Navigation : EXPO21XX > PROCESS INDUSTRY 21XX >

H11: Feeding, Grinding, Shredding, Washing

> ELDAN RECYCLING

ELDAN RECYCLING

Videos

Loading the player ...

- Offer Profile

- Eldan Recycling is recognized as a world leader in supplying equipment for profitable recycling. We are proud to offer you equipment developed based on 60 years’ experience, manufactured in our own factory and delivered to several hundred satisfied customers worldwide. We offer you equipment and recycling solutions for processing of e.g. tyres, cable, electronics (WEEE) and industrial waste.

Product Portfolio

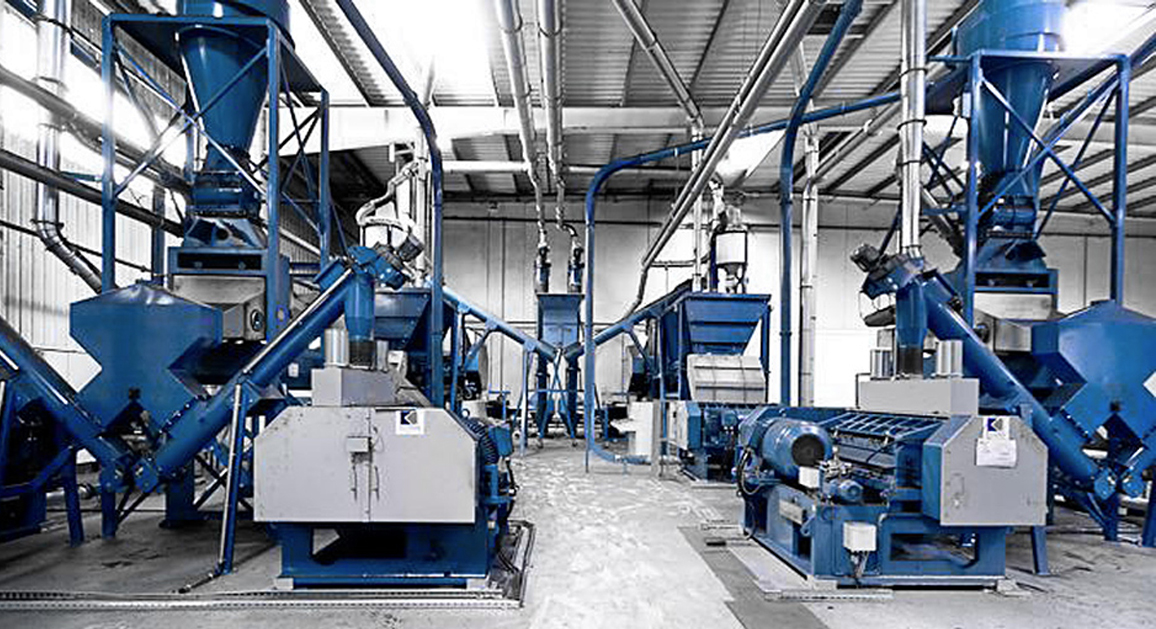

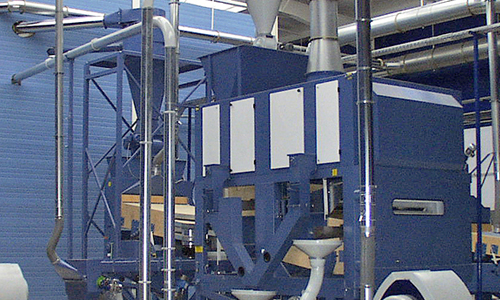

RECYCLING SYSTEMS

-

Equipment manufactured and supplied by Eldan Recycling has converted millions of tons of industrial and consumer scrap into valuable commodities. We have the know-how, the experience and the capability to perform all aspects of a supply contract – from design the recycling system to its commissioning.

All product and system development at Eldan is make with the customer and market in focus. The recycling systems are solutions to the problems and requirements which our customers have faced during the years. All product development and system design is focused to meet market requirements. Since we know that many entering the recycling industry wishes to start off their business small scale with the possibility to expand the system later on, we have a modular design of the systems. If the customer wants to increase production or further improve output quality it is merely a question to change machine to a larger model, or add on to the system.

