "fully loaded" vibration switch. This is an overview of our most popular vibration switch models. To see more vibration switch options click on a subcategory below.

USB Smart Switches

- IMI's revolutionary USB programmable smart switch is an ideal replacement for those unreliable old mechanical shock switches. It features the accuracy and small footprint of a piezoelectric accelerometer along with the simplicity of a two-wire switch. This is an overview of our most popular models but custom programmed options are available as well. Contact IMI or consult the brochure at the bottom of the page.

Electronic Switches

- Vibration switches with built-in precision accelerometers Model 685B features time delays, dual relays, 4-20 mA output and raw vibration output. Model 686B is a simple 2-wire vibration switch with small footprint and selectable threshold and time delay.

Mechanical Switches

- Simple mechanical armature relay action switches that do not require external power.

Load Cells

-

We make it our business to stay on top of emerging industry demands so that the load cells we provide help you meet your ever-changing test requirements. Our broad selection of competitively priced load products will help you meet the most demanding test and measurement requirements. Used in automotive, aerospace, R&D, and process control applications, our drop-in replacement load cells are designed to provide years of dependable performance.

Our load cell offering includes competitively priced general purpose and fatigue rated load cells, which come in a variety of mechanical configurations such as single or dual bridge, low profile, canister, rod-end, and s-beam load cells  all of which provide excellent accuracy at an affordable price. We also provide a complete line of signal conditioners and accessories to complement our load cells.

Features:- Low deflection with high accuracy

- Temperature and pressure compensated

- A2LA accredited calibration

- NIST traceable calibration

- Direct replacement for competitive models

Dual Bridge Load Cells For Aerospace Applications

-

PCB Load & Torque, a division of PCB Piezotronics, manufactures a wide range of high-accuracy, strain gage load cells for aerospace, automotive, industrial, and process control applications.

Series 1400 includes a dual output feature that offers sensor redundancy and the ability to provide control feedback from one sensor while the other is used for data acquisition. These load cells are available in multiple ranges and have a NIST traceable, A2LA accredited calibration to ISO 17025, in both tension and compression directions. Additional features include low deflection, high accuracy and repeatability, thermal compensation and moment compensation.

Fatigue-rated load cells are specifically designed for durability testing machine manufacturers and users, or any application where high cyclic loads are present. Applications include material testing, component life cycle testing, and structural testing. All fatigue-rated load cells are guaranteed against fatigue failure for 100 million fully reversed cycles.

Highlights:- Dual Bridge Output

- High Accuracy

- Fatigue-rated

- Temperature & Pressure Moment Compensate

- NIST Traceable, A2LA Accredited Calibration to ISO 17025

Applications

- Airframe Structural Test Applications

- Fatique Testing

- Material Testing

- Rocket Thrust

- Weighing

- Process Monitoring

- Landing Gear Test

Low Profile Load Cells

-

Our low profile load cells feature an advanced structural design that makes them extremely durable, accurate and resistant to large extraneous shear and moment loads. To perform in a linear and predictable manner, the outside diameter of the load cell must be bolted to a flat rigid surface. To ensure that they can also be properly mounted in applications where there is no flat rigid surface, they include a factory installed base that provides a convenient threaded attachment point for easy installation and use in both tension and compression. All low profile load cells are stocked with the mounting base installed, but we can remove the base upon request Standard capacities are 500, 1k, 2k, 5k, 12.5k, 25k, 50k, and 100k lbs.

Hightlights:

- Versatile

- "Forgiving to general mistakes made during installation

- Includes best-in-class 2-year warranty

- Available in general purpose and fatigue rated types

- FS capacities from 500 lb to 1000 klb

- Temperature, pressure, and moment compensated

- Can handle extraneous loads due to misalignment

- Overload capability 200 to 300% FS

- 0.04% to 0.06% Static Error Ban

Applications:

- Dynamometers (torque arm)

- Static material testing

- General force measurements

- Structural testing

- Component life cycle testing

- Calibration reference

- Bumper Impact testing

- Seat structure testing

- Crash Barriers

- Vehicle road load simulators

- Material test machines

- Lifecycle testing on hip and knee

- Industrial automation

Canister Load Cells

-

PCB's cost-effective canister load cells are easy to install and ideal for low-capacity applications. They are used in applications such as weighing, quality control, tactile forces, and static material test machines, Canister style load cells also include a built-in mounting base for a simplified installation in both tension and compression applications. Standard capacities are 25, 50, 100, 200, and 300 lbs.

