- Offer Profile

-

We are a company that specialises in the manufacture and supply of industrial fluid handling pumps

Founded in early 1993, BOYSER has followed an ascending path in terms of growth and product specialisation. At present, the company is majority owned by the German group ProMinent and its main activity is the manufacture of industrial peristaltic pumps, lobe pumps and accessories under the BOYSER brand.

Today, we export our products to five continents through the industrial group to which we belong or through more than 25 direct distributors across the globe.

New FMP-80 - Peristaltic Pump

FMP-80

-

It’s not just another model. Not just an increase in range.

It is a new concept of industrial peristaltic pump, an evolution that takes advantage of the properties of traditional peristaltic pumps.

PERISTALTIC PUMPS

DS-M SERIES PERISTALTIC PUMP

-

The DS-M pump range; peristaltic pumps specifically designed for dosing or transferring fluids at low flow rates and operating pressures up to 2 bar.

They are pumps that have been designed for continuous operation and great reliability, are self-priming and can pump liquids with small suspended solids or particles. Likewise, they are extremely handy to pumping fluids in a liquid state that contain air, gases or vapours.

The standard version comes with a three-roller rotor and a robust industrial design, while the DS-M/LAB version comes with a pump head design that enables easy tubing change with a maximum operating pressure up to 2 bar. They offer the advantage of having different diameters of tubing for the same pump head, with a double-head version also available.

Applications-

Food

Dosing of additives in breads and pastries, beverages, juices, sauces, colorants, lactic ferments, enzymes, syrup, etc. -

Chemicals

Dosing of all kinds of liquids in the process such as colorants, pigments, resins, latex, acids, dyes, defoamers, glues, oils, etc. -

Water Treatment

Sampling, feeding of filtering membranes, dosing of chemical products: ferric chloride, sodium hypochlorite, ferric sulphate, etc. Dosing of media with suspended solids: lime slurry, potassium permanganate, activated carbon, etc. Dosing of polymers, etc. -

Other Industries

Laboratories, paper industry, printing and packaging, ceramics, agriculture, mining, pharmaceuticals, engineering, etc.

-

Food

AMP SERIES PERISTALTIC PUMP

-

The AMP series peristaltic pumps are industrial pumps for transferring and dosing of fluids.

Available in 4 different sizes, they feature a compact design and offer different drive options depending on whether a continuous or intermittent flow rate is needed.

They are available with a wide range of connections and hoses depending on the type of media to be pumped and the characteristics of the installation, with specific versions for food or corrosive products among other options.

They are available in both continuous flow or regulable flow versions with frequency converters as well as special designs with pneumatic motors, hydraulic motors or DC motors. They are also available in “Skid” version with all the necessary installation and accessories to handle any vital operation in any industrial or sanitation process. They are specially useful for dosing or transferring abrasive products, products with suspended solids, corrosive or viscous products, as well as liquids in general.

Applications- Food

Dosing of additives in breads and pastries, beverages, juices, sauces, colorants, lactic ferments, enzymes, syrup, etc. - Chemicals

Dosing of all kinds of liquids in the process such as colorants, pigments, resins, latex, acids, dyes, defoamers, glues, oils, etc. - Water Treatment

Sampling, feeding of filtering membranes, dosing of chemical products: ferric chloride, sodium hypochlorite, ferric sulphate, etc. Dosing of media with suspended solids: lime slurry, potassium permanganate, activated carbon, etc. Dosing of polymers, etc. - Other Industries

Laboratories, paper industry, printing and packaging, ceramics, agriculture, mining, pharmaceuticals, engineering, etc.

