ITT RHEINHÜTTE Pumpen

Videos

Loading the player ...

- Offer Profile

-

ITT RHEINHÜTTE Pumpen is a market-leading designer and manufacturer of centrifugal and axial flow pumps suited to corrosive, abrasive and high-temperature industrial process environments. Rheinhütte solutions serve specialty applications for the chemical, mining, renewable energy and refinery processes and include solutions for sulfuric acid, molten sulfur, fertilizer and chlorine-alkali electrolysis production among others.

Product Portfolio

Centrifugal and axial flow pumps

- More than 20 different pump types offer the right solution for your specific project. In close communication with you our experienced project teams develop individual concepts for your sophisticated application. And if you need a standardized application just profit from our extensive pump range.

CPDR - Standardized chemical pump in plastic

- Pumps of the CPDR and CPRF type family are horizontal, single-stage, end-suction, top-discharge centrifugal pumps, standardized to EN 22858 (formerly DIN 24256; ISO 2858 and ISO 5199). The installation length of type CPRF is simply longer about the channel width so that a free passage for the fluid is given. The pumps are used for handling chemically aggressive and/or inflammable liquids within the wide field of chemical processing and environmental technology. The CPDR with open impeller is foreseen for clean liquids and fluids with a small content of solids. The CPRF is able to handle fluids with larger solids. Both types are possible in close-coupled design instead of bearing block.

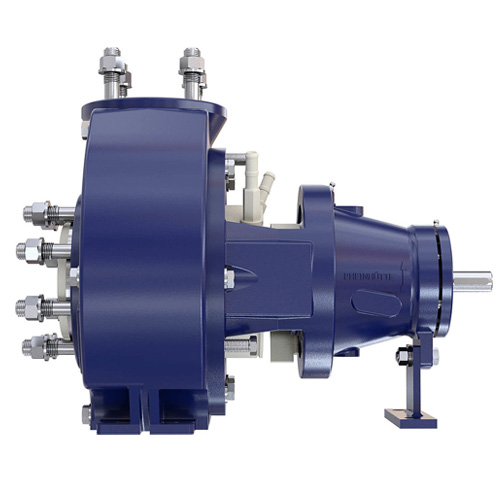

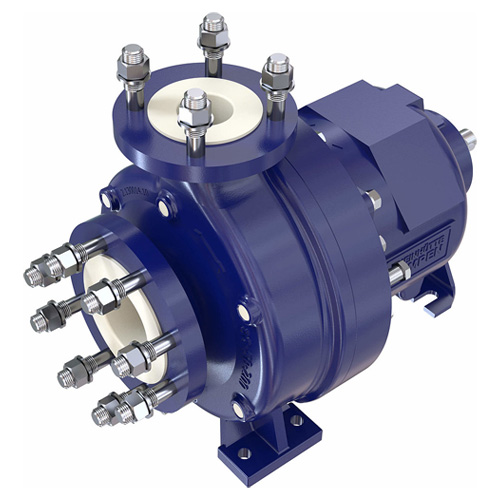

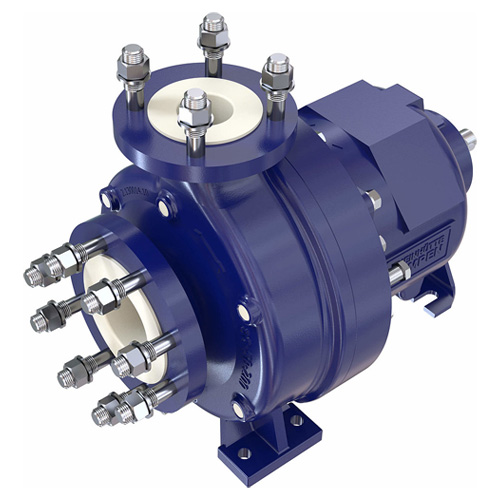

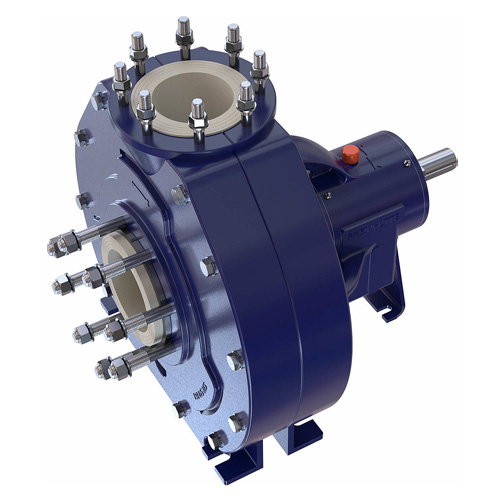

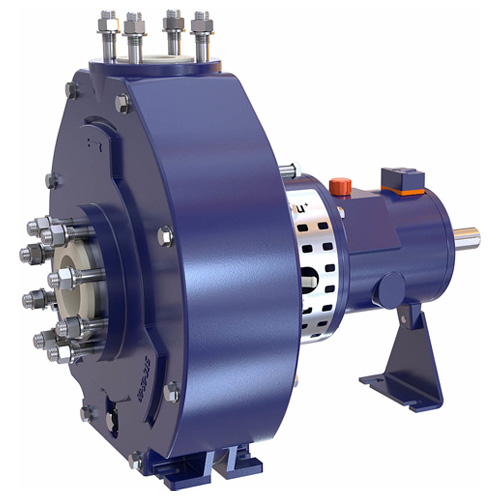

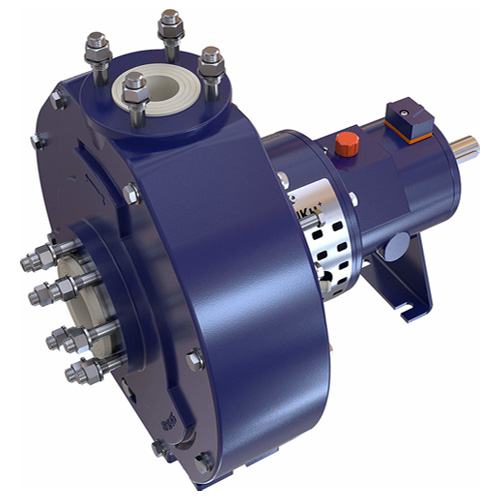

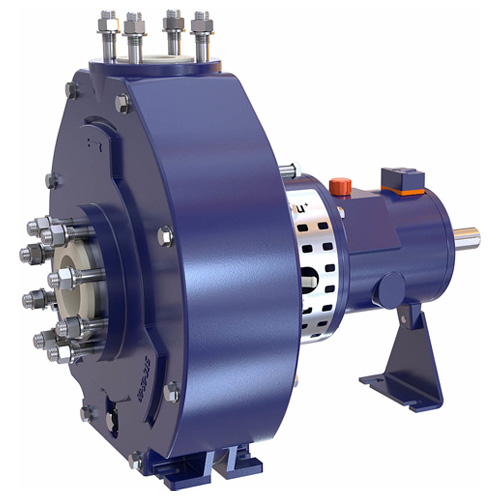

FGP - Liquid ring vacuum pump in ceramic

- Our FGP liquid ring pump is the suitable partner for difficult evacuation and compression processes involving gases and vapours in all corrosion-critical areas of application in the chemical industry. Together with the freely selectable operating medium of the liquid ring, the FGP allows volume flows of up to 700 m3/h. In compressor mode gas pressures of up to p2 max = 2.5 barg are easily created. In vacuum mode for aggressive media the pump produces suction pressures of p1 = 100 mbara up to p1 = 25 mbara with an additional gas ejector. And this all takes place at gas temperatures of up to 120 °C. The highly corrosion-resistant technical ceramic is perfectly suitable for all media containing chlorine and hydrogen chloride.