Many of our customers - especially within tyre recycling - wants the flexibility to produce different sizes of output. Since many of the machines and systems are "multi-size" this is merely a question of changing the screen combination.

To achieve the required type of end-product, different standard recycling plants are available. These standard plants are also the starting point when plants are tailored to suit specific customer requirements.

ALUMINIUM RECYCLING

-

Eldan Recycling offer aluminium recycling solutions with capacities ranging from 3.000-12.000 kg/production hour. Typical input material is: soft and hard aluminium material, clean as well as contaminated material, sheets, blanks, profiles, litho, castings, turnings, foils, Used Beverage Cans (UBC), ”old rolled aluminium” etc. The output material will be "a clean-cut al-material", which size depend on the layout of the plant - i.e. which machines are included.

Input materials

In the Eldan Recycling aluminium recycling solutions typical input material will be soft and hard aluminium material, clean as well as contaminated material, sheets, blanks, profiles, litho, castings, turnings, foils, UBC’s, ”old rolled aluminium” and many others.

Output fractions

The output material will be "a clean-cut al-material". The size of the output depends on the size of the plant - i.e. which machines it includes. A few example:- In a plant that only including a Super Chopper the main fraction size is smaller than 100 mm. Approx. 10 % of the output material is oversize (i.e. larger than 100 mm and smaller than 300 mm).

- In a plant including a Super Chopper and a Multi Purpose Rasper the output size can be varied (according to your needs) between 20 mm and 80 mm.

- In a plant including a Super Chopper, a Multi Purpose Rasper and a Granulator the output size can be varied (according to your needs) between 2 mm and 12 mm.

CABLE RECYCLING

-

Eldan has solutions for processing of dry cables, jelly filled telecommunication cables and greasy underground cables. Depending on type of cable processed a final separation of at least 99.5% clean metal fraction of either aluminium or copper is obtained.

Standard plants are offered with capacities ranging from 200-4.000 kg/production hour. These standard plants are the starting point when systems are tailored to suit specific customer requirements (e.g. production capacities from 6.000 to 10.000 kg/production hour, processing of ACSR cable or further reduction of metal losses).

Input materials

In the different Eldan Cable Recycling Systems you will be able to process the following types of input:- Dry Cables

- Jelly Filled Cables

- Underground Cables

Output fractions

Depending on type of cables and size of plant the Eldan Cable Recycling System can give a final separation of at least 99.5% clean metal fraction of either aluminium or copper. The plastic fraction contains approximately 2-5% of metal. This fraction can then be further cleaned in a dry way with a Classifier and/or in a wet way on a Water Separation Unit.

ELECTRONIC WASTE RECYCLING (WEEE)

-

In the WEEE Recycling Plants from Eldan Recycling the items mentioned in the EU WEEE Directive Annex 1B can be processed. Exceptions are Refrigerators/ Freezers, which instead are processed in Eldan refrigerator plants. We offer standard plants with capacities ranging from 800-7.000 kg/production hour. The standard plants are the starting point when systems are tailored to suit specific customer requirements - e.g. being able to process tyre, cable and WEEE in the same system or further reducing metal losses.

By processing electronic waste in an Eldan system, you will be able to retrieve e.g. various fraction of Ferrous and SS (Stainless Steel), various fraction of non-ferrous metals (Aluminium, Copper, Brass and Printed Circuit Boards (PCB's)), refining material containing e.g. Copper, Brass, Zinc, Lead and Precious Metals (PM), organic fraction with e.g. plastic, rubber, wood, textile and dust.

Input materials

The system offered by Eldan Recycling for processing of Waste Electrical and Electronic Equipment is modular and designed to process the following types of input:- Computer scrap containing main frame computers, personal computers, keyboards, monitors without glass tubes, printers, faxes etc.

- Small home appliances containing videos, TV sets without glass tubes, record players, CD players, hair dryers, toasters, vacuum cleaners, coffee makers, irons, micro wave ovens etc.

- Handheld tools such as drilling machines, grinding machines etc.

- Electrical scrap such as contactors, relays, main breakers, fuses, contact bars, switches, instruments etc.

- Electronic and telegraphic scrap such as electro mechanical switchboards/relays, computerized switchboards, printed circuit boards etc.

