Temposonics

Videos

Loading the player ...

- Offer Profile

-

Temposonics is the pioneer and leading manufacturer of magnetostrictive technology for measuring position and/or liquid level. Our sensors permit high-precision and dynamic position and/or speed measurement in state-of-the-art automation and safety-critical applications.

OUR TECHNOLOGY

Our core technology Temposonics® is based on the physical principle of magnetostriction. With this non-contact measurement technology, users can rely on position and velocity feedback of the moving parts in machines, which increases productivity and safety.

Product Portfolio

Absolute. Non-Contact

Linear Position Sensors & Liquid Level Transmitters

Position sensors for industrial applications

- Industrial fields pose many kinds of challenges, such as extreme temperatures, humidity, and constant shock and vibrations.

These challenges arise from the application itself or from the surrounding environment. For example, a slitter and winding machine in Brazil will have to face higher temperatures and humidity than one in Finland. Other examples where strong shocks and vibrations and lots of waste materials occur are wood trimmers, as well as hot rolling mills, where the hot temperature of the steel is an additional challenge.

There are many more and different examples, but these give you a good picture of the challenges, one can come across when working in these fields. Understanding these, enables users to choose the right Temposonics® position sensors for the corresponding applications.

What are the position sensors doing when they are installed in an application?

The magnetostrictive position sensors deliver the most exact position and velocity measurement. If we take the hot rolling mills example, the sensors are used to to control the roll gap. The rolls are connected to cylinders, which move up and down, and inside are the sensors installed. The user sets the thickness parameter and then the rolls work on the steel until the desired thickness is achieved.

How do you decide which sensor is the right one for your application?

In order to decide which position sensor is the right one for your industrial application, you need to know your system, the requirements the sensor should fulfill, possible approvals or standards that your industrial sector is working with. With this information it is easy to choose "your" sensor among our wide selection of position sensors for industrial applications.

Position sensors for mobile applications

- Looking closer at the mobile hydraulics sector, we can immediately see what kind of challenges, such as unexpected shocks and vibrations, wear and tear of materials or dust and dirt, must be faced because of the manifold of possible applications.

Looking at mobile applications such as tractors, excavators, harvesters and other construction or agricultural machines, one immediately understand why dust, dirt, unexpected shocks, wear and tear, etc. are tough challenges. They are operated in open fields which can be wet, dirty or dusty, must drive on uneven underground like rocks and sand, and must function despite any weather conditions.

This is only one example of possible applications, but it provides a good picture of the challenges, one can come across when working on the field. Taking all these into consideration, enables users to choose the right Temposonics® position sensors for the corresponding applications.

What are the position sensors doing when they are installed in a mobile application?

Magnetostrictive position sensors deliver the most exact position and velocity measurement. If you look at example of the excavator, the sensors are applied in the hydraulic cylinders of the arm with the bucket and help to control the stroke lengths of the cylinders which in turn controls the movement of the arm when excavating.

How do you decide which sensor is the right one for your machine?

As for the second question, how one decides which position sensor is the right one for mobile hydraulics application, one needs to know the machine, the demands the sensor should fulfill, possible approvals or standards that this specific mobile sector is working with. With this information it is easy to choose "your" sensor among our wide selection of position sensors for mobile hydraulics applications.

Position sensors for light industrial applications

- When looking closely at the light industrial sector, we can see the challenges, such as sterile rooms, environmental conditions and more, that must be faced when dealing with fine mechanics and machines.

Fine mechanics and instruments are often used in medicinal applications for operations or for diagnostic tools. They help to take better care of patients because the assist with lifting beds or with fine instruments in the operation room.

This is just one example where fine mechanics are applied but they give you a good picture of the challenges, one can come across when working in these fields. Taking these requirements into consideration, enables users to choose the right Temposonics® position sensors for the corresponding light industrial applications.

What are the position sensors doing when they are installed in a mobile application?

Looking at the medical sector, magnetostrictive position sensors can help with mobility tools for elder people or rehabilitation machinery to support patients to move again for example. The sensors with their high accuracy measurement support for example the control of fine hydraulic cylinders for head rests of beds.

How do you decide which sensor is the right one for your machine?

Upon how one decides which position sensor is the right one for light industrial application, you need to know your machine, the demands the sensor should fulfill, possible approvals or standards that your sector is working with. With this information it is easy to choose "your" sensor among our dedicated selection of position sensors for light industrial applications.

Transmitters for liquid level applications

- Upon taking a closer look at liquid level applications, we can see what kind of challenges must be faced when dealing with tanks and other storage facilities:

- Process temperatures

- Process Pressure

- Chemical Compatibility

- Tank Height

- Cohesiveness

- Hazardous Area Location

- Sanitary Requirements

Once the specifications are defined Temposonics can use our over forty years of level measurement experience to confirm the fit of our level transmitters to the end users' application and define the correct level transmitter. Temposonics has specially designed level transmitters for different applications by adapting the mechanical packaging to fit the mechanics of the tank and the process within the tank.

The Tank SLAYER is designed for bulk storage tanks and can measure tanks with mounting heights over 22 m. The RefineME level transmitter is versatile for almost any process application with multiple materials of construction (Stainless Steel, Hastelloy C, Teflon) and multiple process connections (NPT, ANSI flange, DIN flange). The SoClean level transmitter is design with hygienic connections for sanitary applications found in the Pharmaceutical or Food and Beverage industries. The CHAMBERED level transmitter is designed to be externally mounted on a magnetic level gauge.

Temposonics also uses our position sensors such as the RH, EH, and TH for level measurement when machine language protocols are needed by the end user or if the end user does not need any special approvals. Such applications include hydraulic reservoir tanks.

There are many more and different applications one can come across when working defining level measurement. Understanding these requirements enables users to choose the right liquid level transmitters for the corresponding applications.

Industrial Position Sensors

Temposonics® magnetostrictive position sensors feature all relevant industry outputs to support a large variety of industrial applications. This, together with the reliability of the position and velocity measurement, guarantees superior control of the application.