- Food

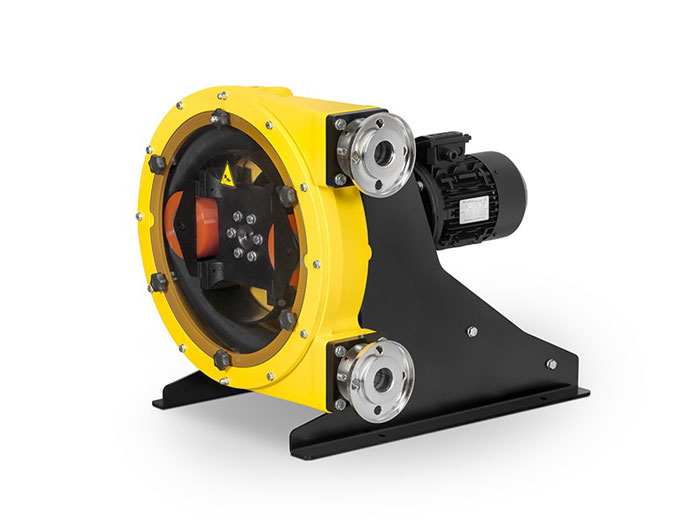

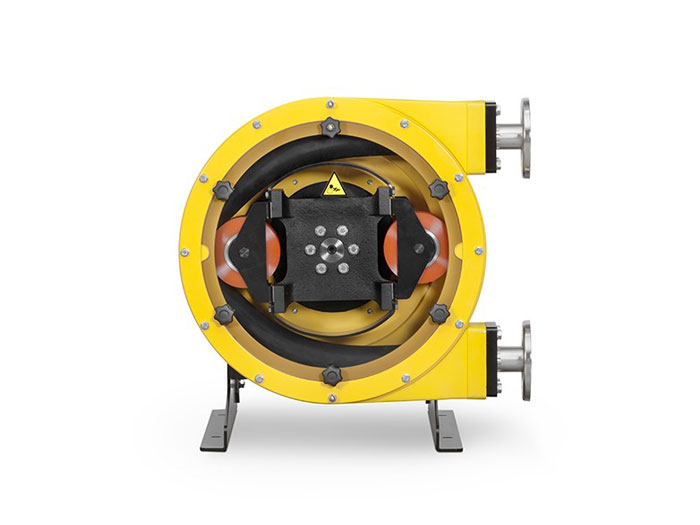

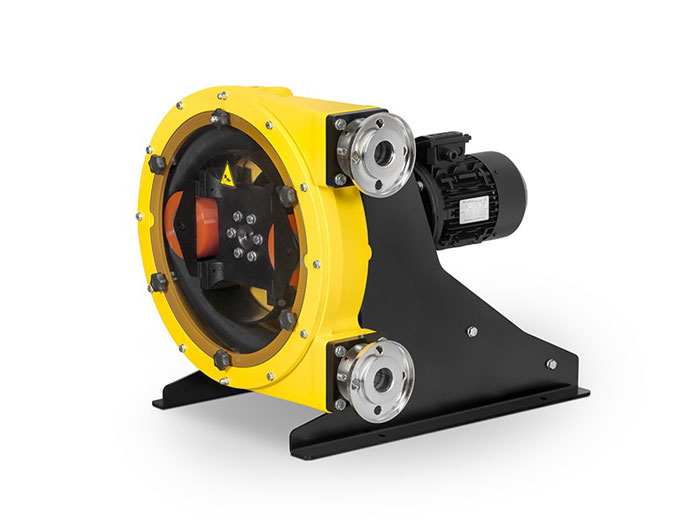

FMP SERIES PERISTALTIC PUMP

-

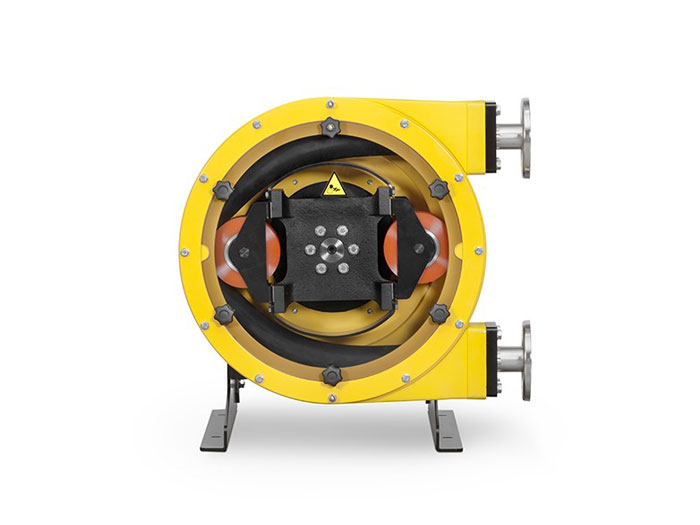

The FMP series peristaltic pumps are industrial pumps for transferring and dosing of fluids.

