- Offer Profile

- Vestas is the only global

energy company dedicated exclusively to wind energy - improving business

case certainty and reducing the cost of energy for our customers.

Vestas works in close partnership with customers to offer the most effective

solutions towards energy independence. Our core business is the development,

manufacturing, sale and maintenance of wind power plants – with competencies

that cover every aspect of the value chain from site studies to service and

maintenance.

Turbines

-

With Vestas as your supplier and business partner, you are basing your investment on documented processes: More than 40 years experience, insights and knowledge of wind.

Vestas wind turbines are checked and tested at our own test centres, after which the results are verified and certified by independent organisations. We also continuously monitor a large number of the turbines in operation, both to determine how the turbine design can be optimised and to use the data and knowledge to make turbine operation even more reliable and cost-effective. Vestas has an extensive portfolio of turbines which are each suited to specific conditions and requirements. EnVentus™ platform

-

Introduced in 2019, the EnVentus™ platform architecture connects proven system designs from the 2 MW platform, 4 MW platform and 9 MW platform turbine technology. The result is one versatile platform architecture that delivers a higher level of robustness and performance with the ability to create an even more finely matched combination of turbines to harness available wind energy in any specific location.

EnVentus™ based variants are designed with global applicability in mind. As part of the suite of Vestas offerings, EnVentus™ turbines offer a wide range of standard hub heights and modes of operation that can be combined with an extensive list of technology options to create customised solutions to suit the needs of each unique project.

V162-6.2 MW™

-

With a swept area of over 20,000m², the V162-6.2 MW™ applies the largest rotor size in the Vestas portfolio to achieve industry-leading energy production paired with a high capacity factor.

Due to the large operational envelope, the V162-6.2 MW™ is relevant for low to medium wind speeds and has extensive applicability in high average wind speeds.

With a standard Sound Power Level of 104.8dB(A) and up to 30 percent higher energy production than the V150-4.2 MW™, the V162-6.2 MW™ establishes a new benchmark in competitiveness.

Options available for the V162-6.2 MW™ IEC S

- Condition Monitoring System

- Oil Debris Monitoring System

- Service Personnel Lift

- Low Temperature Operation to -30°C

- Vestas Ice Detection™

- Vestas Anti-Icing System™

- Vestas InteliLight®

- Vestas Shadow Detection System

- Aviation Lights

- Aviation Markings on the Blades

- Fire Suppression System

- Vestas Bat Protection System

- Lightning Detection System

- Power Optimised Modes

V150-6.0 MW™

- The V150-6.0 MW™ lifts the larger rotor introduced with V150-4.2 MW™ into stronger wind speeds. Combined with its higher generator rating, it increases the production potential at turbine level by more than 20 percent compared to V150-4.2 MW™ in medium wind speed conditions.

Applying Vestas’ most advanced aerofoil blade design combined with lower rotational speeds of the EnVentus™ drivetrain, means realisation of power production potential at very low sound power levels. A comprehensive portfolio of standard and site-specific towers allow for application in tip height constraint markets, varying from 180m to 230m.

Utilising Vestas LDST tower technology, V150-6.0 MW™ can take advantage of favorable wind conditions at 166m hub height.

Options available for the V150-6.0 MW™ IEC S- Condition Monitoring System

- Oil Debris Monitoring System

- Service Personnel Lift

- Low Temperature Operation to -30°C

- Vestas Ice Detection™

- Vestas Anti-Icing System™

- Vestas InteliLight®

- Vestas Shadow Detection System

- Aviation Lights

- Aviation Markings on the Blades

- Fire Suppression System

- Vestas Bat Protection System

- Lightning Detection System

- Load Optimised Modes

4 MW platform

- Our 4 MW platform is designed for a broad range of wind and site conditions, onshore and offshore, enabling you to mix turbines across your site or portfolio of sites, delivering industry-leading reliability, serviceability and exceptional energy capture.

The 4 MW platform was introduced in 2010 with the launch of the V112-3.0 MW®. Since then over 38 GW of the 4 MW Platform has been installed all over the world, making it one of the most popular platforms in our portfolio.

Rotor diameters range from 105 to 155 meters and the rated output power is up to 4.2 MW. Using well proven technologies like a full-scale converter, the 4 MW platform meets even the most challenging grid requirements, providing excellent energy yield in all wind and weather conditions.

The 4 MW platform combines Vestas’ proven track record with our continuous efforts to improve and optimise our products, making it the obvious choice for customers looking to combine reliability with performance.

