- Offer Profile

- Since 1973 COORD3 has been designing, manufacturing and distributing

coordinate measuring machines with superior mechanical structure.

With over 3000 machines and measuring systems installed all over the world, we contribute to guaranteeing the highest quality products to the customers of the companies that have chosen us.

Each of our metrology systems was created with the aim of exceeding customer expectations; this is why our company is dedicated to the constant research and development of cutting-edge technologies, which allow us to offer current and customized solutions based on the needs of the individual customer.

The Coord3 production site is in Italy, in Bruzolo (Turin), but thanks to a capillary network of branches, distributors and agents, we manufacture and install metrology systems all over the world.

CMM BRIDGE

-

THE MOST POPULAR ARCHITECTURE FOR SMALL AND MEDIUM-SIZED MEASURING MACHINES.

THE “BRIDGE” CONFIGURATION IS THE IDEAL SOLUTION FOR SMALL-SIZED MEASURING TASKS, AS IT ENSURES BOTH AN EXCELLENT QUALITY-PRICE RATIO AND THE INDISPUTABLE ADVANTAGE OF HAVING A WORKBENCH INTEGRATED IN THE MACHINE STRUCTURE.

GENERAL FEATURES

Bridge CMMs are equipped with three moving elements which are shifted isostatically on air bearings along three guides perpendicular to each other.

The measuring sensor is fixed to the ram, which slides vertically with respect to the head. This moves horizontally with respect to the crossbeam element, which in turn is held by two struts installed at its ends, and slides horizontally with respect to the cast iron base plate

- BENCHMARK

- ARES

- UNIVERSAL

- KRONOS

CMM BRIDGE - ARES

- High-performance dimensional inspection for a wide range of metrology applications.

ARES CMMs have a lower overall height compared to most cmm solutions available on the market. they may also be provided with a low profile support stand to reduce the overall height by an additional 100 mm.

This particular features makes ARES especially suitable for inspection laboratories with low ceilings.

ARES CMMs are available in manual or CNC configuration; manual units may be optionally upgraded to a full CNC version at a later date.

Two performance levels are available:- ARES: for standard applications.

- ARES NT: per for higher performance requirements. The ARES NT model has a silicon carbide Z-axis column that increases the overall stiffness of the measuring platform.

CMMs are available with bridge widths of 500 mm and 700 mm, and are perfectly suitable for workshops.

FEATURES AND BENEFITS- Ultra-rigid alloy CMM frame provides maximum stiffness for scanning applications

- Rapid thermal diffusion structure when environment conditions change

- FEA-designed bridge beam extrusion to optimize the moment of inertia and ensure minimum deflection when operating at high accelerations

- M8 threaded table fitted in a wide grid pattern

- Rigid air bearings for wide bearing spread ratios

- Pneumatic Z-axis counterbalance

- Free-floating, 0.1-micron resolution measuring scales with incorporated dynamic signal processing

- Fully digital motion control with probe path blending for optimized performance

- Zero hysteresis friction drives on all axes Passive vibration damping system to isolate external vibrations

- Free access to the CMM measuring area from all sides

- Maximum positioning speed: 517 mm/sec

- Maximum acceleration: 1730 mm/sec2

CMM BRIDGE - BENCHMARK

- Budget priced yet high-performance cmm for high-precision inspection of small - and medium - sized parts.

The open structure of the benchmark solution offers an outstanding ergonomic design. thanks to its compact size, it is perfect for quality control rooms or production environments.

The fully equipped BENCHMARK solution with air bearings ensures an accuracy of 2.5 microns. The standard version is equipped with a Renishaw touch-probe and can be supplied with a motorized probe head for fully automated inspection applications.

The BENCHMARK CMM is particularly suitable for small workshops.

The BENCHMARK solution is available in manual or CNC configuration. Manual units can be later upgraded on site to the full CNC version, which offers the opportunity to consider a two-phase investment.