- Developed for linear position measurement in industrial applications

- Stroke lengths from 25 mm to 20 m

- Various sensor models, designs, outputs, approvals and performance classes are available

Quick Guide

Features R-SERIES V R-SERIES T-SERIES GB-SERIES E-SERIES G-SERIES Temposonics® Technology ✔ ✔ ✔ ✔ ✔ ✔ Diagnostics & Programmability (Non-SIL) ✔ ✔ ✔ ✔ Backward compatibility and upgraded performance ✔ ✔ ✔ Advanced performance for high precision applications ✔ ✔ ✔ Fieldbus and industrial Ethernet interfaces ✔ ✔ Embeddable ✔ ✔ SIL ✔ Hazardous rated ✔ ✔ ✔ ✔ IP66, IP67, IP68, IP69K, Nema 4 ✔ Smart Diagnostics R-Series V Position Sensors

Temposonics® R-Series V sensors are the most advanced linear position sensors on the market, combining the latest magnetostrictive technology with innovative smart diagnostics for industrial applications.

- Powerful linear position sensor with high accuracy and reliability

- More robust due to improved shock and vibration resistance

- Up to 30 positions and speeds can be measured simultaneously

- Available as

- rod version (RH5) for cylinder integrated position measurement

- profile version (RP5) for position measurement of a motion axis

- Outputs: Analog, EtherCAT®, SSI, PROFINET, POWERLINK, EtherNet/IPT

- Additional Industry 4.0 (IIoT) operational statistics available via the TempoLink smart assistant

Our linear position sensors offer the performance and reliability needed for critical applications, while providing a platform for future requirements.

R-Series V RH5

- The new generation of high performance rod-style sensors for demanding in-cylinder applications

- Backward compatible

- Increased operating temperature up to +85 °C (+185 °F)

- Increased shock & vibration resistance

- Improved performance with high accuracy & reliability

- Multi-position measurement with up to 30 magnets

- Outputs: Analog, SSI, PROFINET, EtherNet/IP™, POWERLINK, EtherCAT®

- Output of additional status information of the position sensor via the TempoLink smart assistant

R-Series V RP5

- The new generation of high performance profile-style position sensors for demanding, externally mounted applications

- Backward compatible

- Increased operating temperature up to +85 °C (+185 °F)

- Increased shock & vibration resistance

- Improved performance with high accuracy & reliability

- Multi-position measurement with up to 30 magnets

- Outputs: Analog, SSI, PROFINET, EtherNet/IP™, POWERLINK, EtherCAT®

- Output of additional status information of the position sensor via the TempoLink smart assistant

TempoLink® Smart Assistant

- The smart assistant for R-Series V

TempoLink® smart assistant supports the integration of the sensor into the application. It functions as a smart assistant between sensor and user and provides the following information:- Current sensor status

- Internal sensor temperature

- Total hours of sensor operation

- Distance traveled by position magnets

The connection and communication between sensor and TempoLink® is established via the power supply. The smart assistant can transmit the various sensor parameters wirelessly or via USB port.

Your benefits:- Detailed information about the status of your application

- WiFi access point included: no access to company network necessary

- Connect wirelessly via WiFi enabled device like smartphone, tablets or laptops

R-Series Position Sensors

Temposonics® R-Series position sensors feature the highest performance, accuracy and reliability in magnetostrictive linear position technology and are designed for advanced motion control implementations in industrial applications.

- Powerful position sensor with high accuracy and reliability

- Available as

- Rod version (RH) for cylinder integrated position measurement

- Profile version (RP) for position measurement of a motion axis

- Position sensor with detached sensor electronics (RD4) for decoupling the sensor electronics housing from the sensor rod, which can be integrated in the cylinder

- Redundant with detached electronics (RT4) for applications with special safety and availability requirements

- Flexible position sensor rod (RF) for stroke length up to 20 m

- Position sensor with protective housing (RS) with ingress protection IP69K

- Outputs: Analog, SSI, CANbus, Profibus, EtherCAT® , EtherNet/IP™, PROFINET, POWERLINK

- On-site programmable to adapt the sensor to the application

The linear position sensor supports the high performance of your application and is fit for various applications due to the large number of versions available!

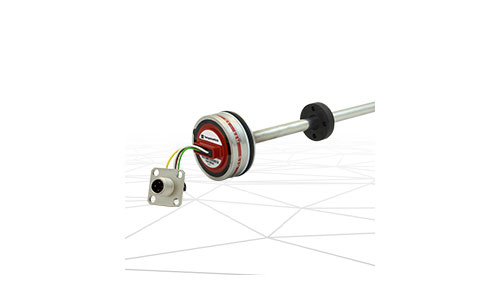

R-Series RH

- Superior performance rod position sensors for demanding applications

- In in-cylinder applications the sensing element & electronics can be easily replaced without interrupting the hydraulic circuit

- Multi-position measurement with up to 20 magnets

- LEDs for sensor status & diagnostics

- Outputs: CANbus, Profibus, DeviceNet

R-Series RP

- Superior performance profile position sensors for demanding applications

- Multi-position measurement with up to 20 magnets

- LEDs for sensor status & diagnostics

- Outputs: CANbus, Profibus, DeviceNet

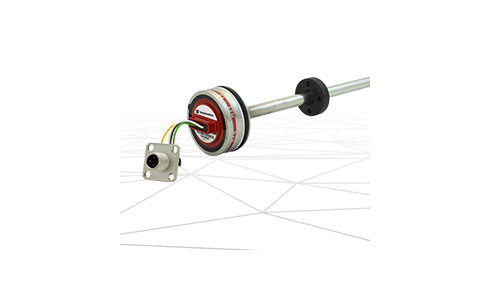

R-Series RD4

- Superior performance position sensor with detached electronics for hydraulic cylinders & machine manufacturing

- Space-saving installation due to detached sensor electronics

- Different mounting options for housing

- Threaded & pressure fit flanges

- Multi-position measurement with up to 20 magnets

- LEDs for sensor status & diagnostics

- Outputs: Analog, SSI, CANbus, Profibus, EtherCAT®, EtherNet/IP™, PROFINET, POWERLINK

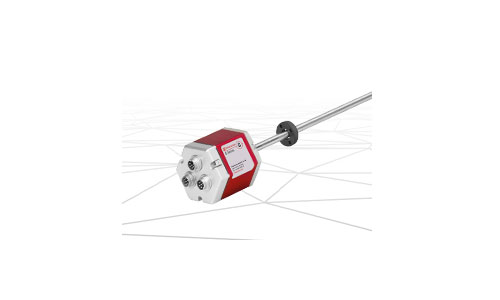

R-Series RT4

- Redundant superior performance position sensor for hydraulic cylinders & machine manufacturing

- Detached sensor electronic housings

- Redundant measurement

- 3 different flange types

- LEDs for sensor status & diagnostics

- Output: SSI

R-Series RF

- Flexible superior performance position sensor for long stroke lengths up to 20,000 mm

