- Offer Profile

- Bekon is a worldwide technological leader in the construction of batch biogas plants for generating electricity from waste.

Technology

The Bekon Process

Production of biogas by dry fermentation

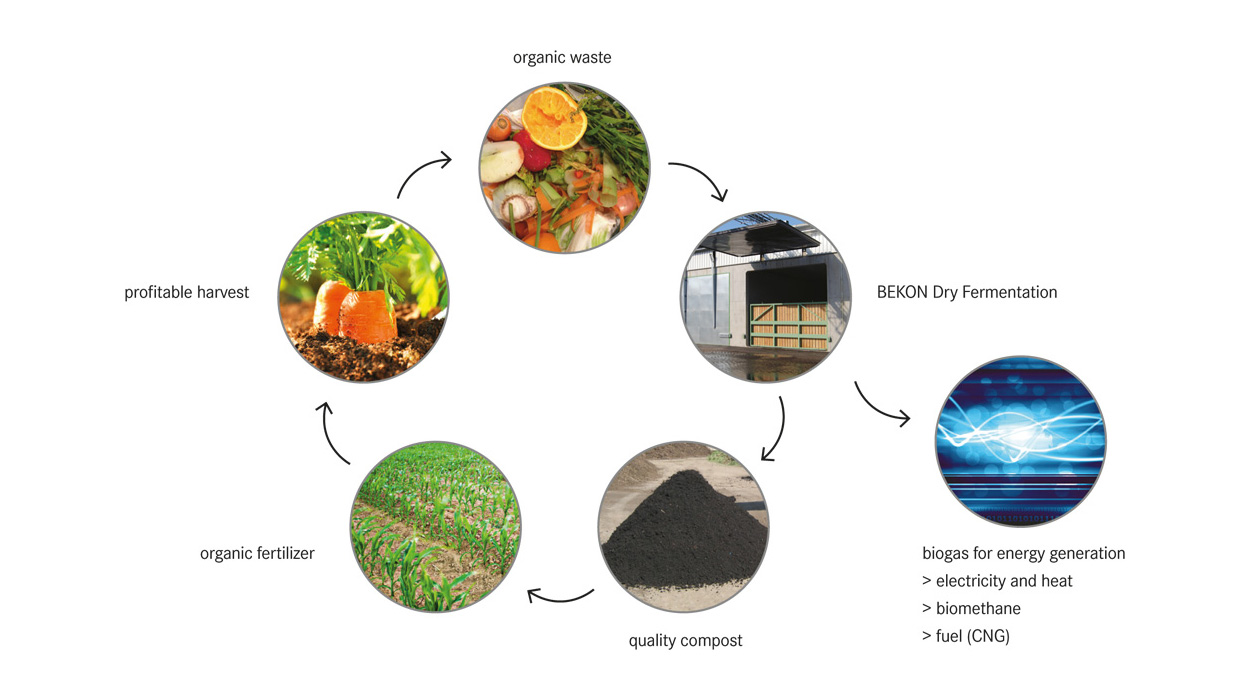

- The superiority of BEKON technology is already apparent from the wide diversity of suitable substrates. Bulk materials with a high dry-substance content can be digested without need for any complex pre-treatment of the fermentation material. The principle is quite simple: in the absence of air and following inoculation by previously fermented material, the biological waste begins to digest, immediately resulting in the production of biogas.