V155-3.6 MW

-

With the introduction of V155-3.6 MW™, Vestas expands the 4 MW platform to strengthen park performance in low and ultra-low wind conditions. V155-3.6 MW™ features the largest rotor of the 4 MW platform, increasing swept area to 18 869m2 and delivering excellent partial load energy production.

Combined with a 3.6MW standard rating, V155-3.6 MW delivers comparable park AEP with 39% fewer turbines for MW-constrained markets.

V150-4.5 MW

-

Building on the commercial success of the V150-4.2 MW™ for low wind conditions, we are ready to introduce the V150-4.5 MW with an expanded global applicability.

Where permits allow, the higher rating variant delivers an over 3 percent increase in annual energy production compared to the V150-4.2 MW, while maintaining the same application space and noise level.

V150-4.2 MW

-

With the V150-4.2 MW™ Vestas leads onshore wind power to new heights. With 73.7 meter long blades and the industry’s tallest steel tower, the V150-4.2 MW™ stretches nearly a quarter of a kilometer into the air and is one of the highest producing onshore low wind turbines in the industry.

Combined with a leading capacity factor in low wind conditions, the turbine delivers a 21 percent increase in annual energy production compared to the V136-3.45 MW® while achieving a sound power level of only 104.9 dB(A) to serve sound sensitive regions.

V136-3.45 MW

-

V136-3.45 MW™ combines Vestas' most advanced aerofoil design to date with the proven 4 MW nacelle and Large Diameter Steel Tower (LDST) technology, to deliver high and efficient energy production in low wind conditions.

The aerofoil design, applied to the 66.7m long blades, enables a 16 percent* increase in annual energy production while at the same time minimising structural loads. Advanced aerodynamics, particularly at the blade tips, decrease the maximum noise emission level.

Vestas has 15 years of experience optimising carbon blade application, and the V136-3.45 MW™ benefits from advanced use of carbon pultrusions, resulting in light-weight, highly robust blades with optimal performance. The industry leading lightning protection system and highly accelerated lifetime testing ensure high product reliability.

V126-3.45 MW

- Built on the same proven technology as the V112-3.0 MW®, the V126-3.45 MW™ IEC IIA/IEC IIB operates on medium-wind sites. Equipped with the industry known structural shell blades, the blades of the V126-3.45 MW™ turbine do not weigh more than those of the V112-3.0 MW®. The 126 m rotor enables greater wind capture, which in turn produces more energy at a reduced cost. The result is exceptional profitability in areas with low wind, and new frontiers for wind energy investment.

V117-3.45 MW

- On high wind-sites the V105-3.45 MW™, V112-3.45 MW™ and V117-3.45 MW™ are excellent turbine choices. A combination of the three variants can optimise your site layout and improve your production significantly. Due to the similar electrical properties, sound emissions and nacelle design, it is easy to mix and match the turbines from the 3 MW platform to maximise production on heavily constrained sites.

V112-3.45 MW

- The V112-3.45 MW™ IEC IA is a high-wind turbine and has a very high capacity

factor. Similar to the other 3 MW turbines, the V112-3.45 MW™ IEC IA turbine

makes efficient use of its grid compatibility and is an optimal choice for sites

with MW constraints.

On high wind-sites the V105-3.45 MW™, V112-3.45 MW™ and V117-3.45 MW™ are excellent turbine choices. A combination of the three variants can optimise your site layout and improve your production significantly. Due to the similar electrical properties, sound emissions and nacelle design, it is easy to mix and match the turbines from the 3 MW platform to maximise production on heavily constrained sites.

V105-3.45 MW

- With a rotor size of 105 m, the V105-3.45 MW™ IEC IA is the turbine that fits

the most severe wind conditions. It has an extremely robust design for tough

site conditions and is especially suited for markets with tip-height

restrictions and high grid requirements.

The V105-3.45 MW™ blade is a shortened version of the proven and tested pre-preg blade used on the V112-3.0 MW®, the V112-3.45 MW™ and the V117-3.45 MW™. Like all 3 MW turbines, the V105-3.45 MW™ is equipped with a full-scale converter ensuring full compliance with the challenging grid codes in countries like the UK and Ireland.

V150-4.2 MW

- With the V150-4.2 MW™ Vestas leads onshore wind power to new heights. With 73.7 meter long blades and the industry’s tallest steel tower, the V150-4.2 MW™ stretches nearly a quarter of a kilometer into the air and is one of the highest producing onshore low wind turbines in the industry. Combined with a leading capacity factor in low wind conditions, the turbine delivers a 21 percent increase in annual energy production compared to the V136-3.45 MW® while achieving a sound power level of only 104.9 dB(A) to serve sound sensitive regions.