- Flexible rod

- Multi-position measurement with up to 20 magnets

- Convenient shipping for long measuring lengths

- LEDs for sensor status & diagnostics

- Outputs: Analog, SSI, CANbus, Profibus, EtherCAT®, EtherNet/IP™, PROFINET, POWERLINK

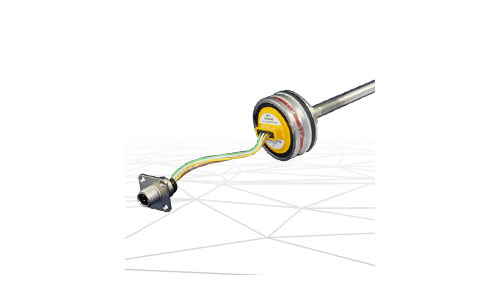

R-Series RH (ATEX)

- Rod style position sensor with ATEX approval

- In in-cylinder applications the sensing element & electronics can be easily replaced without interrupting the hydraulic circuit

- Multi-position measurement with up to 20 magnets

- LEDs for sensor status & diagnostics

- Cable connection

- Outputs: Analog, SSI, CANbus

R-Series RP (ATEX)

- Profile style position sensor with ATEX approval

- Multi-position measurement with up to 20 magnets

- LEDs for sensor status & diagnostics

- Cable connection

- Outputs: Analog, SSI, CANbus

GB-Series Position Sensors

Temposonics® GB-Series position sensors are specially designed to be incorporated into industrial hydraulic cylinder applications in restricted spaces.

- Powerful position sensor for high ambient temperature applications

- Flat and compact sensor electronics housing for installation when space is limited

- Available as

- Rod version with threaded flange

- Rod version with pressure-fit flange

- Outputs: Analog, SSI

- On-site programmable to adapt the linear sensor to the application

The position sensor offers you the certainty of a reliable position measurement in confined spaces and high ambient temperatures!

GB-Series with threaded flange

- Position sensor for limited spaces in in-cylinder applications

- Sensor element & electronics can be easily replaced without interrupting the hydraulic circuit

- 360° rotatable electrical connection after mounting

- Operating temperature up to +100 °C (+212 °F)

- Outputs: Analog, SSI

GB-Series with pressure-fit flange

- Position sensor for harsh environments

- Available in stainless steel 1.4404 (AISI 316L)

- Flat & compact housing with side-mounted signal connection

- High pressure resistant sensor rod for up to 800 bar available

- Operating temperature up to +100 °C (+212 °F)

- Outputs: Analog, SSI

E-Series Position Sensors

Temposonics® E-Series linear position sensors are very compact models suitable to meet the needs of various industrial applications.

- Position sensor with compact design for installation when space is limited

- Available as

- Rod version (EH) for cylinder integrated position measurement

- Profile version (EP) for position measurement of a motion axis

- Ultra low profile version (EL) for position measurement of a motion axis

- Flat profile version (EP2) for position measurement of a motion axis

- Rod & cylinder housing with strong piston (ER) for flexible mounting

- Rod version for embedding in cylinder (EE) for position measurement in a cylinder

- Rod version for high temperatures and hazardous areas withapprovals ATEX, IECEx, CEC and NEC (ET) for cylinder integrated position measurement

- Outputs: Analog, CANopen, IO-Link, Start/Stop, SSI

With a variety of models, this linear position sensor is designed for different industrial applications and offers you the certainty of reliable position measurement!

E-Series EH

- Compact rod design for in-cylinder applications

- Available in stainless steel 1.4404 (AISI 316L)

- Multi-position measurement up to 2 magnets

- Outputs: Analog, CANbus, IO-Link, SSI, Start/Stop

E-Series EP/EL

- Compact profile design for applications with limited spaces

- Ultra low designs for external mounting

- Multi-position measurement up to 2 magnets

- Outputs: Analog, CANbus, IO-Link, SSI, Start/Stop

E-Series EP2

- Developed for use with floating magnet along the entire housing

- Flexible mounting

- Robust aluminum profile

- Multi-position measurement up to 2 magnets

- Outputs: Analog, CANbus, IO-Link, SSI, Start/Stop

E-Series ER

- Position sensor with a guided driving rod which contains sensor element, electronics & position magnet

- Flexible mounting options

- Outputs: Analog, CANbus, IO-Link, SSI, Start/Stop

E-Series ET

- Compact rod position sensor for hazardous areas

- Available in stainless steel 1.4404 (AISI 316L)

- Operating temperature up to +105 °C (+221 °F)

- ATEX / IECEx / CEC / NEC / CCC certified

- Programmable set points

- Outputs: Analog, SSI, Start/Stop

- Available as

- rod version for cylinder integrated position measurement

- profile version for position measurement of a motion axis

E-Series EE

- Compact rod position sensor housing for full cylinder integration

- Pressure-resistant sensor rod

- Compact sensor housing

- Designed for cylinder integration

- High operating temperature

- Output: Analog

T-Series Position Sensors

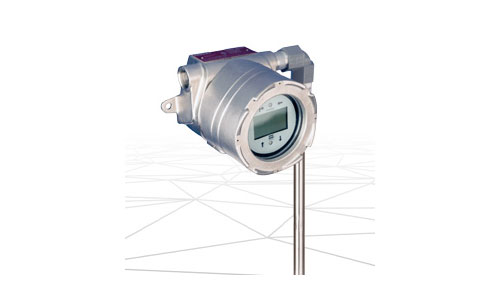

Temposonics® T-Series magnetostrictive position sensors have been specially designed for global installation in potentially explosive areas where they have to be resistant against flames or corrosive substances.

- Developed for use in hazardous areas with approvals ATEX, NEC, CEC, EAC Ex, IEC EX, KCs and for the Japanese market

- Available with SIL 2 for applications with safety requirements

- Available as rod version (TH) for linear position measurement in a cylinder

- Outputs: Analog, CANbus, SSI

This robust position sensor offers you the certainty of reliable linear position measurement for special safety requirements or in hazardous areas!T-Series TH

- Extremely robust position sensor designed & certified for Ex-applications

- Available in stainless steel 1.4404 (AISI 316L)

- Ingress protection IP66, IP67, IP68, IP69K, NEMA 4X

- Approval options: ATEX, IECEx, CEC, NEC, EAC Ex, Japanese approval, ClassNK, KCs, SIL 2, CCC

- Flame- & explosionproof

- Multi-position measurement with up to 4 magnets

- Outputs: Analog, CANbus, SSI

G-Series Position Sensors

Temposonics® G-Series linear position sensors provide high durability and accurate position measurement solutions in harsh industrial settings.