Highlights::

- Easy to install

- Cost-effective

- Standard Full scale ranges are available from 25 to 300 lbs

- Built-in mounting base and same thread on both sides

- Low mass

- Ideal for low-capacity applications

- Simple Installation for tension and compression applications

Applications:

- Opening and closing car doors

- Auto component test

- Trunk doors

- Switch test stands

- Life cycle testing on small automotive components such as hinges, latches, and handles

- Industrial automation

Rod End Load Cells

-

Our rod-end load cells are designed for integration into tension measurement in applications such as process automation, quality assurance, and production monitoring. We also offer a sphere and clevis style model, which is particularly effective for off-axis/side loading applications due to their excellent bending strength. They are versatile, durable, and fit easily into small spaces such as inline with vehicle tie rods. Standard capacities are 500, 1k, 2k, 5k,10k, and 20k lbs.

Highlights::

- Excellent side- and moment-loading capabilities

- Cost-effective

- Standard Full Scale ranges are 500 to 20,000 lbs

- Fatigue resistant

- Tension and compression

- Proprietary design for optimal side-loading strength due to misalignment and off axis loading

- Industry standard mounting threads 3/4-16 (500 to 2k lb capacities and 1-14 (5k to 20k lb capacities

Applications:

- Automotive durability and reliability testing in small spaces, such as in-vehicle load measurements and in-line with vehicle tie rods

- Adapts directly to hydraulic cylinders used in vehicle component validation

- Cable/rope tensile testing

- Industrial control/feedback testing

- Industrial food processing

S-Type Load Cells

-

S-Type load cells are low-cost and high performance side mounted load cells suitable for a number of weighing and general force measurement applications. They come with a 6-foot strain relieved integral cable with pigtail leads that are stripped and tinned for electrical interface. Standard capacities are 50, 100, 250, 500, 1k, 2k, and 5k lbs.

Highlights::

- Low cost and high performance

- Side mounted

- Comes with a 6-foot strain relieved integral cable with pigtail leads that are stripped and tinned for electrical interface

- Standard full scale ranges are 50 to 500 klb

- Calibrated in tension only

Applications:

- Structural performance testing on automotive systems such as doors, hoods and trunks

- Automotive component lifecycle

- Weighing

- Shore hardness

- Material strain testing of polymers and elastomers

- Industrial control/feedback

- Industrial food processing

Fatique Rate Low Profile Load Cells

-

Fatigue rated load cells are specifically designed for component durability and fatigue test machines where highly cyclical loading is present. These rugged load cells are extremely resistant to extraneous bending and side loading forces. They are used for material testing, component life cycle testing and structural testing. All fatigue rated load cells are guaranteed against fatigue failure for 100 million fully reversed cycles.

Highlights::

- Versatile

- "Forgiving to general mistakes made during installation

- Includes best-in-class 2-year warranty

- FS capacities from 250 lb to 500 klb

- Temperature, pressure, and moment compensated

- Can handle extraneous loads due to misalignment

- Overload capability 200 to 300% FS

- 0.04% to 0.06% Static Error Band

Applications:

- Dynamometers (torque arm)

- Static material testing

- General force measurements

- Structural testing

- Component life cycle testing

- Calibration reference

- Bumper Impact testing

- Seat structure testing

- Crash Barriers

- Vehicle road load simulators

- Material test machines

- Concrete structures

- Lifecycle testing on hip and knee replacements

- Industrial automation

Pedal Force Load Cells

- Pedal Effort Sensors are designed to measure load applied to the brake, accelerator, and clutch pedals during acceleration, deceleration, and transmission shift events. The units are compact and light weight, making them easy to install and remove.