Filling the digesters using batch operation

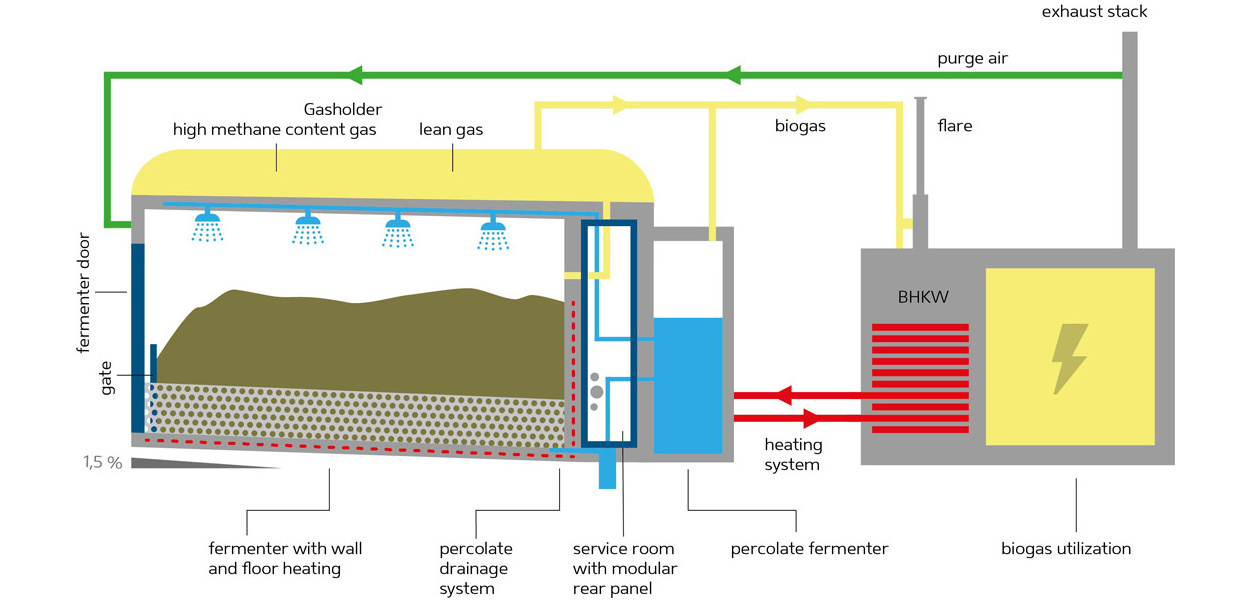

- The organic waste is collected in a tipping building and taken to the garage-shaped fermenter by wheel loader. Inoculation takes place by mixing the fresh material with material that already has been in a fermenter. Once it has been filled, the fermenter is closed off by a hydraulic hatch and the process of organic waste fermentation initiated. Excess cell fluid (percolation liquid) discharged during the fermentation process is collected by a drainage system and returned to the fermenting material in a cycle to keep it moist. Wall and floor heating is used to keep the temperature of the microorganisms constant. In this way, the conditions in the fermenter are maintained at an optimum level for the bacteria used in biogas production. This requires neither further mixing of the materials nor the addition of further material.

Continuous generation of electricity and heat

- The biogas thus produced is generally utilised in combined heat and power (CHP) units for generating electricity and heat. Continuous operation of the CHP is ensured by filling and operating several fermenters at staggered time intervals. The electricity generated is fed into the electrical grid and is remunerated or sold on, subject to the national feed-in tariffs.

Generation of biomethane

- Alternatively to power generation, the produced biogas can be processed into biomethane. This can then be fed into the natural gas grid or used as vehicle fuel (compressed natural gas). Thereby the generated energy can be stored and used in a wider market.

Sustainable cycle for the future

- Digestate turned into quality compost

Once the fermentation process is finished, each fermenter is fully emptied by a wheel loader. The BEKON process generates a dry fermentation residue which means that it is not necessary to separate or press the digestate allowing further compost processing. Part of the material is used for inoculating new biomass and is returned to the cycle. BEKON has developed an enclosed tunnel composting process for treating the dry fermentation residue. The exhaust air emitted by tunnel composting is cleaned using a biofilter, thus avoiding the emission of odours. The final composting stage generally takes the form of windrow composting. The final compost is a valuable organic quality fertiliser used in agriculture and gardening, possibly generating additional revenue.

Innovation – thermophilic dry fermentation

The BEKON process can be operated at both mesophilic (37 – 40°C) and thermophilic (50 – 55°C) temperatures. The thermophilic treatment (50 – 55°C) of biological waste ensures that it is safely sanitized in accordance with the biowaste ordinance. The BEKON process complies with the Animal By-product Regulation (ABPR), the German BioAbfV and the Swiss VTNP. This hygienisation process in the fermenter is not affected by weather influences and there is no need for the standard and time-consuming monitoring of the post-composting phase. The thermophilic microorganisms are characterised by a high metabolism which leads to a biogas yield up to 20 % higher than other technologies. The fast thermophilic process enables a reduction of the retention time in the fermenter, leading to a higher throughput for each fermenter. BEKON´s first thermophilic plant has been operating successfully in Thun (Switzerland) since the end of 2010. This was followed in December 2013 by a second thermophilic plant in Steinfurt (Germany) with an annual capacity of 45,000 tons of source separated waste.