- Different position sensor models for different purposes of position measurement:

- Rod version (GH) for cylinder integrated position measurement and for retrofitting legacysensor models

- Profile version (GP) for position measurement of a motion axis and for retrofitting legacysensor models

- Redundant rod version (GT2/3) for cylinder integrated position measurement. Two or three independentmeasuring systems contained in one compact housing for use in applications withspecial safety and availability requirements

- Redundant rod version for embedding in cylinder (GTE) for position measurement in a cylinder.Two or three independent measuring systems contained in one compact housing foruse in applications with special safety and availability requirements

- Outputs: Analog, Start/Stop, PWM

This diverse series of linear position sensors offers you the certainty of reliable position measurement in applications with special safety or availability requirements and when retrofitting existing systems!- Different position sensor models for different purposes of position measurement:

G-Series GH

- Rod-style for use in cylinders

- Repeatability less than 0.001% F.S.

- Backward compatibility for retrofitting legacy sensor models

- Outputs: Analog, Start/Stop

G-Series GP

- Profile-Style for External Mounting

- Designed for external mounting

- Rugged

- Backward compatibility for retrofitting legacy sensor models

- Enhanced diagnostics and programming capability

- Outputs: Analog, Start/Stop

G-Series GTE

- Redundant position sensor with Ex certification for enhanced safety applications

- Designed for high pressure applications

- Embedded for extra protection in harsh environments

- IECEx certified version available

- Output: Analog

G-Series GT2/GT3

- Position sensor with multiple redundancy for enhanced safety applications

- Double or triple redundant

- Output: Analog

G-Series GH (ATEX)

- Rod style position sensor with ATEX approval

- Repeatability less than 0.001% F.S.

- Backward compatibility for retrofitting legacy sensor models

- Outputs: Analog, Start/Stop

G-Series GP (ATEX)

- Profile style position sensor with ATEX approval

- Repeatability less than 0.001% F.S.

- Backward compatibility for retrofitting legacy sensor models

- Outputs: Analog, Start/Stop

L-Series Position Sensors

L-Series LD

Position Sensors for Hazardous Areas

T-Series TH

- Extremely robust position sensor designed & certified for Ex-applications

- Available in stainless steel 1.4404 (AISI 316L)

- Ingress protection IP66, IP67, IP68, IP69K, NEMA 4X

- Approval options: ATEX, IECEx, CEC, NEC, EAC Ex, Japanese approval, ClassNK, KCs, SIL 2, CCC

- Flame- & explosionproof Multi-position measurement with up to 4 magnets

- Outputs: Analog, CANbus, SSI

G-Series GTE

- Redundant position sensor with Ex certification for enhanced safety applications

- Designed for high pressure applications

- Embedded for extra protection in harsh environments

- IECEx certified version available

- Output: Analog

E-Series ET

- Compact rod position sensor for hazardous areas

- Available in stainless steel 1.4404 (AISI 316L)

- Operating temperature up to +105 °C (+221 °F)

- ATEX / IECEx / CEC / NEC / CCC certified

- Programmable set points

- Outputs: Analog, SSI, Start/Stop

- Available as

- rod version for cylinder integrated position measurement

- profile version for position measurement of a motion axis

HPH Housing

- Designed for G- and R-Series position sensors

This High Pressure Housing is ATEX Ex approved and UL and cUL approved for use in hazardous locations with Temposonics position sensors.

R-Series RP (ATEX)

- Profile style position sensor with ATEX approval

- Multi-position measurement with up to 20 magnets

- LEDs for sensor status & diagnostics

- Cable connection

- Outputs: Analog, SSI, CANbus

G-Series GH (ATEX)

- Rod style position sensor with ATEX approval

Repeatability less than 0.001% F.S. Backward compatibility for retrofitting legacy sensor models Outputs: Analog, Start/Stop

G-Series GP (ATEX)

- Profile style position sensor with ATEX approval

- Repeatability less than 0.001% F.S.

- Backward compatibility for retrofitting legacy sensor models

- Outputs: Analog, Start/Stop

Mobile Hydraulics Position Sensors

Temposonics magnetostrictive position sensors for mobile hydraulics applications feature all relevant outputs to guarantee superior control and reliability of position and velocity measurement.

- Developed for linear position measurement in mobile hydraulics machinery

- The position sensors are available with a stroke length from 50 mm to 5000 mm

- Designed for cylinder integration or external mounting

- High robustness against shock and vibration provide more safety, comfort and machine availability

You get the right linear position sensor for your mobile application!

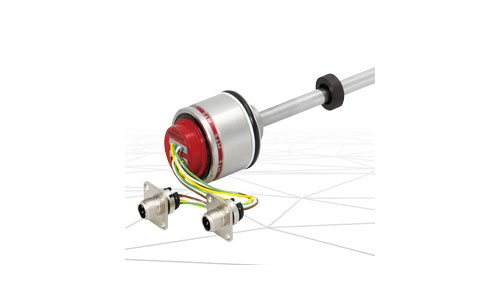

MH-Series MH Position Sensors

- Temposonics® MH-Series model MH position sensors measure the absolute position of hydraulic cylinders in mobile applications.

- Designed for full sealing and embedding in hydraulic cylinders

- The position sensor features the proprietary M12 connector system to enable IP69K

- Outputs: Analog, CANbus, PWM

The linear position sensor offers safety and reliability to increase your machine’s productivity and avoid maintenance and downtime!

MH-Series MH200 Position Sensors

- Temposonics® MH-Series model MH position sensors measure the absolute position of hydraulic cylinders in mobile applications.

- Designed for full sealing and embedding in hydraulic cylinders

- The position sensor features the proprietary M12 connector system to enable IP69K

- Outputs: Analog, CANbus

- Stroke length up to 5000 mm

MH-Series MHRM Position Sensors

- Temposonics® MH-Series model MHRM linear position sensors are specially developed for railway applications.

- Designed for internal and external mounting

- Compliant to railway standards and industry specific shock, vibration, and EMC approvals

- The proprietary M12 connector system is featured to enable IP69K

- Output: Analog

The MHRM position sensors offer the same high standard you are familiar with from the MH Series MH sensors which guarantees the reliable operation of the mobile machine!