Available in 6 different sizes, they boast a very robust design with an integrated bearing housing and rollers with large diameters. They also offer different drive options depending on whether a continuous or regulable flow rate is needed.

They are available with a wide range of connections and hoses depending on the type of media to be pumped and the characteristics of the installation, with specific versions for corrosive products among other options. They are available with different drives and speed control options.

They are designed for an operating pressure of up to 8 bar and can handle flow rates from 300 to approximately 40,000 l/h. Its design allows great flexibility when selecting the materials of the hose, its process connections or its drive, keeping maintenance very simple, intuitive and easy to perform.

They are self-priming pumps, with unlimited dry-running capacity, reversible and very gentle with the media to be pumped. They are characterized by a high resistance to abrasion and the capacity to pump products considered as difficult due to their viscosity, corrosion, abrasion or fragility.

For decades now, the FMP range by BOMBAS BOYSER, S.L. has been used in multiple applications across five continents, with the number of users and their satisfaction increasing year after year.

Applications-

Food

Dosing/Transferring of additives in breads and pastries, beverages, juices, sauces, colorants, lactic ferments, enzymes, syrup, etc. -

Chemicals

Dosing/Transferring of all kinds of liquids in the process such as colorants, pigments, resins, latex, acids, dyes, defoamers, glues, oils, etc. -

Water Treatment

Sampling, feeding of filtering membranes, dosing of chemical products: ferric chloride, sodium hypochlorite, ferric sulphate, etc. Dosing/Transferring of media with suspended solids: lime slurry, potassium permanganate, activated carbon, etc. Dosing/Transferring of polymers, etc. -

Other Industries

Laboratories, paper industry, printing and packaging, ceramics, agriculture, mining, pharmaceuticals, engineering, etc.

-

Food

RBT SERIES PERISTALTIC PUMP

-

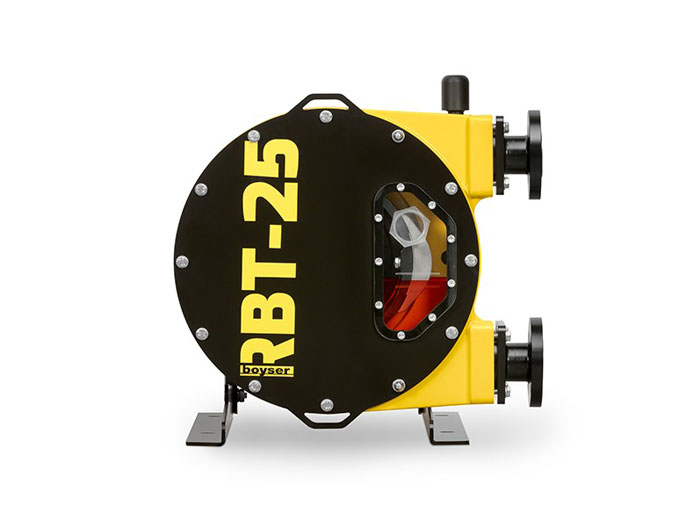

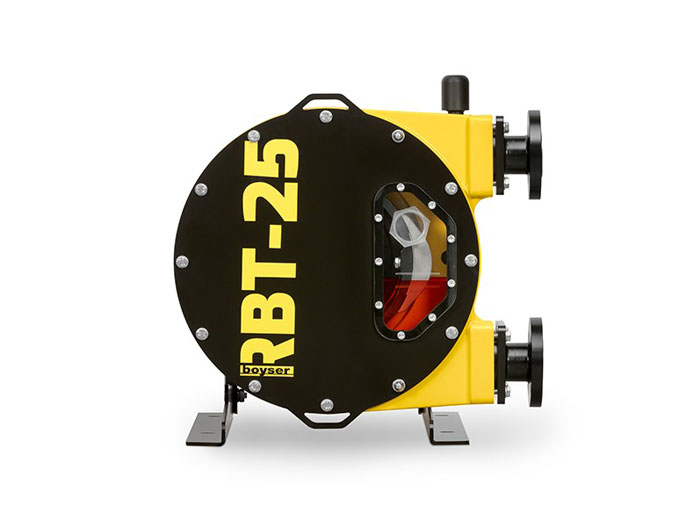

The RBT series peristaltic pumps are industrial pumps for transferring of fluids.

