Maag

Videos

Loading the player ...

- Offer Profile

- Maag Pump Systems, Automatik Plastics Machinery, Gala Industries and Reduction Engineering Scheer – four successful and well experienced companies have joined forces to become the global partner for the polymer industry. As manufacturer of gear pumps, pelletizing and filtration systems and also pulverizers we offer top-grade equipment for your demanding requirements – not only for polymer applications, but also for the chemical, petrochemical, pharmaceutical and food industry.

Product Portfolio

Strand pelletizing for dry cut, wet cut and pultrusion

-

Back in the late 1950s, Automatik sold its first strand cutter. Over the decades, the companys established know-how in strand pelletizing has produced many innovative systems for an ever widening range of applications. Together with Reduction Engineering Scheer, which has been part of the MAAG Group since 2015, even better and more efficient pelletizing solutions are being developed in cooperation with the other business segments. Today, strand pelletizing is carried out by pellet machines and pelletizing system covering the three basic pelletizing processes (wet cut, dry cut, pultrusion).

For all strand pelletizing technologies, there are machine series and individual machines in different designs covering the various requirements of the polymer industry. Complete high-performance polymer pelletizing production systems can be served. The product range includes a selection of small strand cutters for laboratory applications, as well as solutions for everything in between. MAAG is continually developing new solutions for wet cut pelletizers, dry cut pelletizers, and pultrusion machines, because markets, materials and requirements are constantly evolving and changing. We meet demands for the highest production quality from the production of raw materials to the finished compound or masterbatch. WSG Dry-cut Strand Pelletizer

PRIMO 60/120 E- WSG dry-cut strand pelletizing systems for utmost flexibility during production

-

Successfully applied by hundreds of customers, the proven WSG dry-cut strand pelletizing systems with PRIMO E pelletizers produce the highest quality of cylindrical pellets or microgranular compounds particularly suitable for further processing. Variable system configurations allow for optimal matching with your specific production requirements and also provide utmost flexibility in terms of product changeover.

Benefits- Shortest possible unguided section from feeding unit to cutting unit to meet highest pellet quality standards, with single-sided bearing of the cutting rotor

- Quick and easy access for cleaning and servicing; quick product changeover

- System configuration suitable for soft, brittle, and abrasive polymers

- Changes on the pellet length and weight to be made with Dual Drive

- Quick exchange of tools and rollers

PRIMO S - WSG dry-cut strand pelletizing systems for best pellet quality

-

Successfully applied by hundreds of customers, the proven WSG dry-cut strand pelletizing systems with PRIMO S pelletizers produce the highest quality of cylindrical pellets or microgranular compounds particularly suitable for further processing.

Benefits- Shortest possible unguided section from feeding unit to cutting unit

- Sturdy, double-sided bearing of the cutting rotor

- Very high system availability due to wear-resistant cutting tools

- Quick and easy access for cleaning and servicing; quick product changeover

- Consistent pellet quality

PRIMOplus - WSG dry-cut strand pelletizing systems for all cases of application

-

The proven WSG dry-cut strand pelletizing systems with PRIMOplus pelletizers produce the highest quality of cylindrical pellets particularly suitable for further processing. Variable system configurations allow for optimal matching with your specific production requirements and also provide utmost flexibility in terms of product changeover.

Benefits- Shortest possible unguided section from feeding unit to cutting unit

- Sturdy, double-sided bearing of the cutting rotor to meet highest stability and precision standards

- Upper feed roll driven by separate motor

- Changes on the pellet length and weight to be made with Dual Drive

- Integration into JSG system feasible

- Very high machine availability due to wear-resistant cutting tools

- Quick and easy access for cleaning and servicing; quick product changeover

M-ASG - WSG dry-cut strand pelletizing systems for high production capacities

-

The proven WSG dry-cut strand pelletizing systems with M-ASG pelletizers produce the highest quality of cylindrical pellets particularly suitable for further processing.