MH-Series MH Threaded Position Sensors

- Temposonics® MH-Series model MH Threaded magnetostrictive position sensors measure the absolute position of hydraulic cylinders for mobile machinery.

- Designed for external mounting on mobile applications

- The position sensor features the proprietary M12 connector system to enable IP69K

- Output: Analog, CANbus

The linear position sensor’s ruggedness gives you the certainty that your machine operates reliably!

MH-Series FMH Position Sensors

- Temposonics® MH-Series model FMH position sensors are designed for challenging hydraulic cylinder applications.

- Designed for external mounting on mobile applications

- Flexible position sensor element up to 5000 mm

- Exchange internal components with just 200 mm of clearance – regardless of stroke length of the position sensor and without breaking the hydraulic seal

- Outputs: Analog, CANbus

The flexible linear position sensor element enables easy serviceability which leads to decreased downtime in your mobile application!

MH-Series MS Position Sensors

- Temposonics® MH-Series model MS magnetostrictive position sensors are designed for direct stroke measurement in hydraulic cylinders with bore diameters of 28 mm or greater.

- Designed for full sealing and embedding in hydraulic cylinders

- The proprietary M12 connector system is featured to enable IP69K

- Can be installed from the head- or the rod-side depending on the cylinder design

- Outputs: Analog, CANbus

This linear position sensor allows you to integrate the quality and standard of the MH Series MH into mobile applications with smaller bore diameters!

MH-Series MH Safety Position Sensors

- Temposonics® MH-Series MH Safety position sensors are developed for use in safety circuits/safety functions for measuring linear position as part of the functional safety of machinery and equipment

- Meet the requirements of SIL2 to EN 61508 and there with also the requirements of PLd to EN 13849-1

- The position sensors feature the M12 connector system to ensure IP69K protection

- Stroke length ranges from 50 to 2500 mm Outputs: Analog, CANbus

This linear position sensor supports the safety and reliability of your mobile applications!

MH-Series MT Position Sensors

- Temposonics® MH Series model MT linear position sensors are solutions for in-cylinder applications of mobile machines.

- Designed with two redundant sensor elements in a single pressure resistant rod

- The position sensor features the dual M12 connector systems to ensure IP69K protection

- Output: Analog

The linear position sensor with its redundant technology maximizes the safety and availability of your mobile machines!

C-Series Off-Highway Position Sensors

- Core sensor for mobile hydraulic applications

- 4…20 mA output for mobile hydraulic standards

- Rugged design for off-highway applications

- Stroke lengths up to 275 mm

- Designed for battery powered systems with an operational voltage of 12/24 VDC

MH-Series MB Position Sensors

- Temposonics® MH-Series model MB position sensors are developed for application in hydraulic cylinders.

- Designed for threaded port assembly in hydraulic cylinders

- The position sensors feature the dual M12 connector system to ensure IP69K protection

- Output: Analog

This compact position sensor offers you the benefit of implementing Temposonics technology even in smaller mobile applications!

MH-Series MXR Position Sensors

- Temposonics® MH Series MXR position sensors with stainless steel housing are ideal for retrofitting older equipment or for external mounting.

- Designed for retrofitting

- Designed for external cylinder mounting

- The position sensors are available in four discrete stroke lengths up to 250 mm, as well as stroke lengths from 100 to 600 mm (50 mm ordering increments)

- Output: Analog

This magnetostrictive position sensor allows you to upgrade your existing machinery with Temposonics technology to increase the reliability of the application!

Light Industrial Position Sensors

Temposonics Light Industrial position sensors are specifically developed for use in fine or small applications, where a common linear sensor does not fit, that need exact position measurement.

- OEM version for cylinder integration

- M1 and H2 housing available for external mounting

- Stroke length ranges from 72 to 250 mm

- Outputs: Analog, PWM (OEM version only)

These linear position sensors allow users to get exact position measurement in small applications!

C-Series OEM Position Sensors

- Core sensor for embedded sensor applications

- For large-series OEM production Protective housing options available

- Stroke length up to 250 mm

- Operating voltage 5 VDC or 12 VDC

- Outputs: Analog, PWM

C-Series Position Sensors with M1 Housing

- Temposonics Light Industrial position sensors are specifically developed for use in fine or small applications, where a common linear sensor does not fit, that need exact position measurement.

- OEM version for cylinder integration M1 and H2 housing available for external mounting

- Stroke length ranges from 72 to 250 mm

- Outputs: Analog, PWM (OEM version only)

These linear position sensors allow users to get exact position measurement in small applications!

C-Series Position Sensors with H2 Housing

- Housing solution for external mounting

- IP67 housing

- Ring and floating magnets available

- Output: Analog

Liquid Level Transmitters

Developed for automatic tank gauging of above ground storage tanks and process vessels.

- Designed for application in the oil, gas, chemical, pharmaceutical, and mining industries Five different transmitters allow users to find the right solution for their tank application

5-IN-1 Measurement allows users to save space and construction costs by measuring level, interface, temperature, volume, and HI Level alarm with only one sensor!

Tank SLAYER® Transmitters

- Designed for bulk storage inventory monitoring

The Level Plus Tank Slayer® liquid level transmitter satisfies the demand for an accurate and robust liquid-level sensor with unsurpassed flexibility to meet most process application conditions. The Tank Slayer® transmitter provides 4-in-1 measurement using one process opening for product level, interface level, temperature and volume measurements. Once the transmitter is installed and calibrated there is no requirement for scheduled maintenance or recalibration for the expected 10 year life of the sensor.- 4-IN-1 Measurement (Product, Interface, Temperature, Volume)

- Inherent Accuracy ±1 mm

- Flexible hose for ease of installation

- No scheduled maintenance or recalibration

- Hazardous area certified

RefineME® Transmitters

- Designed for process control in industrial environments

The Level Plus RefineME® liquid level transmitter satisfies the demand for an accurate and robust liquid-level sensor with unsurpassed flexibility to meet most process application conditions. The RefineME® transmitter provides 4-in-1 measurement using one process opening for product level, interface level, temperature and volume measurements. Once the transmitter is installed and calibrated there is no requirement for scheduled maintenance or recalibration for the expected 10 year life of the sensor.- 4-IN-1 Measurement (Product, Interface, Temperature, Volume)