Torque Transducers

-

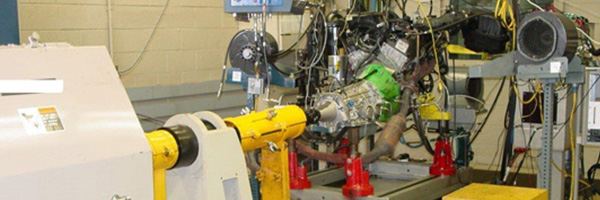

For more than 25 years, PCB Load & Torque’s torque sensors have helped customers meet the most demanding test and measurement requirements in the areas of automotive, aerospace, R&D and process control.

Applications:

- Dynamometers

- Electric motor testing

- Hydraulic pump testing

- Fan testing

- Torsion test machines

- Automotive brake testing

- Bearing friction and lubrication studies

Rotary Slip Ring

- Rotating Slip Ring torque sensors are designed to mount in-line between a driving source, and an absorber, or load. They are used in engine dynamometers, electric motor testing, hydraulic pump testing, fan testing, and a multitude of other applications.

Rotary Transformer

- Rotary transformer torque sensors offer high accuracies and RPM ratings. They are designed with an advanced transformer, shaft and housing to provide enhanced durability in rugged industrial applications. Rotating shaft torque sensors are available in a wide range of configurations. For Rotary Transformer products with a higher temperature range, please contact PCB Load & Torque, Inc. at 866-684-7107 or ltinfo@pcbloadtorque.com.

Reaction Torque

- Reaction torque sensors are suitable for a wide array of torque measurement applications. They are typically used in torsional test machines, motor dynamometers, or in any application where rotation is limited to 360° or less. Due to the fact that these sensors do not utilize bearings, slip-rings, or other rotating elements, their installation and use can be very cost effective.

TORKDISC®

- The TORKDISC® In-Line Rotary Torque Sensor System is a short-coupled, torsionally stiff structure that is ideal for a wide range of applications requiring high-accuracy, in-line rotary torque measurements. The sensor consists of a spring element which is torsionally loaded as torque is applied between an inner and outer mounting surface. Male and female pilots are provided to ensure good concentricity as the TORKDISC® is bolted into a driveline. Torque is transmitted by friction created between the mounting surfaces of the TORKDISC® and customer-provided mounting fixtures.

Single Channel Rotor Telemetry

-

If it rotates, we can instrument it and provide real-time wireless data!

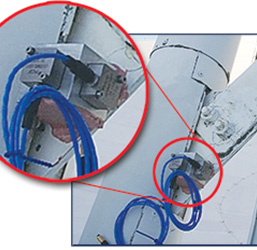

Our Load & Torque Division and Accumetrics (a PCB Group Company) offer a comprehensive line of telemetry products that provide a simple, accurate method of conditioning and transmitting strain, thermocouple, voltage, or ICP® signals on rotating or moving machinery while operating in a completely contactless mode. This configuration allows users to measure torque without interrupting existing shaft systems to install in-line torque transducers.

Our solutions are ideal for:- Automotive driveshaft/halfshaft testing

- Torsional vibration testing

- Marine drive shafts

- Dynamometers

- Industrial drives/process monitoring

- Turbo machinery

- Drivetrain testing.

Battery Powered Solutions

-

AT-5000 EasyApp

Looking to measure torque in high-G environments or in small spaces?Accumetrics, a PCB Group Company, offers battery-powered digital telemetry systems that feature a low mounting profile and low power consumption, and directly measure, digitize, and transmit true torque data from automotive rotating half-shafts, drive shafts and rotors of all sizes and speeds.

A replacement for slip rings and legacy FM telemetry

A revolutionary advance in miniature telemetry, the AT-5000 series replaces slip rings and legacy FM telemetry, offering a perfect solution for applications requiring dependable data retrieval and easy installation (even in tight places).

Designed for fast and dependable driveshaft measurements, the AT-5000 EasyApp uses a small, battery powered, strap-mounted transmitter to directly measure, digitize, and transmit true torque data from rotating half-shafts, drive shafts and rotors. The system is also used for temperature, voltage, and acceleration sensing.

Dual Powered Solutions

-

Series 8179 and 8180

Need to take measurements in dynamic applications or small areas? Our Load & Torque Division offers dual powered, or "mu-metal" telemetry systems that are compact in size and lightweight, allowing for easy installations in areas where space is at a premium.