Available in 7 different sizes, they boast a very robust design with an integrated bearing housing, a highly reinforced rotor and shoes with an excellent coefficient of friction. They also offer different drive options depending on whether a continuous or regulable flow rate is needed.

They are available with a wide range of connections and hoses depending on the type of media to be pumped and the characteristics of the installation, with specific versions for corrosive products among other options. They are available with different drive and speed control options.

They are designed for an operating pressure of up to 15 bar and can handle flow rates from 200 to approximately 70,000 l/h. Its design allows great flexibility when selecting the materials of the hose, its process connections or its drive.

They are self-priming pumps, with unlimited dry-running capacity, reversible and very gentle with the media to be pumped. They are characterized by a high resistance to abrasion and the capacity to pump products considered as difficult due to their viscosity, corrosion, abrasion or fragility.

For decades now, the RBT range by BOMBAS BOYSER, S.L. has been used in multiple applications across five continents, with the number of users and their satisfaction increasing year after year.

Applications-

Food

Transferring of additives in breads and pastries, beverages, juices, sauces, colorants, lactic ferments, enzymes, syrup, etc. -

Chemicals

Transferring of all kinds of liquids in the process such as colorants, pigments, resins, latex, acids, dyes, defoamers, glues, oils, etc. -

Water Treatment

Sampling, feeding of filtering membranes, transferring of chemical products: ferric chloride, sodium hypochlorite, ferric sulphate, etc. Transferring of media with suspended solids: lime slurry, potassium permanganate, activated carbon, etc. Transferring of polymers, etc. -

Other Industries

Laboratories, paper industry, printing and packaging, ceramics, agriculture, mining, pharmaceuticals, engineering, etc.