- Small electrical motors up to approx. 1 - 1,5 HP

Output fractions

From an Eldan WEEE Recycling Plant you can as example retrieve the following output:- Various fraction of Ferrous and SS (Stainless Steel).

- Various fraction of non-ferrous metals (Aluminium, Copper, Brass and Printed Circuit Boards (PCB's))

- Refining material containing Copper, Brass, Zinc, Lead and Precious Metals (PM) etc.

- Organic fraction with plastic, rubber, tree, textile etc.

- Dust

MUNICIPAL SOLID WASTE (MSW) RECYCLING

-

The Eldan Recycling System is designed for size reduction of MSW (Municipal Solid Waste) such as plastic wrappings, plastic films, paper, madresses, carpets etc. System capacities range from 5,000-15,000 kg/production hr. The final setup of a recycling system for processing of MSW will depend on the requirements of the customer and the specific input material.

Input material

The system offered by Eldan Recycling for processing of MSW is modular and designed to process for example the following types of input:- Plastic wrappings

- Plastic film

- Paper

- Madresses

- Carpets

Output fraction

To optimize the process, it is important to reduce the waste volume into a homogeneous fraction size of for instance < 50 mm (or according to your needs). The output material will be free from non-ferrous and ferrous materials - also depending on your needs.

REFRIGERATOR RECYCLING

-

The Eldan refrigerator recycling plant is designed for processing refrigerators operating with CFC/pentane gasses in order to prevent harmful substances to evaporate into the atmosphere and to achieve the most efficient recycling of the solid materials. A complete refrigerator recycling system includes everything from pre-chopping to separation of the material.

The system downsizes and separates the refrigerator into Fe (smaller than 30 mm, ready for re-sale), PUR pellets (usable for incineration plants, rest gas in the pellets less than 0,2%), Organic (mostly plastic smaller than 40 mm, ready for re-sale) and Non-ferrous metals (smaller than 40mm, ready for re-sale). The standard system can handle up to 80 refrigerators/production hour.

Input materials

The plant is constructed for crushing of refrigerators of up to a maximum size of 2000 x 1200 x 1000 mm. Larger fridges must be reduced in size prior to processing.

Output fractions

The refrigerator is downsized and separated into;- Fe (smaller than 40 mm, ready for re-sale)

- PUR pellets (usable for incineration plants, rest gas in the pellets less than 0,2%)

- Organic (mostly plastic smaller than 40 mm, ready for re-sale)

- Non-ferrous metals (smaller than 40mm, ready for re-sale)

SHREDDER LIGHT FRACTION (SLF) RECYCLING

-

For further processing of the SLF material originating from ELV (End of Life Vehicle), Eldan is able to offer various standard recycling plants. If required, the standard plants are can be customized to suit specific customer requirements.

Input materials

Dismantled ELVs (End of Life Vehicles) are sold to shredder operators and are reduced to fist-size pieces by large rotating hammer mills. The shredder light fraction (SLF) is removed from the stream by suction, the intensity of which determines the amount and composition of the SLF.

SLF consists essentially of:- Plastics/rubber (~60%)

- Glass/sand i.e. mineral substances (~15%)

- Textiles/leather/wood (~10%)

- Paint dust/rust (~10%)

- Residual metals (~5%)

Output fractions

- Ferrous metals

- Metals, cables and wires

- Fluff/organic fraction

TYRE RECYCLING

-

Eldan Recycling have recycling solutions for processing of all types of tyres; whole car and truck tyres including mining tyre, super singles, earth mover tyres, OTR etc. The capacity of the systems range from 1.500-8.000 kg/production hour. The system is "multi-size” which means that the size of rubber granulate easily can be changed by merely altering the screen combination. During production of rubber granulate flexibility is a very important factor since the market demand of various fraction sizes will vary.

Within tyre recycling the solutions from Eldan are recognized to offer highest production output quality and flexibility as well as lowest operating and production costs.

Input materials

In the Eldan Tyre Recycling System you will be able to process whole car and truck tyres including mining tyre, super singels, earth mover tyres, OTR etc.

Output fractions- Shreds (approx. 50-300 mm).

- Chips (down to approx. 12 mm).

- Rubber granulate (depend on requirements).