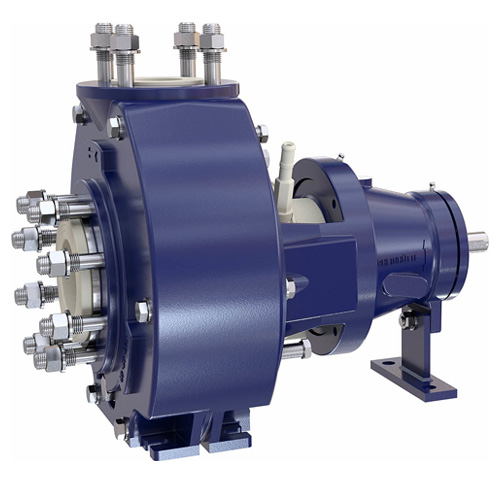

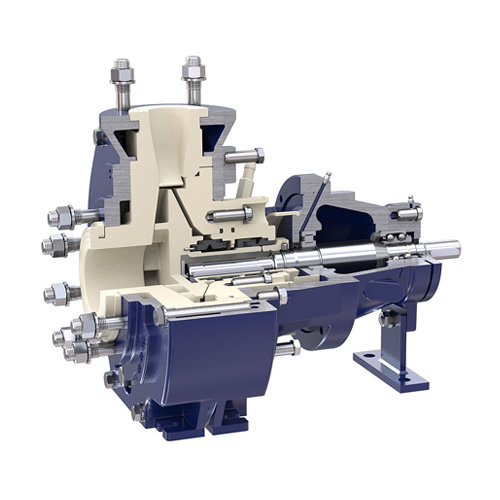

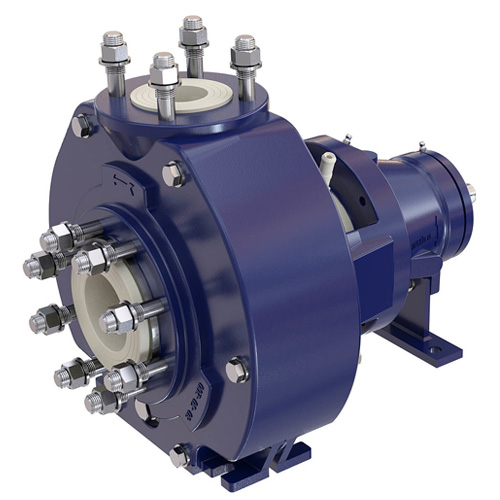

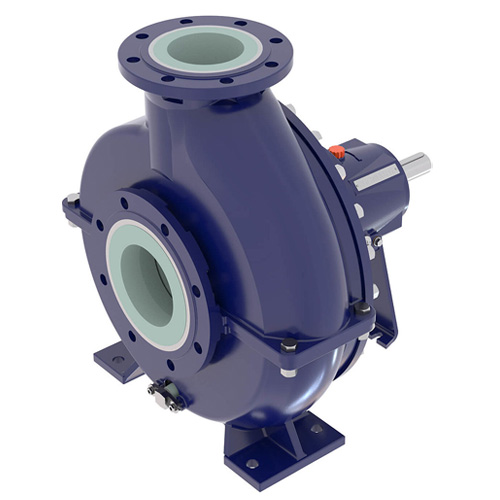

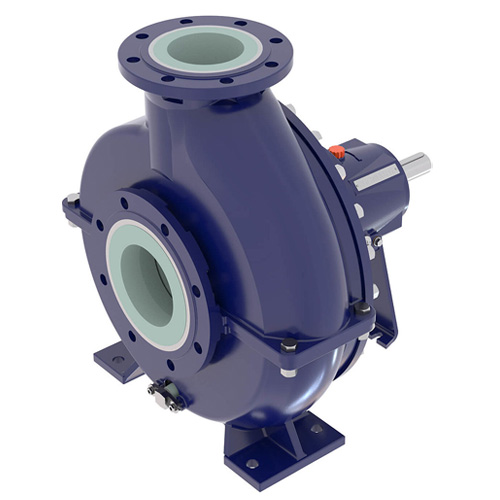

FNC - Standardized chemical pump in ceramic

- Pumps of the FNC are horizontal, single-stage, end-suction, top-discharge centrifugal pumps, standardized to EN 22858, ISO 2858 and ISO 5199. The wear resistance and universal chemical resistance offers great advantages for use in corrosive and abrasive media. FNC pumps are used for handling chemically aggressive and/or abrasive liquids within the wide field of chemical processing and environmental technology.

FNP - Standardized chemical pump with pfa-lining

- The standard chemical pump FNP according to EN 22858, ISO 2858, NF 44-121, BS 5257 and ISO 5199 is universally applicable in the chemical and pharmaceutical industry, in petrochemistry and general process engineering for pumping chemically aggressive and corrosive media.

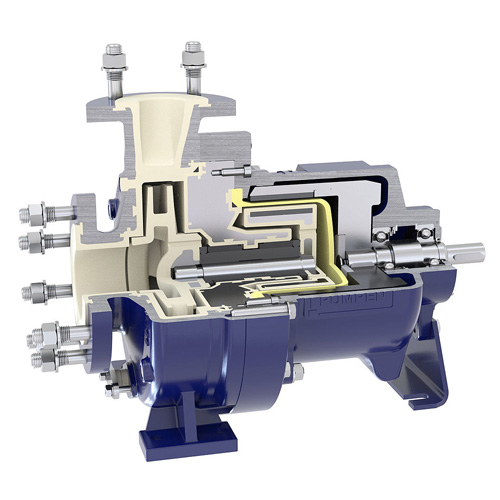

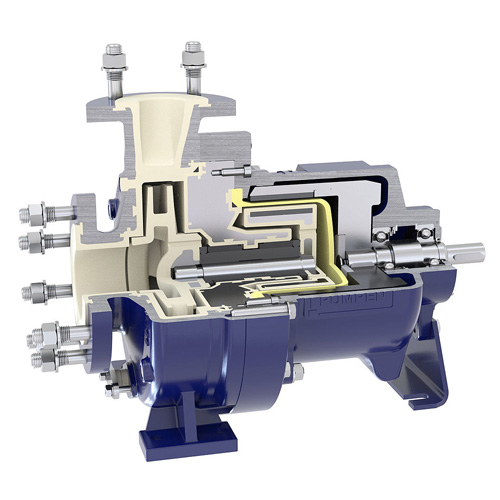

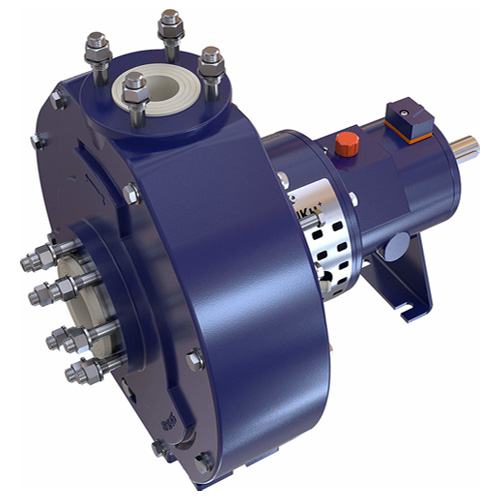

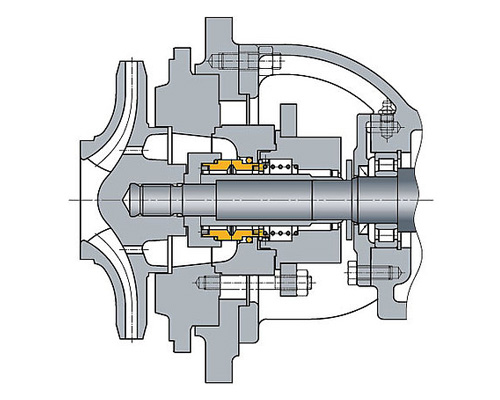

FNPM - Magnetic drive pump in plastic

- Pumps type FNPM are horizontal, single-stage, end-suction, top-discharge centrifugal pumps with magnetic coupling, dimensioned to comply with standards EN 22858, ISO 2858.

The scope of application covers the wide fields of chemical processing and environmental technology where chemically aggressive fluids of various concentrations at up to 190°C are to be handled. The constant standardization of the drive components and the unique magnetic cartridge reduce the variety of parts and enable cost-saving stocking concepts. The magnet cartridge is a pre-assembled, ready-to-use unit containing all core components of the magnetic drive pump (e.g. plain bearings, impeller and containment shells). Replacement takes only a few minutes - then the old unit can be reconditioned. The cost advantage over the usual quick-coupler unit: up to 25%.

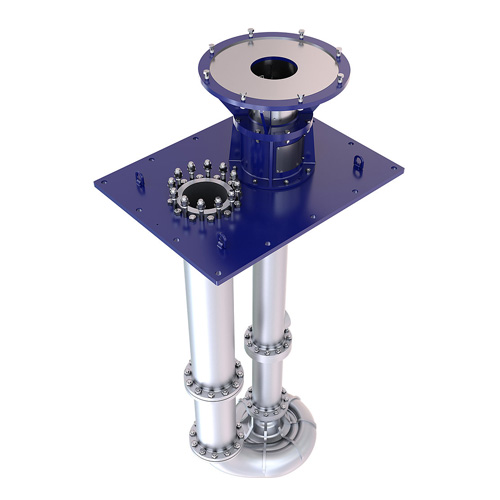

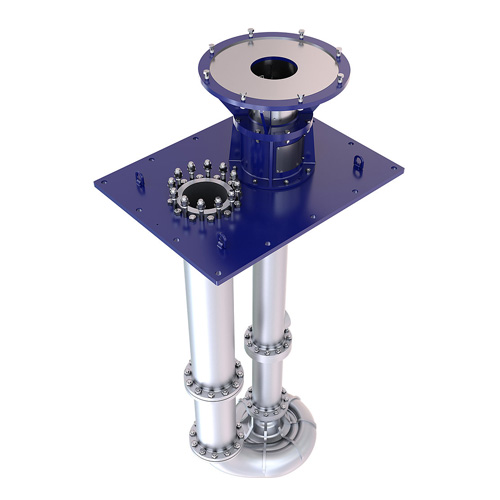

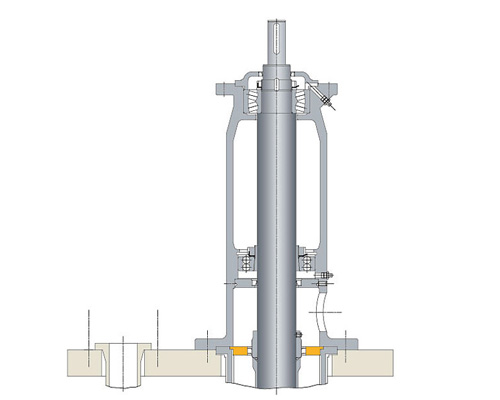

GVRN - Vertical chemical centrifugal pump in metal

- The GVS series was developed more than 50 years ago by Rheinhütte specially for use in acid applications in Germany. Constant further technical development and adaption to suit individual customer requirements have resulted in today's GVSO and GVRN pump series which have firmly established themselves on the international pump market.