Types of organic waste that can be processed using the BEKON technology

- source separated waste

- green waste

- organic fraction of municipal solid waste

- other organic waste materials

The BEKON process is also suitable for all types of bulk or stackable biomass without any preliminary treatment being required. Bekon Technology Advantages

Wide range of suitable organic waste materials

- Besides municipal source separated wastes, other organic wastes with a high dry-substance content can be processed for energy production. Contaminants only have a minor effect on the BEKON process. The robust wheel loader operation enables also the use of difficult input materials.

Modular construction, easy maintenance

- Fermenters are constructed as water retaining concrete structures and are technically gas-tight. The wall and floor heating system (patented) is integrated into the concrete wall and floor sections during plant construction in order to optimise the organic degradation processes in the fermenter. The plant’s modular construction consisting of several fermenters allows for expansion if desired to increase the plant capacity. Maintenance costs for the overall plant are very low. Thanks to its patented process, BEKON does not need to use any stirring equipment in the fermenter. The hydraulic hatch of the fermenter is opened upwards to ensure that the integrated inflatable sealing cannot be inadvertently damaged while the wheel loader is loading or unloading. BEKON plants are regarded as extremely reliable in their operation because of the robust technology and sophisticated construction. BEKON’s technological leadership is established by these factors.

Simple, robust technology with low operating costs

- BEKON provides proven and reliable technology which can be ideally employed alongside existing composting facilities. The existing infrastructure with wheel loaders can be used ideally. No pumps or mixers are necessary for operation. The material for fermentation generally requires no pre-treatment. For these reasons the machine and personnel operation costs are less expensive compared to the wet fermentation process.

Automatic software system with remote control

- The controlling system is designed for fully automatic operation; it clearly visualises the entire fermentation process, including the percolation cycle, temperature regulation and production of the CHP modules. To control the various process parameters is easy and user friendly. Moreover the plant can be comfortably monitored worldwide via the Internet using a mobile device (e.g. smartphone or iPad).

Superior safety concept

- The complex safety system integrated in BEKON plants is patented and includes a patented fermenter flushing process. This process ensures that the transfer from the methane atmosphere in the fermenter head space to the air atmosphere (before emptying the fermenters) and vice versa (after filling the fermenters) can be performed safely. Therefore a dangerous air-methane mixture can never form up inside the fermenter and odour emissions are avoided. Moreover the fermenters are operated at a slight overpressure (20 mbar). Overall the innovative and patented developments of BEKON technology facilitate to maintain high technological standards while allowing the operator to enjoy maximum safety.

Three-way profitability

- BEKON’s customers profit three times by feeding electricity and heat into local grids and by producing and marketing quality composts. BEKON fermentation plants show above-average gas yields which particularly makes them cost-effective.

Flexibility from biogas to biomethane

- The BEKON process is flexible with respect to the use of biogas. Besides being suitable for use in CHP modules, it can also be used as biomethane – following treatment of the biogas to bring it up to the quality of the natural gas grid. This means that the biomethane can be fed directly into the natural gas grid or used in compressed natural gas vehicles.

Range of services

- General Contractor As a general contractor, BEKON is responsible for all phases of the plant construction, including its cost-effective operation. The scope of BEKON’s offer is determined solely by the customer’s requirements. Planning, designing and constructing a biogas plant is carried out under consideration of all relevant legal requirements, guidelines and standards and always takes the latest scientific findings and technology developments into account. Technology Supplier As a technology supplier, BEKON takes over the general design, supply of core components, monitoring of critical construction phases, commissioning and proof of compliance with the agreed service parameters. Other works are carried out either by the customer or through a general contractor.

Financing

- Upon request, BEKON can also help you to find financing or investment partners. The wide experience that BEKON has gained from the construction and successful commissioning of numerous plants (see list of references) results into an excellent network of reliable partners and financial supporters.

Design

- BEKON designs each individual plant exclusively in accordance with the customer’s particular circumstances and land availability or as an expansion of an existing composting plant. Furthermore as an experienced partner with an established design team, BEKON takes care of all permit formalities.

Construction and commissioning

- Thanks to the modular structure of BEKON’s fermentation plants, construction phases are clearly defined with manageable time intervals. BEKON takes care of construction site supervision and commissioning of the plant. Implementations are of course CE and UL compliant and in line with international ISO standards. The technology’s performance is confirmed by a test operation to be followed by a performance test run by BEKON.

