- Offer Profile

- SIEBTECHNIK TEMA is your specialist in the field of solid-liquid separation and bulk material processing.

With our Technology Center and main production site in Mülheim, Germany, we offer customized solutions to a broad variety of different industries globally. Quality and reliability have been the key to our success for 100+ years.

Solid-liquid separation

-

Sustainable & effective dewatering using centrifuges

Our solutions are sustainable and customized for a wide range of applications in a variety of industries. For each project, we discuss the various process steps with the customer and evaluate different process alternatives. This enables us to select the best solid-liquid separation concept and the most suitable centrifuge for each specific case. Our goal is to find the optimal solution for your needs.

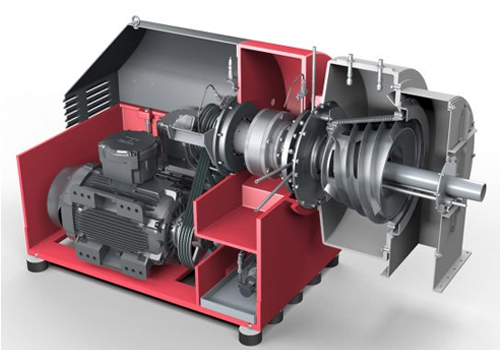

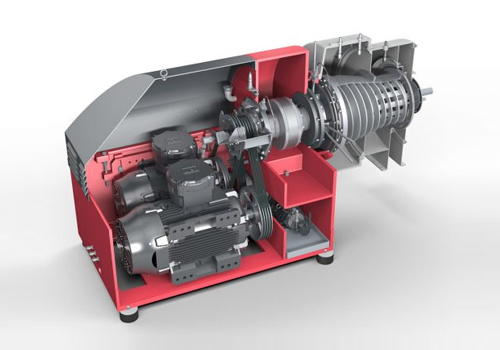

Filtering centrifuges

- Here you will find information about our filtering centrifuge types. These include the SHS pusher centrifuge, the CONTURBEX screen scroll centrifuge, the TURBOCASCADE sliding centrifuge and the HSG vibrating centrifuge.

Screen decanter

- Our decanter screens combine the special advantages of sedimentation and filtration. Find out here what advantages this has for you.

Sedimenting Centrifuges

- Our SBD and DZ decanter types offer the right solution for almost all process areas thanks to our customer-oriented, individual design for every user.

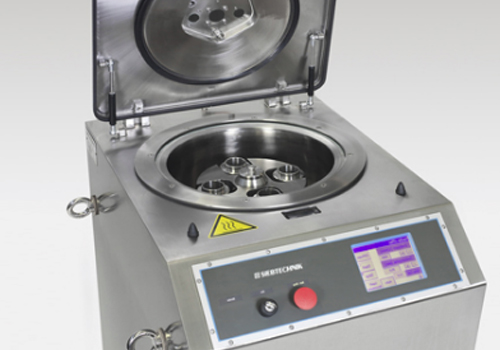

Laboratory Centrifuges

- SIEBTECHNIK TEMA offers two different Laboratory Centrifuges for laboratory-scale tests and for the preparation of small quantities. Find out more about CENTRILAB and CENTRIFLEX.

Mineral Processing Equipment

- Multotec designs, builds, manufactures, installs and maintains equipment throughout the entire value chain of mineral processing plants across all commodity sectors, from diamonds to coal, gold, iron ore, platinum and phosphates.

Solid-liquid separation & dewatering

- Multotec's solid-liquid separation solutions provide optimal dewatering and metals/product recovery in various markets, including chemical and mineral processing.

System Solutions - Tailor-made, directly from the OEM

Lithium 3

- The perfect solution for lithium processing: continuous centrifuges, peeler centrifuges and dryers

Centrifuge systems

- Our centrifuge & dryer systems offer you state-of-the-art technology, customer and product-specific special equipment, individual advice in pre-sales and reliable support in the after-sales process.

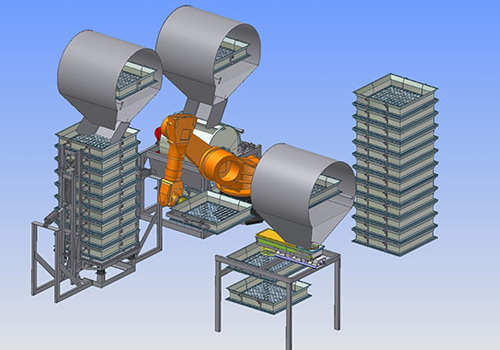

Automated sample preparation and analysis

- With our robot-based sample preparation and analysis systems, we free the laboratory from routine analyses and relieve employees of constantly repetitive tasks.