Series 8179 and 8180 dual powered systems for automotive, aerospace & defense, wind power plant, test benches and other industrisl testing provide a simple, accurate method of conditioning and transmitting strain, thermocouple, voltage, or ICP® signals on rotating or moving machinery while operating in a completely contactless mode. Power is transferred inductively and the signal is RF-transferred between the moving and static component - no brushes or wires required. This method guarantees an absolute maintenance-free continuous operation and accurate transmission of measured data.

Induction Powered Solutions

- Need to take highly precise measurements over a longer duration? PCB Group Company Accumetrics offers induction powered solutions that directly measure and digitize sensor data on a rotating shaft then transmit it off-shaft using wireless technology. These systems are ideal for taking precise measurements for torque, temperature (RTD), and electrical measurements on drive shafts of motor-generator field excitation.

Fastening Technology

-

Configurable Fastener Testing Solutions for:

- Torque vs. Tension Testing

- Friction Coefficient Testing

- Locknut Prevailing Torque and Breakthrough Torque Testing

- Yield Determination Testing

- Assembly Strategy Testing

- Bolted Joint Analysis & Troubleshooting

- Bolted Joint Modeling and Analysis

Fastener Assembly Products for:

- Power tool set-up

- Performance verification

- Post-assembly audits

- Hand torque wrench calibration

Fastener Testing

-

For more than 20 years, our user-friendly fastener test systems have provided OEMs and suppliers alike with accurate, reliable test data.

We offer a comprehensive line of user-friendly fastener test products,custom-configured into systems to suit your needs. Our systems are used in number of applications in industries such as automotive, aerospace & defense, and power generation. To complement fastener test systems, we offer expert technical support and services including testing, system maintenance and upgrades, and calibration in our A2LA accredited laboratory.

Portable Data Recorder (Model 962)

-

For Torque-Angle-Tension Testing of Threaded Fastener Components

PCB's Model 962 Portable Data Recorder is a battery-operated, transient recorder with two transducer inputs that can be used with torque-only, torque-angle, or force transducers. It can serve as a portable threaded fastener laboratory for measuring fastener torque, angle of turn, and clamp load. Ideal for performing fastener analysis, for auditing and certifying power tools, and for testing hand torque wrenches; Model 962 is a cost effective, versatile, and easy-to-use recorder that can collect numeric peak data, XY graphic plots, and store the data to a thumb drive. The data can be easily displayed or printed on a PC running FastPlot2 software. The alphanumeric setup and calibration menus assure ease of operation. The unit can be used with all RS Technologies' rotary torque-angle and clamp force transducers and other conventional and industry-standard strain gage transducers.

Highlights::

- Measure and record torque, angle, and clamp load characteristics of threaded fastener components

- Streamlined menu system with a tactile feel keypad, USB ports, and analog output

- Two input channels for torque transducers, torque-angle transducers, or fastener tension load cells

- Record graphic data to plot: torque vs. angle, torque vs. tension, torque vs. time, and more

- Print both numeric and graphic data

- Upload numeric and graphic data to a PC via FastPlot2 software

Applications:

- Verify Fastener Torque-Tension

- Analyze Torque Angle Signatures

- Audit, Calibrate, or Certify Performance of Power Tools and Hand

- Torque Wrenches

- Dynamic Monitoring of Power Tool Testing

- Troubleshoot Problematic Joints

Rotary Torque Transducers

-

Series PC9000 Rotary Torque Sensors are widely used in the fastener assembly market to verify the performance of hand and power torque tools. These strain gage-based transducers are fitted on the output drive of a power tool and measure the torque applied by the tool to the fastener on an actual assembly. This measurement provides important information about tool shut off and can assist in establishing specifications for proper assembly.