GVSO - Vertical chemical centrifugal pump in metal

- 28 basic sizes in a single-stage or multi-stage design allow maximum flexibility even during the planning stage. This means that the GVSO covers volume flows of up to 4.000 m3/h and pumping heights of up to 150 m. Individual immersion depth adjustment from 0.5 to 17,5 m through the use of one or more intermediate bearings completes the maximum level of flexibility.

At the customer‘s request, the connecting dimensions and the shape of the sole plate can be individually adapted to the container and pressure flange. If constant temperatures and viscosities are required, e.g. in the case of molten sulphur, the GVSO is also available as a heated version. Here we offer a customised heating jacket system for steam and other heat transfer media. Only two additional connections for feed and discharge are required here.

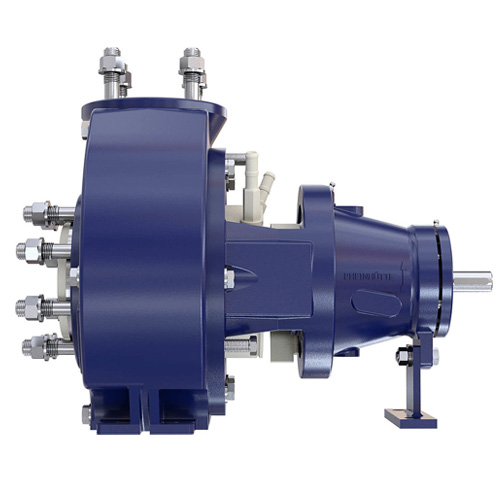

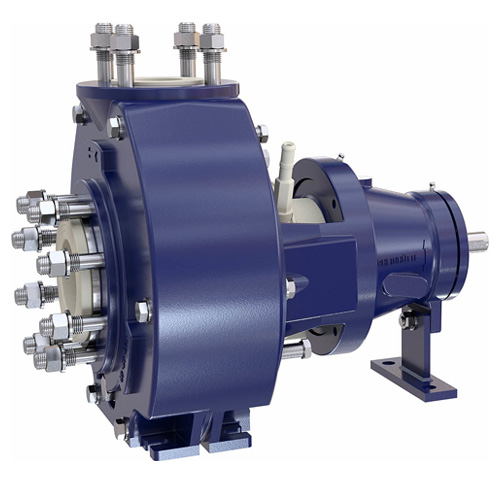

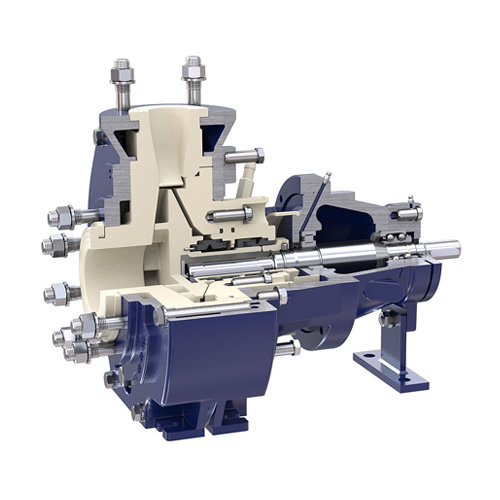

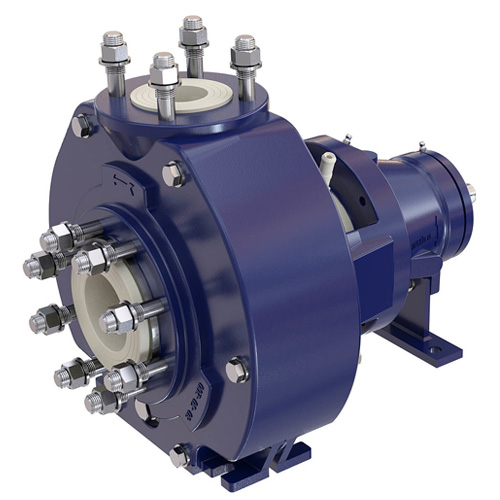

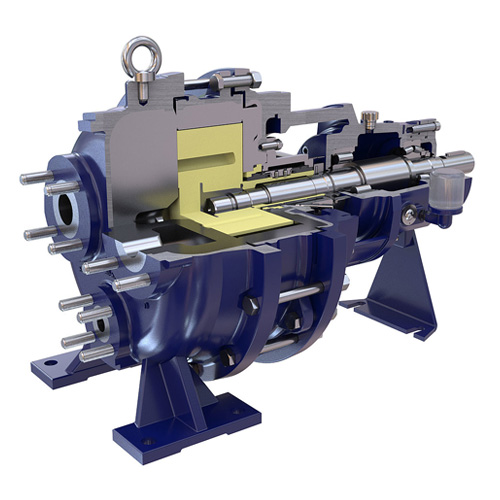

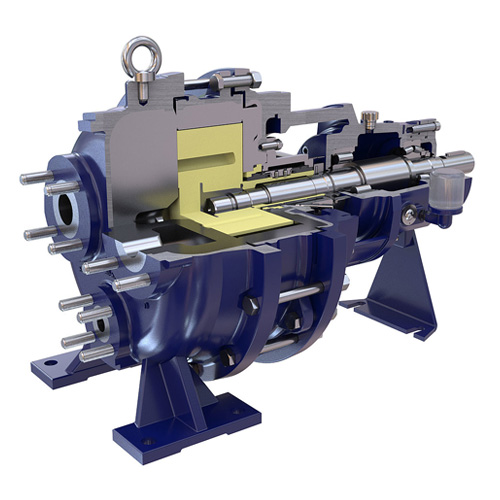

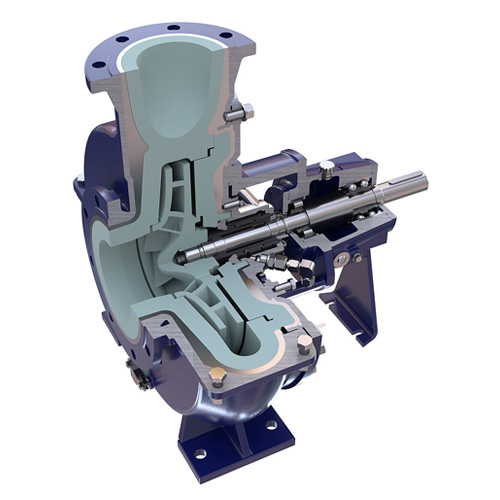

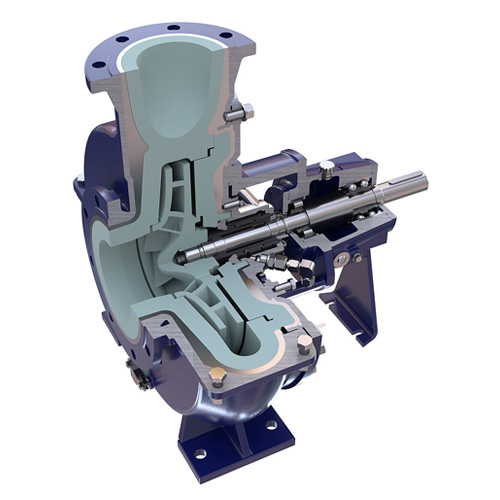

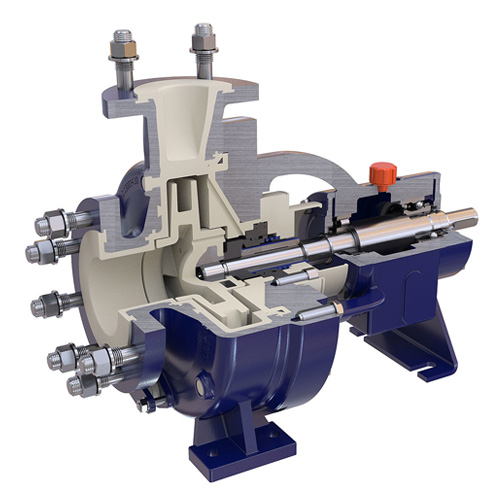

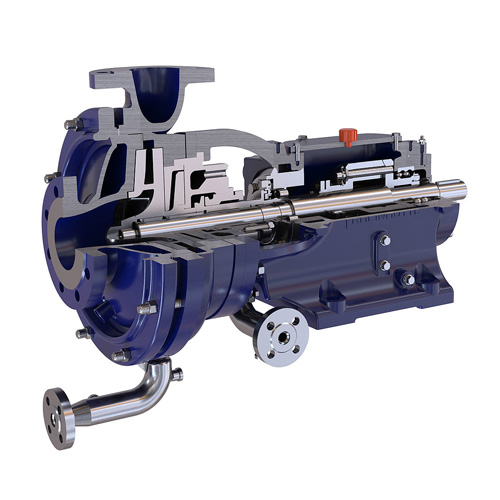

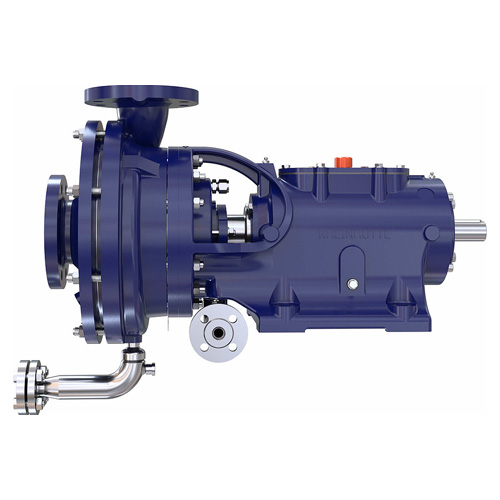

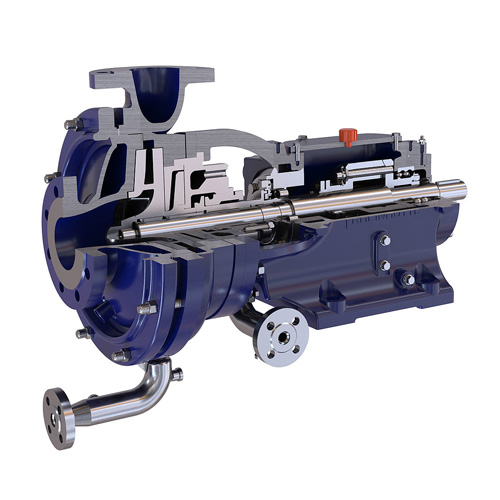

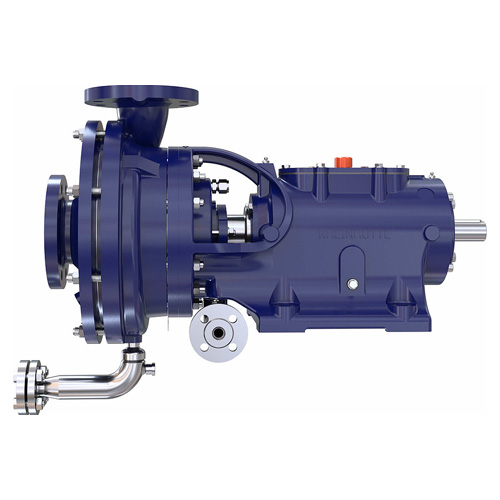

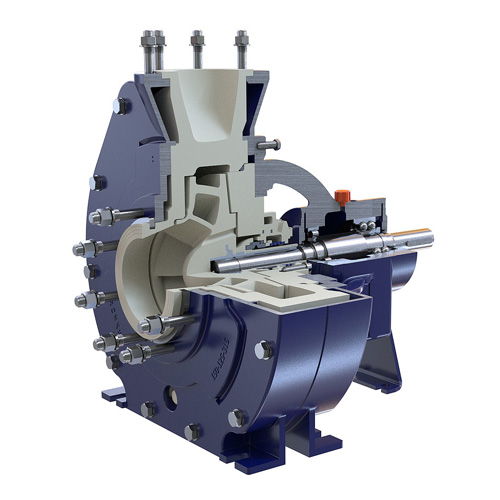

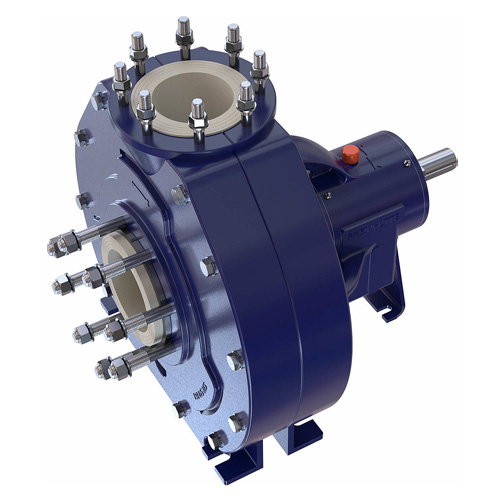

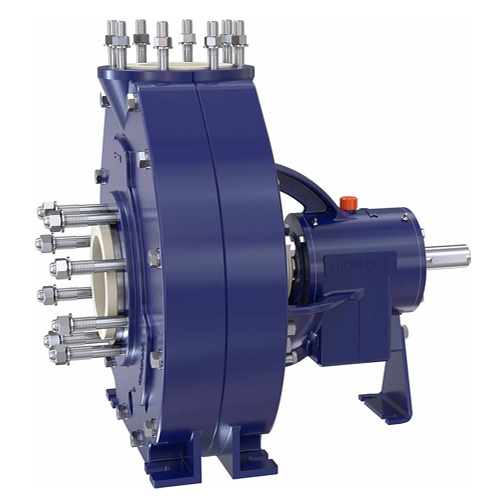

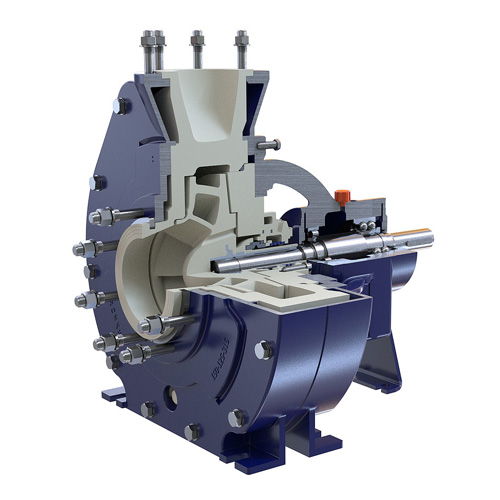

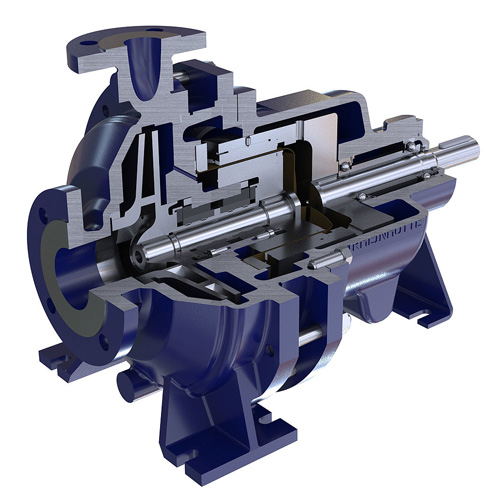

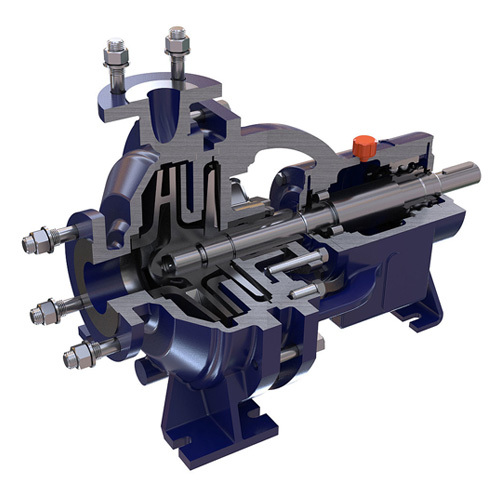

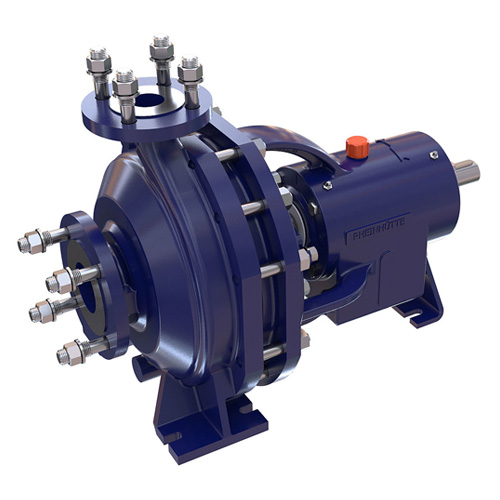

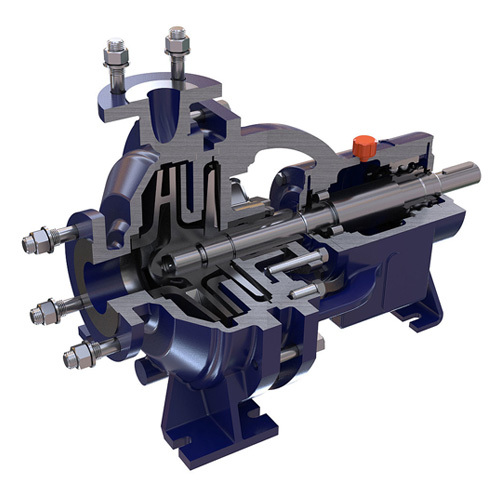

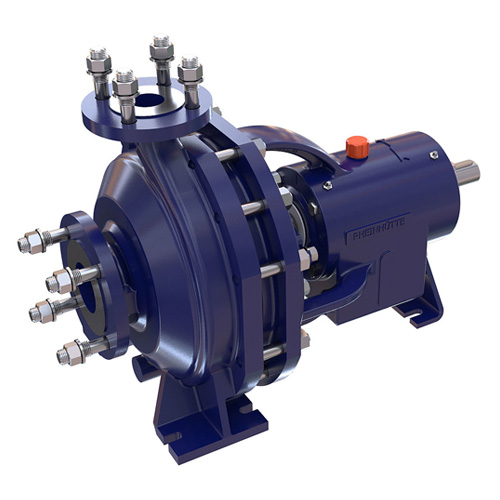

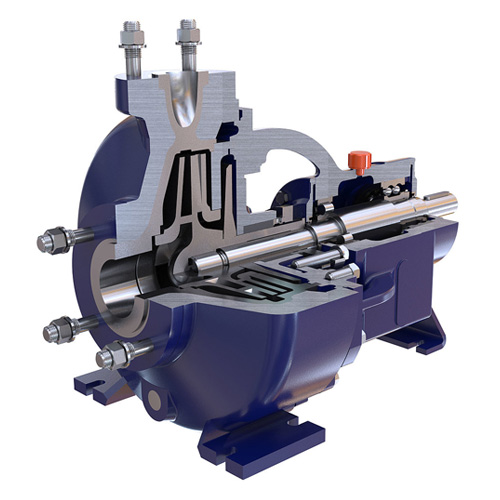