APS Unpacking Station

- Optimize your workflow with the APS Unpacking Station! Our ergonomic, low-dust solution ensures excellent visibility while unpacking SLS parts from changing frames. Featuring efficient recycling of used powder, our Unpacking Station enhances the downstream processes of unpacking, sieving, and waste powder collection in additive manufacturing.

Semi-mobile pulsator jig

- Our Semi-mobile pulsator jig is always the perfect solution if you want to avoid long transportation routes or if the time limit on the amount of material makes the construction of a plant uneconomical.

Pneumatic Tube System

- The fully automatic transport of bulk material samples to the laboratory is carried out by our Pneumatic Tube Systems, which are individually designed and manufactured for your spatial conditions.

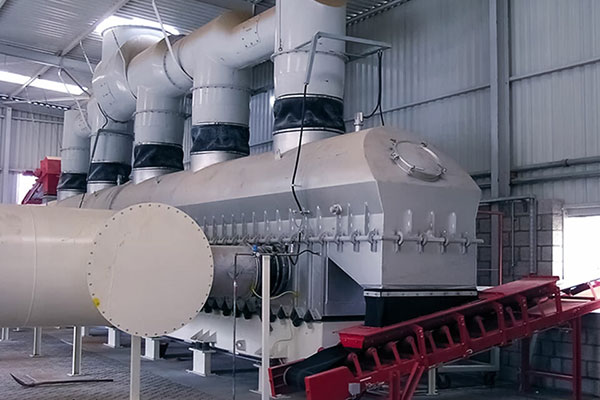

Drying - Thermal dryers & Fluidized bed systems

- In the field of drying, we work closely with our German sister company ALLGAIER PROCESS TECHNOLOGY GmbH in Uhingen. ALLGAIER PROCESS TECHNOLOGY GmbH has a broad portfolio of fluidized bed, drum and dispersion dryers and can offer our customers the optimum dryer type for every application. Upon request, SIEBTECHNIK TEMA can also combine centrifuges and dryers into a complete package, including interface responsibility.

Drying

- In industrial drying, the most important thing is an energy-efficient process. ALLGAIER PROCESS TECHNOLOGY offers its customers dryer systems and plants that are adapted to different products. They are based on the technology of rotating Drum Dryers, Spray Dryers and Cdryer as well as fluidized bed technology.

Cooling

-

In the industrial processing of raw materials, in many cases the dried or heated product must be cooled before further processing.

ALLGAIER PROCESS TECHNOLOGY cooling systems and plants are used in the processing industry for construction and mineral materials, in the mining, stone and soil, plastics and ceramics sectors, as well as for waste/recycling, bio fuels/pellets, in the foodstuff and the chemical and pharmaceutical industries.

Sample Dryers

- The Sample Dryers are used for the automatic, batch-wise drying and deagglomeration of moist or wet bulk samples.

Sampling

-

For the sampling and sample preparation of bulk materials and suspensions of all kinds, we plan and manufacture sample taking & sample preparation systems tailored to your individual requirements.

SIEBTECHNIK has the right solution for every task or can create one together with you. Improve the precision of your analysis with our technology, because the analysis begins with the sampling of the substances!

SIEBTECHNIK machines are also user-friendly, easy to maintain and, above all, future-proof – thanks to our specialized service personnel and exemplary spare and wear parts service, even for older machines.

Basics of sampling

- The first step towards successful analysis is representative sampling and sample preparation. Read here what needs to be considered.

Sampling Equipment for Conveyor Systems

- Removal of a single sample from the moving belt, over the full material cross-section directly from the belt or at the belt discharge.

Sampling Equipment for Downpipes

- Safe sampling from unpressurized pipes or chutes with our cross-sectional samplers or point samplers.

Sampling Equipment for Suspensions / Turbidity

- Sampling of minerals, ores and concentrates during wet processing from unpressurized pipelines.

Automated sample preparation and analysis

- With our robot-based sample preparation and analysis systems, we free the laboratory from routine analyses and relieve employees of constantly repetitive tasks.

Splitter

- We have various devices in our range for dividing samples. With the Turnstile divider, the Rotary divider and the Rotary pipe divider, you can divide a wide variety of sample materials.