-

Food

LOBE PUMPS

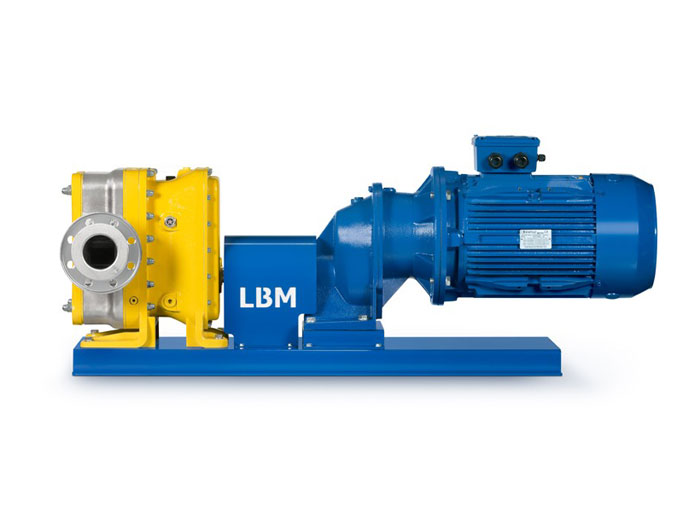

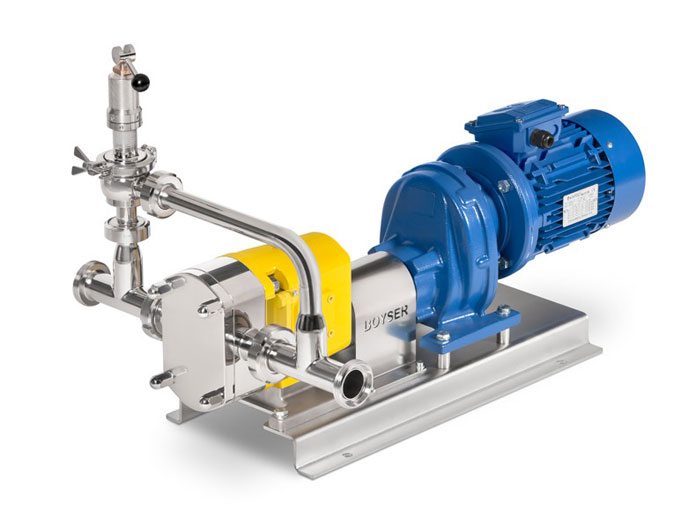

LB INDUSTRIAL ROTARY LOBE PUMPS

-

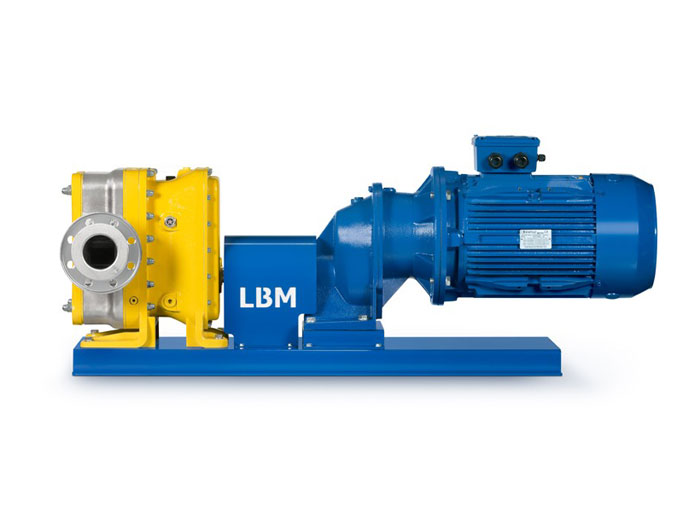

The LB series lobe pumps are industrial pumps with rubber-coated rotors, available in 4 different sizes whose technology is based on the design of two rotors featuring a modern design which are perfectly synchronised through their shafts and high-precision gears.

They are available with a wide variety of connections and made of two different kinds of stainless steel – either martensitic stainless steel for aqueous and industrial applications in general or austenitic stainless steel for more demanding applications in terms of corrosion or hygiene.

They are generally driven by geared electric motors with the option to integrate frequency converters for flow rate/speed regulation and control. They can also be driven by a hydraulic motor.

They are designed for an operating pressure of up to 10 bar depending on the size of their body and can handle flow rates from 4 m3/h to up to approximately 100 m3/h. Its design makes it possible to choose among different types of elastomers or even all-metal rotors depending on the application.

They are self-priming, reversible pumps suitable for fluids of practically any viscosity and feature a large solids passage, which – together with axial wear plates – makes them particularly interesting for pumping solids laden media. They come with mechanical seals as their shaft sealing system, which are particularly interesting due to their easy maintenance, compact size and mobile versions.

For a decade now, the LB range by BOMBAS BOYSER, S.L. has been used in multiple applications across five continents, with the number of users and their satisfaction increasing year after year.

Applications-

Food

Vegetable oils, molasses, glucose, different raw materials, food precessing residue, etc. -

Enology

Pumping of wine, must, grapes, destemmed grapes and practically any pumping or transfer operation within the winemaking process. -

Chemicals

Fertilisers and their corresponding raw materials, detergents and their corresponding raw materials, gels, glycerine, oils and fats, etc. -

Water Treatment

Transfer of sludge, MBR filtration, waste water, seawater, contaminated water, etc. -

Other Industries

Paper and cardboard, construction, petrochemicals, waste management, etc.

