BUTTING

Videos

Loading the player ...

- Offer Profile

- The continuous development of new product solutions in stainless steel, clad materials and special alloys has a long tradition at BUTTING: We are your contact if innovative solutions are required.

Product Portfolio

Innovative product solutions

-

Expertise in stainless steel

Since 1777 we have been known for our expertise in the processing of stainless steels, and we play a leading role in forming, welding machining and materials technology.

Our production programme offers you a wide range of high-performance materials for specifically corrosive applications. Here, the individual requirements of our customers almost always call for innovative solutions. Our metallurgists, welding engineers and production staff are happy to meet new challanges.

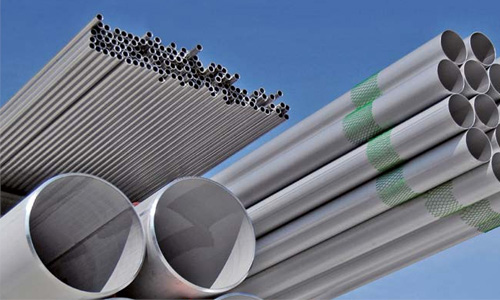

Stainless steel welded pipes made by BUTTING

-

The production of high quality longitudinally welded stainless steel pipes is our core business. Only very few companies in Europe can point to the know-how and big variety of stainless steels, special alloys and clad materials used for the production of such pipes.

With dimensions ranging from OD 20 to 3 000 mm and wall thicknesses of up to 70 mm we supply to numerous industrial sectors. Random lengths of up to 24 m, as well as fixed lengths with precise end preparations are available and all technical product characteristics, e.g. sizes, tolerances or test requirements can be agreed upon with us.

Our staff are qualified and certified according to all current welding procedures, thus guaranteeing our customers longitudinally welded stainless steel pipes in line with the requirements.

Spools & plant construction

-

The production of stainless steel pipes has always been our core competence. In addition, we offer our customers extensive prefabrication of stainless steel pipelines according to models, isometric drawings and piping plans.

By extensive prefabrication and further processing of our pipe at our works we are able to optimise the quality of the pipelines and offer products ready for installation at reasonable prices.

Advantages to the customers will pay off:- Savings in terms of space and staff on site

- Reduced installation time

- Improved product quality

- Reduced extent of testing

- Reproducibility

Our expertise in forming, welding, machining and materials technology, as well as quality assurance guarantee our customers the supply of first class products. BUTTING is a reliable supplier of pipelines for numerous industrial applications all over the world.

Vessel, tanks and apparatus

-

BUTTING produces vessels either in several pieces or in one piece according to customers drawings and specifications. The production in one piece is possible due to the extensive prefabrication possibilities available at BUTTING, providing not only higher quality but also quite obvious cost savings. Vessels having a height of 16 m and a diameter of up to 6 000 mm can be produced in one piece. An installed vessel production line furnished with the latest tools and testing procedures guarantees an optimum production process.

For decades many industrial sectors have been relying on BUTTING vessels produced to varying requirements.- Vessels for the paper and pulp industry

- Water separators made of Duplex

- Tanks for the food industry

- Columns with shelves

- Tailored vessels and oxygen vessels

- Pressure vessels

At the Rio Uruguay, the border river to Argentina, one of the largest pulp plants of South America has been built within two years. The concern Metsä-Botnia entrusted BUTTING Anlagenbau not only to deliver the pipes but also to produce vessels with a total weight of more than 3 500 tons. We produced, delivered and installed 53 internal vessels.

With our recent production capacities and the experience gathered over many years in the production and installation of vessels and piping systems, there is not much left we cannot do for our customers. We would be pleased to support you on your next project.

All over the world: BUTTING - Assemblies / Installation on site

-

The assembly of high quality equipment is a responsible task. Especially when using stainless steel, the professional handling of the pipeline parts and their further treatment and installation are crucial for the quality of a technical plant.

Since the foundation of BUTTING in 1777 we offer the assembly of pipelines and vessels. In 1950, we installed the first stainless steel pipelines and vessels at the paper mill in Oberau. During the past decades, the know-how, the reliability and versatility of our staff have become one of our trademarks. We have realized more than 1 000 projects all over the world. Our team consists of skilled fitters and turners who ensure customer oriented and smooth processing of a project both at our workshops and at site.