- Powder (10 to 50 Mesh).

- Steel.

- Textile.

VARIOUS SCRAP

-

Input material could be paint cans, coins, incineration steel, automotive parts like plastic pumpers and plastic interior, and any other product you would may want to recycle.

If you are curious to know what kind of output you would get if processing casino coins, wings of a wind mill or the material of your choice, in one of our machines, or plants, you are now able to try it our in our Test Center in Faaborg, Denmark.

RECYCLING MACHINES

-

All Eldan Recycling machines are designed to meet the most demanding market requirements. High quality equipment and production and low maintenance costs are merely a few of the advantages which makes our customers choose us over and over again. Our machines are reliable and robust at the same time offering high flexibility during production. Many of the machines can easily be adjusted to produce a different output size - just change the screen. It is also possible to process different materials in some of our machines. Please note that even though one machine can be used for processing e.g. tyres and electronic waste (WEEE), modifications often have to be made to suite the specific recycling area. Do not use the same machine for different recycling areas without consulting Eldan first.

The Eldan machine assortment consist of size reduction equipment e.g. pre-choppers, shredders, raspers and granulators as well as downstream equipment e.g. cable cutters and shears, material separation, silos and magnets. PRE-CHOPPERS / SHREDDERS

- The Eldan pre-choppers/shredders are used for initial size reduction of the input material to in order for it to be further processed in upcoming equipment. The pre-choppers are also used to increase the capacity of the plant as a whole.

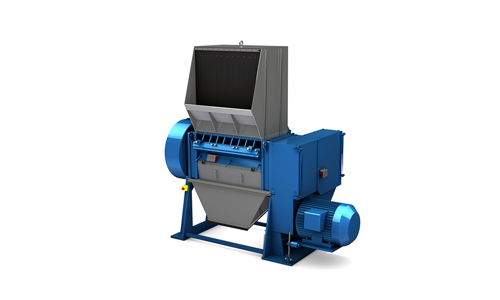

MULTI CHOPPER

-

The Multi Chopper is designed for effective pre-chopping and size reduction of various materials like

- Aluminium (e.g. used beverage cans)

- Cables

- Electronic and electrical waste (i.e. WEEE)

- Municipal solid waste (i.e. MSW)

- Etc

The Multi Chopper has a low speed, high torque rotor enabling processing of tough materials. It is powered directly by Hägglund hydraulic motor and power unit enabling automatic reverse for overload protection thus minimizing knife damages. Knives available in different steel qualities providing the optimum solution for processing of your specific material. Easily exchangeable wear parts give you a virtually indestructible machine which is easy to maintain. Screens with different hole sizes available to make your production flexible.

RING SHREDDER

-

The Eldan Ring Shredder is the optimum solution for size reduction of light scrap such as:

- Electronic waste (WEEE directive)

- Non-ferrous fractions from Car Shredders

- Aluminium

- Small electric motors, starters

Impact rings ensures opening of material and liberation of metals. The impact rings are mounted on 4 secondary shafts located on the rotor. Easily exchangeable grates available with different hole sizes. Exchangeable wear parts give you a virtually indestructible machine.

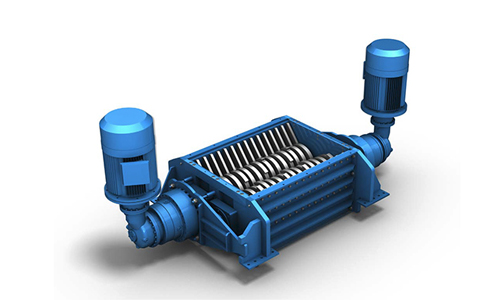

TWIN SHAFT PRE-SHREDDER

-

The Eldan Twin Shaft Pre-Shredders are a perfect complement to cable and tyre plants for initial size reduction. They can be used for size reduction of materials like:

- Copper cable

- Aluminium cable

- Tyres (TS1460-2)

- Refrigerator

The simple construction makes the change of the hooked knifes easy, by lifting up the entire rotor. Two rotors are each equipped with electrical motors and high torque gearboxes. Provided with 2 rotors and wear resistant hooked knives for efficient pre‐shredding. The hooked knifes are available in different thicknesses for controlling the size of the output. Two frequency converters ensures a very flexible operation i.e. individual setting of RPM, overload protection, auto reverse at overload and high torque from zero RPM. Stand and inlet hopper is customized for the individual set up.