V136-4.2 MW

- The V136-4.2 MW™ is designed for low to medium wind sites. It boosts performance by 11 percent compared to V136-3.45 MW®, and with 103.9 dB(A) max sound power level enables permitting and project realisation in sound critical areas.

V117-4.2 MW

- V117-4.2 MW™ is designed for medium to high wind speeds, and it boosts performance by 13 percent compared to V117-3.45 MW. Applying the existing upgraded gearbox from V136-3.45 MW and V126-3.45 MW Htq, the V117-4.2 MW™ is able to withstand extreme wind conditions, making new sites possible for wind energy projects.

V136-4.5 MW

- The V136-4.5 MW™ is designed for low to medium wind conditions. For sites where permits allow, it boosts energy production performance by +3 percent compared to the V136-4.2 MW®. With the same max sound power level as the V136-4.2 MW, it enables permitting and project realisation in sound-critical areas.

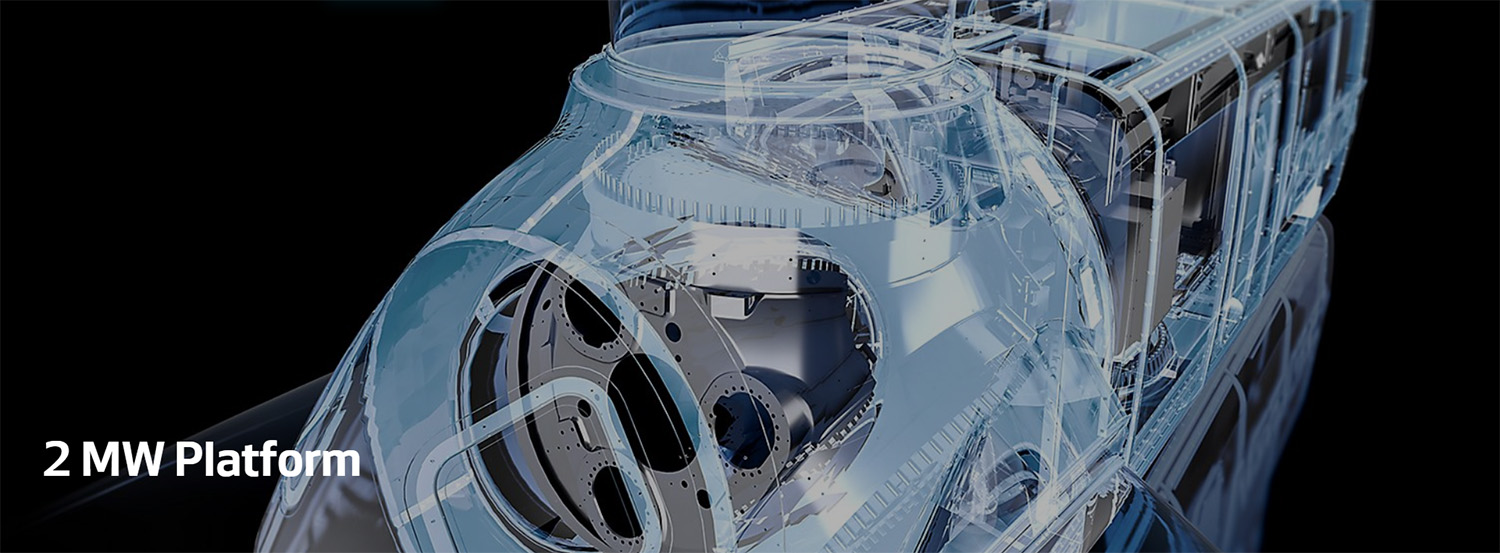

2MW platform

-

Our 2 MW platform provides industry-leading reliability, serviceability and availability and is one of the most trusted platforms in the industry.

With the latest addition of rotor sizes, the 2 MW platform offers a competitive selection of turbines for all wind segments. The platform’s predictability allows customers to forecast confidently, while the tried-and-tested design ensures lower cost of energy for low, medium and high-wind onshore sites, even in extreme weather conditions.

V110-2.0 MW

-

The V110-2.0 MW™ IEC IIIA is an extremely reliable turbine, which is documented through its strong availability and performance. This turbine allows you to increase productivity by opening up low-wind sites which were previously regarded as non-viable. To maximise power output at such locations, the turbines' 110 m rotor gains more from the available wind – starting at an incredibly low 3 m/s. With its 54 m blades, the V110-2.0 MW™ IEC IIIA delivers a notable rotor-to-generator ratio producing a remarkable capacity and yield at low- and medium-wind sites.

