Maag

Videos

Loading the player ...

- Offer Profile

- Maag Pump Systems, Automatik Plastics Machinery, Gala Industries and Reduction Engineering Scheer – four successful and well experienced companies have joined forces to become the global partner for the polymer industry. As manufacturer of gear pumps, pelletizing and filtration systems and also pulverizers we offer top-grade equipment for your demanding requirements – not only for polymer applications, but also for the chemical, petrochemical, pharmaceutical and food industry.

Product Portfolio

Pulverizers for polymers and other materials

- In the pulverizers segment, MAAG offers a wide range of Reduction Engineering Scheer pulverizers for different throughput ranges and applications. Our state-of-the-art product portfolio is based on 25 years of research, development, ongoing system improvement, and in-depth know-how in the grinding of plastics and other materials. The range of pulverizers extends from units for small throughputs such as for laboratory or pilot plant operations to pulverizer systems for medium to high throughputs. Key process parameters are the pulverizer disk geometry, the grinding gap setting, the feed rate of the input material, the temperature in the grinding chamber, and the screen fineness. Our pulverizer systems are characterized by high efficiency and top performance in terms of the ratio of produced kilograms to consumed energy.

Lab Pulverizer REX tech - The plastic cryogenic pulverizer is manufactured for cryogenic operation

-

The REX tech, our lab scale pulverizer, makes sampling and trials for R&D fast and simple. Depending on the selected equipment, the REX tech can be cooled with ambient air or nitrogen. This versatile cryogenic plastic pulverizer can service a wide variety of applications in which top-quality sample powders are required. Almost anything can be trialed on this unit engineered resins, rubber, adhesives, pharmaceuticals, and food grades on the lab pulverizer.

Benefits- Elimination of outside services for trials

- Less waste for in house testing

- Ambient & Cryogenic ready

- Versatile hopper design for inlet/outlet

- Small footprint, equipped with casters for easy portability

- Elimination of outside services for trials

Pulverizer REX basic - Ambient pulverizer for several different processes

-

The REX basic pulverizer was designed for users who do not require tight particle distribution specification. It can be used to pulverize a wide variety of materials. This air-cooled pulverizer serves compounding, extrusion, molding, and recycling markets. To further enhance its process capabilities, several different process cooling innovations can be added to the machine. Some engineered polymers require extremely low temperatures to enable processing. These cooling options make this unit a viable alternative to a full cryogenic plastic pulverizer.

Benefits- Wide field of applications

- Heavy-duty construction

- Special cooling systems for engineered Polymers

- Versatile and space-saving configurations

- Different disc configurations to increase output

- Wide field of applications

Pulverizing System 85XLP - The plastic cryogenic pulverizer with the ideal solution for in-house production

-

The Reduction Engineering pulverizer 85XLP, with its compact design, is the perfect fit for the medium throughput range or the ideal solution for In-House production. This unit, with its integrated PLC controls, assures the highest quality performance with minimal man-machine interface. As with all Reduction Engineering pulverizers, this unit incorporates our state-of-the-art technology that facilitates quick clean downs and change-over times.

Benefits- Energy efficient

- Shim-less gapping of discs

- Small footprint

- Remote access to machine interface

- Best control of particle size distribution

Pulverizing System REX duo - The plastic pulverizer is an economical ambient air-cooled solution for production

-

The REX duo series serves the demanding end user with expectations of best quality powder and highest throughput rates. Efficient utilization of its entire available power makes the REX duo Series the most economical ambient pulverizer in relation to kilograms produced versus power consumed. A small footprint (owing to its very compact dimensions) make this the right choice for the serious producer or toll processor. The duoPLUS version outperforms all other machines of its size in the market.

Benefits- High energy efficiency

- Small footprint

- Remote access to machine interface

- Various Disc configurations available

- Best control of particle size distribution

REC 100 - Plastic cryogenic pulverizer for systems

-

Our cryogenic plastic pulverizer systems use liquid nitrogen to cool down a feed material prior to and/or during milling to either help prevent its melting or decomposition, or achieve embrittlement. Because each product is unique, throughput rates vary for powder production in ambient air.

Benefits- Higher yield of particles in your target range

- Higher production rates

- Improved process safety due to the nitrogen inertness

- Higher yield of particles in your target range

Accessories for pulverizers

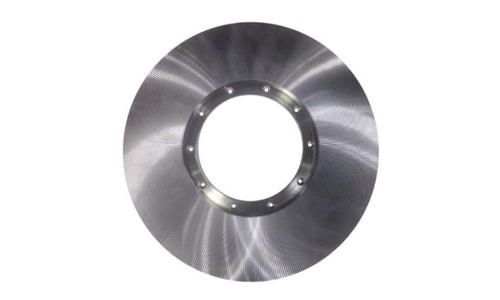

Disposable Disc Technology - Disc mill perfomance with reduced operation costs for pulverizer disc technology

- The patented Disposable Disc Technology eliminates the cost- and time-consuming regrinding off-site as was the case before. Instead, the discs are simply replaced by a set of new ones. The disposable discs are only 8 mm thick and weigh 6 kg per piece. Compared to the discs previously used, which can weigh 25 kg or more each, not only are the costs of transport considerably reduced, but the low weight also improves handling during installation and removal and shortens conversion time by approximately one third. The opening that passes through the center of the disc is 40% larger in the Disposable Disc design. This results in a significantly higher air flow, which improves cooling of the milling chamber and increases throughput rates.

Special retrofit kits are available to convert existing Reduction Engineering pulverizers to the Disposable Disc Technology.

Benefits- Lower cost of operation

- Light weight for easy handling

- Reduced shipping cost

- Increased airflow for better cooling

- Retrofit kits for existing RE pulverizers

COLORex - Color Mixer for ambient pulverizers and color pulverizers

- The COLORexTM Color Mixer is used to mix product in-line with a pulverizer to eliminate the typical cleanup time of a central mixer. It is designed for most polymers and for production rates up to 907 kg/h (2,000 lbs/hr). The COLORex can also be used off-line with a loader system and multiple feeders. The COLORex mixer is a great alternative to traditional high-speed mixers which are timeconsuming and costly to clean and maintain. The COLORex Color Mixer will allow the operator to color natural or virgin resins directly out of the pulverizer or from a silo. This is a high intensity mixer that will incorporate any pigment or additive homogeneously. The COLORex Color Mixer is controlled by variable frequency drive for the motor speed and 480V for the mixer itself. The loss-in-weight feeder (LWF) uses 110V. International voltages available. Spare parts are available upon request.

Benefits- COLORex Color Mixer is portable, easily moved to alternate locations

- On Demand Color (portable, versatile)

- Eliminates Batch Mixing

- Changeover time decreased (i.e. from black to yellow in under 1 hour)

- No confi ned space permits needed

- Color straight from the pulverizer or a weigh station

- COLORex Color Mixer is portable, easily moved to alternate locations