FEATURES AND BENEFITS- Ultra-rigid platform in advanced alloy

- Rapid thermal diffusion through advanced alloy CMM frame when temperatures change

- FEA design provides optimum moment of inertia and stiffness, allowing high accelerations

- One-piece granite base plate with M8 threaded table inserts with wide grid pattern

- Rigid air bearings Pneumatic Z-axis counterbalance 0.1-micron resolution measuring scales with dynamic signal processing

- Fully digital motion control with probe path blending for optimized CMM performance

- Zero hysteresis friction drives to all axes Passive vibration damping system to isolate external vibrations

- Free access to the CMM measuring area

- Maximum positioning speed: 500 mm/sec

- Maximum acceleration: 1500 mm/sec2

CMM BRIDGE - KRONOS

- BRIDGE CMMs for measuring large mechanical parts without the need for specially constructed foundations.

Its robust construction and the protection system of covers and bellows, allows the kronos series to operate in several production environments, ranging from metrology rooms to manufacturing areas.

This CMM is equipped with a portable lever unit formanual control of motorised motions (Arkey).

The KRONOS is also available in the NT, version, which features an innovative silicon carbide ram for enhanced metrological performances.

FEATURES AND BENEFITS- Moving alloy bridge frame on granite table machine base with isostatic supporting system

- Z ram made of micro-machined alloy extrusion or Silicon Carbide (NT)

- Mixed rack and pinion drives with zero-hysteresis friction drive for smooth and repeatable operations

- Measuring system with high-resolution linear transducers (0.1 μm)

- Multi-sensor temperature compensation system complete with part temperature probe

CMM BRIDGE - UNIVERSAL

- The new generation of cmms designed by COORD3 builds upon 40 years of experience

The universal series represents the ultimate generation of cmms.

It is perfectly suitable both for traditional point-to-point measurements and for more sophisticated contact scanning and laser scanning cycles. Thanks to its outstanding structural rigidity, the UNIVERSAL range is an ideal platform for 5-axis scanning systems and gear measurement applications.

The technical features are specifically designed to reduce the number of parts, streamline construction and minimize maintenance times and costs.

The COORD3 UNIVERSAL range offers the first CMM on the market equipped with wireless thermal compensation system. This fully automatic system dynamically compensates for changes in CMM operating environment in a temperature range from 16°C to 26°C. In addition, the use of high-resolution (0.1 μm), free-floating optical linear scales eliminates any distortion due to deformations of the main structure.

FEATURES AND BENEFITS- Ultra rigid alloy CMM platform provides maximum stiffness for scanning applications

- Structure highly responsive to any ambient temperature change

- FEA designed bridge beam extrusion provides optimum moment of inertia for minimum deflection operating at high accelerations

- Monolithic granite base plate with integral Y dovetail guide-way

- M8 threaded table inserts in generous grid pattern

- Sliding system on air bearings with ultra-rigid isostatic support on all measuring axes

- Pneumatic Z-axis counterbalance

- High-resolution optical linear scales (0.1 micron) mounted in carriers with dynamic signal processing

- Full digital motion control with probe path blending for optimized CMM performance

- Zero hysteresis toothed belt drives to all axes

- Passive vibration damping system to isolate external vibrations

- Easy access to the measuring area

- Maximum positioning Speed 866mm/sec

- Maximum acceleration 1500mm/sec2

CMM BRIDGE - U-CONTROL

- Economic and compact cmm thanks to the integrated high-performance control for high precision testing of small and medium parts.

The open structure of the u-control solution offers an outstanding ergonomic design. thanks to its compact size, it is perfect for quality control rooms or production environments.

The fully equipped U-CONTROL solution with air bearings ensures an accuracy of 2.5 microns. The standard version is equipped with a Renishaw touch-probe and can be supplied with a motorized probe head for fully automated inspection applications.

The U-CONTROL CMM is particularly suitable for small workshops.

The U-CONTROL CMM has a measuring volume of 600mm x 500mm x 500mm

FEATURES AND BENEFITS- Ultra-rigid platform in advanced alloy

- Rapid thermal diffusion through advanced alloy CMM frame when temperatures change

- FEA design provides optimum moment of inertia and stiffness, allowing high accelerations

- One-piece granite base plate with M8 threaded table inserts with wide grid pattern