Operational management

- BEKON can also take over the operational management and monitoring of the plant. The focus is to maximize profitability, continuity and safety. The plant owner always has access to the plant’s performance data using the remote monitoring function via the Internet.

Maintenance, repair and service

- BEKON offers an optimum service agreement with regular maintenance intervals and short audits. The main benefits of the BEKON technology are reliability, high cost-effectiveness and low maintenance requirements.

Long-standing experience

- As market leader in the field of dry fermentation, BEKON stands for particularly efficient processes and high gas yields. Numerous certifications and patents prove that BEKON has the necessary Know-How for the efficient construction of dry fermentation plants. The steadily growing number of international reference projects is proof of the reliability of BEKON plants. Thanks to its proven expertise and professionalism BEKON has so far successfully installed 20 plants in four countries. Further markets in the USA, China and Mexico have been successfully developed as a result of targeted internationalisation.

References

- SSOW*: Source segregated organic waste OFMSW**: Organic fraction of municipal solid waste

Germany

Munich – pilot plant

- Input: SSOW*

Electrical power: 190 kW

Plant capacity: 6,500 t/a

Process: Mesophilic

In operation since: 07/03

Schmölln

- Input: Renewables

Electrical power: 1,000 kW

Plant capacity: 16,000 t/a

Process: Mesophilic

In operation since: 11/09

Kusel

- Input: Renewables

Electrical power: 330 kW

Plant capacity: 7,500 t/a

Process: Mesophilic

In operation since: 01/07

Marburg

- Input: SSOW*

Electrical power: 500 kW

Plant capacity: 12,000 t/a

Process: Mesophilic

In operation since: 11/09

Nieheim

- Input: SSOW*

Electrical power: 780 kW

Plant capacity: 24000 t/a

Process: Mesophilic In operation since: 07/07

Warngau

- Input: SSOW*

Electrical power: 365 kW

Plant capacity: 14000 t/a

Process: Mesophilic In operation since: 11/10

Munich - expansion

- Input: SSOW*

Electrical power: 570 kW

Plant capacity: 18,500 t/a

Process: Mesophilic

In operation since: 11/07

Aschaffenburg

- Input: SSOW*

Electrical power: 508 kW

Plant capacity: 15,000 t/a

Process: Thermophilic

In operation since: 04/11

Saalfeld

- Input: SSOW*

Electrical power:1,050 kW

Plant capacity: 20,000 t/a

Process: Mesophilic

In operation since: 11/07

Gütersloh

- Input: SSOW*

Electrical power: 800 kW

Plant capacity: 35,000 t/a

Process: Thermophilic

In operation since: 09/11

LRA Schweinfurt

- Input: Renewables

Electrical power: 365 kW

Plant capacity: 17,000 t/a

Process: Mesophilic

In operation since: 12/07

Hamburg-Bützberg

- Input: SSOW*

Electrical power: 300-700 m³/h

Plant capacity: 60,000 t/a

Process: Mesophilic

In operation since: 10/11

Melzingen

- Input: Renewables

Electrical power: 526 kW

Plant capacity: 13,000 t/a

Process: Mesophilic

In operation since: 06/08

Bad Oeynhausen

- Input: SSOW*

Electrical power: 100 kW

Plant capacity: 3,500 t/a

Process: Thermophilic

In operation since: 12/11

Göhren

- Input: Renewables

Electrical power: 625 kW

Plant capacity: 14,000 t/a

Process: Mesophilic

In operation since: 06/08

Würselen

- Input: SSOW*

Electrical power: 537 kW

Plant capacity: 30,000 t/a

Process: Mesophilic

In operation since: 01/12

Erfurt

- Input: SSOW*

Electrical power: 660 kW

Plant capacity: 20,000 t/a

Process: Mesophilic

In operation since: 11/08

Mainz Essenheim

- Input: SSOW*

Electrical power: 1200 kW

Plant capacity: 40,500 t/a

Process: Thermophilic

In operation since: 06/12

Rendsburg

- Input: SSOW*

Electrical power: 1,050 kW