- Stainless steel, Nickel Alloy C-276, or FEP wetted parts

- Inherent Accuracy ±1 mm

- No scheduled maintenance or recalibration

- Hazardous area certified

SoCLEAN® Transmitters

- Developed for hygienically demanding applications

The Level Plus SoCLEAN® liquid level transmitter satisfies the demand for an accurate and robust liquid-level sensor with unsurpassed flexibility to meet most process application conditions. The SoCLEAN® transmitter provides 4-in-1 measurement using one process opening for product level, interface level, temperature and volume measurements. Once the transmitter is installed and calibrated there is no requirement for scheduled maintenance or recalibration for the expected 10 year life of the sensor.- 4-IN-1 Measurement (Product, Interface, Temperature, Volume)

- Standard Sanitary (Ra 25) or Electropolished (Ra 15) finish

- Inherent Accuracy ±1 mm

- No scheduled maintenance or recalibration

- 3-A Sanitary certified

CHAMBERED Transmitters

- Designed for magnetic level gauge

The Level Plus CHAMBERED liquid level transmitter satisfies the demand for an accurate and robust liquid-level sensor with unsurpassed flexibility to meet most process application conditions. The CHAMBERED transmitter provides external measurement of most Magnetic Level Gauges (MLG) from popular suppliers. Once the transmitter is installed and calibrated there is no requirement for scheduled maintenance or recalibration.- Designed for magnetic level gauge (MLG)

- No scheduled maintenance or recalibration

- Hazardous area certified

LevelLimit Transmitters

- Designed for combined tank gauging and overfill protection

The Level Plus LevelLimit liquid level transmitter satisfies the demand for an accurate and robust liquid level transmitter with integral HI level overfill protection. The level transmitter offers the ability to measure the product level, interface level, temperature, and volume. The electrically isolated HI level detection uses a separate set of electronics and reed switch technology to offer a Digital I/O output based off of the movement of an independent HI level float. The HI level float offers mechanical testing for verification.- 5-IN-1 Measurement

- Integral HI level Digital I/O

- Level Inherent Accuracy +/- 1 mm API

- Temperature Corrected Volumes

- No Scheduled Maintenance or Recalibration

- Hazardous Area Certified

Accessories for Liquid Level transmitters

- Temposonics offers a variety of accessories to support your application needs. The Level Plus Accessories Catalog shows all of the available accessories from Temposonics including a wide selection of floats, process meters, Modbus Terminals, programming accessories and hardware. In the table below are only those accessories that also have individual datasheets and/or manuals.

Industrial Applications

Plastic & Rubber Manufacturing: Blow Molding

- Blow molding machines are used for the production of bottles and containers for the food, pharmaceuticals, and chemical industry. Our sensors are used for four different controls:

- The parison thickness

- The mould clamping

- The carriage movement

- The nozzle position

The sensors control the parison width, the plate position, the mold closing movement and the blow pin movement inside the form. The Temposonics position sensor is used on blow molding machines for its high accuracy, linearity and speed.

Standard industry bus communication or Analog outputs allow for easy integration of position sensors with advanced machine controls.

Plastic & Rubber Manufacturing: Injection Molding

- The conventional solution of position feedback by potentiometers is often not suitable due to susceptibility to wear and lower performance.

Our sensing technology is routinely used in 3 axes of plastic injection molding machines: injector control, ejector control, and mold closure. Superior ruggedness and reliability, as well high speed and accuracy make Temposonics linear position sensors the smart choice for this application.

Plastic & Rubber Manufacturing: Thermoforming

- Accurate positioning of the hydraulic press in the thermoforming machinery is critical for maintaining the proper tolerances on the final product.

Temposonics position sensors are used for positioning feedback on horizontal and vertical axes with no requirement for additional maintenance and calibration.

The linear position sensors with industry standard bus communication protocols allow an easy integration in multi-axis positioning controls.

Metals & Metalworking: Grinding

- The X-Y-Z profile of the grinding process needs an accurate position description on each moving axis.

The Temposonics absolute linear position sensor is used for precise measurement with insensitivity to thermal expansion and requires no maintenance and calibration.

Standard industry fieldbus communication protocols allows for easy integration with advanced motion controllers.

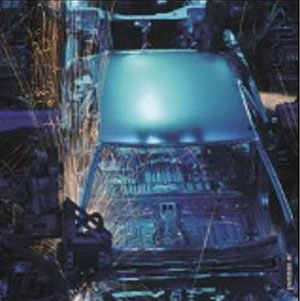

Metals & Metalworking: Spot Welding

- Precise positioning of the welding gun to the metal sheets is done using a linear position sensor as the feedback device for the pneumatic actuator.

Having a position control loop enables the welding gun to adapt to different thicknesses of metal sheets, have programmable electrode positions based on the tip dressing and reduce operating noise and maintenance due to the controlled approach to the final position.

Standard industry bus communication protocols or Analog output allows for easy integration of Temposonics position sensors with welding position controllers.

Metals & Metalworking: Presses

- Temposonics position sensors are well suited for press applications because of the need of high performance repetitive operation under high shock lead conditions. Today, as manufacturers and users demand better part quality, repeatability and shorter cycle times, our sensors are favored because of their high resolution and responsiveness.

Metals & Metalworking: Plasma Cutting

- Positioning of the plasma torch on the X-Y cutting table requires feedback devices that are less sensitive to electrical noise.

The absolute linear position sensor uses a non-contact permanent magnet for position reading and requires no maintenance and calibration. Removing electrical wires from proximity with the plasma torch, combined with a signal-to-noise ratio greater than 25:1 makes the Temposonics sensor a good fit for this difficult application.

Standard industry bus communication protocols allows for easy integration in advanced CNC motion controls.

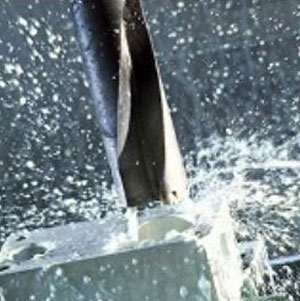

Metals & Metalworking: Machining

- To maintain control of the spindle position on the Z axis of a CNC machining center, the application requires a quality linear measurement instrument, free of recalibration, maintenance and mechanical wear.

Temposonics magnetostrictive position sensors fit this specification and integrate easy into CNC Controls by means of Analog or bus communication. With resolutions down to 0.5 μm, exceptional vibration tolerance and fast update times, the R-Series sensor is the right choice for CNC machines.