Benefits- Sturdy, double-sided bearing of the cutting rotor to meet highest stability and consistency standards

- Changes on the pellet length and weight to be made with Dual Drive

- Roller bearings positioned outside the cutting chamber to allow high production temperatures

- Integration into JSG system feasible

- Very high machine availability due to wear-resistant cutting tools

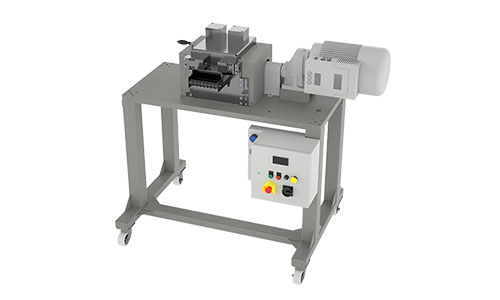

SGS 25-E4 - Lab Pelletizer

-

The extremely compact and robust lab pelletizer SGS 25-E4 is based on the proven technology of the SGS E-series. It features many of the functions and advantages of its popular „big brother“. On a laboratory scale, real full-scale trials can be carried out with the SGS 25-E4. Two independently- controllable drives permit infinitely adjustable length of the pellets.

Benefits- For 1:1 production trials in the laboratory

- Steplessly variable pellet length (0,5 – 12 mm)

- Access possible to the cutting chamber without using tools

- Parts subject to wear easily changed: rotor, upper and lower feed rolls

- Completely accessible for simple visual inspection and cleaning

- Maintenance-free bearing

S3500 Series - Strand pelletizing and dry cut pelletizing for polymer manufacturing

-

The S3500 Series Strand Pelletizer has been engineered to provide easy, tool-less entry into the stainless steel cutting chamber for strand pelletizing and dry cut pelletizing. The Slide Series pelletizers are designed to substantially reduce maintenance and cleaning time for polymer manufacturers. The front section of these plastic pelletizers is mounted on a linear slide mechanism allowing access into the cutting chamber. Maintenance and cleaning of the feedrolls, doctor blade, and bed knife are quick and easy.

Benefits- Unique Rotor Design for Maximum throughputs

- Wide Feed Entrance

- Insulated sound hood optional

- Stainless Steel contact areas

- Tool-less entry

- Air Actuated Upper Feedroll

- Dual drive optional

- Designed per customer application

- Unique Rotor Design for Maximum throughputs

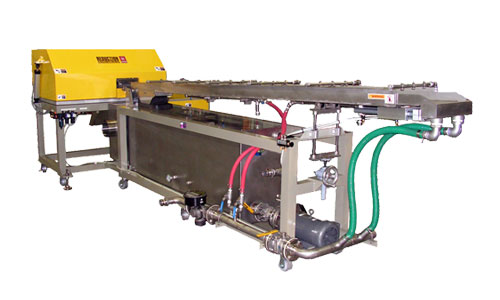

Dry Cut WD Series

-

The Dry Cut WD Series Waterslide pelletizing systems and dry cut strand pelletizing system have been developed to allow for a wide variety of materials to be run with little or no operator assistance. Strand conditioned water is used to improve pellet quality.

Benefits- Custom Built

- Superior Service

- In-house Engineering Support

- Increased Production

- Less Floor Space Required

- Custom Built

Bullet Series Strand Pelletizer - The best of both worlds

-

In order to combine the cutting geometry of the Conair style Model 304 with the innovative features of the Scheer E-Series pelletizer, the Bullet Series was created. The merger of the two market leaders in the basic design results in a strand dry cut pelletizer that is easier and faster to clean and service. Designed for 24-hour operation, the unit is ideally suited for both laboratory and production users. The inlet and discharge chutes can be removed without tools, making this pelletizer desirable for compounders that carry out multiple material changes over several times a shift. A large pneumatic cylinder above the upper infeed roller that remains parallel with the lower roller produces a greater uniform pulling force with varying diameter strands for less scrap in production. Higher throughputs, less waste, better product quality, and ease of operation were the goals when designing the strand pelletizer.

