- Offer Profile

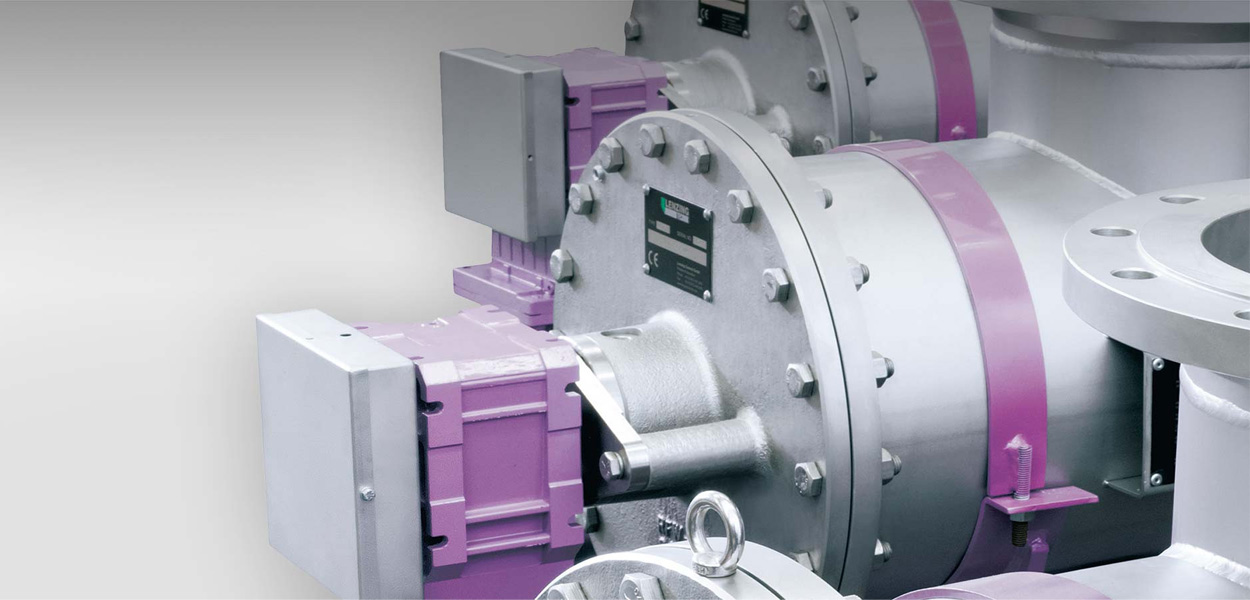

- Lenzing Technik GmbH is a globally leading supplier of pulp technology as well as filtration and separation technology.

Filtration and Separation Technology

- The filtration and separation technology department is specialized in the development and manufacturing of high-quality filter devices for the solid-liquid-separation. Originally designed for cleaning high viscose spinning solutions of the parent companys fiber production, the filtration experts of Lenzing Technik have been able to continuously improve and adapt the product portfolio in the last 40 years.

Today Lenzing Technik focuses on automatic backwash filter systems for the cleaning of low and high viscose media as used in many different industries. Thanks to the companys untiring ambition to continuously develop its filtration systems, the department has become a worldwide technology leader of solid-liquid filtration.

Our expertise- Own planning and construction department

- In-house manufacturing with state-of-the-art machining centers

- Piping and apparatus manufacturing in all materials of construction

- Pilot tests in our in-house technical center, labor analysis

- Piloting and customer specific analyses

- Turn-key constructions

AUTOMATIC BACKWASH FILTERS

AKF/KKF

- The Lenzing AKF / KKF filter is a fully automatic, continuous depth filtration system. A sintered metal fleece is used as the filtration layer of the multi-layer cylindrical screen. This depth filter fleece layer captures various sized and shaped solid particles. After the predetermined degree of solids contamination has been reached, the screen is cleaned via a systematic backwashing of small sections in a circular rotation pattern. Filtration continues during the backwash process.

Features- Applicable for very highly viscous fluids

- Filter fineness down to 3 µm

- Gel removal capability

CanFil

- The CanFil filter is a fully automatic, backwash system that operates continuously. Small diameter wedgewire or metal fiber fabric candles are used to capture solid particles on their inside surface. After a preset pressure differential has been reached as a result of solids build-up on the surface of the candles, one or alternatively two candles are isolated and cleaned at a time. During this step, a small volume of unfiltered fluid is used for backwashing while filtration continues during the sequence.