Metals & Metalworking: Tube Bending

- The positioning of the bending rolls for the desired bending radius is controlled by hydraulic cylinders equipped with absolute linear position sensors.

The sensors are mounted inside the cylinders and provide continuous position reading.

Standard industry bus communication protocols or Analog output allows for easy integration of the Temposonics sensors in advanced controls.

Metals & Metalworking: Rolling Mill

- Rolling mills depend on linear position sensors to precisely control the roller displacement using Automatic Gauge Control (AGC) cylinders.

The sensor models with SSI output and optional linearization provide the speed and accuracy required for this application. With the robustness of Temposonics technology, the lifetime maintenance costs and system downtime are minimized.

Lumber & Paper: Curve Sawing

- Active curve chipping and active curve sawing enable the lumber mills today to have up to 20 % more lumber recovery compared with the traditional straight line sawing.

Enabling the log to be positioned per the computer calculated optimal sawing pattern, the Temposonics sensor integrated into a hydraulic actuator offers the precise linear feedback needed by the saw motion controller.

Working in high vibration environment, high humidity, large temperature variations, the absolute linear position sensors from Temposonics are maintenance and calibration free.

Lumber & Paper: Wood Harvesting and Sawmills

- Temposonics sensors are designed and built to withstand the high shock and vibration of sawmill applications, and have been the industry standard for more than 30 years. As sawmill products are turned into paper or consumer wood-based products, magnetostrictive position sensors ensure dimensional integrity, and production efficiency and versatility.

Lumber & Paper: Stacker for the Cutter

- By providing rapid, multi-position measurement for up to 30 simultaneous positions, the linear position sensors from Temposonics significantly reduce setup time in applications such as stacking for die cutting.

Replacing individual encoders or proximity switches with a single, multi-position sensor allows customers to adjust multiple trim belts or knives and improve productivity.

The Temposonics sensor models are available in lengths up to 7,620 mm (300 in.) and a variety of outputs for a wide range of controllers.

Fluid Power & Linear Actuators: Hydraulics & Pneumatics

- High performance, durability and value have made Temposonics position sensors the standard for in-cylinder applications in the fluid power industry. In addition, our sensors feature excellent linearity, EMC immunity and resistance to shock and vibration. The innovative modular design of the position sensor allows for easy sensing element replacement and electronics without breaking the cylinder's high-pressure seal, significantly reducing maintenance costs and downtime.

Fluid Power & Linear Actuators: Linear Motors & Actuators

- Temposonics position sensors are ideally suited for electric linear motor and electro-mechanical actuators. By providing an absolute, linear position feedback signal near the load, the controller is able to compensate for backlash or other transmission effects and improve positioning accuracy. The Temposonics technology ensures that no homing position is required and the sensor never loses track of where it is, regardless of traverse speed.

Automation & Assembly: Factory Automation

- Factory automation involves multiple coordinated manufacturing procedures performed in the various production stages. Temposonics linear position sensors are used to ensure the proper position, quantity, forming, painting, or other fabrication process requirements.

With no maintenance, calibration or mechanical wear, accepting a wide range of temperature, humidity and vibration, the absolute position sensor is tied into the automation controls by industry standard analog or digital protocols.

Automation & Assembly: Wood and Metal Assembly

- Temposonics standard and new modular product lines allow embedding of the position sensor into applications such as sprayers, dispensing machines, fastener magazines, x-y positioners, small presses, grinders, planers, saws, clamps, small robots, grippers, filling mechanisms, marking equipment and many other assembly tool applications to determine actuator position, fluid levels or part measurements.

Explosive Environment: Explosive Environment

- Temposonics linear position sensors as well as liquid level transmitters are tested and approved according to UL, FM, CSA and ATEX. They implement the requirements of intrinsic safety and Ex safety for installation in explosive facilities.

Mobile Hydraulics Applications

- The Temposonics® position sensors for mobile machinery are specifically designed for direct stroke measurement in hydraulic cylinders but can also, if required, be mounted externally. Due to their reliability, these sensors increase the machine's productivity, automate recurring operation sequences and reduce maintenance and downtime. Even in harsh environments, at high temperature or high pressure they work reliably and maintenance-free because of its ruggedness. Stroke lengths range from 50 mm - 5000 mm and outputs include CANbus, J1939, PWM and Analog. Redundant models or SIL2 sensors grant maximum safety for critical applications.

Agricultural Equipment

- Agricultural machinery has become high tech. More electronics and software are powering agricultural evolution, both in the office and on machines. Answering the demand for higher precision, more machine adaptability, higher efficiency and less operator fatigue, the manufacturers of tractors, harvesters and specialized implements are using Temposonics position sensors to get the job done.

Construction Machinery & Mining

- Off-road building and mining equipment is quickly evolving from hydraulic joystick control to control-by-wire. This evolution allows on-board intelligent controls to improve accuracy through automated control and avoid dangerous situations with envelope control all while improving productivity. Additionally, demands to reduce operator fatigue, improve ergonomics and add expert control algorithms provide opportunities for Temposonics position sensors to close the loop in steering, cab or seat suspension and implement control.

Transport & Utility Vehicles

- The world's hard working air, marine, rail and over-the-road vehicles depend upon position sensors for critical test, measurement and control. Whether aircraft training simulation, marine steering, snow plow blade control, train door closure, recreational vehicle automation or something new, you can rely on the measurement of Temposonics sensors.

Materialhandling & Logistics

- Efforts to improve efficiency, yield, and throughput in packaging construction, material movement from place to place, and storage or retrieval of parts or inventory can be aided by the precision and versatility of Temposonics position sensors.

Boat Steering Control

- Learn how sensor solutions from Temposonics provide steering position feedback and empower independent steering control on modern watercraft such as sport fishing boats, catamarans, yachts, pleasure craft, racing boats, and more. Affordable and rugged Temposonics sensors enable the automated position of multiple engines for docking, sideways travel, and other complex maneuvers. These non-contact linear position sensors are available in multiple mounting styles and signal outputs.

Wake Boat & Trim Tab Control

- Learn how sensor solutions from Temposonics enable automated trim tab and wake shape control on pleasure craft, wake boats, sport fishing boats, and other modern watercraft. Affordable and rugged Temposonics sensors provide responsive position information along the stroke of the actuator allowing control surfaces to be deployed or return to known positions at the press of a button. These non-contact linear position sensors are available in multiple mounting styles and signal outputs. Simplify your automation.