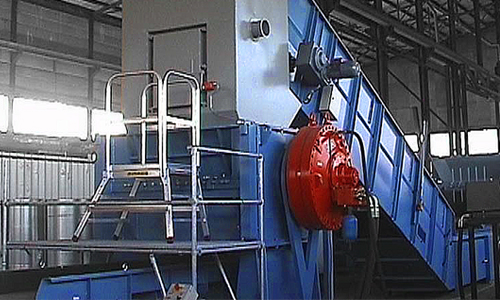

SUPER CHOPPER

-

The Eldan Super Choppers are heavy duty pre-choppers designed as first step in any recycling process - e.g.:

- Tyres (without prior debeading)

- Aluminium scrap (all types)

- Cables

- Electronic and electrical waste (i.e. WEEE)

- Refrigerators

- Municipal solid waste (i.e. MSW)

- Wind mill wings (cut-off)

- Plastics

- Industrial waste

A low speed and high torque makes the Super Chopper suitable for processing of tough materials. It is powered directly by Hägglund hydraulic motor and power unit enabling automatic reverse for overload protection thus minimizing knife damages. Adjustable knife clearance optimize the cut function. The knives can be reground multiple times on a “flat-bed” grinder ensuring long life and low operation costs. Unique rotor manufactured and designed for minimum wear.

It is also possible to get the Super Chopper as twin rotor (SC-II) as well as heavy duty (SC-HD) version.

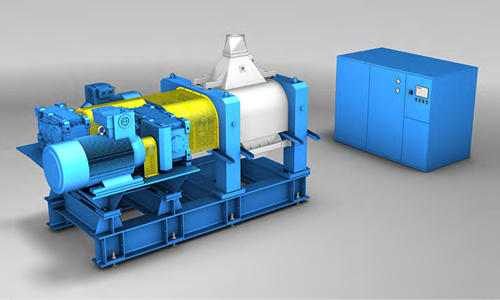

SUPER CHOPPER II (TWIN ROTOR)

-

The Eldan Super Choppers are heavy duty pre-choppers designed as first step in any recycling process. The twin rotor version of the Super Chopper is a further development which enable you to process voluminous and tough material. Proven technology at its best. The Eldan Super Chopper-II process e.g.;

- Tyre (car and truck tyres without prior de-beading)

- Aluminium (profiles, used beverage cans)

- Cable

- Electronic and electrical waste (i.e. WEEE)

- Refrigerators

- Municipal solid waste (i.e. MSW)

- Magnesium

- Wind mill wings (cut off)

The Super Chopper-II has a unique double rotor design. A low speed and high torque makes the Super Chopper suitable for processing of tough materials. It is powered directly by two Hägglund hydraulic motor and power unit. Both rotors are equipped with flying knives and there are two tables for static knives. The twin rotor technology is combined with the advantages that the adjustable knife clearance offers.

SUPER CHOPPER-HD (HEAVY DUTY)

-

The Eldan Super Choppers are heavy duty pre-choppers designed as first step in any recycling process. The multifunctional heavy duty Super Choppers are designed to process more voluminous and tough waste than the standard SC-series.

- Tyre (car and truck tyres without prior de-beading)

- Aluminium (profiles, used beverage cans)

- Cable

- Electronic and electrical waste (i.e. WEEE)

- Refrigerators

- Municipal solid waste (i.e. MSW)

- Magnesium

- Wind mill wings (cut)

A low speed and high torque makes the Super Chopper suitable for processing of tough materials. It is powered directly by Hägglund hydraulic motor and power unit enabling automatic reverse for overload protection thus minimizing knife damages. Adjustable knife clearance optimize the cut function. The knives can be reground multiple times on a “flat-bed” grinder ensuring long life and low operation costs. Unique rotor manufactured and designed for minimum wear.

RASPERS

- The Eldan Raspers are used for primary size reduction of material. The type of Rasper recommended depend of type of material processed and desired capacity of plant.