-

Food

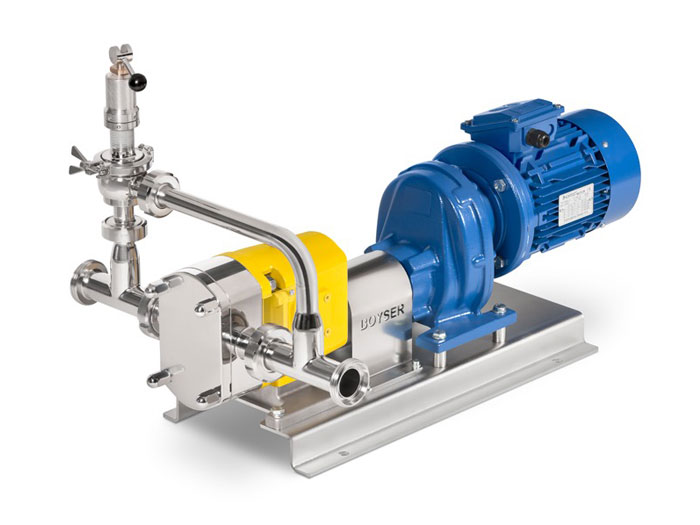

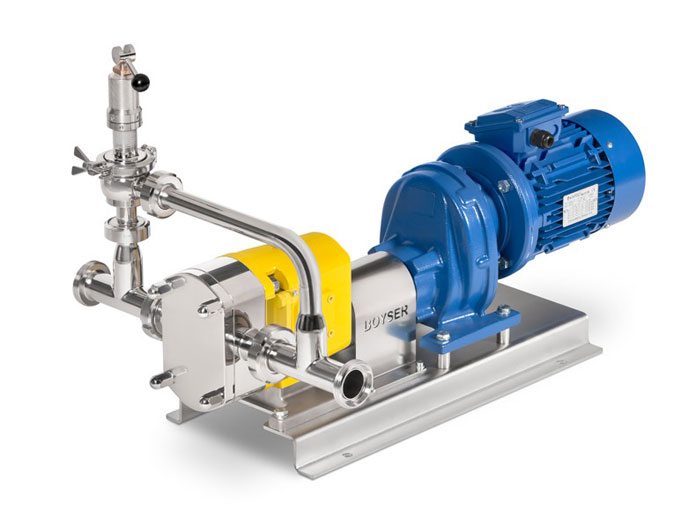

LIS - LIH SANITARY ROTARY LOBE PUMPS

-

The LIS and LIH series lobe pumps are sanitary rotary lobe pumps with rubber-coated rotors, available in 8 different sizes and designs whose technology is based on the design of two rotors featuring a modern design which are perfectly synchronised through their shafts and high-precision gears.

They are available with a wide variety of connections, featuring a sanitary or hygienic version and two other versions depending on the application and the required degree of certification – always in AISI316L stainless steel. The rotors are available with a tri-lobe or bi-wing design.

They are generally driven by geared electric motors with the option to integrate frequency converters for flow rate/speed regulation and control. They can also be driven by a hydraulic motor.

They are designed for an operating pressure of up to 12 bar depending on the size of their body and can handle flow rates from 50 l/h to approximately 30 m3/h.

They are reversible, pulsation-free, continuous flow pumps suitable for fluids of virtually any viscosity. They come with mechanical seals as their shaft sealing system and offer different lubrication or pressurisation options, such as the version with the double mechanical seal.

For a decade now, the LIS – LIH range by BOMBAS BOYSER, S.L. has been used in multiple applications across five continents, with the number of users and their satisfaction increasing year after year.

Applications-

Food

Dairy products, juices, concentrates, syrups, chocolate, honey, mayonnaise, ketchup, liquid egg, mustard, liqueurs, etc. -

Cosmetic

Cosmetic creams, toothpaste, shampoos, gels, essential oils, liquid soap, emulsions, etc.

-

Food

PERISTALTIC METERING PUMPS

DSM-CONTROL SERIES PERISTALTIC METERING PUMP

-

The DSM-CONTROL metering pumps with peristaltic pump heads are state-of-the-art metering pumps boasting a wide range of possibilities to ensure precise operation.

It offers valuable information, massive communications capabilities and cutting-edge automation or customisation options.

BASIC FEATURES- Flow rate: 0,01 – 30 l/h

- Pressure:

- Electrical connection: Universal, 100 – 230 V + 10%, 50/60 Hz.