Benefits- Utilizing the Best of the Conair Design and Scheer Technology

- Ease of Operation

- Minimal Cleaning Time

- Minimized Pellet Hold Up Points

- Tool-Less Entry

- Small Foot Print

- Recessed Electrical Panel

- Push Pull Bed Knife Adjustment

- Self-Tensioning Serpentine Belt Driven Lower Feedroll

- Optional Dual Drive Available and Tungsten Carbide Rotor Option

- Utilizing the Best of the Conair Design and Scheer Technology

BAOLI 3 - Dry-cut strand pelletizer for compounding and recycling

-

Supported in bearings on both sides, the BAOLI dry-cut strand pelletizer reliably produces cylindrical pellets of excellent quality ideally suited for further processing. BAOLI-3 combines the advantages of the proven pelletizer in a compact design that can be easily integrated into existing production lines. Due to the height adjustability and the selectable operating side, the BAOLI-3 can be ?exibly adapted to any downstream equipment. Its modern cutting tools guarantee high throughput levels and provide long-term availability of the strand pelletizer.

Benefits- High adaptability due to patented height adjustable design

- Easy to operate as operator panel selectable on both side

- Reduced noise level with the new frame damping structure

- Easy to clean and maintain with patented open frame design

- High reliability with rotor supported by bearings on two sides

- Longer lifetime and cost-effective solution for dry-cut demand

- High adaptability due to patented height adjustable design

BAOLI S - Dry-cut strand pelletizer for compounding and recycling

-

Supported in bearings on both sides, the BAOLI dry-cut strand pelletizer produces cylindrical pellets of excellent quality ideally suited for further processing. BAOLI offers three machine sizes with working widths of 100 mm, 200 mm and 300 mm for pelletizing up to 75 polymer strands. Its modern cutting tools guarantee high throughput levels and provide long-term availability of the strand pelletizer.

Benefits- Cutting rotor supported by bearings on both sides

- Maintenance-friendly

- Reliable - Economic to run and cost-effective

- Easy to clean

- User-friendly

Strand Pelletizer T200 Series - Strand pelletizing and dry cut pelletizing for manufacturing

-

The T200 Series Strand Pelletizer has been designed to substantially reduce maintenance and cleaning time by strand pelletizing and dry cut pelletizing. What would typically take 30 minutes to disassemble now takes only 2 minutes. Hand knobs and the pivoting feedroll assembly tips forward for access to the lower feedroll and bed knife for easy cleaning and adjustment. The T200 Series can produce up to 6000 lbs/hr while running 85 strands at 700 RPM for manufacturing. The specific gravity for the materials being pelletized may increase or decrease the capacity. A Stellite tipped rotor on a 3° helix provides scissor-like cutting action for clean quality pellets. Rotor to bed knife adjustment is easily accomplished with the use of eccentrics. The eccentrics allow the rotor to be dialed into the bed knife to provide precise adjustments for even cuts. The lower feedroll also operates with eccentrics minimizing the gap between the doctor blade and the lower feedroll. The solid carbide bed knife is very economical with four usable edges. A Hypalon upper feedroll and diamond-knurled lower feedroll is belt driven for uniform pulling force on the incoming strands. The upper feedroll is offset, directing strands directly into the bed knife, producing quality pellets. Safety features include safety interlocks and a dynamic braking system. The rotor automatically stops before the cover can be opened to avoid injury. The T200 Series Strand Pelletizer offers a variety of options. Quick-ship machines, spare part deliveries, and rotor sharpening service are all part of Reduction Engineering Scheers guarantee of service and manufacturing excellence.

Benefits- Tipped design for quick cleaning

- Tool less entry

- Stainless steel contact areas

- Optimum strand control

- Optional wear package for abrasive materials

- 3° Helical Milling Style Rotor

- Dual drive option available

- Tipped design for quick cleaning

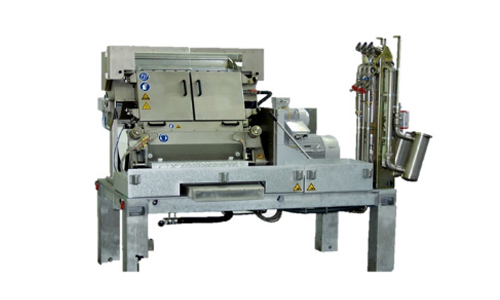

EBG Belt Conveyor Pelletizing System - Dry cut pelletizing and strand pelletizing system

-

The belt conveyor pelletizing system EBG is specifically designed for the compounding of water-sensitive or highly filled (> 60 %) or fragile products in strand pelletizing and dry cut pelletizing. Variable system configuration permit a perfect adaptation to the product to be processed. Using the belt conveyor, even elastic and very flexible polymers may be handled easily and efficiently.