RCE - Chemical centrifugal pump in metal

- The RCE is a horizontal single-stage, end-suction, top-discharge, centrifugal pump with heavy duty bolted-down bearing pedestal. The sturdy design with front and back vanes on the impeller is primarily intended to fulfil very specific requirements as a standard chemical pump.

As a product-related special version, the RCE is the first choice in the chemical industry, the basic industry - especially in fertilizer production - environmental technology and many other industrial sectors.

It pumps organic and inorganic as well as aggressive liquids with high solid contents and is particularly suitable for hot media up to 450 degrees. Examples of applications include ammonium nitrate, molten sulphur, phosphoric acid, tar, pitch, urea melt, caustic soda, water glass, mash and cataphoretic paints.

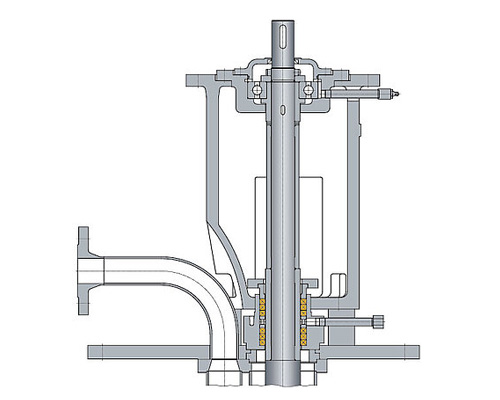

RCEV - Vertical chemical centrifugal pump in metal

- Due to its non-pedestal design and impeller equipped with front and rear blades, the RCEV pump type is highly suitable for handling solids-laden liquids. It is possible to pump up to 30 percent solids with this type of pump, where the type and composition of the solids (hard, soft, light or heavy) plays a important role.

The decision whether to use an open or closed impeller depends heavily on the type of the solids. The RCEV is used to convey mechanically contaminated, corrosive or neutral liquids such as phosphoric acid, highly contaminated sulphur, titanium dioxide slurries, copper dissolution acids as well as liquids that cannot tolerate localised heating by sliding bearings, e.g. concentrated ammonium nitrate solutions, DNT mixtures.

RCKu - Standardized chemical pump in plastic