Watercraft Tank Level

- Learn how sensor solutions from Temposonics enable simplified coordination of steering position and reliable tank level measurements on modern watercraft such as the catamaran featured in this video. Affordable and rugged Temposonics sensors enable the automated positioning of multiple rudders providing streamlined and simplified controls. In addition, the same sensor technology can be utilized in liquid tanks (fuel tanks, grey water, black water, fresh water tanks, etc.) for robust and reliable level measurements. These non-contact linear position sensors are available in multiple mounting styles and signal outputs. Simplify your automation.

Light Industrial Applications

- Some applications are so fine and small, that they require special sensors for critical position control. Automotive and medical equipment are just two of these sectors where the specifically designed linear transducers for precision engineering can be applied.

Automotive

- Temposonics position sensors provide critical position control for closed or open loop system designs. With magnetostrictive position sensors, control-by-wire in active and semi-active ride control suspensions, energy conserving electric power-assisted steering, lighter and more efficient electronically shifted manual transmissions, and automatic headlight dimming systems can be made possible.

Medical Equipment & Mobility

- In medical equipment such as diagnostic tools, treatment instruments, patient care appliances, and rehabilitation or patient mobility devices, Temposonics position sensors offer more precise and repeatable positioning and smoother, more controlled linear motion. The magnetostrictive linear position sensors and liquid level transmitters measure critical treatment fluid and valuable biotech process with high repeatability, accuracy and reliability.

Liquid Level Applications

- The Level Plus® liquid level transmitters feature up to 5-in-1 measurement of level, interface, volume, HI level switch, and temperatures of a vessel from one opening. The Temposonics® technology provides wear-free, continuous level measurement that does not require maintenance or recalibration. The absolute level is detected directly with one or more floats, which operate reliably even in harsh applications.

AST Tank Gauging

- Level Plus liquid level transmitters offer 4-in-1 measurement of the product level, interface level, temperature, and volume in an aboveground storage tank through one process opening. Combining the measurement of four process variables from one instrument reduces cost and allow for installation without tank modifications.

The Tank SLAYER® level transmitter is designed to offer the 4-in-1 measurement as well as determine the volume in the tank from a 200 point strap table that is entered by the user. The addition of simple calibration and no scheduled maintenance or recalibration allow for Tank SLAYER® to have a lower installed costs and lifetime costs than alternative technologies such as radar and servo gauges.

Level Monitoring of Liquid Gas

- Level Plus liquid level transmitters offer unsurpassed performance in LPG bullet tanks due to their ability to measure the product level and temperature level from one process opening.

The RefineME® level transmitters can be installed in a standard 2 inch process opening and all of the electronics can be fully serviced without having to enter the tank. By not having to enter the tank, the user can expect less downtime and more profit.

Chemical Blending Tanks

- Level Plus liquid level transmitters are designed to work in most harsh environments. One main benefit of magnetostrictive technology is its ability to function in harsh environments including steam, foam, vapors, mixing, and changes in dielectric constant.

The RefineME® level transmitter is able to function through changing environmental conditions while providing a steady and accurate output. The RefineME® level transmitter also offers HART for programming and calibration.

Inventory Monitoring of Spirits

- Everyone wants accurate inventory monitoring in order to know how much of a liquid is being produced or consumed. The need for distilleries is increased due to taxes. Distilleries are taxed on how much alcohol they produce and the more accurate the inventory level the less distilleries overpay in taxes.

The Tank SLAYER® level transmitter was chosen due to the high level of accuracy offered as well as the intrinsically safe rating. Distilleries are classified as hazardous locations due to the flammability of alcohol and the Tank SLAYER® offers both an intrinsically safe rating and an explosion proof / flameproof rating.

Level Measurement Through Foam

- Beer enthusiasts enjoy a nice head of foam on top of their favorite pint. However, very few level measurement technologies are capable of detecting a liquid level under a layer of foam. Magnetostrictive level technology is one of the technologies that can measure through foam and is also approved for use in sanitary applications.

The SoClean® level transmitter is available in a standard sanitary finish of Ra25 µin and also an electropolished finish of Ra 15 µin. The SoClean® level transmitter is also capable of meeting the 3-A standards including the float.

Pharmaceutical Production Tank

- Pharmaceutical applications require a high level of accuracy and a sanitary package. Level Plus® liquid level transmitters are able to provide both qualifications and have been doing so for the pharmaceutical industry for over 25 years.

The SoClean® level transmitter provides an analog output for the tank level and is available in a sanitary Ra 25 µin finish or an electropolished Ra 15 µin finish. The complete stainless steel construction allows the SoClean® to be used in CIP, SIP, and washdown applications.

Sanitary Applications in Harsh Environments

- Bioreactors and blending tanks in the pharmaceutical industry typically demand accuracy and the ability to meet CIP, SIP, and washdown procedures. Level Plus transmitters are available with 316 (1.4404) stainless steel pipes and housings. The chemical compatibility of stainless steel allows the transmitter to be washed with caustic chemicals without compromising performance or longevity.

The SoClean® level transmitter is also available in alternative materials to meet customer applications. The materials include FEP, Nickel Alloy C-276, and Sanitary Nickel Alloy C-276.

Further Applications

- The Temposonics® positions sensors are not only used industrial, mobile, light industrial, or liquid level applications but can also be used in wide array of other sectors such as entertainment, tracking of satellites, or geomonitoring to enable forecasts for avalanches or hang slippings.

Entertainment

- Flooding in the canyon, shark attacks, train derailments due to giant gorilla rampages, cannon fire sinking pirate ships, wild rides into the earth and outer space. All of these are simulations with controlled realism because Temposonics linear position sensors provide the motion feedback. All of the major theme parks have thousands of our transducers giving life to their creations.

Satellite Tracking

- NASA Deep Space Network (DSN) antennas are using Temposonics absolute position sensors for tracking spacecraft activity. With more many years of service, the DSN antennas are operating under open skies, being exposed to weather conditions 24/7.

With no maintenance, calibration or mechanical wear, and accepting of a wide range of temperature, humidity and vibration influences, the Temposonics sensors have proven their quality and reliability over the years in this highly demanding application.

Geomonitoring

- Temposonics position sensors are used in unstable mountainsides for position measurement. Thereby dangerous situations – like sudden hang slippings and avalanche – can be detected and the evacuation can be done in time.

The robust sensors guarantee maximum reliability, high-precision position measurements and long term operation in the harshest environments. Temposonics sensors are ideal for enduring automatic geo-monitoring systems.