When equipped with an optional angle encoder, the rotary torque transducer can also measure the angle of fastener rotation which is an important indication of joint integrity. Torque-angle transducers can provide the data to draw torque vs. time or torque vs. angle plots that can help analyze problematic joints and determine appropriate tightening strategies. They are also a key component of a threaded fastener torque tension testing machine.Highlights::

- Measure torque only or torque & angle

- Industrial-rated for power tool and fastener testing applications including pulse tools

- On-board auto ID technology simplifies sensor setup and calibration when used with RS Technologies digital instruments

- Industry-Standard Transducers compatible with all RS Technologies Fastener, Joint Analysis, and Tool Certification Equipment, and most conventional strain gage readout instrumentation

- 2 mV/V output with matched shunt Calibration

Applications:

- Power Tool Calibration & Performance Verification

- Threaded Fastener Testing

- Bolted Joint Troubleshooting

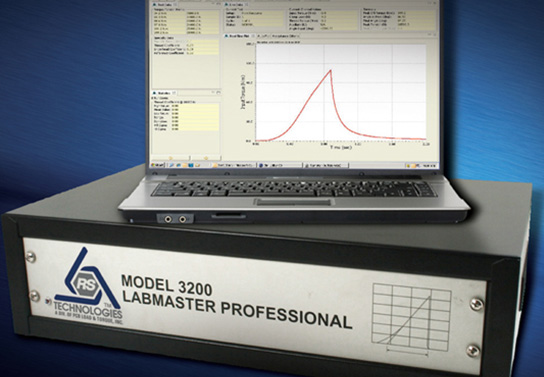

LabMaster Professional

-

For Complete Torque-Angle-Tension Testing & Analysis of Threaded Fastener Components

PCB Model 3200 LabMaster Professional is the key part of a fastener torque-tension test system. It provides complete data acquisition of applied torque, angle of fastener rotation, clamp load and thread torque. This system allows graphing of any input versus any other such as torque vs. angle, torque vs. clamp load, etc., and also provides multiple plotting capabilities so that plots of several tests can be overlaid. When thread torque is measured, the LabMaster Professional can calculate friction coefficients to help determine fastener performance. PCB provides calibration services for this and their other torque and force products at its A2LA Accredited Calibration Laboratory in Farmington Hills, Michigan.

Highlights::

- 4-channel data acquisition & signal conditioning

- I/O signals for drive motor control

- Windows-based fastener testing & plotting software

- USB port to interface with Windows® PC

Applications:

- Fastener Torque-Tension Testing

- Prevailing Torque Testing

- Underhead and Thread Friction Coefficients Determination

- Yield Determination

- Angular Ductility/Rotational Capacity Testing

- Power Tool Testing and Analysis

Fastener Drive Systems

-

PCB's Fastener Drive Systems are available in a variety of speed and torque configurations, depending upon the size and type of fasteners and testing requirements. The systems are comprised of a rugged, heavy-duty industrial DC brushless electric motor and a dependable servo controller, that together provide the precise and accurate torque and speed that is required for threaded fastener testing. The system can be supplemented with torque multipliers to extend their torque and speed range.

Fastener Drive Systems are used in conjunction with other PCB fastener technologies (formerly known as our RS Technologies product line) Model 3200, LabMaster Professional, to provide control. Model 3200 is an advanced multipurpose system designed to perform automated threaded fastener testing and joint analysis. When the Fastener Drive System is used with the LabMaster Professional, the unit provides real-time data display as well as printing, plotting, and automatic data storage capabilities.

A complete test system also includes a rotary torque-angle transducer, a combination tread torque and clamp force transducer, a text fixture assembly for mounting all components, and a printer for data reports and plots.

Force Washer Transducer

- PCB's Series FT4000 Force Washer Transducers are miniature load cells designed specifically for measuring fastener clamping forces. The design provides high stiffness in a small package, making these load cells ideal for static and dynamic measurements on fasteners, or structural test applications where space limitations exist. Force washer transducers come in a variety of English and Metric sizes.

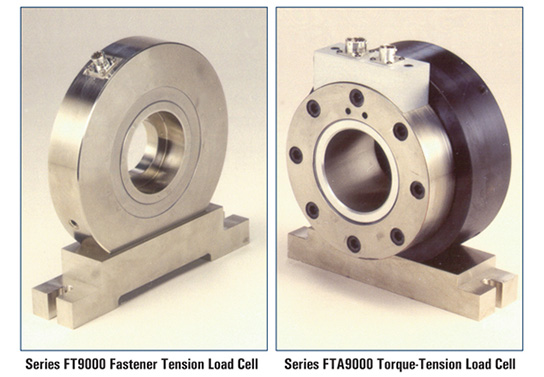

Fastener Torque-Tension Load Cells

-

For Use in Measuring and Analyzing Threaded Fastener Characteristics in Production Lot Testing and R&D Studies