- The RCKu is a cost-effective and place-saving bearing block pump for small power ratings.A variant of the RCKu is the RCKuF in close-coupled design instead of bearing block. The pumps are used for handling chemically aggressive and/or inflammable liquids within the wide field of chemical processing and environmental technology.

RCNKu - Standardized chemical pump in plastic

- Pumps of the RCNKu and RCFKu type family are horizontal, single-stage, end-suction, top-discharge centrifugal pumps, standardized to EN 22858, ISO 2858 and ISO 5199. With RCFKu, only the overall length is increased by the amount of the spiral width to ensure a free housing passage. The pumps are used for handling chemically aggressive and/or inflammable liquids within the wide field of chemical processing and environmental technology.

The RCNKu with closed impeller is foreseen for clean liquids and fluids with a small content of solids. The same applies for the RCKu with open impeller design. The RCFKu is able to handle fluids with larger solids.

RCNKu+ - Standardized chemical pump in plastic

- Pumps of the RCNKu+ type family are horizontal, single-stage, end-suction, top-discharge centrifugal pumps, standardized to EN 22858 and ISO 5199. The pumps are used for handling chemically aggressive and/or inflammable liquids within the wide field of chemical processing and environmental technology. The RCNKu+ with closed impeller is foreseen for clean liquids and fluids with a small content of solids.

RKuV - Chemical centrifugal pump in plastic

- The vertical centrifugal pump RKuV has been specially developed for pumping aggressive media that are contaminated with solids or that crystallize out. The series is insensitive to dry running and operation against closed slide valves, as there is no plain bearing in the pumped medium. The series is also available as lightweight design RKuVL.