- Screen: Digital display available in 12 languages

- Operation: manual, automatic, proportional or via process control systems.

- Motorisation: brushless integrated AC motor

- Electrical protection: Integrated NEMA 4X (IP-66) ingress protection

Applications-

Food

Dosing of additives, colorants, ferments, enzymes, sugar solutions, oils, sulphites, etc. -

Chemicals

Dosing of pigments, dyes, glues, peroxide, colorants, latex, etc. -

Water Treatment

Dosing of products with suspended solids, lime slurry, activated carbon, potassium permanganate, etc. Dosing of chemical products such as ferric chloride, sodium hypochlorite, ferric sulphate, etc. Dosing of polymers and flocculants, defoamers, etc. -

Other Industries

Mining, paper and cardboard, ceramics, construction, printing and packaging, etc.

AMP-CONTROL PERISTALTIC METERING PUMP

-

The AMP-CONTROL metering pumps with peristaltic pump heads are state-of-the-art metering pumps boasting a wide range of possibilities to ensure precise operation.

It offers valuable information, massive communications capabilities and cutting-edge automation or customisation options.

BASIC FEATURES- Flow rate: 5 – 410 l/h Pressure:

- Electrical connection: Universal, 100 – 230 V + 10%, 50/60 Hz.

- Screen: Digital display available in 12 languages

- Operation: manual, automatic, proportional or via process control systems.

- Motorization: AC motor with encoder. Electrical protection: IP-55

Applications-

Food

Dosing of additives, colorants, ferments, enzymes, sugar solutions, oils, sulphites, etc. -

Chemicals

Dosing of pigments, dyes, glues, peroxide, colorants, latex, etc. -

Water Treatment

Dosing of products with suspended solids, lime slurry, activated carbon, potassium permanganate, etc. Dosing of chemical products such as ferric chloride, sodium hypochlorite, ferric sulphate, etc. Dosing of polymers and flocculants, defoamers, etc. -

Other Industries

Mining, paper and cardboard, ceramics, construction, printing and packaging, etc.

Industries

WATER TREATMENT

-

Solutions for the water treatment industry, for both waste water and potable water.

Using our metering pumps with peristaltic pump heads, you can accurately meter any fluid commonly used in water treatment, whether they are abrasive products, chemical products, flocculants, defoamers, gaseous media or with a tendency to create gases, etc.

Transferring sludge and waste water and filtration or solids separation processes are also some common examples of applications for our large peristaltic pumps or our lobe pumps with rubber-coated rotors.

To supplement the range, we also have corrosion-resistant, magnetic drive, plastic centrifugal pumps as well as self-priming centrifugal pumps with open impeller.

MINING

-

Solutions for the mining industry as most applications involve abrasive and corrosive products for which the peristaltic pump is the best choice.

In mining, it is common to process fluids with a high level of suspended solids, which are very abrasive, causing frequent actions or process stoppages for equipment maintenance. With our peristaltic pumps, the only maintenance that needs to be done is replacing the pump hose and its lubricant, without abrasion affecting other vital parts of the pump as is the case with other pumping techniques. It is therefore an effective solution that stands out for its simplicity and versatility. The absence of mechanical seals or gaskets is just one of its many advantages, leading to hassle-free maintenance.

Another application in mining has to do with flocculants and coagulants that require gentle pumping of the media in order to preserve their fragile main chain segments and deliver optimal product use.

Other common applications are the metering of abrasive reagents and acids, with our pumps increasingly used in the leaching and filtration techniques of the modern mining process.

CHEMICALS

-

Solutions for the chemicals industry, for both the metering and transfer of media.

Using our metering pumps with peristaltic pump heads, you can accurately meter any fluid commonly used in the chemicals industry, whether they are abrasive products, corrosive materials, viscous substances, gaseous media or a combination of these.

The transfer of products during the manufacturing, storage or transportation process and filtration or solids separation processes are also common examples of applications for our large peristaltic pumps or our lobe pumps with rubber-coated rotors.

Shear-sensitive media or media with a tendency to polymerise are also a common application for our peristaltic pumps.