Highlights::

- Fastener tension load cell capacities range from 3372 lbf to 112 klbf (15 kN to 500 kN)

- Fastener Torque -Tension load cell capacities range from 4496 lbf to 405 klbf (20 kN to 1,800 kN)

- Uses standard Skidmore-Wilhelm plates

- Slotted base allows for fast and easy securing to existing test fixtures

Applications:

- Measure/Analyze Threaded Fastener Characteristics

- Perform Laboratory Evaluation of Fastener Tension & Thread Torque Characteristics

- Measure Fastener Tension and/or Thread Friction Torque During Rundown Operations

- Test Special Devices (such as locknuts, serrated underheads, etc.)

- Measure Effects of Materials, Surface Finishes, Platings, & Coatings

Fastener Assembly

-

Ensuring quality assembly of threaded fasteners begins with proper setup of the assembly tools and may include periodic testing of the tools on the assembly line, torque audits of assembled fasteners, and the capability of testing and analyzing fasteners if problems arise. These efforts should begin with an understanding of the behavior of individual fasteners, recognizing the interaction of the material properties of the fastener, clamped components, and internally threaded components, as well as the influence of coatings, lubricants, and adhesives on the performance of fasteners in bolted joints.

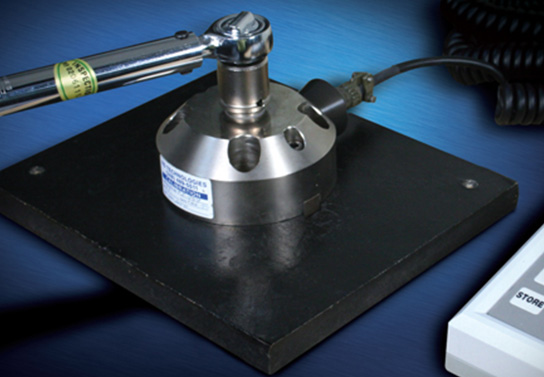

Hand Torque Wrench

-

Series HT7000 Electronic Hand Torque Wrenches are lightweight, yet durable enough to be used in the toughest industrial environments. The narrowed head is ideal for access when space is at a premium. The comfortable foam handgrips allows for operator comfort. Series HT7000 Wrenches are available with an optional tri-color LED, and when used with Model 920 Portable Digital Transducer Instrument, provide inspec/out-of-spec feedback.

Highlights::

- Durable, ergonomic design

- Lightweight, high strength

- Excellent overall accuracy

- Compatible with most strain gage instruments and data collectors

- Comfortable foam handle

- Available in a variety of drive sizes and capacities

- Optional tri-color LED to signal within limits, high, or low measurement

Applications:

- Post-assembly Torque Auditing

- Bolted Joint Troubleshooting

- High Precision Final Assembly

Portable Data Recorder (Model 962)

-

For Torque-Angle-Tension Testing of Threaded Fastener Components

Highlights::

- Portable data recorder with 4-channel high-speed data acquisition card

- Transducer signal conditioning card

- Durable hard shell case enclosure

- Includes LabMaster for Windows® fastener testing software for PC interfaced via USB port

- Accepts inputs for torque angle transducers and load cells

Applications:

- Torque-Tension Testing

- Bolted Joint Analysis

- Fastener Coatings, Lubrication, Finish and Plating Evaluation

- Power Tool Testing and Analysis

- Prevailing Torque Testing

- Yield Determination

- Bolt, Nut, Locknut, and Self-tapping Fastener Testing

Hand Torque Angle Wrenches

-

PCB's Series HTA7000 Hand Torque-Angle Wrenches are rugged and lightweight, yet durable enough to be used in the toughest industrial environments, and the narrowed head is ideal for access when space is at a premium. With high-resolution angle measurement, these wrenches are ideal for troubleshooting bolted joints and torque-angle audits using Torque Angle Signature Analysis techniques as well as employing the M-Alpha Audit Method patented by RS Technologies. Equipped with an ID chip, setup and calibration is quick and easy when used with instruments from RS Technologies, such as the Model 962 Portable Data Recorder and the Model 920 Portable Digital Transducer Instrument.