Benefits- Wide processing window

- Retro-fitting to existing pelletizing lines possible

- Due to linear pelletizer feed, no strand breaks

- Very slow drawing speed possible, starting at 8 m /min – Strand cooling by air, water, or both

- Processing belt adaptable to different pelletizing heights

- Wide processing window

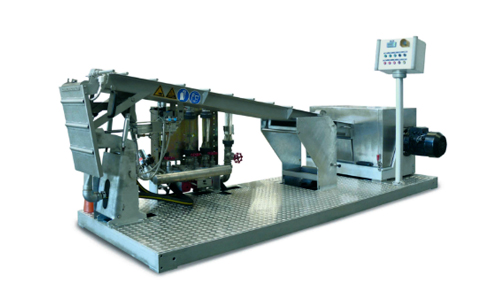

JSG - Automatic dry cut strand pelletizing system and dry cut belt conveyor pelletizing system

-

The proven JSG strand pelletizing systems are designed to achieve highest throughput rates in plastics compounding. The JSG systems produce cylindrical pellets of perfect quality for automatic dry cut strand pelletizing systems and dry cut belt conveyor pelleitizing systems, ideally suitable for further processing. Variable system configurations allow for optimal adaptation to the material to be processed.

Benefits- Utmost stable process due to automatic strand feed into the pelletizer upon start-up and during production

- Minimum residual moisture due to integrated drying section

- Throughput rates of up to 9,000 kg/h with superb pellet quality

- Perfectly adaptable for a wide range of filled and unfilled polymers; extended process window

- Very high machine availability thanks to wear-resistant cutting tools and minimal maintenance requirements

- Low staff requirements due to automatic mode operation

- Utmost stable process due to automatic strand feed into the pelletizer upon start-up and during production

Wet Cut

P-USG - High-performance underwater strand pelletizing systems for cost-effective production

-

The P-USG underwater strand pelletizing systems made by Automatik Plastics Machinery have been particularly designed for both the production of virgin polymers with lower throughput rates and for recycling applications. The simple design of the machine stands for engineering reduced to the essentials while heading for high process stability and pellet quality.

Benefits- Consistent outstanding pellet quality

- Automatic strand lacing on start-up and during production

- Operating speeds up to 250 m/min

- Excellent quality of the feed tools and cutting tools

- Simple operation

M-USG - High-performance underwater strand pelletizing systems for cost-effective production

-

The P-USG underwater strand pelletizing systems made by Automatik Plastics Machinery have been particularly designed for both the production of virgin polymers with lower throughput rates and for recycling applications. The simple design of the machine stands for engineering reduced to the essentials while heading for high process stability and pellet quality.

Benefits- Outstanding, constant pellet quality

- Throughputs up to 20,000 kg/h

- Increased degree of system availability thanks to quick

- change cutting head

- High level of automation

- user-friendly for operation and maintenance

- Easy accessibility

- Long service life of extremly wear resistant cutting tools

- Most reliable

Pultrusion

PRIMOPlus for pultruded LFT pellets

-

The proven WSG dry-cut strand pelletizing systems with PRIMOPlus pelletizers produce the highest quality of cylindrical pellets particularly suitable for further application processing. Variable system configurations allow for optimal matching with your specific production requirements and also provide utmost flexibility in terms of product changeover for strand pelletizing and dry cut pelletizing.

Benefits- Shortest possible unguided section from feeding unit to cutting unit

- Sturdy, double-sided bearing of the cutting rotor to meet highest stability and precision standards

- Lower feed roll driven by separate motor

- Changes on the pellet length and weight to be made with Dual Drive

- Very high machine availability due to wear-resistant cutting tools

- Quick and easy access for cleaning and servicing

- Shortest possible unguided section from feeding unit to cutting unit

M-ASG for pultruded LFT pellets

-

The proven WSG dry-cut pelletizing and strand pelletizing systems with M-ASG pelletizers produce the highest quality of cylindrical pellets particularly suitable for further processing.