To supplement the range, we also have corrosion-resistant, magnetic drive, plastic centrifugal pumps, double-diaphragm pneumatic pumps, as well as internal gear pumps for viscous products.

PAPER

-

Solutions for the paper and cardboard industry, for both the metering of additives and transfer of media.

Using our metering pumps with peristaltic pump heads, you can accurately meter any fluid commonly used in the paper industry, whether they are abrasive products, corrosive materials, viscous substances, gaseous media or a combination of these.

The transfer of products during the manufacturing, storage or transportation process and filtration or solids separation processes are also common examples of applications for our large peristaltic pumps or our lobe pumps with rubber-coated rotors.

Products such as paper pulp, lime slurry, water with fibres, manganese hydroxide are just some of the common applications in transferring such as the metering of pigments, suspensions of talc and other chemicals in general.

To supplement the range, we also have self-priming centrifugal pumps with open impeller and double-diaphragm pneumatic pumps.

CONSTRUCTION

- Solutions for the construction and civil engineering industry, for both the metering of additives and transfer of media.

Using our metering pumps with peristaltic pump heads, you can accurately meter any fluid commonly used in the construction industry, such as waterproofing additives, accelerants or pigments.

The transfer of products such as cement, cement slurry, fibre-reinforced concrete, cellular concrete or bentonite is very common in our large peristaltic pumps.

Products such as different colourants, additives or solutions are some examples of common metering applications such as diatomaceous earth in filtration processes or the transfer of algae or other shear-sensitive media.

Products such as asphalt and bituminous solutions can be pumped using our internal gear pumps.

CERAMICS

-

Solutions for the ceramics industry, for both the metering of additives and transfer of media.

Using our metering pumps with peristaltic pump heads, you can accurately meter any fluid commonly used in the ceramics industry, whether they are abrasive products, corrosive materials, viscous substances, gaseous media or a combination of these.

The transfer of products during the manufacturing, storage or transportation process and filtration or solids separation processes are also common examples of applications for our large peristaltic pumps.

Products such as lime slurry, potassium permanganate, barium carbonate or manganese dioxide are some examples of common applications in metering such as the transfer of ceramic slip or kaolin.

To supplement the range, we also have self-priming centrifugal pumps with open impeller and double-diaphragm pneumatic pumps.

FOOD

-

Solutions for the food and beverage industry, for both the metering of additives and transfer of media.

Using our metering pumps with peristaltic pump heads, you can meter any fluid commonly used in the food industry, whether they are products with suspended solids, viscous substances, gaseous media or a combination of these.

The transfer of products during the manufacturing, storage or transportation process and filtration or solids separation processes are also common examples of applications for our lobe pumps or large peristaltic pumps.

Products such as different colourants, additives or solutions are some examples of common metering applications such as diatomaceous earth in filtration processes or the transfer of algae or other shear-sensitive media.

Our sanitary lobe pumps are intended for generally viscous products such as dairy products, honey, sauces, jams, fruit concentrates, syrups, etc. In contrast, our lobe pumps with rubber-coated rotors are used to pump products such as vegetable oils, molasses, fats and similar products. To supplement the range, we also have double-diaphragm pneumatic pumps and drum pumps for emptying drums.

ENOLOGY

-

We have specific solutions for the wine industry.

Without a doubt, our most popular products for this industry are our lobe pumps with rubber-coated rotors. One of its most attractive features for the industry is the fact that it can be used at any point of the winemaking process, as they can be used to pump anything from whole grapes to the finished wine for its final filtration and bottling, including destemmed grapes, must or even lees and fermented paste.

Transferring between tanks or emptying and filling lorries are also auxiliary jobs that our pumps can perform throughout the year as thanks to its mobile trolley and electronic speed control equipment, they are truly versatile and particularly useful pieces of equipment.

For winemakers who prefer peristaltic pumps, we also have a wide range of pumps whose gentle pumping of the media is truly unparalleled.

Our metering pumps with peristaltic pump heads also handle the metering of additives, sulphites, enzymes or gum arabic, to cite some examples of metering specific to the industry.s