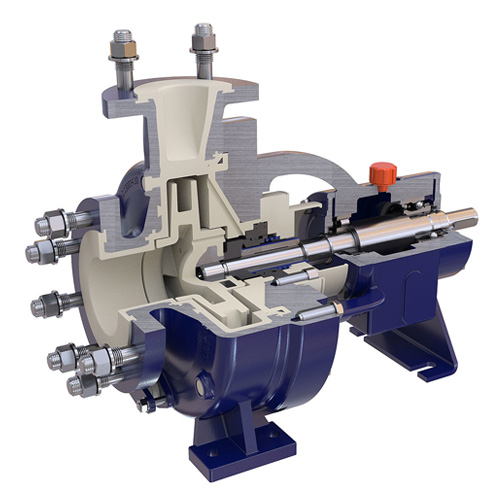

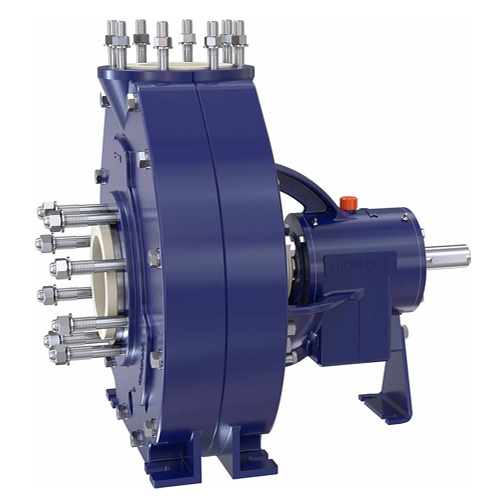

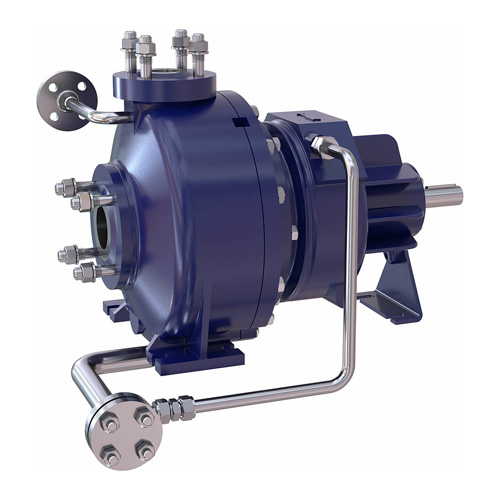

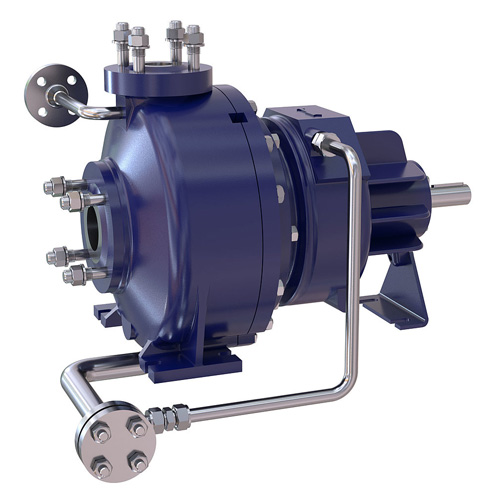

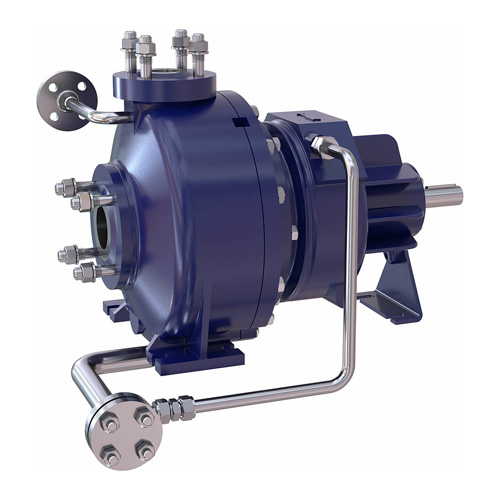

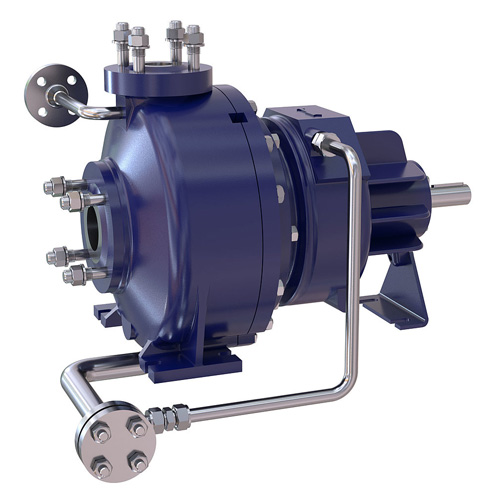

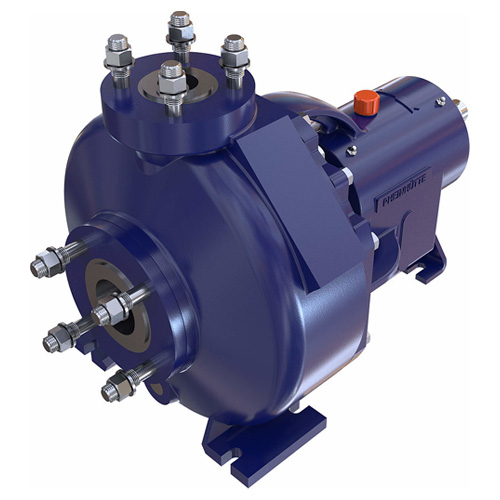

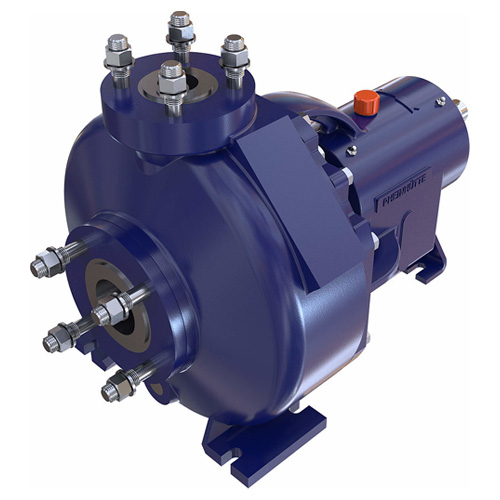

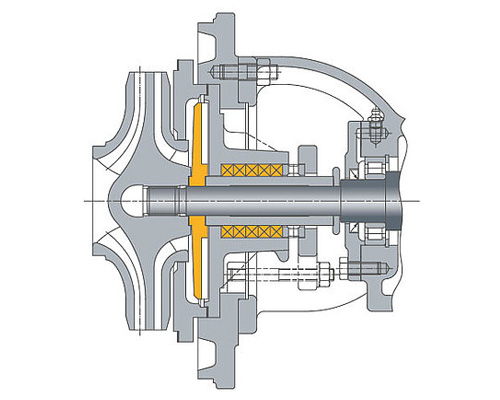

RMKN - Magnetic drive pump in metal

- The RMKN is a horizontal, single-stage, end-suction, top-discharge centrifugal pump with magnetic coupling, dimensioned to comply with standards EN 22858 (former DIN 24256) and ISO 2858.

The pumps are designed to meet the technical requirements for magnetic drive pumps as determined by VDMA 24279 and DIN EN ISO 15783. The scope of application covers the wide fields of chemical processing and environmental technology where chemically aggressive fluids of various concentrations at up to 250°C are to be handled. For applications where the medium is kept at a constant temperature

RN - Standardized chemical pump in metal

- The pump RN is a horizontal, single-stage, endsuction, top-discharge centrifugal pumps, standardized to EN 22858 (formerly DIN 24256) ISO 2858 and ISO 5199. RN (RNSI) pumps are used for handling chemically aggressive and/or inflammable liquids within the wide field of chemical processing and environmental technology.

RNSi - Standardized chemical pump in SIGUSS

- The RNSi (ferro-silicon cast iron "Si-Iron") is a horizontal, single-stage, endsuction, top-discharge centrifugal pump, standardized to EN 22858, ISO 2858 and ISO 5199. RN (RNSi) pumps are used for handling chemically aggressive and/or inflammable liquids within the wide field of chemical processing and environmental technology.