With its strong customer orientation, a team of experienced staff ensures that projects are completed smoothly in:- Fabrication and installation of vessels

- Prefabrication and installation of pipelines

- Monitoring and supervising of installation

- Industry service

- Material sales for the paper and pulp-making industry

The combination of the production of pipelines and vessels, CAD-planning, economical prefabrication and assembly at site are rolled into one package at BUTTING. This concentrates responsibility and increases the economy of your project.

Clad pipes – Equal to all challenges

- BUTTING has been processing clad materials into pipes and piping components for more than 25 years. By using clad materials, the excellent strength and toughness of carbon-manganese steels are combined with the corrosion resistance of high-alloyed materials. The use of clad pipes is recommended in all areas where dynamic stress, high pressure and a high level of corrosiveness can be found in the media transported.

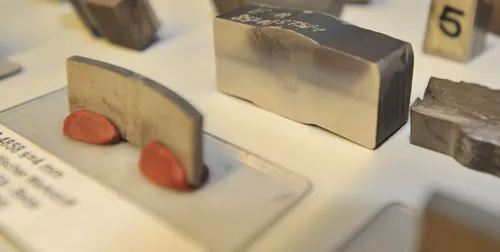

Metallurgically clad pipes

-

Already since the mid eighties we have been producing pipes from metallurgically clad plates for renowned customers all over the world. The tight bond between the metal layers of these pipes is achieved by a diffusion bridge.

Depending on their intended application and technical requirements metallurgically clad pipes are used, for example, as SCR pipes, riser pipes, process or line pipes.

Technical details at a glance:- Sizes range OD 114,3 (4") up to 1 219 mm (48")

- Wall thicknesses up to 70 mm

- Maximum wall thickness / OD ratio 1:10

- Random lengths up to 24 m (6 m and 12 m lengths without circumferential weld)

- Suitable for S-Lay and J-Lay method, bundle or reel-lay process

Advantages of metallurgically clad pipes:- Reduction of wall thickness

- Advantages in terms of cost already in case of small dimensions versus full-wall pipes

- Reduction of weight

- Wide variety of material combinations possible

Mechanically lined pipes – the BuBi® pipe

-

At the beginning of the nineties we developed the mechanically lined BUTTING-Bimetal-pipe, short: BuBi® pipe.

The BuBi® pipe is a corrosion resistant pipe which is telescopically aligned inside a pipe in carbon-manganese material and the tight mechanical bond between the pipes is achieved in a hydroforming facility.

For many years the BuBi® pipes have been successfully used in very demanding and sensitive onshore and offshore areas of the oil and gas industry. They are used as pipelines, riser pipes and SCR-pipes for highly corrosive media.

Technical details at a glance:- Size range from OD 114,3 mm (4") up to 660 mm (26")

- Random lengths up to 24 m (up to 12 m without circumferential weld)

- Production acc. to API, ASTM, DNV or ISO

- Suitable for S-Lay, J-Lay method, bundle or reel-lay process

Advantages of mechanically lined pipes:- Cost savings of up to 40 % compared to solid pipes

- High corrosion resistance at the inside and high pressure resistance at the outside

- Project-specific material combinations

Clad components ready for installation

-

In order to optimise the quality of the pipeline and to reduce costs we process clad pipes directly into components ready for installation. For this purpose we use clad semi-finished products, like weld-clad flanges, elbows, tees and reducers. The corrosion resistant layer is subjected to pickling and passivation at the works, as well as non-destructive testing according to the relevant specifications. Thus, potential savings with regard to the installation time on site later are achieved.

Advantages of clad components ready for installation:- Use of high quality semi-finished products made by BUTTING

- High degree of automation and high reproducibility

- First class manufacturing quality, among others through a continuous quality assurance

- Minimisation of welds and installation times on site

Special pipes and components ready for installation

-

In addition to longitudinally welded pipes for the industrial use, BUTTING manufactures special pipes and components ready for installation. By combining modern production technology with technical skills and long-standing experience in the stainless steel processing, we are able to implement individual product solutions for our customers.