MULTI PURPOSE RASPER

-

The Eldan Multi Purpose Rasper is a heavy duty rasper for initial size reduction. It can be used for size reduction of materials like:

- Tyres

- Steel cord cleaning

- Aluminium scrap (all types)

- Cables

- Electronic and electrical waste (i.e. WEEE)

- Refrigerators

- Industrial waste

- Oil filters

The high inertia from the flywheel gives a more even load of the machine, and therefore a higher cutting power. The machine is belt driven for simple transmission. The rotor is manufactured and designed for minimum wear. The machine is designed for quick and easy change of knives and screens. Screens with different hole sizes available for flexible production. Exchangeable wear parts give you a virtually indestructible machine.

RASPER R400-3

-

The Eldan Rasper R400-3 is used for primary size reduction of material in small capacity cable systems. This is the ideal solution for preparing all types of dry cables including steel armoured cables for granulation. Max. cable diameter of Ø40 mm.

The smaller Rasper 400-3 has many similarities with the larger Raspers. It has an adjustable knife clearance which optimize the cutting function. The knives can be reground multiple times on a “flat-bed“ grinder ensuring long life and low operation costs. The rotor is manufactured and designed for minimum wear. The screens are available with different hole sizes. Easy change of screens ensures flexible production.

RASPER R800/1200 AND R807/1207

-

The Eldan Rasper R800/1200 and R807/1207 is used for primary size reduction of material in small and medium capacity recycling plants. It is typically used for granulation of materials like cables and electronic and electrical waste (i.e. WEEE).

The Raspers has both flying and static knives. The flying knives are either wedge mounted or bolt mounted. Adjustable knife clearance optimizes the cutting function. Shear pins protects the drive system from momentary overload. The rotor is manufactured and designed for minimum wear. Screens with different hole sizes available for flexible production.

GRANULATORS

- The Eldan Granulators turn the input material into granulates. Which Granulator is recommended depend of type of material processed and desired capacity.

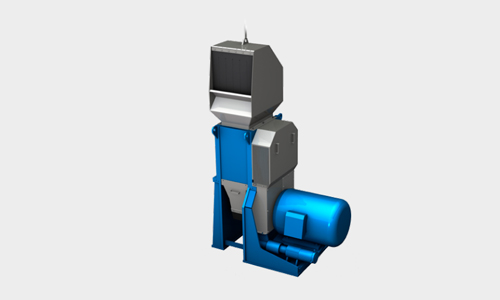

FINE GRANULATOR

-

The Eldan Fine Granulator is a high speed, single shaft granulator for the final granulation step. The Fine Granulator is specially designed for processing material like:

- Tyres

- Cables

- Aluminium scrap (all types)

- Plastics

The Fine Granulator has an adjustable knife clearance optimizing the cutting function. The knives are not only easy to access and change, but can also be reground on a “flat-bed” grinder. Exchangeable wear parts give you a tough machine. Screens with different hole sizes available to ensure a more flexible production

HEAVY GRANULATOR

-

The high-speed, single shaft Heavy Granulator is ideally suited for the initial stage of granulation. It can for example be used for size reduction of materials like:

- Electronic and electrical waste (i.e. WEEE)

- Cables (pre-chopped)

- Aluminium scrap (all types)

- Shredder light fraction (SLF/ASR)

- Municipal solid waste (i.e. MSW)

- Plastics

To make you production flexible, easily changeable screens with different hole sizes are available. Exchangeable wear parts give you a virtually indestructible machine. Straight knives in exchangeable cassettes ensures a clean cut.

MATERIAL SEPARATION

- The Eldan material separation eqiupment use air or water flow and oscillating movements or magnets to separate materials depending on their specific properties. Which equipment you will be recommended depend on which fractions you wish to separate.

ASPIRATORS

-

The Eldan Aspirators are used in tyre recycling to separate the textile from the rubber granulates and to classify the rubber granules into three sizes and dust.

The machine uses two separate separation devices, to ensure optimum purity. Initially, a dust suction system that removes the dust fraction. Secondly, screens separating the textile and sorting the rubber. An efficient anti-clogging system, consisting of bouncing rubber balls ensures that the screens are not getting blocked by material. The required screens with different hole sizes are available for various output material requirements.

The Aspirators ensure a high cleaning efficiency on a wide range of rubber granules and powder.