Benefits- Sturdy, double-sided bearing of the cutting rotor to meet highest stability and precision standards

- Lower feed roll driven by separate motor

- Changes on the pellet length and weight to be made with Dual Drive

- Very high machine availability due to wear-resistant cutting tools

- Quick and easy access for cleaning and servicing

- Sturdy, double-sided bearing of the cutting rotor to meet highest stability and precision standards

Pharma

PRIMO PFS

-

The widely tried and proven dry-cut strand pelletizer produces top quality cylindrical or micro-pellets, which are ideal for further downstream processing. Its compact design makes the strand pelletizer very suitable for lab applications. The variable system configuration enables a perfect adaptation to the product being processed with high flexibility when changing products

Benefits- Narrow distribution of particle size

- Homogeneous pellet shape featuring great flow-ability

- Quick and easy to clean

- Viewable process space

- Product-specific cutting geometries for an optimal cut

- Continuously variable particle length adjustment

- Process data monitoring on touch screen display

- Easy up-scaling; from the laboratory line to commercial production scale

- Narrow distribution of particle size

Strand Cooling Belt PFS

-

Unlike conventional extrusion in a water bath, the Strand Cooling Belt PFS does not require manual threading of strands. Strands are deposited directly on the conveyor belt and automatically conveyed to the strand pelletizer. The cooling is done by special air nozzles with high cooling capacity.

Benefits- Low mechanical stress on the srands

- Special air nozzles for minimal air consumption, reduced noise and high cooling capability

- No process water treatment is necessary

- Retrofitting into existing extrusion lines is possible

- Quick and easy to clean

- Possibility to Wash-in-Place (WIP)

- Process data monitoring on touchscreen display

- Easy up-scaling: from the laboratory line to commercial production scale

- Low mechanical stress on the srands

Belt-Cooling Pelletizing System PFS Series 30

-

The Belt-Cooling Pelletizing System PFS is specially designed for water soluble and brittle formulations. The variable system configuration enables perfect adaptation to the product being processed and guarantees continuous manufacturing. Even elastic and very flexible polymers can be handled by the belt system in a simple and efficient way. The system produces top-quality cylindrical pellets or micro-pellets which are ideal for further downstream processing.

Benefits- Rheologically designed die head tailored to the extrusion’s formulation

- Simplified start-up by pneumatic intake

- Narrow distribution of particle size

- Homogeneous pellet shape featuring great flow-ability

- Quick and easy to clean

- Retrofitting to existing extrusion lines is possible

- Process data monitoring on touchscreen display

- Integration to a higher level DCS (Data control System) is possible

- Rheologically designed die head tailored to the extrusion’s formulation

Accessories for strand pelletizing

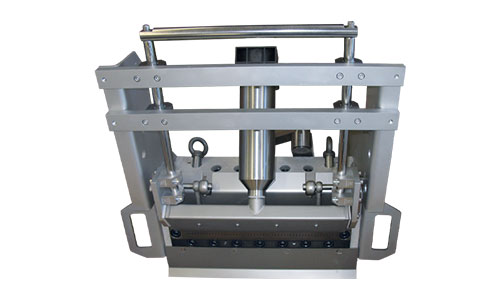

Die head SG

-

Die heads or pelletizing units are used in strand pelletizing systems for extrusion of strand profiles. They are responsible for even strand flow and uniform pellet shape. SG series die heads have been specifically developed for applications in masterbatch, compounding and recycling processes. Adapted to your process and product, they can be used downstream of single or dual screw extruders, pumps or melt filters.

Benefits- Uniform and homogeneous melt distribution

- Minimized dwell-time and short flow path of the melt

- No separation or de-mixing of the components

- Minimum pressure drop

- Simple and easy cleaning

- Mounting tool for the die plate

- Cleaning Device for reduction of die drools (Hot-Air-Knife)

- Uniform and homogeneous melt distribution

HAK Hot Air Knife

-

The hot air knife (HAK) is an optional or retrofitting device mounted to the die head of dry cut strand pelletizing systems which efficiently removes melt residues, outgassing remains, and die drools (such as build up of glass fibers) from both the die holes in the die plate as well as from the extruded strands themselves. With the hot air knife, product contamination can be reliably prevented and disruptions to production minimized.

