- Offer Profile

- Since 1995, Molinari has been producing refining mills to reduce rubber chips from 0 to 4mm. To complete the range of our products, we have designed two completely new machines: the primary shredder TP and Helyos, the granulator with vertical axis.

THE MACHINES

TPm SERIES

-

Single-shaft Shredder

Optimal performance in terms of energy saving, maintenance and productivity

MATERIALS- END LIFE TYRES

- ORGANIC WASTE

- UNDIFFERENTIATED WASTE

FEATURES- LOW SPEED

- ADJUSTING BLADES

- SCREEN

- TELEASSISTANCE SERVICE

- PRESSER

TPm SERIES

The single-shaft shredder of TPmSeries is a perfect machine in the grinding sector.

The trapezoidal blades and the speed of rotation guarantee an optimal performance in terms of energy consumption, production and maintenance.

The structure of the machine is made by very thick plates, in order to guarantee long lasting, robustness and reliability.

A presser guarantees the grinding of material with big dimensions, avoiding the clogging phenomenon. The motorization varies in function of the types of materials that have to be ground.

A screen is installed under the rotor. Differently from the other shredders on the market, thanks to this screen you can get a final homogenous ground product according to the dimensions of the screen chosen. The dimensions of the holes of the screen vary from a range of 40 to 400mm. The productivity varies in function of the dimensions of the holes of the screen: the hourly output increases as the size of the hole.

A PLC management allows the customer to modify certain operating parameters autonomously, or to follow a preset machining cycle.

TP SERIES

-

primary shredders for PFU

The perfect machine for the volume reduction of ELTs and the production of alternative fuels.

MATERIALS- END LIFE TYRES

- WOOD

- BIG BAG

- FISHING NETS

- COPPER CABLES

FEATURES

- TRUCK TIRES UP TO 120 CM DIAMETER

- LOW SPEED OF SHREDDING

- TWO INDEPENDENT SHAFTS

- SCREEN

- ADJUSTABLE FIXED BLADES

TP SERIES

The machines of TP Series are perfect for the volume reduction of ELTs and the production of alternative fuels.

The machines of TP Series are the first that make a recovery of used tyres.

They can treat either car and truck tires up to 120 cm diameter, and some types of industrial and agricultural tires. Low-speed rotation is the winning feature of this shredders.

They consist of two rotors with opposite rotation, independent of each other. The cut is possible thanks to the action of the rotating blades on fixed blades installed on a traverse between the two rotors.

The machines can be equipped with a screen, which allows to obtain a product of defined dimensions, suitable for use as TDF.

The rotating blades and the fixed blades are interchangeable and can be sharpened. TP SERIES ELTs primary shredders

hTP SERIES

-

primary shedders

Ideal for general waste, loose or in bales

MATERIALS- UNDIFFERENTIATED WASTE

FEATURES- RIGIDITY AND RELIABILITY IN TIME

- INDEPENDENT ROTORS

- FOR GENERAL WASTE, LOOSE OR IN BALES

hTP SERIES

For material such as unsorted municipal waste and similar to urban, the shredder of the 'h' series completes the TP series.

Fixed blades are welded on a mobile central traverse. Fixed blades can be renewed by welding a wear-resistant material.

The central bar is designed to absorb any shock and it is released at presence of bulky intriturabile material. The traverse movement is effected by a hydraulic control unit dedicated.

MT SERIES

-

alternative fuels

Single-shaft secondary shredder for RDF

MATERIALS- UNDIFFERENTIATED WASTE

- WOOD

- PLASTIC

- FISHING NETS

- BIG BAG

FEATURES

- UP TO 30% OF ENERGY SAVING

- OUTPUT HOMOGENEOUS

- FOR ALTERNATIVE FUELS AND RDF

MT SERIES

The Molinari single-shaft shredder is an innovative machine in the field of grinding technology. It provides greater productivity than traditional fine shredders with presser, and may reduce energy consumption by up to 30%.

Unlike the other machines on the market, the Molinari single-shaft shredder does not need a presser to push the material against the rotor, thanks to the patented 'hollow rotor'. In fact, it is able to 'grab' the material without the aid of other devices, with the advantage of working in a continuous way and with a constant energy consumption.

Speed can be adjusted from 100 to 300 rpm, to use its full potential in terms of productivity and quality. Above the grinding chamber, a feeding device is mounted, which is composed of two rollers with teeth. They have the function of opening any agglomerate and bulky material, and particularly, of regulating the flow of material in the lower part where the cutting down takes place.

On the basis of the energy consumption, the rollers can stop interrupting the supply of the material, allowing the consumption to fall within the optimum parameters. It is equipped with a safety Release System designed to protect the rotor in case of presence of non-compliant materials.

The screen covers the 50% of the rotor. It is manufactured on Client's requirements. The model MT3000 is the perfect machinery for the production of RDF and other alternative fuels, because it guarantees the homogeneity and the final size of the treated material.