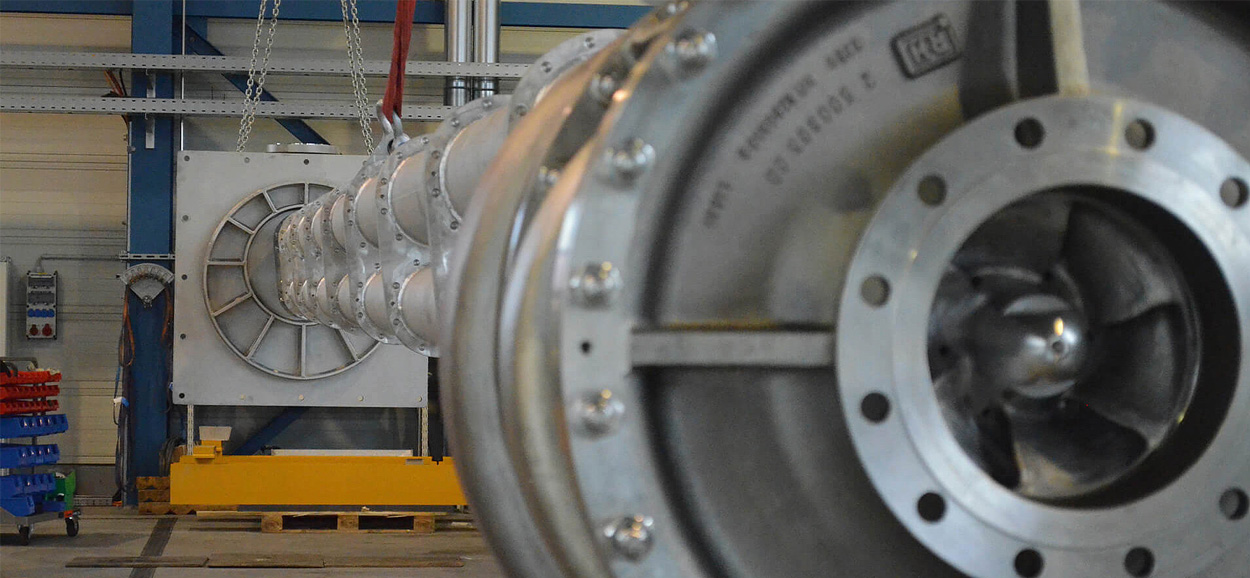

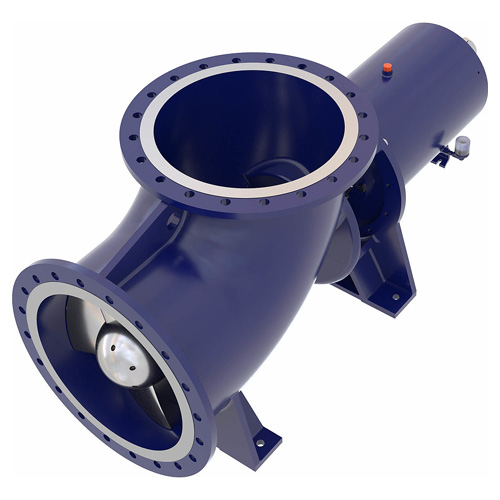

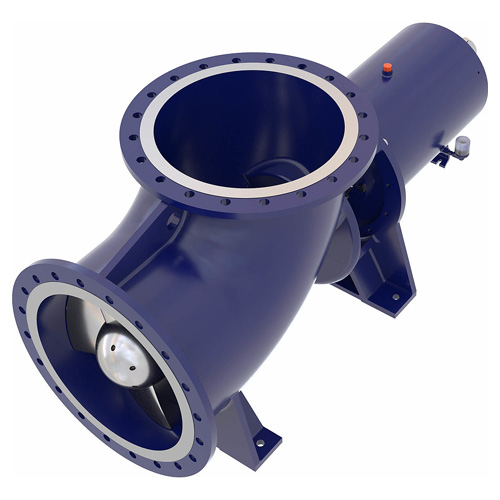

RPROP - Axial flow centrifugal pump in metal

- Pumps of type RPROP are horizontal, axial flow circulation pumps, which are fitted in standard with propeller impeller and could be executed in special cases also with inducer impeller. Additionally, there is a close-coupled design (RPROPF) available. The RPROPF can also be executed with propeller or inducer impeller, but the flow direction is only one-sided. This pump type is installed in evaporation plants, crystallisation plants, pulp and paper industries, plastic production, regeneration plant for spend acid and reaction solutions and production of titanium dioxide.

RSU - Axial flow centrifugal pump in metal

- Horizontal chemical circulating pump type RSU is designed for high flow rates at relatively low heads. By using specially designed screw impellers or propellers in Siguss is excellent suitability for the circulation of different acids, e.g. for the evaporation of spent and contaminated sulphuric acids as well as for the concentration of raw phosphoric acid. In order to achieve a sufficiently resistant - usually difficult to cast and machinable - materials, armoured versions are available.

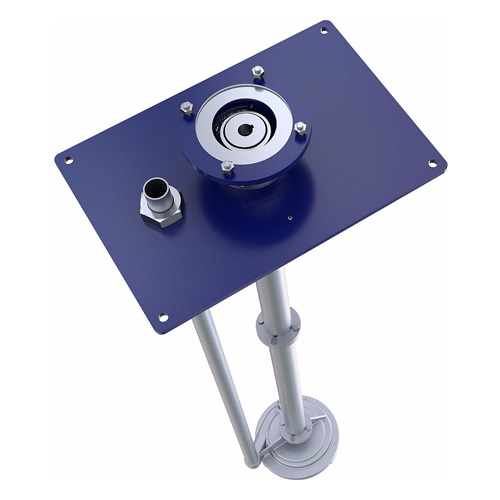

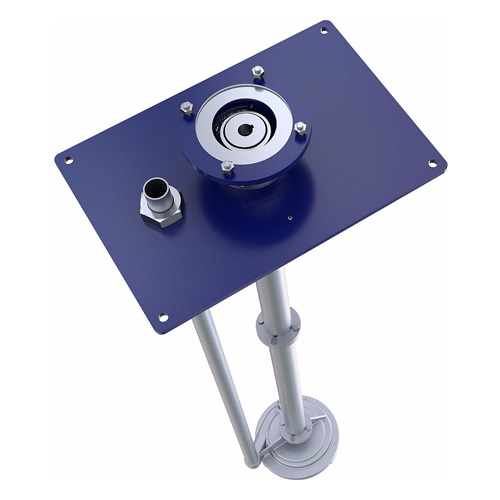

RVKu - Chemical centrifugal pump in plastic

- The vertical centrifugal pump RVKu is specially designed for pumping aggressive, slightly contaminated media such as acids, alkalis and chemical waste water. The closed impeller design with long axial throttle gaps allows immersion depths of up to 3m at operating temperatures of 90°C. Smooth running of the shaft is ensured by the use of a ball joint bearing located outside the aggressive zone as well as an immersion plain bearing made of SIC, carbon or ceramic.

RK - Vertical chemical centrifugal pump in metal

- Vertical centrifugal pumps type RK are normally designed for open vessels/pits, to drain these objects rotational. This type of pump is not suitable for continuous operation or process operation. RK pumps are used for handling chemically aggressive media, contaminated liquids with solids up to a maximum grain size of 8 mm.

Materials

-

SPECIAL MATERIALS FOR SPECIAL REQUIREMENTS

As experts in corrosion and wear resistant materials we offer process and media-specific solutions. We will select the right material for your conveyance requirement and will ensure minimum wear during long operational life - even when handling difficult media.

RHEINHüTTE Pumps in metals

- The range of metallic materials encom-passes a wide variety of very different types of material which are distinguished mainly by their alloy composition, their structure and their manufacturing process. This gives each material its characteristic properties and allows an optimal material to be selected to suit the application.

RHEINHüTTE Pumps in plastics

- In pump engineering the non-metallic materials which are mainly used, are predominantly fluoropolymers and polyolefins. The advantage of these materials is their high resistance to acids and alkalis at low to medium temperatures. To resist external forces these pump types are usually protected by a metal casing.

RHEINHüTTE Pumps in ceramics

-

Pumps made of ceramic materials are particularly suitable for media which are highly abrasive and at the same time corrosive, where pumps made from metallic materials and plastics may have a relatively short operational life.

- FRIKORUND®

Sealings

-

SEALING SYSTEMS

If the plant is to work safely and economically the pump design and sealing system must be perfectly matched with each other. A wide variety of seal variants is available when designing pumps:

perfectly matched

Hydrodynamic sealing

-

The hydro-dynamic shaft seal works without contact and without wearing parts. It requires no maintenance of any sort and is particularly suitable for continuous operation. With the aid of impeller back blades and a downstream auxiliary propeller the shaft gland is completely relieved hydro-dynamically from the pump and inlet pressure. The medium is kept away from the shaft gland.

When the pump is operating a liquid ring appears in the auxiliary impeller which isolates the inner pump chamber from the atmosphere without any leakage. The hydro-dynamic shaft seal thus only functions fully during operation of the pump. After switching off the pump a stationary seal takes over the task of sealing the shaft gland from the outside. For this a choice can be made between a simple packing gland, a pneumatic system or even a mechanically controlled ring valve of various designs.

The hydro-dynamic shaft seal, with few exceptions, is suitable for all pure or solids bearing media which occur in the chemical industry, based materials industry, environmental technology etc.

Mechanical seal

-

Single or double acting mechanical seals are used to seal the shaft gland. Sealing is achieved through axial sliding faces which are pressed against each other by spring force and this prevents them opening when at rest. The stationary part of the mechanical seal usually sits in a housing and the rotating unit on the shaft sleeve. In the sealing gap between the sliding faces a lubricating film is generated by the pumped medium in order to prevent the sliding faces running dry.

Allpac S

The standard mechanical seal Allpac S can be used universally, even with abrasive media, and is also characterised by its ease of maintenance due to the small number of components. With the double acting mechanical seal two seals are arranged one behind the other so that an additional space occurs between the sliding face of the seals which in turn can be supplied with a pressurised external sealing medium. This ensures that no product can escape into the atmosphere.

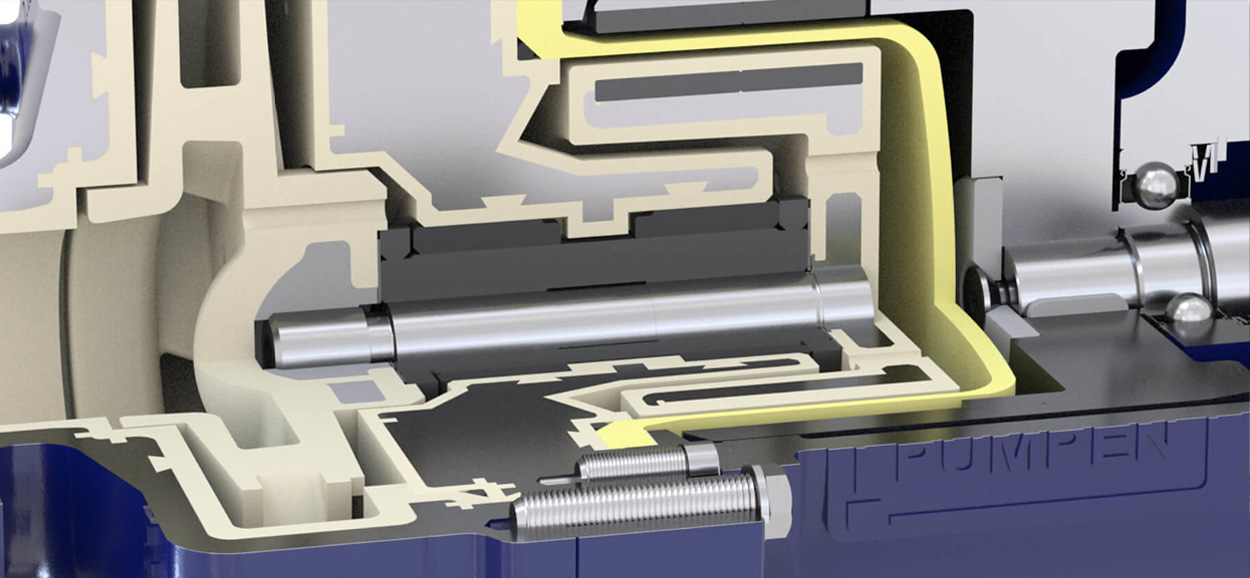

RHETA

RHETA - designed by RHEINHüTTE and EASY TO ASSEMBLE. The metal-free mechanical seal is characterized by its high service friendliness. Disassembly is quick and easy from one side. Changing from CS to CST is also uncomplicated and quick. In contrast to conventional mechanical seals, RHETA consists of innovative materials that ensure a long service life. The seal is completely metal-free so that components cannot corrode. Both the housing and the sealing cover are made of durable plastic, which can handle high temperatures of up to 130°C without any problems. RHETA also offers the advantage of integrated service flushing so that occasional flushing can be performed easily and cost-effectively.