Benefits- Efficient reduction of deposits and fi ber residues

- Available for die head operating widths from 100 mm to 900 mm

- Increased availability of your production line

- Reduction in overall production costs - Improved product quality

FRU/SRK Classifier

-

The classifier is used for separating spears, spelts, chains, oversizes, and multiples from plastic pellets. Classifiers of the SRK-I-C and SRK-I-V type have been designed for the separation of oversized particles both in virgin polymer and compounding applications. The type SRK-II-V classifiers are used for the separation of oversizes and fies in any operation of plastics pelletizing.

Benefits- Flat throwing angle

- No stand-up of over lengths on screening surface

- High operating comfort

- Small inclination angle and favorable outlet height - Robust design

- Very low vertical acceleration

- Easy cleaning

- Robust design

KW Cooling Trough

-

The cooling trough KW assures uniform tempering of strands during strand pelletizing in dry cut strand pelletizing systems. Variable modular length and width as well as many additional options allow adapting the cooling trough KW to almost every requirement.

Benefits- Uniform water flow on the entire width of the cooling trough

- Enhanced process stability

- Supporting rollers swiveling and slidable - Trough lengths available in increments of 1 meter

- All components in contact with product or process water are made of rust-free materials

- The base frame can be moved on rollers for precise alignment

- Level setting by adjustable overflow weir at the cooling trough exit

SE Air Knife

-

The SE air knife guarantees efficient strand drying during pelletizing in both compound and masterbatch applications. Filled and reinforced materials require effective strand drying to minimize the residual moisture of the pellets, reduce dust and avoid premature wear of the cutting tools.

Benefits- High suction power for low residual moisture values

- Dehumidification of suction air and water recirculation

- Targeted water return via pump - Low sound emission < 80 dB(A) - Short delivery times

- Easy start-up (»plug & run«)

Model JV Air Knife Series

-

Designed for 24/7 operation and very low noise levels, this vacuum strand dryer has been recognized by many compounders as the preferred method for drying strands. Built on a compact frame, the JV series air knife application has proven itself as a very effective method of drying strands utilizing vacuum only. Each model has a cantilevered vacuum strip that can be positioned and placed anywhere along the water bath to draw the water off the strands as they exit the water by strand pelletizing. This takes up less floor space and maximizes the efficiency while utilizing the heat of the strands to expel surface moisture that results in drier polymer entering the pelletizer. A stainless steel cyclone continuously separates the water from the air stream and the water exits to a drain port. The JV air knife head assembly is designed to positively separate and support the strands before and after the suction bar. When placed at the end of the water tank, these units can be outfitted with an optional drip tray. This tray collects the dripping water and returns the water back to the water tank. To further increase water savings, a sump pump can be installed to pump the water from the drain to the water bath.

Benefits- Ease of Operation

- Minimal Cleaning Time

- Small Footprint

- Casters for Mobility

- Wear Protection Optional

- Adjustable Strand Guide Rolls

- Various Strand Ratings

- Optional Drip Tray)

- Ease of Operation

PWA Process Water Treatment

-

The process water treatment unit PWA serves to filter, temper, and circulate process water for dry-cut systems in centrifugal pellet dryers of underwater pelletizing systems during compound and masterbatch production. PWA can be integrated into the base frame of the cooling trough or positioned externally. Using a heat exchanger, the PWA separates the contaminated process water circuit from the primary cooling circuit from the central water supply.

Benefits- Targeted process water cooling via plate heat exchanger

- Operation free of emissions – Low operation and consumption costs

- High process reliability

- Separation of process water from the central cooling water supply

- Integrated stainless steel centrifugal pump

- Low energy consumption

- Targeted process water cooling via plate heat exchanger

Die Head PFS Series 50

-

Die heads are used in all strand pelletizing systems for extrusion of strand profiles. The PFS series of die heads has been specifically developed for applications in pharmaceutical processes; for example, for the production of products with active pharmaceutical ingredients. It is used downstream of single and dual screw extruders for hot-melt extrusion as well as after reactor vessels.

Benefits- Rheologically designed die head tailored to the extrusion’s formulation

- Absolute uniform and homogeneous melt distribution

- No seperation or de-mixing of the components

- Short flow path ensures minimal dwell time of polymer melt

- Low pressure drop

- Easy up-scaling; from the laboratory line to commercial production scale

- Compatible with all extruders and reactors

- Rheologically designed die head tailored to the extrusion’s formulation