- Rigid air bearings

- Pneumatic Z-axis counterbalance

- 0.1-micron resolution measuring scales with dynamic signal processing

- Quick and easy installation with pre-assembled monobloc shipping

- Overall dimensions optimized due to an integrated control

- Zero hysteresis friction drives to all axes

- Passive vibration damping system to isolate external vibrations

- Free access to the CMM measuring area

- Maximum positioning speed: 500 mm/sec

- Maximum acceleration: 1500 mm/sec2

CMM GANTRY

-

COORDINATE MEASURING MACHINES FOR LARGE PIECES

IN ADDITION TO MINIMIZING ERRORS OF INERTIA AND DISTORTIONS IN SHAPE, THE COLUMN ARCHITECTURE ENSURES EXCELLENT METROLOGICAL PERFORMANCES EVEN IN CASE OF LARGE MEASURING VOLUMES, WHILE OFFERING FULL ACCESS TO THE WORK AREA FOR PROGRAMMING, LOADING AND UNLOADING OPERATIONS.

GENERAL FEATURES

Gantry CMMs are equipped with three moving elements which are shifted on air bearings along three guides perpendicular to each other.

The sensor is fixed to the ram, which slides vertically with respect to the head. This moves horizontally with respect to the crossbeam, which in turn slides horizontally with respect to the machine base plate.

The crossbeam is motorised by a rack and pinion drive system along two guide-ways (beams) located over the machine base plate. These guides are supported by a column structure, which thanks to a crossbow system compensates for any lengthwise elongation.

- MCT NT

- MCT STARLIGHT

- MCT PLUS

CMM GANTRY - MCT PLUS

- Large-scale cmm designed for industrial workshops

MCT PLUS is a range of large-scale gantry cmms designed for industrial measuring applications.

Its unique structure incorporates the “Dual Drive” and the “Dual Read” system on the beams to limit structural distortion during motion while ensuring excellent metrological performance levels.

GANTRY MCT PLUS systems are particularly suitable for inspections of large components, such as marine engines and transmissions, aeronautical structures, rotors and components for nuclear and thermal power plants, as well as components of wind turbines.

FEATURES AND BENEFITS- Wide distance between bearings for optimum mechanical stability

- X and Y axes with rack and pinion drive system to ensure an efficient motion of the main axes

- X beams with large transversal section in stabilised steel, equipped with pillar support system to allow for linear expansion without risking stress or distortion

- Measuring system with high-resolution linear transducers (0.1 μm) and with “Dual Reader” and “Dual Drive” systems on the longitudinal X-axis

- Automatic, multi-sensor system for compensating errors due to the thermal elongation of structural elements

CMM GANTRY - MCT NT

- The new gantry range with state-of-theart technologies

The MCT NT series is characterised by an innovative mechanical design, which ensures long-term metrological accuracy while reducing periodic calibration costs.

MCT NT is also available in the NT LIGHT configuration, which features a Z ram in light aluminium alloy and a “Single Read” system on the X-axis.

FEATURES AND BENEFITS- Y main carriage in advanced alloy: ensures high rigidity combined with low weight to reduce inertia effects

- Z ram in silicon carbide: the use of this material ensures outstanding performance levels in terms of both rigidity and thermal stability

- Automatic, multi-sensor system for compensating errors due to the thermal elongation of structural elements

- “Dual Read” system on both X beams to ensure excellent metrological performance levels up to cross sections of 2500 x 1800 mm

- Machine beams are free to expand (no constraints) on their main axis (machine X axis)

- Optical scales free to expand lengthwise. Resolution: 0.1 microns

- It may be equipped with a full fairing and bellows system on the main mobile structure (X and Y axes)

CMM GANTRY - MCT STARLIGHT

- Medium-large column cmm – an all-rounder that ensures an excellent structural rigidity.

MCT SL is a range of medium-to-large gantry cmms that stand out for their excellent structural stability and flexibility.

These solutions may be tailored to any measuring requirements and are available in many different sizes.

MCT STARLIGHT is also available in the NT LIGHT configuration, which features a Z ram in light aluminium alloy and a “Single Read” system on the X-axis.

FEATURES AND BENEFITS- Generous distance between bearings for optimum mechanical rigidity

- Main Y carriage with high rigidity and exclusive tubular steel structure

- Z ram in extruded aluminium alloy to guarantee rigidity and minimize inertia

- X beams with large transversal section in stabilised steel, equipped with a support system to allow for linear expansion without risking distortion Ground X/Y axes guide-ways in high-resistance epoxy resin (roughness 0.4 mm)

- Measuring system with high-resolution linear transducers (0.1 μm) with “Dual Reader” system on the longitudinal Xaxis “Dual Drive” system on main X carriage (optional, standard for stroke Y=3000)

- Automatic, multi-sensor system for compensating errors due to the thermal elongation of structural elements

CMM HORIZONTAL

-

THE IDEAL SOLUTION FOR MEASURING THIN-WALLED COMPONENTS.