Features:- Vestas OptiStop pitch control strategy included to reduce loads and enable a lighter structure

- Select products from the Vestas PowerPlus™ range are added to maximise output

V100-2.0 MW

-

The V100-2.0 MW™ IEC IIB turbine allows you to increase productivity by opening up low- and medium-wind sites which were previously regarded as non-viable. To maximise power output at such locations, the turbines' 100 m rotor gains more from the available wind – starting at an incredibly low 3 m/s. Thanks to the 49 m blades, the turbines deliver a notable rotor-to-generator ratio producing a remarkable capacity and yield at low- and medium-wind sites.

Features:- Vestas OptiStop pitch control strategy included to reduce loads and enable a lighter structure

- Select products from the Vestas PowerPlus™ range are added to maximise output

V120-2.2 MW

-

Vestas' V120-2.2 MW™ is built on the successful installation of more than 48 GW of the 2 MW turbines. The V120-2.2 MW™ is built to generate more energy in stable low to medium wind conditions, achieving AEP improvements of up to 14%*.

With its 19 %* larger swept area , the V120-2.2 MW™ is harvesting more energy from available wind and setting a new benchmark for park level LCoE performance.

This latest extension to the globally trusted 2 MW platform combines advanced aerodynamic engineering with deep, insight-based operational data to aggressively drive down the cost of energy where it matters - at park level. On a MW constrained site, the V120-2.2 MW™ benefits from larger rotors, delivering a more stable energy production with a higher power output at lower wind speeds. Ultimately, this means higher certainty in power performance.

V90-2.0 MW

- The V90-2.0 MW™ IEC IIA/IEC S turbines build on proven technology over several generations ensuring great reliability, serviceability and availability. The high level of availability of the V90-2.0 MW™ IEC IIA/IEC S allows you to forecast confidently and strengthens the business case for investment, while their design and performance ensure that you can produce energy from low- to medium-wind sites at a low cost.

Services

-

The largest fleet of wind turbines under service in the world

Vestas now service more than 50,000 wind turbines and around 9,000 dedicated service technicians across 71 countries work committedly to maintain and support the biggest wind turbine fleet in the world.

As the world's leading fleetwide service provider, Vestas is undergoing a growing level of scale and volume that can support the acceleration of the global energy transition in the years to come. Backed by unmatched industry experience and data insights gathered by servicing thousands of wind turbines all over the world, Vestas have the resources needed to elevate the maturity of the renewables industry, and the systems that support it.

With more than 120 GW under service, Vestas helps remove over a hundred million tonnes of CO2 every year from the atmosphere by providing reliable, sustainable and cost-effective renewable energy, meeting global energy.

Maintenance

-

Active Output Management® can release the full potential of your wind energy business

At Vestas, we are relentlessly committed to wind. That’s why we recognise that making the most of your wind farm is about more than engineering – it’s about capturing the maximum available wind to ensure the highest energy output at the lowest costs. Our unique Active Output Management® (AOM) service concept, based on our three decades of industry experience, helps you achieve just that.

To realise the best possible return on your investment, an effective operations and maintenance strategy is just as important as reliable turbines. We offer a flexible service product landscape (AOM 1000 - 5000) that you can tailor according to your needs.

Parts & Repair

-

Better performance, higher efficiency - across platforms

With Vestas as your service partner, you get access to a one-stop-shop for spare parts and repair solutions across your fleet, independent of platforms. From over-the-counter spare parts on Shop Vestas to fixed-fee main component coverage services, Vestas can deliver a spare parts set-up that fits your business needs.

Our investments into innovation and R&D means that we also offer a broad range of industry-leading and cost-efficient repair solutions. It is all delivered through the combination of a truly global supply chain and a strong local presence, allowing us the bring our worldwide wind expertise right to your doorstep.

Fleet Optimisation

-

PowerPlus®

As wind technology matures, turbines already in operation can be upgraded to yield more energy and thereby improve an existing wind park business case.

Improvements of the production efficiency of a wind power plant can be carried out through site-specific optimisation of operational parameters, implementation of intelligent software algorithms, and enhanced aerodynamics add-ons. All designed to make your turbine work smarter and harder.

Vestas PowerPlus® can boost your energy production by up to 5% annually at virtually no risk. Our DNV-GL-certified siting process ensures that design life is not impacted. Our DNV-GL-certified validation methods accurately measure power curve performance improvements from the upgrades.

PowerPlus® covers a range of upgrade possibilities that can be combined or installed independently, counting Aerodynamics Upgrades, Extended Cut Out, Power Performance Optimisation and Power Uprate.