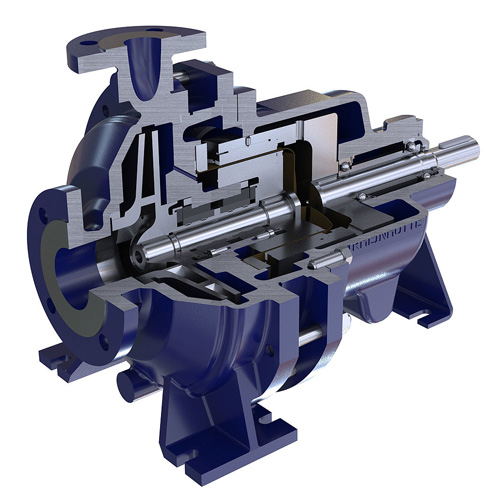

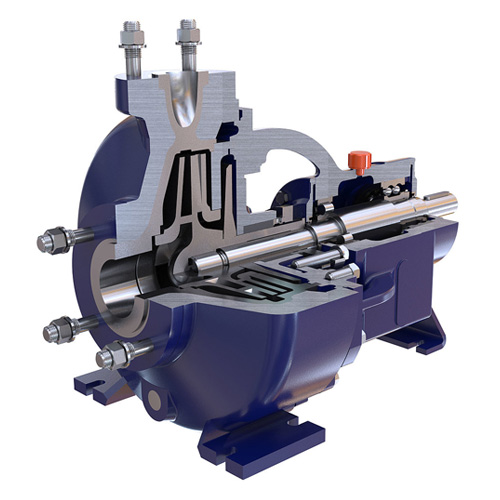

Magnetic coupling

-

The magnetic coupling is based on a completely different sealing principle. Here the drive for the hydraulic part of the pump takes place through the pairing of permanent magnets whose external unit transmits the torque generated by the motor to an internal unit, which in turn transfers this to the impeller.

The external or atmosphere side magnet system is separated from the internal product side magnetic system by a spacer can made of non-magnetic material. The torque needed to drive the impeller is transmitted exclusively by magnetic forces which act through the spacer can. The pump it is thus hermetically sealed.

The axial and radial mountings for the pump shaft are through hydro-dynamic sleeve bearings made of silicon-free silicon carbide. Bearing lubrication and heat removal normally takes place through the pumped medium, in two separate circuits.

Stuffing box packing

-

For a long time the packing gland was the standard in plant technology. It still proves its validity today in special applications.

A packing gland must continually exhibit a minimal leakage. This leakage serves to cool and lubricate the packing string. At the optimal setting of the packing gland the is a minimal leakage of 20 to 40 drops per minute. This figure however is heavily dependent on the pressure, the sliding speed, the medium and the temperature.

Often a lantern ring with two connections is fitted in order to dilute and discharge the product leakages. Different materials and combinations are used depending on the application.

Lip ring seal

-

This type of shaft seal is used mainly on vertical pumps, to protect the anti-friction bearings from water splashes. Different lip rings made of different materials can be used.

So for example a friction optimised shaft seals are used, and also pretensioned PTFE lips, which rotate on hardened shaft sleeves. For horizontal pumps the quench chambers are usually sealed by single acting mechanical seals with a lip ring. This sealing principle is also applied as stationary sealing for hydrodynamic shaft seals.

Labyrinth seal

-

This type of shaft sealing is used mainly in vertical pumps in order to protect the anti-friction bearings from water splashes. Different lip rings made of various materials can be used. Thus for example friction optimised shaft seals are used and also pretensioned PTFE lips which then rotate on hardened shaft sleeves. Depending on the application several lip rings can also be fitted one behind the other.

The intermediate spaces can then also be furnished with a grease lock. ith horizontal pumps the quench chambers are usually sealed by single acting mechanical seals with a lip ring. This sealing principle is also put to use as a station which seal for hydro-dynamic shaft seals.

Applications

-

CUSTOMISED SOLUTIONS

We will develop individual pump designs for you. Always matched with your specific application and therefore providing you with flexible and economic solutions for your special conveyance requirement.

for your application Fertilizer

- Pumps for the production of fertilizer

Chlor-Alkali Electrolysis

- Pumps for Chloralkali Electrolysis

Molten sulphur

- Pumps for the handling of molten sulphur

Molten salts

- Pumps for the handling of molten salt

Sulphuric acid

- Pumps for the production of sulphuric acid

Titanium dioxide

- Pumps for the production of Titanium dioxide

Flue gas cleaning in waste incineration plants

- Pumps for flue gas cleaning in waste incineration plants

Solar power

- Pumps for solar power

Steel and stainless steel pickles

- Pumps for steel and Stainless steel pickles

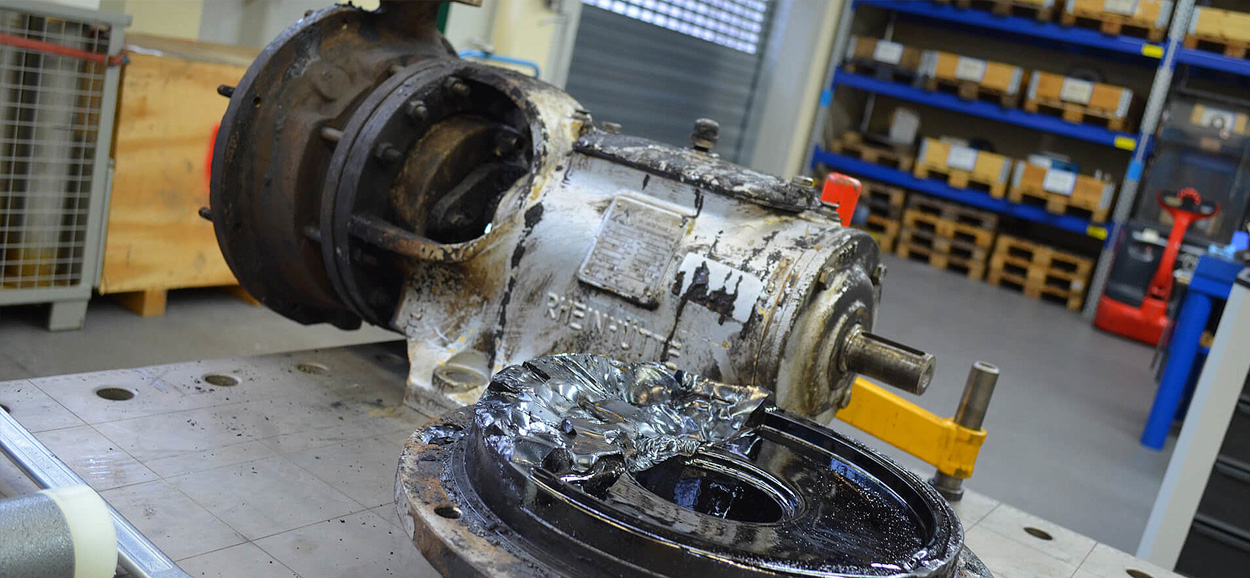

Service Service

-

OUR SERVICE FOR YOU

Fast and reliable services at a high quality level ensure maximum operational reliability, minimal downtime and a long service life for your pumps.

Fast. Reliable. Individual.

The high quality standard of all services is based on decades of experience in the design and production of pumps of the widest variety of designs. This pool of experience is also the basis for our Service Centers.

The fully equipped, state-of-the-art workshops in conjunction with our experienced and continuously trained specialist staff allow us to carry out repairs and perform maintenance work, not only in the Service Centers but also on site at the customer's premises - worldwide.

All Service Centers are available around the clock and offer a wide range.