HORIZONTAL ARM CMMS ARE THE IDEAL SOLUTION TO MEASURE COMPONENTS SUCH AS CAR BODIES, SHEET METAL PANELS, VEHICLE GLASS AND DASHBOARDS, AND ARE PARTICULARLY SUITABLE FOR THE DIMENSIONAL TESTING OF MECHANICAL PARTS SUCH AS ENGINE BLOCKS, GEARBOXES AND CASTINGS, AS WELL AS AERONAUTICAL AND AUTOMOTIVE COMPONENTS.

GENERAL FEATURES

Horizontal arm CMMs are equipped with three moving elements which are shifted along three guides perpendicular to each other.

The sensor is fixed to the ram, which slides horizontally with respect to the carriage. This moves vertically with respect to the column, which in turn slides horizontally with respect to the machine base plate.

- SWAN SI

- SWAN L

- JUPITER

CMM HORIZONTAL - SWAN SI

- Horizontal arm measuring system with longitudinal x guide attached to the floor (“runway” structure)

The SWAN SI range offers a technologically advanced and cost-optimised solution for dimensional inspection of thin-walled metal sheet or plastic components typically used in the automotive industry.

SWAN SI CMMs are equipped with air bearings on both the Y-axis and the Z-axis, which ensure excellent results and high accuracy. The X-axis guide is located on the side of the cast iron or granite base plate.

The light and robust carriage, built entirely of light alloy, as well as the dual mechanical guide-way on the X beam, provide reliability, precision and rapid measurements.

When used in manufacturing environments, the SWAN SI machine may be installed on a pneumatic vibration isolation system without requiring specially constructed foundations.

FEATURES AND BENEFITS- Measuring system with optical linear transducers

- Motion control thanks to DC servomotors

- Air bearing guides on Y and Z axes, precision guide on X-axis

- Mechanical head balancing with safety brake

CMM HORIZONTAL - SWAN L

- Horizontal arm measuring system with longitudinal x guide attached to the side of the surface plate (“console” structure)

SWAN L CMMs feature a horizontal arm installed on guides (tracks) and may be installed flush with the floor of the plant.

Its walkable covers allow operators to control large and heavy parts, which may be placed on a separate floor, on a system installed on the ground or on an automated system.

Their “Console” structure with integral support plate is extremely modular and easy to configure, and thus combines the flexibility and programmability of measuring machines with the speed and intuitive use of traditional measurement gauges.

FEATURES AND BENEFITS- Measuring system with optical linear transducers

- Motion control thanks to DC servomotors

- Air bearing guideways on all axes

- Mechanical head balancing with safety brake

CMM HORIZONTAL - JUPITER

- Horizontal arm measuring system with longitudinal x guide attached to the floor (“runway” structure) with mobile arm equipped with fairing

JUPITER CMMs are reliable, high-performance machines designed for direct use in production areas and developed specifically for body and subassembly inspection applications.

JUPITER CMMs are mounted on tracks and available both in single and dual arm versions. They are totally encapsulated to guarantee thermal insulation, and feature a system that prevents contamination from the workshop floor.

Their open built-in structure, the walkable covers that protect the X guideways and the fairing that protects the entire structure ensure maximum accessibility to the measuring area and simplify part loading and unloading operations, in addition to being designed for direct use in production areas.

These CMMs, which may be installed with Flush-floor level equipped with walkable covers as a standard feature, stand out for their high dynamics and metrology performances.

The air bearings mounted on both the Y-axis and the Z-axis are the key element of this high-performance measurement solution. In the dual arm configuration, the measurement volumes of the two horizontal arms overlap by 100 mm in order to allow for measurements the entire structure.