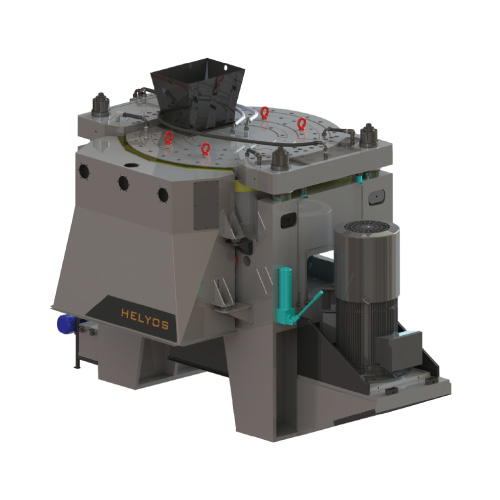

HELYOS

-

Granulator for used tyres

One technology for maximum gain

MATERIALS- END LIFE TYRES

- COPPER CABLES

FEATURES

- STEEL-FREE CHIPS, SUITABLE FOR AF AND SRM

- LOW TEMPERATURE OF THE OUTPUT

- LOW ENERGY CONSUMPTION

- EXPLOITAITON OF WIRE LIBERATED FROM SHREDS

HELYOS

Helyos is the perfect machine for granules and alternative fuel steel-free. It is a granulator having a vertical axis with opposing cutting planes.

This technology makes it possible to easily separate the steel contained in tires.

The principle of operation is unique in the field of ELT recovery, in fact enables the shreds to be quickly expelled from the grinding chamber, avoiding overheating.

Harmonic steel liberated from rubber can be removed by a magnetic separator. Helyos allows to adjust the grain size of the output, according to the needs of the customer market.

The possibility of easy adjustment of the rotors allows to obtain 40 x 40 mm chips suitable for use as an alternative fuel, or a 15 mm granules for rubber recovery as a secondary raw material. In both cases, the steel that is released from the rubber can be economically enhanced.

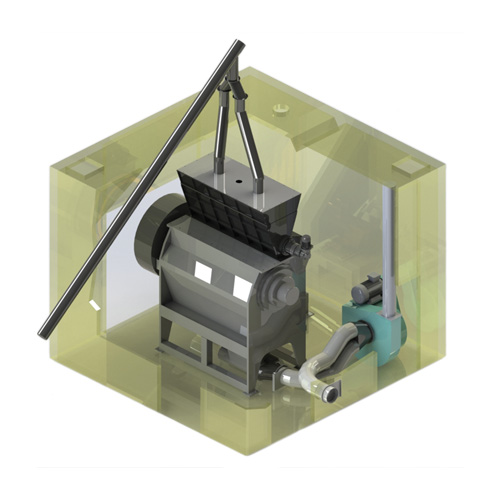

GRANULATOR MILLS MP Series

-

Rubber refiners

Rubber refiners from PFU

MATERIALS- PLASTIC

- END LIFE TYRES

- COPPER CABLES

- BIG BAG

- FISHING NETS

- MATTRESS

- WOOD

FEATURES

- ADJUSTABLE DISTANCE BETWEEN FIXED BLADES AND ROTARY BLADES

- STRENGTH

- EASY MAINTENANCE OPERATIONS

- EXCELLENT PERFORMANCES IN THE REFINING OF RUBBER CHIPS

MP SERIES

The Molinari mill/grinder is an innovative machine in the grinding sector.

Our grinder allows to obtain higher output than the conventional mills (such as hammer mills, blade mills) or to save up the energy consumption to 30-50% while maintaining the same production. It is a high performance machine, especially with products hard to be treated (such as wood of medium and large size, polyethylene pipes, PVC) that can be ground with screens having 12,8,6,4,3 mm holes (for instance to obtain sawdust from wood).

All the parts of Molinari machines can be cooled: machine body, bearings support, fixed blades and rotor shaft. Therefore, also materials such as rubber can be processed without difficulties.

A presser can be installed in the back part of the loading hopper thus making it possible to grind drums and tanks without having to shear or pre-shred them. The motion of the presser is controlled by photocells installed on the loading hopper.

MATERIALS

END LIFE TYRES

-

Molinari manufactures turnkey plants for end life tyres, from the whole tyre to

the rubber granule.

The machines involved in the process of tyres shredding are the following:

ORGANIC WASTE

- For organic waste shredding, Molinari suggest the following machines

UNDIFFERENTIATED WASTE

- For undifferentiated waste shredding, Molinari suggest the following machines

COPPER CABLES

- For copper cables shredding, Molinari suggest the following machines

PLASTIC

- For plastic shredding, Molinari suggest the following machines

BIG BAG

- For big bag shredding, Molinari suggest the following machines

MATTRESS

- For mattress shredding, Molinari suggest the following machines

FISHING NETS

- For fishing nets shredding, Molinari suggest the following machines

WOOD

- For wood shredding, Molinari suggest the following machine s