CLASSIFIERS

-

As a basic principle, the Eldan Classifiers use oscillating motion and screens to separate either textile and rubber or metals and the plastic fraction. In tyre recycling an Overband Magnet is also used to retrieve remaining steel.

- Classifiers PC10T/PC15T (tyre recycling) is an efficient Pre-Classifiers used as ”first step” in removal of liberated textile and steel from rubber granulate.

- Classifiers PC15/PC17.5 (tyre recycling) is an efficient Classifiers used as “second-step” in removal of liberated textile from rubber granulate.

- Classifier PC1000 (tyre recycling) is an efficient Classifier which is typically used in quality upgrading systems for scaling of rubber granulate. Efficient pre-classifier used as ”first step” in removal of liberated textile and steel from rubber granulate.

- Classifiers PC12C/PC15C (cable and WEEE recycling) is an efficient Classifiers to recover metals from the plastic fraction originating from the separation tables. This results in minimal loss of metal.

All of the Eldan Classifiers have an efficient anti-clogging system, consisting of bouncing rubber balls, ensures that the screens do not get blocked by material, and have exchangeable screens with different hole sizes. The type of Classifier which you will be recommended depend on which materials you with you separate/remove.

DRUM WIND SCREEN

-

The Drum Wind Screen have been developed to separate crushed complex scrap into:

Light fraction and possible cyclone fraction.

Heavy fraction. The heavy fraction is classified into coarse and fine particles.

The effective separation of the raw material is achieved through:- Variable speed of the drum itself.

- Big range of angle of inclination.

- Big range of adjustment of air velocity.

- Visual contact with the separation process.

- Easily exchangeable end screen, when processing different types of material.

To minimize wear and reduce the noise level, the interior of the drum is clad with rubber.

The System works by feeding the mixed fraction to the centre of the inclined rotating drum. As the material is tossed by the rotary action, the lighter fractions are taken up the incline by the air stream and the heavier fractions fall down the incline by passing over the rotary screen.

OVERBAND MAGNET

- The Overband Magnet seperate ferrous particles from other material e.g. aluminium or rubber granulate.

SEPARATION TABLE

-

The Eldan Separation Table in an essential machine for material separation in recycling of e.g.

- Cables (aluminium or copper)

- Electronic and electrical waste (i.e. WEEE)

- Aluminium scrap

- Tyres (upgrading quality by removing foreign objects)

- Shredder light fraction (SLF/ASR)

The material is divided into the following output fractions to ensure optimum purity:- Dust: removed via the dust suction system

- Main fraction: taken from the top of the incline

- Light fraction: taken from the bottom of the incline

- Middling fraction: taken from the middle of the incline (and taken back for reprocessing)

The separation table gives a high quality result – almost 100% clean main fraction. Easily accessible adjustment controls enables adjustment during actual operation.

WATER SEPARATION TABLE

-

The Water Separation System is a cost effective solution to recover metal dust and fine wires from the plastic fraction after the metal separation. By using a well-balanced combination of water, table inclination and oscillating movements you will get an almost clean plastic fraction with metal losses as low as 0.2%. The metal fraction will have a purity of 98-99% (by weight) after drying of the metal. The water is cleaned through sedimentation and is recirculated in a closed system.

The Water Separation System is mainly used in the recycling of:- Cables (aluminium and copper)

- Electronic and electrical waste (i.e. WEEE)

ADDITIONAL EQUIPMENT

-

To complement the downsizing equipment Eldan offer a number of additional equipment:

- feeders and buffer silos - all with the purpose of optimizing the material flow through the plants

- cable peeler and shears - cut or strip the cables

- cracker mill - rubber powder production from rubber granulate

ACSR CABLE SHEAR

-

If processing ACSR Cable or similar type of cable, the ACSR Shear (M16-2) provides a safe and efficient means of reducing long cable lengths in seconds.. It is simple to load, to operate and to maintain. The ACSR Shear M16-2 offers a very useful and economic way of preparing solid cables for granulation in a granulation system.

The principle of operation of the shear is a flying knife and a static knife. During every revolution the flying knife passes the static knife and creates a scissors action, which cuts through any cable that overhangs the static knife. The flying knife operates at a constant speed of 400 rpm, which means that the speed of the cutting measured in meters per minute is determined by the feed rate of the cable through the hydraulic feed rollers.