The base product is the longitudinally welded pipe out of our production. Consequential numerous benefits are resulting for you:

- Cost-effectiveness through direct processing of our pipe

- Assurance of product quality through chemical pickling

- Customised complete solutions through the use of specific procedural applications along the value added chain

Special pipes with particular

-

>> Surfaces

>> Form and position tolerances

>> Geometries

>> Mechanical finishing

>> Laser processing

>> Forming Stainless steel pipes with special surfaces

-

Depending on the material and the industrial application, BUTTING satisfies a range of requirements for inner and outer surfaces and the weld seam area. We therefore offer you both chemical surface treatments and a variety of mechanical ones.

Chemical pickling after production is standard at BUTTING. This guarantees pipes and components with optimum corrosion resistance.

You can also specify different surface types:- The choice of raw material depends on the specified nature of the surfaces

- Rolling operations / flattening

- Individual requirements for roughness

- Grinding the inner and outer surfaces

- Blasting the inner and outer surfaces

- Deliberate roughening of the surfaces through raumatic surface finishing

Tolerances of form and position

-

Our stainless steel pipes and components are produced according to national and international standards, e.g. DIN, ISO or ASTM.

Beyond this, we implement any other requirements the customer may have with regard to special tolerances of the inside and outside diameter and the wall thickness. This is why numerous pharmaceutical companies have been relying on BUTTING pipes with very tight tolerances of the outside diameter for years.

We also produce stainless steel pipes for piggable plants, diaphragm pipes or valve housings, where the inside diameter is of the essence. Also in this sector we are your quality supplier. Our Quality Assurance system is part of each process, thus ensuring compliance with all individual requirements, e.g. squareness of the pipe ends - an important prerequisite for subsequent orbital welding.

Big variety of forms: Stainless steel pipes with special geometries

-

We have been producing corrosion resistant pipes in special geometries for many years, either as series production from coil or from plates for special components. Owing to the many production processes we have, a nearly unlimited range of different forms is possible:

- Triangular pipes

- Square pipes

- Hexagonal pipes

- Oval pipes

- Elliptical pipes

- Half shells

Renowned manufacturers of pumps, companies in process technology and research institutions rely on BUTTING's expertise. This is why we have supplied the Research Centre CERN in Geneva with special copper-clad oval pipes and half shells for the largest particle accelerator.

Mechanical treatment: turning, milling and drilling

-

Turning, milling and drilling are the processes which make our corrosion resistant pipes suitable for meeting various demands and fulfilling many purposes. Modern CNC and universal lathes are available in our production centre. In a single clamping operation we manufacture complete parts and components. Our production facilities in the lathering area include sizes up to 1 200 mm in diameter and 6 000 mm in length. Milling is possible for components of up to 14 000 x 2 800 x 1 500 mm in length, height and depth.

The BUTTING HeRo® - Heat Resistant Roller - illustrates the very precise production results. Our "hero" is used in the roller hearth furnances of the steel industry. Its high running accuracy represents a crucial advantage.

Depending on the field of use, not only standard materials, but also special materials with a high alloy content or titanium alloys are processed. Precise milling and turning results are the BUTTING quality criteria for special pipes and components ready for installation.

Laser processing

-

Laser technology offers many opportunities for the processing of pipes into complex components. Our own laser processing centre provides up-to-date laser technology.

Demanding cutting geometries and notches up to 10 mm in wall thickness are performed - deformation and burr-free, and complying with very tight tolerances.

Though our manufacturing possibilities and product variations are almost infinite; we realize e. g. support pipes and jacket pipes, flare tips, sorting trays and many other stainless steel solutions. We will be happy to advise you.

Forming

-

In addition to the production of longitudinally welded pipes in a variety of lengths, BUTTING offers a wide range of services for forming comprises. The forming of our quality pipes is done by means of mechanical and hydraulic calibration, bending and forming procedures, while complying with very strict tolerances.