Highlights::

- Durable, ergonomic design

- Lightweight, high strength

- Excellent overall accuracy

- High resolution angle measurement

- Compatible with most strain gage instruments and data collectors

- Wide range of torque capabilities

- Comfortable foam handle

Applications:

- Post Assembly Torque Auditing

- Torque-Angle Signature Analysis

- Bolted Joint Troubleshooting

Stationary Torque Transducers

-

Highlights::

- Capacities from 100 lbf-in to 500 lbf-ft

- (11 to 678 Nm)

- 1/4 to 3/4-inch square drives

- Bi-directional

- Includes internal square drive adapter

- Keyed base for secure installation in tool shop or on test cart

Applications:

- Measure and Record Torque Load Characteristics of Electric, Pneumatic, or Mechanical Torque Tools

- Audit and Certify Transducerized Tool Calibration and Performance Capability

- Test Torque or Torque-angle Power Tools or Hand Torque Wrenches

Portable Peak Meter (Model 910)

-

Highlights::

- Accommodates most transducers with output ranging from 0.8 to 5.0 mV/V

- Compatible with most strain gage torque transducers & load cells

- Stores and recalls up to five readings

- Data can be used to create statistical process control charts

- Calibrates using external shunt calibration resistors

- Reverse switch allows the measurement of torque in counter-clockwise direction

- Three selectable decimal point positions

- Analog output receptacle

Applications:

- Monitoring Dynamic or Static Torque Applied to Threaded Fasteners

- Monitoring Compression or Tension Force

Portable Digital Transducer Instrument (Model 920)

-

Highlights::

- Simultaneous display of track and peak data

- Collects up to 300 time and date stamped readings

- Compatible with most conventional strain gage transducers

- Selectable units of measure

- Selectable filter for use with power tools

- Calculated population and sample size statistics

- Serial port for printing reports or uploading data to a computer

- Reads RS Technologies' auto ID chip for simple set up

Applications:

- Calibrate Hand Torque Wrenches Including ÂClick Type Wrenches

- Setup and Test Assembly Tools

- Perform Post-Assembly Torque Audits On Threaded Fasteners

- Troubleshoot & Analyze Bolted Joints

- Measure Fastener Clamp Load

- Monitor Press Force

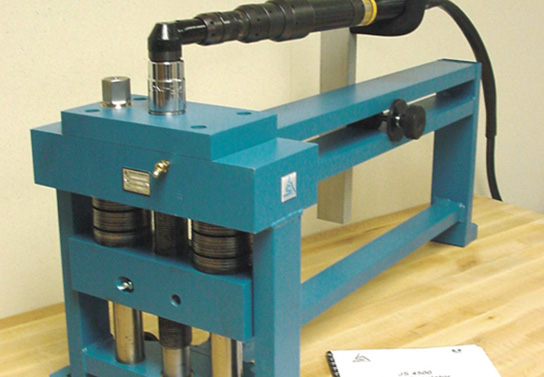

Joint Simulators

-

For Use in Calibration & Certification of Power Tools

Highlights::- Easily configured soft, medium, or hard joints

- Robust and durable design

- Bench-top mounting

- Reversing drive

Applications:

- Power Tool Testing

- Power Tool Setup

- Performance Verification

Environmental Noise

Sound Level Meters

-

Larson Davis manufactures a wide range of Advanced Sound Level Meters to meet all your envirnmental noise monitoring application needs.

Powerful, yet easy-to-use design

Full suite of firmware / software options

24-hr technical support

Cost competitive

Noise Monitoring Systems

-

Permanent Noise Monitoring

System  Model 831-NMS

The Model 831-NMS permanent noise monitoring system is designed for long term monitoring around airports, industrial facilities, motorsport complexes, wind farms, mining operations, and within the general community.

Larson Davis Sound Sources

-

Applications:

Architectural Acoustics: In-situ Façade Measurements

Room Acoustics: In-situ Reverberation Time Measurement

Building Acoustic Measurements)

Evaluation of the Acoustic Indexes for the Transmission Loss of Horizontal or Vertical Partitions

Sound Insulation

Sound Power Determination per Referenced Standards

Qualification Tests on Acoustical Environments

Sound Absorption Determination by the Steady-state Method

Sound Power Determination In-situ

Sensor Cables

-

PCB manufactures a wide variety of cable assemblies that will mate to different sensor types, signal conditioners and data acquisition systems.