FEATURES AND BENEFITS- Measuring system with optical linear transducers

- Motion control thanks to DC servomotors

- Air bearing guides on Y and Z axes, recirculating ball bearings on X-axis

- Mechanical head balancing with safety brake

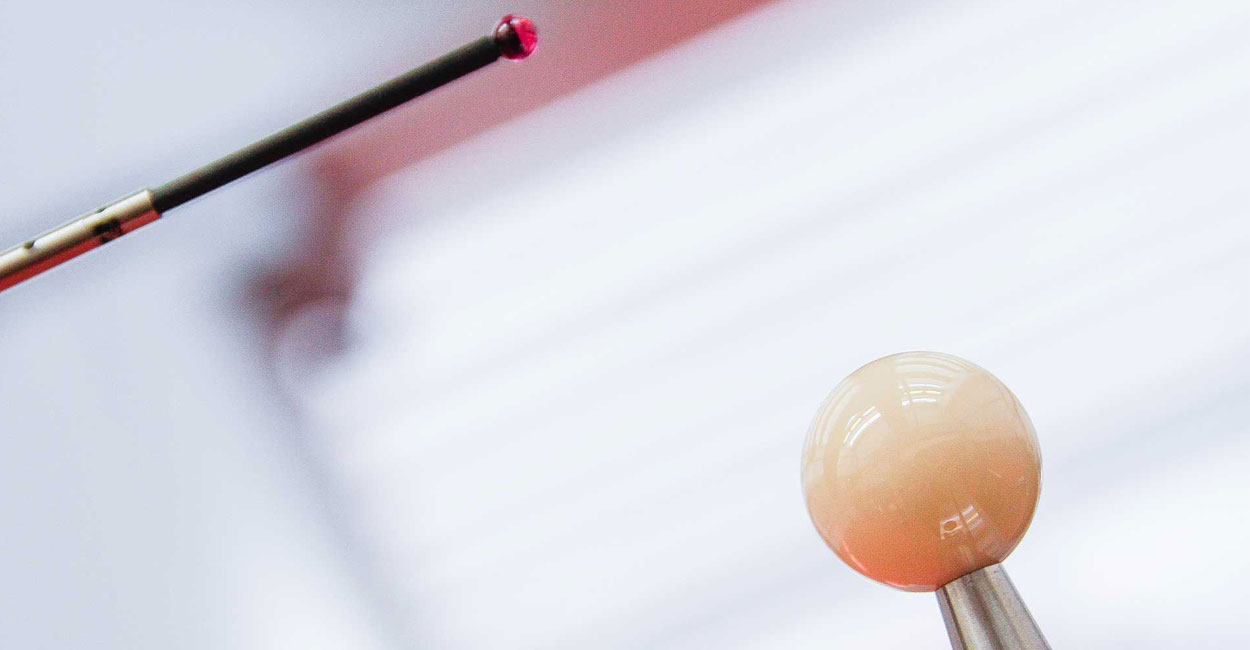

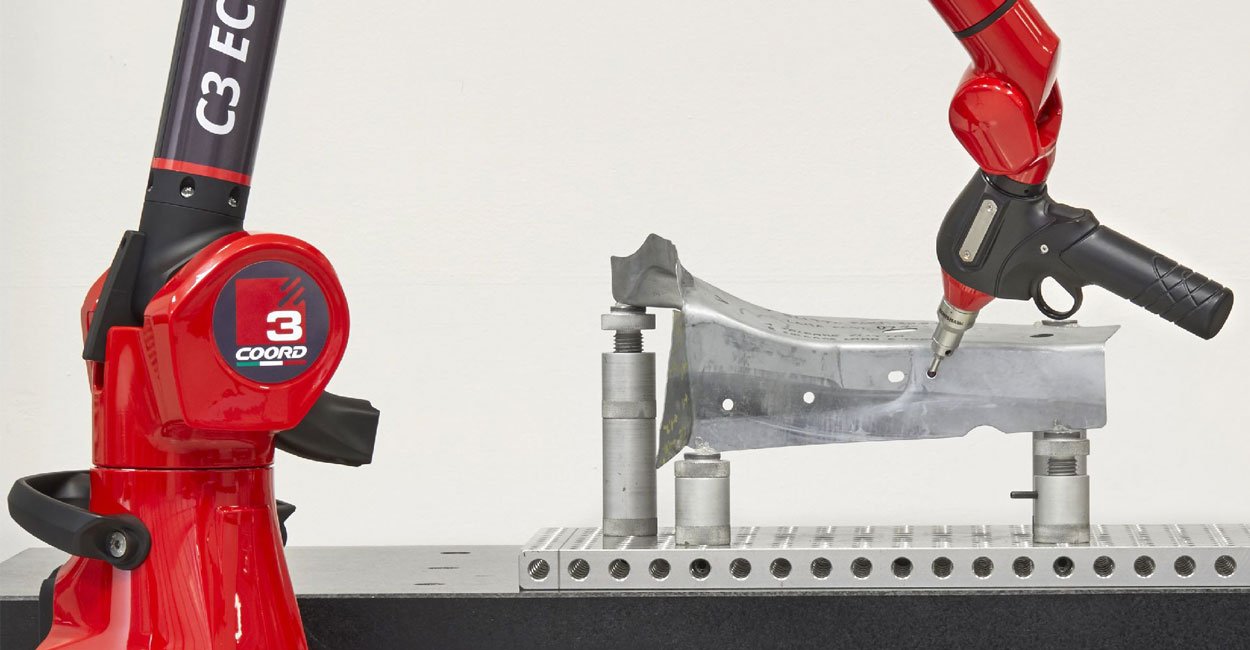

ECHO PORTABLE ARM

- As the market keeps evolving and customers demand increasingly tailored solutions for professional measuring tasks, we integrated our product portfolio with 6- or 7-axis 3d measuring arms.

ECHO PORTABLE ARM

- COORD3 enriches its product portfolio by inserting portable measuring arms (pcmm) with 6 or 7 axes.

C3 ECHO | PLUS 6A

Budget priced, lightweight and easy-to use solution with an aluminium/carbon structure.

Work volume: 2.6m/3.2m/4.2m/4.6m

C3 ECHO | PRO 6A

The ideal solution for 3D contact and contactless measurements, combining accuracy and ease of use.

Technical features: Ready for use / compatible with the main software solutions available on the market / ergonomic handle / Stable, magnetic rest position / Automatic detection of the probe diameter.

Work volume: 2m / 2.5m / 3m / 3.5m / 4 m / 4.5m

C3 ECHO | PRO SCAN 7A

A well-designed combination of arm and 3D scanner to save time.

Technical features: the scanner may be removed without tools / the probe may be applied directly on the scanner / high resolution/ high accuracy even on complex surfaces (dark and glossy carbon surfaces).