Sample Collectors

- If samples can only be collected at longer intervals, we offer the option of storing them in so-called Sample Collectors of various sizes until collection.

Sample Dryers

- The Sample Dryers are used for the automatic, batch-wise drying and deagglomeration of moist or wet bulk samples.

Crushing

-

Machines for industrial processes, for pilot plants or for sample preparation in the laboratory

From our standard product range, we customize your jaw crusher, Hammer- and hammer impact mills, single/double roller mills, Cone crushers, Disc mills, Ball mills and Vibrating mills to best suit your requirements.

Industrial

-

Machines for the continuous or batchwise Crushing & Milling of materials or mixtures of materials.

Do you need machines for product development and initial pilot productions? We can also offer you suitable machines for this.

In the Laboratory

- Machines for sample preparation in the laboratory.

Low contamination, easy to inspect and clean - for reproducible analyses.

Analyzing

-

grain size distribution, drum strength, skeleton density and moisture content

In addition to devices for analyzing and determining particle size distribution, trommel strength, skeletal density and moisture, we also offer Dividers for the representative reduction of sample quantities and Laboratory Centrifuges for separating solids from suspensions.

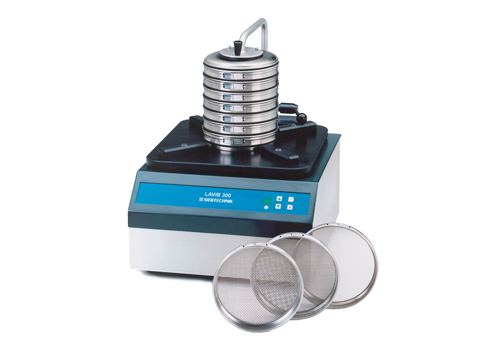

Analytical Screening

- Grain size and grain distribution play an important role in quality assurance, processing, research and development. Our portfolio of machine types is as diverse as the areas of application for test sieve shakers.

Solid Testing Drums

- The automatic Solid Testing Drums are used to determine the drum strength in accordance with the relevant DIN, ISO and ASTM standards for coke, iron ore and sinter.

BULKINSPECTOR gas pycnometer

- With the BULKINSPECTOR, the world's first fully automatic gas pycnometer, weighing and volume determination are carried out automatically in the device.

Automated laboratory sample preparation and analysis

-

We free your laboratory staff from routine analyses and relieve them of repetitive tasks.

Reliable, precise, reproducible and documented!

Laboratory Centrifuges

- SIEBTECHNIK TEMA offers two different Laboratory Centrifuges for laboratory-scale tests and for the preparation of small quantities. Find out more about CENTRILAB and CENTRIFLEX.

Laboratory sample splitter

- Laboratory sample splitters can be used for the quantitative division of dry, granular, powdery samples.

Divider 8/200

- This distributor is suitable for simple, fast distribution of free-flowing powders and granulates to 8 samples.

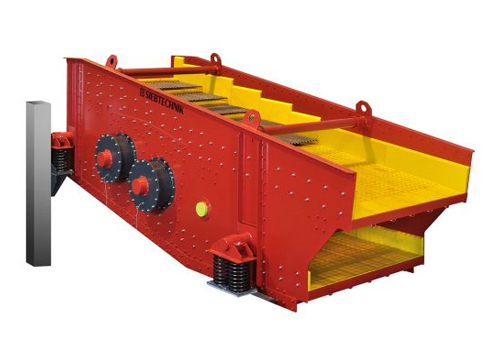

Screening - Modern machines for individual requirements

- SIEBTECHNIK TEMA has the right solution for every task. Our screening machines are suitable for the filtration, screening and classification of liquids and solids in a wide range of industrial processes. Reliable and clean separation of heavy, light, large, small, dry, dusty or even wet, sticky materials is always guaranteed.

Classify

- Whether processing raw materials, manufacturing end products or recycling - our screening machines offer a fast and effective method of classifying materials by size and preparing them for further use.

Dewatering

- Our wide range of screening machines enables the industrial dewatering of bulk materials for a wide variety of applications. Whether elliptical vibrators, linear vibrators or curved screens, our products are tailored to the specific requirements of your industry.

Analytical Screening

- Grain size and grain distribution play an important role in quality assurance, processing, research and development. Our portfolio of machine types is as diverse as the areas of application for test sieve shakers.

Control screening

- Foreign substances contained in powders and suspensions that remain undetected can result in downtime or expensive repairs to machine and equipment parts. That's why you can protect your production with our Control Screening Machines.