Plant capacity: 30,000 t/a

Process: Mesophilic

In operation since: 11/08

Iffezheim

- Input: SSOW*

Electrical power: 527 kW

Plant capacity: 18,000 t/a

Process: Mesophilic

In operation since: 08/13

Aiterhofen

- Input: SSOW*

Electrical power: 365 kW

Plant capacity: 15,500 t/a

Process: Mesophilic

In operation since: 11/08

Steinfurt

- Input: SSOW*

Electrical power: 1,054 kW

Plant capacity: 45,000 t/a

Process: Thermophilic

In operation since: 11/13

Vechta

- Input: SSOW*

Electrical power: 330 kW

Plant capacity: 10,000 t/a

Process: Mesophilic

In operation since: 12/08

Ahrenshöft

- Input: SSOW*

Electrical power: 45 m³/h

Plant capacity: 4,500 t/a

Process: Thermophilic

In operation since: 01/14

Ostrhauderfehn

- Input: Renewables

Electrical power: 526 kW

Plant capacity: 12,000 t/a

Process: Mesophilic

In operation since: 12/08

Ostrhauderfehn – expansion

- Input: Renewables

Electrical power: 150 kW

Plant capacity: 5,000 t/a

Process: Mesophilic

In operation since: 08/14

Pohlsche Heide

- Input: SSOW*

Biogas upgrading: 500 Nm3/h

Plant capacity: 40,000 t/a

Process: Mesophilic

In operation since: 11/09

Rendsburg – expansion

- Input: SSOW*

Electrical power: 700 kW

Plant capacity: 34,000 t/a

Process: Thermophilic

In operation since: 01/17

Bassum

- Input: SSOW*

Electrical power: 526 kW

Plant capacity: 18,000 t/a

Process: Mesophilic

In operation since: 11/09

Dresden

- Input: SSOW*

Electrical power: 800 kW

Plant capacity: 30,500 t/a

Process: Thermophilic In operation since: 01/17

Main-Essenheim

- Input: SSOW*

Electrical power: 1200 kW

Plant capacity: 40,500 t/a

Process: Thermophilic

In operation since: 02/17

Italy

Cesena

- Input: SSOW*

Electrical power: 1,000 kW

Plant capacity: 35,000 t/a

Process: Mesophilic

In operation since: 12/09

Voltana

- Input: SSOW*

Electrical power: 1,000 kW

Plant capacity: 35,000 t/a

Process: Mesophilic

In operation since: 12/12

Naples

- Input: SSOW*

Electrical power: 1,000 kW

Plant capacity: 35,000 t/a

Process: Mesophilic

In operation since: 08/11

Rimini

- Input: SSOW*

Electrical power: 1,000 kW

Plant capacity: 35,000 t/a

Process: Mesophilic

In operation since: 12/12

Cozzo Vuturo

- Input: OFMSW**

Electrical power: 600 kW

Plant capacity: 20,000 t/a

Process: Mesophilic

Under construction since: 03/17

France

Berneuil

- Input: Agri-Waste

Electrical power: 450 kW

Plant capacity: 21,300 t/a

Process: Thermophilic

Start of construction exp.: 10/17

Portugal

Valnor

- Input: OFMSW**

Electrical power: 500 kW

Plant capacity: 25,000 t/a

Process: Mesophilic

Start of construction exp.: 09/11

Switzerland

Baar

- Input: SSOW*

Electrical power: 526 kW

Plant capacity: 18,000 t/a

Process: Mesophilic

In operation since: 10/09

Galmiz

- Input: SSOW*

Electrical power: 150 kW

Plant capacity: 4,500 t/a

Process: Thermophilic

Comissioning: 05/15

Thun

- Input: SSOW*

Electrical power: 950 kW

Plant capacity: 20,000 t/a

Process: Thermophilic

In operation since: 12/10

Krauchthal

- Input: SSOW*

Electrical power: 440 kW

Plant capacity: 12,000 t/a

Process: Thermophilic

Comissioning: 01/17

Poland

Poznan

- Input: SSOW*

Electrical power: 716 kW

Plant capacity: 24,000 t/a

Process: Thermophilic

Start of construction exp.: 06/16

Bulgaria

Han Bogrov

- Input: SSOW*

Electrical power: 855 kW

Plant capacity: 44,000 t/a

Process:

Start of construction exp.: 01/14

Brazil

Jacarei

- Input: OFMSW**

Electrical power: 190 kW

Plant capacity: 10,000 t/a

Process: Mesophilic

Start of construction exp.: 2017

Mexico

Culiacan, Sinaloa

- Input: Agri-waste

Electrical power: 100 kW

Plant capacity: 4,500 t/a

Process: Thermophilic

In operation since: 11/16