Advantages- Filter fineness down to 50 µm

- Throughput as high as 10.000 m³/h (44,000 gpm)

- Simpel and robust

OptiFil

- The OptiFil® filter is a fully automatic, continuous backwash filtration system capable of capturing solids as fine as 1 micron. It can achieve this fine filtration level as a result of a patented backwash mechanism design that prevents solids bypass. In the center of the OptiFil® multi-layer cylindrical screen lies one single filter media layer. That layer is available in metal fabric, sintered stainless steel fleece or woven synthetic media, all in a multitude of micron ratings. Solid contaminants are either retained inside depth media or on top of surface media. After the preset pressure drop across the OptiFil has been reached, the backwash mechanism is triggered and the screen is cleaned methodically in a matter of seconds via backwash. An extremely small percentage of the process flow is used at any given moment for backwashing purposes, therefore the reject volume is extremely low. The filtration process continues throughout the backwash sequence.

Advantages- Filter fineness down to 1 µm

- High backwash efficiency

- Patented backwash mechanism

ViscoFil®

- The ViscoFil® system is a fully automatic, continuous depth filtration system. A sintered metal fleece is used as the filtration layer of the multi-layer cylindrical screen. This depth filter fleece layer captures various sized and shaped solid particles. After the predetermined degree of solids contamination has been reached, the screen is cleaned via a systematic backwashing of small sections in a circular rotation pattern. Filtration continues during the backwash process.

Advantages- Filter fineness down to 3 µm

- Applicable for very highly viscous fluids

- Gel removal capability

CAKE AND PRECOAT FILTRATION

CakeFil

-

The Lenzing CakeFil is a fully automatic self-cleaning tubular pressure filtration system, otherwise known as a candle filter. This sophisticated filtration technology is centered around cake building, that is, a cake of solid contaminants in the liquid stream builds on each of the porous cake support cloths that cover the full length of the candle elements. This results in the cakes themselves becoming the filter media through which the clean liquid (filtrate) passes. Since the cake`s solids are size graduated, that is, the largest particles are in contact with the cloth and smaller ones are further away, very fine filtration is possible. Specifically, 1 micron filtration is achievable without filter aid and 0.5 microns is possible with filter aid. Captured solids can either retained or discarded as waste. The waste discharge can either be "dry to the touch" (around 40-50 % moisture content) following the automatic blowdown step or in pumpable wet slurry form. An automatic cake wasting step (prior to cake blowdown step) is also possible in the case of the dry cake discharge design. The sophisticated design of the filter candles used by Lenzing ensures uniform cake structure, thus fine filtration, as well as efficient cake discharge.

Precoat Filtration - Advantages- Filtration down to 0.5 microns with filter aid

- Suitable for corrosive fluids

- Dry-to-the-touch as well as slurry discharge

- Filter fineness down to 1 µm without filter aid

- Solid contents in the liquid feed of up to 10% in specific cases and operating conditions

- Efficient cake discharge

AUTOMATIC SELF-CLEANING FILTERS

ScrapeFil

-

The Lenzing ScrapeFil uses a cylindrical wedge wire screen to remove solid contaminants. The solids are captured on the outside surface of the screen as a result of an outside-to-inside flow of fluid. The wedge wire screen continuously rotates and is in contact with one single spring actuated scraper blade which serves to scrape off captured from outside surface of the screen, such that they fall into the conical sump of the housing. The geometric profile of the wedge wire strips that are welded together to form the screen dictate the micron rating of the screen as well as ist cleaning efficiency. A valve located at the bottom of the housing is actuated on a regular interval (timed) basis to discharge solids that have been removed by the scraper blade.

Cake Filtration - Advantages- Filter fineness down to 50 µm

- Excellent for viscous fluids

- Can filter fluids having a high solids content

FILTER HOUSINGS

Filter Housings

-

Filter housings available

- Bag filter side-liner

- Bag filter top-liner

- Multi bag housing

- Single cartridge housing

- Multi cartridge housing

- Plastic housing for bags or cartridges

- Unlimited flow rates

- Low solid content

- Filter fineness from 0,1 µm to 100 µm

Multi bag filter housing

-

- Closing design: lid including eyebolts or clamp, with or without lid lifting device