Accessories for Screening Machines

- Here you will find an overview of our extensive range of screening machine accessories, e.g. atomization, wear protection, drive consoles, air suspension, counter-swing frame, dust protection, double imbalance gearbox, hybrid suspension or special screen linings.

Sorting

-

Efficient sorting for first-class results

Sorting is an essential step in processing and recycling. Density sorting is particularly important for materials with small differences in density. Conventional methods such as simple counter-current rinsing reach their limits here. Instead, a vertical, pulsating flow through the sedimentation bed is required to ensure efficient separation. This technique is particularly invaluable for materials such as sand, gravel, slag, ores, construction waste and contaminated soils.

Pulsator Jig

- Our oscillating Pulsator Jig is specially designed for separating light material from heavy material with a grain size >1 mm.

Semi-mobile pulsator jig

- Our Semi-mobile pulsator jig is always the perfect solution if you want to avoid long transportation routes or if the time limit on the amount of material makes the construction of a plant uneconomical.

Mineral Processing Equipment

- Multotec designs, builds, manufactures, installs and maintains equipment throughout the entire value chain of mineral processing plants across all commodity sectors, from diamonds to coal, gold, iron ore, platinum and phosphates.

Filtering

-

Seperate, clarify, clean & increase performance

Filtration is an important process in many branches of industry and is crucial for the purity and quality of products as well as for environmental protection. Filtration is used to separate solids from liquids, which plays a key role in the chemical, pharmaceutical and food industries, among others.

Filtering centrifuges

- Here you will find information about our filtering centrifuge types. These include the SHS pusher centrifuge, the CONTURBEX screen scroll centrifuge, the TURBOCASCADE sliding centrifuge and the HSG vibrating centrifuge.

OPTIMA industrial filters

- STEINHAUS OPTIMA industrial filters are available in various designs.

OPTIMA slotted screens

- STEINHAUS OPTIMA wedge wire screens are made of wear-resistant, alloyed, corrosion-resistant steels. Flat screens, curved screens and slotted screen baskets are available.

Continuously Washing Up Flow Sand Filter

-

SIEBTECHNIK TEMA Continuously Washing Up Flow (CWUF) sand filters are deep bed gravity filters, that continuously self-clean during operation.

Lamella Clarifier / Settler

- Our Lamella Clarifier / Settler is the space efficient settling solution for purification of water and wastewater, including re-use of process and backwash water.

Gravity Drainage Deck

- Gravity Drainage Decks are used to thicken sludges with low suspended solids of 0.3 - 1.5 %. Free drainage of liquid by gravity through porous belt, aided by plough turning action.

Belt Filter Press

- Our SIEBTECHNIK TEMA Belt Filter Press (BFP) is designed to provide a versatile and cost-effective solution for dewatering a wide range of sludges.

Solid-liquid separation & dewatering

- Multotec's solid-liquid separation solutions provide optimal dewatering and metals/product recovery in various markets, including chemical and mineral processing.

Conveying

-

Conveying is at the heart of modern industry and with a focus on Pneumatic Tube Systems and Channel Conveyors, we specialize in the manufacture of bespoke conveying systems that are indispensable in a wide range of industries.

Conveyor systems tailored to your process

Our Pneumatic Tube Systems and Channel Conveyors move your materials precisely, efficiently and reliably. Imagine bulk material samples being transported effortlessly to the laboratory, product distribution chutes evenly feeding screening machines or discharge chutes emptying material bunkers in primary crushing plants – all with maximum precision and efficiency.

We know that no conveyor system can meet all requirements. That’s why we offer a diverse portfolio of conveyor systems that can be individually adapted to the needs of your industry. Whether bulk goods, piece goods or sensitive materials – our Pneumatic Tube Systems and Channel Conveyors offer tailor-made solutions to optimize and speed up your processes.

Pneumatic Tube System

- The fully automatic transport of bulk material samples to the laboratory is carried out by our Pneumatic Tube Systems, which are individually designed and manufactured for your spatial conditions.

Channel Conveyors

- SIEBTECHNIK TEMA Channel Conveyors are used for conveying granular bulk materials.

Vibrating Equipment

- Exciter driven screening machines & vibrating motor driven equipment, which includes screening machines, grizzly feeders, tube feeders and other specialty equipment for mineral processing.

Conveyor System Solutions

- Multotec’s conveyor system solutions are proven to reduce downtime and belt slippage. Each product in the conveyor belt system solution range works to increase the lifespan of your loading points.