Our wide range of services for forming comprises:- Flanges

- Extrusions

- Hydroforming

- Shrinking and expanding

- Fitting of inner and outer beads

Components ready for installation

-

>> Valve and pump housings

>> Well pipes and riser pipes

>> Flare tips

>> Fuel baskets

>> BUTTING HeRo® Valve and pump housings

-

Valve and pump housings are impressive examples of the close cooperation between BUTTING and its customers. By using specially developed processing methods and tools, we create individual components and optimise the value chain for our customers.

We produce valve and pump housings from almost every group of materials: in 300 different versions, ready for installation. The starting point for all of these housings is our high-quality stainless steel BUTTING pipe. The pipes are processed further in several stages into components ready for installation, by methods including welding, milling, turning, laser treatment, forming, drilling and treating the surfaces.

We guarantee the functional safety and long life of the stainless steel components by using high-quality primary products, a high degree of automation and through our well-qualified staff.

Pipes for pumps and riser pipes

-

Components used in drilling and well building industry must provide a high degree of operational safety and corrosion resistance, hence selection of the right material, careful fabrication of the raw material and compliance with very tight tolerances are crucial. We can point to many years of experience in the production of special products and are a reliable supplier and partner.

We produce according to the customer's requirements:- Riser pipes, filters and flanged pipes

- Well heads

- Suction filters

- Bends

For these applications we use pipes in different material grades. Depending on the intended use, the well heads can also be furnished with shut-off valves or water meters.

Flare tips – special components for the energy and environmental technology

-

Flare tips are used to burn off gases given off in chemical plants, refineries and LNG plants in an environmentally-friendly way. Since the eighties BUTTING has been producing flare tips ready for installation according to customer's requirements for the energy and environmental technology.

Depending on the intended use and the composition of the gases BUTTING produces different types of flare tips in the relevant heat resisting materials. These components are prefabricated complete in our plant in Knesebeck, ready for use. This offers the customer a lot of benefits, as no additional welding work is required on the construction site. Only the flare tip has to be mounted to the flare pipe.

Fuel baskets for power engineering

-

Since 1980 we have been producing various containers for customers in energy sector. Compliance with tightest tolerances and the highest level of quality are the prerequisites for the manufacture of components used in nuclear plants. Each production process is precisely documented by our highly qualified staff, thus reproducibility is ensured.

On the basis of the KTA 1401, AVS D 100/50 and IAEA 50-c-Q regulations of Areva, BUTTING has received approval to manufacture components (pipes and pressure vessels) in stainless steels for nuclear plants.

You can select the individual material grades for processing from a wide range, such as boron-alloyed stainless steels, copper or aluminium.

BUTTING HeRo® – The heat resisting furnace roller from BUTTING

-

The BUTTING HeRo® - Heat Resisting Roller - is a product solution developed at our plant: a heat resisting furnace roller which is used by the steel industry in roller-hearth furnaces for the manufacture of long and flat products.

Most of the furnace rollers used hitherto are water cooled, cause considerable energy and maintenance costs and are not noted for their longevity. This is where our uncooled furnace roller comes in very handy: the BUTTING HeRo® offers a long service life due to its very low tendency to oxidation and minor mechanical wear. This means considerable cost reductions, as furnace stand-stills and maintenance costs are avoided. The energy costs are also lowered, as cooling with water can be dispensed with.

Depending on its intended use our "hero" is individually produced from appropriate materials like Alloy 602 CA, 601 H or 800 H. Our furnace rollers can be produced in outside diameters from NB 100 up to 700 and wall thicknesses of up to 60 mm.

Knowledge – bundled and to the point

-

Our long-standing experience is shown today in our welding technology and our quality assurance system. At the same time, we regard forming and materials technology as "our" disciplines, since we have been collecting, bundling and boiling down our knowledge through the generations.

As always, the corrosion resistant pipe serves as the primary product for the production of special pipes and components ready for installation, prefabricated pipelines / spools and welded constructions. BUTTING is seen as a solution provider for products with special surfaces, tolerances, forms and geometries. Our portfolio is completed by our expertise in metal cutting and laser processing. On this basis, we were able to bring products to maturity, also in partnership with customers.

Preserving and expanding knowledge is both a task and an obligation. That is why BUTTING continuously invests in training and developing the staff at all our locations. Alongside commercial and occupational safety training sessions, training courses on welding and on testing procedures are a matter of course.