Work volume: 2m / 2.5m / 3m / 3.5m / 4 m / 4.5m

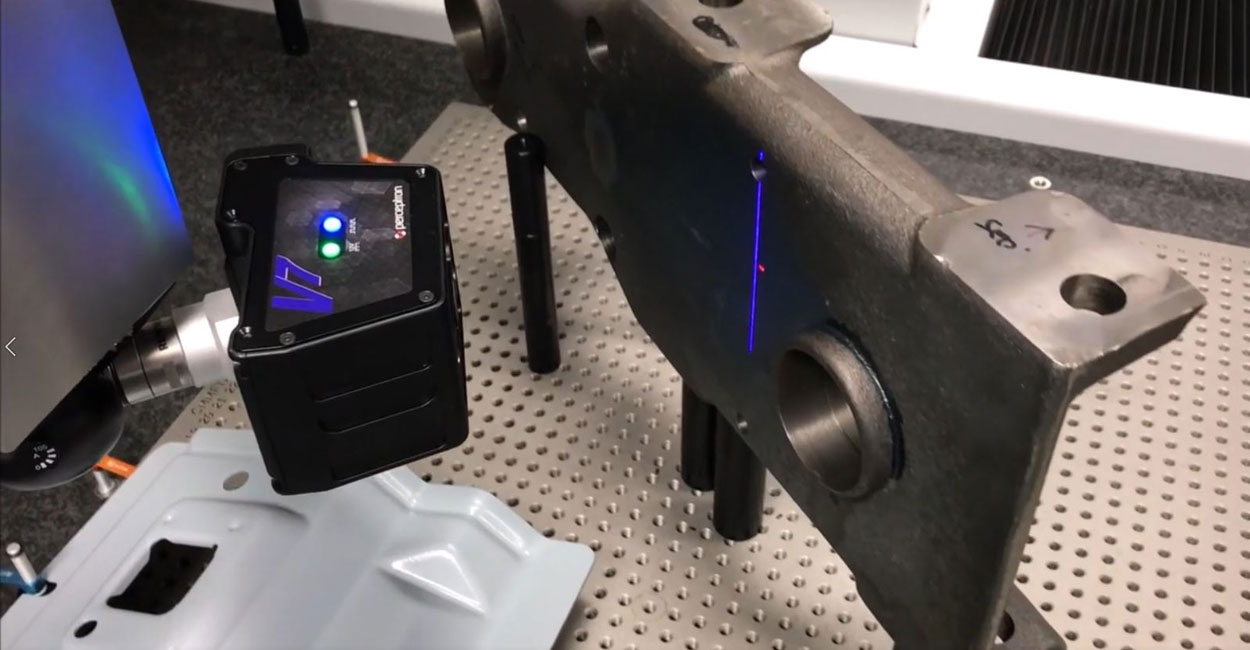

LASER SCANNER V7

PERCEPTRON IS HAPPY TO ANNOUNCE THE MARKET LAUNCH OF THE NEW V7 LASER SCANNER

Perceptron’s latest v7 3d laser scanner is built using cutting edge technology, including the use of blue laser at a price lower than the competition, making scanning affordable for all coord3 cmm users

This versatile 3D scanning tool allows reverse engineering, point cloud and CAD comparison, 3D visualization, and inspection applications.GENERAL CHARACTERISTICS

SENSOR- Length: 114.26 mm

- Height: 112.65 mm

- Width: 65 mm

- Weight: 456 g

- Connections: GiGE Ethernet

- Operating temperature: 10°C - 40°C

- Laser class: 2M

- Laser wavelength: 450 nm (blu)

- Certification: UL, CSA, CE

- Safety: IEC 60825-1:2007

- Protection: IP54

- Depth of field: 100 mm

- Near field width: 48 mm (+/-2 mm)

- Far field width: 88 mm (+/-4 mm)

- Mean point resolution: ≤ 40 μm at mid field

- Points per line: 1280

- Scan rate: >64,000 points per second

- Frequency: >50 Hz

FEATURES

- Speed: up to 1,280 points along the laser line at a rate up to 50Hz provides high-density scan data.

- Dynamic range: The V7 sensor blue laser captures data accurately even on dark and reflective surfaces without the need for harmful white powder sprays and paints.

- Field of view: thanks to maximum width of 88m and to a maximum depth of 100mm, it can capture large and complex areas.

- Real-time integration: direct integration with easy-touse TouchDMIS software to allow the user to scan wihin a familiar interface.

METROLOGY SOFTWARE | TOUCHDMIS

NEW RELEASE 6.1 SP2 - MEASURE WITH ERGONOMICS AND SIMPLICITY

- The new version of TouchDMIS 6.1 SP2 has been released; here the main new capabilities:

MANUAL ALIGNMENT USING V7 LASER SCANNER DIRECTLY- TouchDMIS allows now to make the first part alignment directly with the V7 laser scanner.

- It is not required (although it is possible) to make a pre-alignment with a tactile probe.

- It is enough to roughly scan the areas to be used for the alignment even manually by joystick.

- The features extracted by the scanned cloud of points can be used to make any possible type of required alignment.

POINTS OF INTEREST- It is now possible, easy and intuitive to extract single points from a scanned cloud of points.

- For each required point, a text or graphic report can be made.

- Each single operation, will be automatically saved in the DMIS program so that, starting from the second part, everything will be done automatically.

TRUE POSITION TOLERANCE

In this version an extensive changes were done in True position calculations in case datum is used. Calculations are now more universal, which leads to cover more datum combination cases

EASY RUNNER-JOB ORGANIZER

The Job Organizer option of Easy Runner allow to run the execution of multiple different parts measure by “One click”. All programs will be launched and run without the need of human presence. All reports will be automatically created and saved locally or wherever required, for example, by industry 4.0 specifications.

CAD LAYER OFFSET

The possibility to apply an offset to features covers now every features type.

SURFACE PROFILE TOLLERANCE

Not symmetrical surface profile tolerances are now supported. Modifiers from both ASME and ISO can be used.

THERMAL COMPENSATION

Thermal compensation settings are now in the main measuring environment.