- Nominal pressure: 6 bar

- Temperature range: 110°C

- Bag size: 2

- Number of bags: 2 to 16

- Material: AISI 304, AISI 316L

- Ring design: steel / stainless steel and plastic ring

Multi cartridge housing

-

- Nominal pressure: 7 bar, 10 bar

- Temperature range: 110°C

- Cartridge length: 10“, 20“, 30“, 40“

- Number of elements: 3 to 160

- Material: AISI 304, AISI 316L

- End cap style: DOE, Code 3, Code 7, Code 8

Plastic housings for bags or cartridges

-

- Single bag / cartridge housing

- Nominal pressure: 6 bar

- Temperature range: 60°C

- Material: PP, PVDF upon request

- Bag size: 2, 5

- Connections: 2“

- Ring design: steel / stainless steel and plastic ring or special element

Sideline bag filter housing

-

- Closing design: flange lid including eyebolts

- Nominal pressure: 10 bar

- Temperature range: 110°C

- Bag size: 1, 2, 3, 4

- Material: AISI 304, AISI 316L

- Ring design: steel / stainless steel and plastic ring

Single cartridge housing

-

- Closing design: vee clamp

- Operating pressure: 7 bar (16 bar upon request)

- Temperature range: 110°C

- Cartridge length: 10“, 20“, 30“, 40“

- Material: AISI 304, AISI 316L

- End cap style: DOE, Code 3, Code 8

Topline bag filter housing

-

- Closing design: lid including eyebolts

- Nominal pressure: 20 bar

- Temperature range: 110°C

- Bag size: 1, 2

- Material: AISI 304, AISI 316L

- Ring design: steel / stainless steel and plastic ring

FILTER ELEMENTS

Filter Elements

- Filter elements available

- Meltblown filter cartridge

- String wound cartridge

- Pleated absolute filter

- Membrane filter cartridge

- Stainless steel filter

- Economic filtration for low solid content

- Resistant to all media depending on material selection

- Interchangeable with different brands

HisoFil

-

The Lenzing HisoFil filter cartridge is a unique pleated cartridge that was developed to filter liquids containing high solid loads. The HisoFil cartridge was designed with the benefits of flow velocity reduction in mind. At these low flow velocities, even small or soft solid particles can form a filter cake on the high surface area pleated media, contributing to high dirt holding capacity. The HisoFil cartridge design results in reduced cartridge replacement intervals as well as lower filtration costs. The best HisoFil cartridge applications include those in which labor costs associated with cartridge changeout are significant and operator safety is deemed to be critical.

- High dirt holding capacity

- Low filtration cost

- Very long service life

Meltblown filter cartridge

-

- Material: polypropylene

- 3-layer structure

- High dirt capacity at low pressure drop

- Temperature up to 60°C

- Filter fineness: 0.5-100 µm, nominal retention rate

- NSF42 certified, FDA conform

Pleated absolute filter

-

- Material: double layer polypropylene

- Without additives or adhesives

- High dirt capacity at low pressure drop

- Temperature: max. 60°C, 95°C upon request possible

- Filter fineness: 0,2-40 µm, absolute retention rate

Stainless steel filter

-

- Available in pleated or cylindrical design, basket filter

- Material: sintered stainless steel, wire cloth in many versions

- Filter fineness: 3-1.000 µm, absolute retention rate

- Temperatures up to 300°C

- Rigid construction for high differential pressures

- Manufacturing of customer specific designs possible

String wound cartridge

-

- Material: polypropylene or cotton

- Polypropylene or stainless steel core

- High dirt capacity at low pressure drop

- Temperature up to 70°C (PP) or 120°C (cotton)

- Filter fineness: 1-100 µm, nominal retention rate

Filter Bags

Absolute rated filter bags

-

- Multiple layer composite matrix with high quality microfiber and meltblown material

- Material: polypropylene

- Filter fineness: 0,75-25 µm

- Retention rate > 99%

- FDA conformity, free of silicone and other types of contamination

Active carbon bags

-

- Combination of active carbon media and polypropylene needle felt

- Large carbon contact surface and volume through loose carbon tablets fill

- FDA conformity, free of silicone and other types of contamination

- Adsorption of paint-, taste- and odor residues, removal of free chlorine or ozone, removal of disinfectant and other organics

DoubleFil

-

- Combination of active carbon media and polypropylene needle felt

- Large carbon contact surface and volume through loose carbon tablets fill

- FDA conformity, free of silicone and other types of contamination

- Adsorption of paint-, taste- and odor residues, removal of free chlorine or ozone, removal of disinfectant and other organics

Filter Bags

-

Filter bags available

- Needle felt bags

- Monofilament bags

- Microfiber bags

- Absolute rated bags

- Active carbon bags

- Economic filtration for low solid content

- Resistant to all media depending on material selection

- Interchangeable with different brands

Microfiber filter bags

-

- Multiple layer composite matrix with protective needle felt and compressed non-woven material