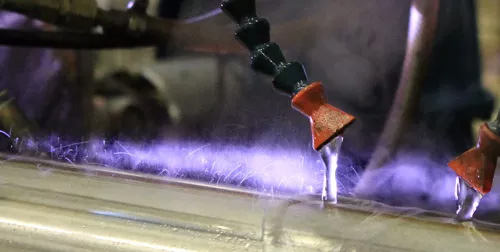

Task: Improve welding processes

-

BUTTING is noted for its long-standing experience in welding stainless steel, special and clad materials. Improving welding processes is seen as a central task of our welding technology.

At BUTTING, all the current arc and beam welding processes are used. In pipe production from coils we use plasma and TIG welding, and increasingly laser beam welding processes. Laser beam welding is used especially with pipes for the pharmaceutical, chemical, food technology and solar technology industries. It is ultimately the customer's specification which prescribes the welding process to be applied.

BUTTING customers benefit from our know-how:- Approx. 1 500 Weld Procedure Qualification Tests in line with German and international rules

- 480 welders are tested and certified in line with German and international rules

- 45 welding machine operators licensed under ASME IX

- 150 welders licensed under ASME IX

Quality management under DIN EN ISO 9001

-

For more than 235 years the name BUTTING has stood for quality and reliability in the metal processing industry. BUTTING has always been a trail-blazer in quality control and the documentation of production results. As early as 1962, we were routinely using X-ray technology. Since 1988 we have been monitoring and documenting the entire production process - from goods receipt to the dispatch of the finished product. Thus the manufacturing of a component can be traced back in the long term.

Our quality management system has been certified by the Germanische Lloyd Group in accordance with DIN EN ISO 9001. We also hold approvals from other classification companies and supervisory authorities, such as Bureau Veritas, DNV, API and BDLI. This is a criterion for renowned customers in the oil and gas industry to choose us as their preferred supplier. Because sustainability and environmental protection play a central role here - and can only be ensured through an impeccable product.

A variety of shapes and sizes thanks to know-how in forming technology

-

BUTTING products are the result of forming technology. An almost unlimited variety of shapes and sizes characterises our production possibilities. Thus we produce triangular, square and hexagonal pipes, oval and ellipse pipes and half pipes.

BUTTING specialises in the prefabrication of spools and components ready for installation. For example, integrated bends and multiple bends are produced on state-of-the-art machines; for multiple bends, different angles and positions are possible. The elbows are cold-formed, and no subsequent heat treatment is required. The use of integrated and multiple bends saves a number of fittings. As a result we reduce the welding required and the amount of testing - and the cost for our customers.

Materials technology for industry-specific applications

-

The BUTTING production programme offers its customers a broad range of high-performance materials for industry-specific applications.

Austenitic steels

Thus steels are mainly used in the chemical and pharmaceutical industry, in the paper and pulp industry and for household goods. They are also used in food and drink manufacturing and processing and in apparatus and vessel construction, for example in the production of biodiesel fuel.

Austenitic-ferritic steels

Austenitic-ferritic steels, the so-called duplex steels, are very suitable for all offshore installations, such as for vessels and process pipes on platforms or in desalination plants.

Nickel alloys

The group of nickel alloys has excellent local and acid corrosion resistance properties. This benefits many applications, particularly in the chemical and pharmaceutical industry and in oil and gas production.

Packaging and dispatch – quality assurance criteria

-

Safe, quick and undamaged - that's how our products reach any destination all round the world. The appropriate packaging ensures quality, because what matters is to deliver the pipes and components safely to the end user in the quality in which BUTTING produced them.

To assure comprehensive quality, BUTTING has developed its own packaging methods that prevent damage in transit. Standard packaging in the form of seaworthy pipe bundling, cases and crates is used, and containers too can be chosen as packaging or shipping options.

BUTTING packaging simplifies logistical processes through:- Shorter loading and unloading times

- Less effort and expense for securing the load

- Easy transshipment of general cargo

- Recyclability

- Storage without additional equipment

The use of wood under the Integrated Pollution Prevention and Control standard, International Standard for Phytosanitary Measures (ISPM) 15 is possible, as is special packaging for particular piping components.