ALLIGATOR SHEAR (CABLE)

-

Eldan Alligator Shear is a heavy duty hydraulic metal and cable shear. It is designed to cut e.g.:

- Metal bars and rods

- Light and heavy electrical cables

- Coils and bundles of insulated and non-insulated wires and other types of items

- Scrap from bare metals or mixed with plastic

The cutting power of the Eldan Alligator Shear is 40 ton making it suitable for more demanding materials. The machine is operated by a foot pedal, making it easy to operate. Adjustable gap opening to optimize the cutting. Turnable knifes, i.e. 4 cutting edges, maximize time between knife changes.

CABLE STRIPPERS

-

The Eldan Cable Stripper is one of those tools that will serve you for years and years. It is a reliable cable peeler, suitable for most cable types including plastic, paper, textile insulated cables, rubber insulated cables, including butile rubber, lead armoured cables and steel armoured cables.

It has an adjustable knife for different isolation thicknesses, and interchangeable input bushes for various cable sizes. It also has a fully locked guard system.

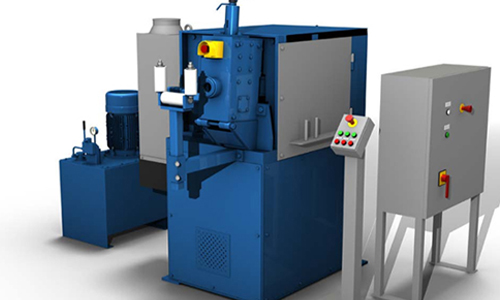

CRACKER MILL

-

The Eldan Cracker Mill is the key machine by powder production in Eldan Powder Systems. The Cracker Mill can be used for powder production of rubber originating from basically any type of tyre - e.g. car tyres, truck tyres, OTR tyres, mining truck tyres, van tyres, super singles and agricultural tyres.

It consists of 2 parallel individually driven rolls. The rolls counter rotate in different and adjustable speeds (ratio) creating a friction between them. This friction generates tearing forces that breaks and tear the rubber apart.

SILOS

-

Eldan Recycling offer a few different silos to optimize operation and enhance throughput throughout the plant.

The Buffer Silo (BFS5) is often located between the Super Chopper and the Rasper. It balances the output from the Super Chopper to the input rate of the Rasper. It is a 5 m3 Silo with slatted steel conveyor belt. It has a heavy rotating flail to control the feed rate.

The Buffer bin (BF3.0) has an open rectangular storage vessel with a slatted steel conveyor base, which transport the material at a constant but variable rate to control the amount. The slatted steel conveyor base is driven by a hydraulic motor with belonging pumping station which gives infinitely variable control. The out feed from the Buffer Silo can be varied in such a way that the successive machine is operating with optimum load. Volume: 3 m3.

The Silo FB200 is an closed cylindrical storage vessel with a propeller in the bottom. It balances the output from a Fine Granulator to a Separation Table C15 depending on Granulator output particle size. Volume 0.2 m3.

The Silo SMV200/400 is often located between the Granulator and the separation equipment. It balances the flow of granulated material to ensure that the separation works at maximum capacity, thus ensuring that the quality of separation is maintained. It is centred around an open rectangular storage vessel with a vibrating base. Outlet ø200mm/ ø400mm.

The Silo V2/V4 is most often located between the Rasper and the Granulator. It balances the output from the Rasper the input rate of the Granulator. It has a 4 m3 Silo with vibratory base to control the feed rate. Volume: 2 m3 or 4 m3.

The Tumble Back Feeder (TBF) which ensure optimum feeding of the successive machine. Volume: 5 m3.

TYRE FEEDERS

- Two types of Eldan tyre feeders are available depending of which type of tyre needs to be fed. The Car Tyre Feeder (CTF25) has a feeding capacity of approx. 5,0-6,0 ton of car tyres per production hour. The Truck Tyre Feeder (TTF10) has a feeding capacity approx. 5,0-6,0 ton of truck tyres per production hour, and can contain approx. 10 truck tyres per at the time. After the tyre feeder the tyres fall down onto a transport conveyor which take them to the inlet conveyor for the Super Chopper.