Cables are an important part of every measurement system. PCB® carefully selects different raw cable types from trusted suppliers and time is taken to design cable to connector interfaces that will be reliable. All cable assemblies are produced at one of PCB®Âs manufacturing locations to tightly controlled assembly procedures that ensure durability in various applications and environments. 4-conductor Cables for Sensors

- 4-conductor cables are used with ICP® triaxial sensors and single axis MEMS sensors. This table provides the most relevant specifications for five cable types. Type 010 and 034 are the most commonly used, but three other types are also available.

General Purpose Coaxial Cables for Sensors

- General purpose coaxial cables are used with single axis ICP® sensors. This table provides relevant specifications for four cable types. Type 002 is the most commonly used, but three other types are also available.

Low Noise Coaxial Cables for Sensors

- Low noise coaxial cables are used with single axis and triaxial charge mode sensors. This table provides relevant specifications for four cable types. Type 003 is the most commonly used, but three other types are also available.

Callibration

-

Whether you're a calibration service provider or you commission your own in-house calibration capability, your calibration vendor's reputation for knowledge, reliability and education are key to your success.

PCB Piezotronics Inc. and The Modal Shop, PCB Group Companies, have the equipment, expertise and the experience to help you gain the control and confidence needed for your calibration capability. From services to reference sensors to complete calibration systems, we are here to help. We also offer portable calibration equipment for simple pre-test verification of your sensors and measurement systems.

The PCB Group has dynamic sensor calibration expertise across multiple generations. PCB Piezotronics serves as the hub for sensor manufacturing and calibration services, while The Modal Shop, brings in additional expertise in measurement systems, world class uncertainty and global standards. As a team, we provide innovation in reference sensors and calibration actuators at both the primary and secondary level. As you learn about dynamic calibration, rest assured that calibration products (components and systems) are proven in the national metrology laboratories around the world. Portable Vibration Calibration

- Shakers and portable calibration units are available for on-site validations.

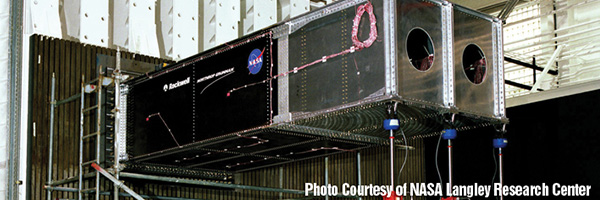

Precision Vibration Calibration

-

The Accelerometer Calibration Workstation Model 9155 provides users with control and confidence in their calibration practice. From the world's largest aerospace companies and major automotive manufacturers, to research facilities and national laboratories, Model 9155 Calibration Systems are installed worldwide and viewed as the market leading choice for precision calibration.

Reference Accelerometers

- PCB Piezotronics offers a selection of proven ICP® reference accelerometers for your calibration process. With the benefits of both simplicity of use and reliability of design, PCB dynamic reference standard sensors are the preferred choice for vibration and shock calibration systems.

Portable Dynamic Pressure Calibration

-

Precision Handheld Acoustic Calibrators

PCB® offers calibrators for microphones that meet IEC and ANSI standards. These units are easy to use and available with optional adaptors for use with a variety of microphone diameters. Calibrators are lightweight, portable, and battery operated.

Precision Dynamic Pressure Calibration

- To service the wide range of pressure events measured by dynamic pressure sensors, The Modal Shop offers six different systems that calibrate sensors designed for acoustic measurements, atmospheric blast experiments, gas turbine exhaust fluctuations, internal combustion engine measurements and hydraulic or fuel line measurements. These systems have been proven in tens of thousands of factory calibrations performed at PCB Piezotronics Inc. This rich metrology heritage is leveraged with a digital hardware and software platform that is shared with The Modal Shop's 9155 Vibration Calibration System.

Calibration Services

-

PCB Piezotronics Inc. provides a wide range of calibration services for shock, vibration, pressure and force sensors. Choose us as your partner for an accurate, controlled and confident transducer calibration program. View the details of our Quality System Certifications.