- Material: polypropylene

- Filter fineness: 1-100 µm, absolute retention rates: > 92%

- High oil absorptive properties

- FDA conformity, free of silicone and other types of contamination

Monofilament filter bags

-

- High quality monofilament

- Material: polypropylene, polyester, Nylon 6, Nylon 66

- Single layer design

- Filter fineness: 25-1.000 µm, absolute

- Retention rate: 98%

- High tensile strength

- Free of fiber migration

- FDA conformity, free of silicone and other types of contamination

Needle felt filter bags

-

- High quality needle felt with graded pore structure

- Material: polypropylene, polyester

- Filter fineness: 1-200 µm, nominal

- Retention rates up to 85%

- FDA conformity, free of silicone and other types of contamination

- Single and multiple layer designs with increased dirt capacity and / or extended service life available

Mechanical production

- We offer a wide range of production technologies - from challenging mechanical processing to the highest level of welding technology. Our experienced manufacturing engineers and welding experts support our customers in terms of design layout, material selection and by choosing the best possible production technology.

As a competent partner for the mechanical construction technology, we dispose of long lasting experience in the field of surface treatment. Depending on dimension and construction we are able to offer different technologies for the production of rust-resistant and acid-resistant steel.

Our competencies- Great variety of production capabilities from made-to-order production to series production

- Highest level of welding technology

- Processing of a wide range of material:

- Construction steel

- Acid- and heat-resistant steel

- Duplex steel

- Surface treatment

- Immersion and spray pickling

- Electrochemical polishing

- Extensive quality and safety management

- CNC-machining centers and boring machines with travel length up to 6,000 mm

- Turning centers up to 6,000 mm length and 1,300 mm diameter

- Universal milling machines

- Various approved welding procedures

- Pickling lines for components up to 7,000 mm length resp. 2,000 mm diameter

Production Technology and Machinery

- Range of Services

Our machinery and the associated production techniques make us a specialist in precise individual and special part production, as well as in the manufacture of small-series parts. The use of the right technology and highly precise production at the highest quality level mark us out as a reliable partner.- Vertical boring and 5 axis milling center with a travel length of up to 6,000 mm

- Several 5 and 6 axis processing centers, bed milling machines with travel lengths of up to 2,500 mm, simultaneous processing, as well as use of CAM software

- Turning with CNC and cycle-controlled turning machines with lengths of up to 6,000 mm and diameters of up to 1,290 mm

- Planing and slotting machines

- High-precision laser micro-boring systems

- Autogenous and plasma-cutting as well as water jet cutting

- A wide variety of sheet processing machines such as plate shears, mechanical press brakes and 4-roller roll-in machines

- Indoor cranes with a load-bearing capacity of up to 20 tons and span widths of up to 21 meters

Apparatus and Tank Construction

- Range of Services

According to our customers requirements, we manufacture apparatuses, tanks, and heat exchangers for storing, bottling, handling, manufacturing, and treating various media. The apparatuses and tanks can be adapted to local conditions in optimal fashion and can also be assembled on site in the case of difficult integration situations. Our welding engineers will be happy to support you in selecting the right materials.

Our range of services includes:- Pressure tanks

- Storage tanks for acids and lyes

- Heat exchangers

- Columns

- Reactors

Welding Technology

- Range of Services

Manufacturing high-quality welded seams requires a good command of the extremely complex welding processes. It requires a lot of experience and expertise regarding the different welding processes and the materials used. We have the necessary expertise to implement the projects of our customers and partners. Our workshop is excellently equipped with welding robots and machines.

Surface Technology

- Range of Services

As a qualified service provider in the area of mechanical production technology, we have many years of experience in numerous areas of surface technology. We offer a wide variety of technologies for surface and corrosion protection as well as for surface refinement for the optimal solution for your task.

Wear Technology

- Range of Services

Surface wear is one of the main reasons for component damage and the associated breakdown of machines and devices. Wear technology offers various processes for increasing the lifespan of machines and devices and thus avoiding breakdown and maintenance costs.

Maintenance / Assembly

- Range of Services

Our highly qualified employees characterizes to a large degree by a great level of awareness of safety matter, expertise, and technical production skills. This ensures a punctual, safe assembly of systems and machines, and, further down the line, safe operation.

Thanks to our many years of experience in the production and assembly of machines and in the construction of systems, our employees posess in the areas of- Workshop mechanics

- Assembly mechanics

- Transportation

Quality Assurance

- The center of excellence for quality assurance bundles our knowledge in the field of quality and offers this knowledge to our customers as a service.

We offer quality assurance with special equipment:- Optical measuring machine

- Material analysis device

- Hardness measurements

- Surface measurements

- Classic quality assurance

Our range of quality assurance services includes:- Production monitoring

- Verification of the established quality requirements

- Product and system approvals

- External supplier audits