- Offer Profile

- Waste sorting plants with cutting-edge technology Made In Germany

STADLER is a global specialist in the design, production and assembly of automated sorting systems and machines for the recycling industry. With experience of more than 400 implemented plants as well as more than 3,000 manufactured individual components and a team of nearly 450 experienced specialists, we are ideally positioned.

Traditional Values. Sustainable Thinking and Action. Forward-Looking Engineering Expertise. In this way, we make our contribution to counteracting the constantly growing waste mountains all over the world.

Sorting Plants

-

Our high-performance, highly efficient large-scale plants are state-of-the-art. Whether engineering, steel construction, electrical installation or assembly – with our team of experienced specialists, we are ideally positioned in every respect.

Well sortedIn order to be sure, we test everything thoroughly in advance in our "STADLER Test Centre". Engineers from our company accompany you through the entire project from planning to production and assembly to commissioning.

One of the world market leaders in the field of waste sorting technologies:

- Municipal solid waste

- Dry mixed recyclables

- Commercial waste

- Lightweight packaging

- Plastic bottles

- Film

- Paper and cardboard

- Refuse derived fuel

- Electrical and electronic waste

- Mixed construction materials / bulky waste

- Waste wood

Municipal Solid Waste

-

Sorting plants for municipal solid waste

STADLER stands for individually planned, turnkey sorting plants for municipal solid waste with a processing capacity of 40,000 t/year up to high-capacity plants with a capacity of 1,000,000 t/year, such as the one we recently successfully constructed in Spain.

Dry Mixed Recyclables

-

Sorting Plants for Dry Mixed Recyclables

Although disposal of the material essentially takes place in a similar way, the material properties vary from country to country. The fact that STADLER was involved in developing the first plants of this type from the outset is extremely useful in this regard. STADLER is familiar with each material in the individual countries, and knows which plant model will produce the best overall results for the customer in each individual case.

Commercial Waste

-

Sorting Plants for Commercial Waste

Commercial waste consists of a wide range of different products, substances and materials with greatly differing volumes and a rather high density. This means that high demands are placed on the machinery used. This poses no problem, thanks to our extremely high quality standards.

Lightweight Packaging

-

Sorting Plants for Lightweight Packaging

Thanks to our broad wealth of experience, our high-performance plants achieve a high degree of sorting purity – which is particularly vital today, in times of worldwide plastic waste pollution.

Plastic Bottles

-

Sorting Plants for Plastic Bottles

One of our areas of expertise is the pre-sorting of bottles for washing plants. Thanks to our extensive experience, we achieve a high degree of purity in the final output fraction, which enables seamless further processing.

Film

-

Sorting Plants for Film

The subject of film sorting has only recently become a focus of the recycling industry. STADLER identified the demand – and responded immediately. We were the first plant constructor to develop a corresponding sorting concept, which is specially tailored to the properties of film produced from different polyolefins.

Paper and Cardboard

-

Sorting Plants for Paper and Cardboard

Equipped with our 4-wave ballistic separator PPK, the paper and cardboard sorting plants designed by us are genuine all-rounders. The result is material fractions with the highest degree of purity.

Refuse Derived Fuel

-

Sorting Plants for Refuse Derived Fuel

Refuse derived fuels for cement production must be of consistently high quality. Our plants therefore preferably use mechanical separation processes.

Electrical and Electronic Waste

-

Sorting Plants for Electrical and Electronic Waste

Sorting plants for the so called "e-waste" are required to satisfy the highest demands: before separating different types of metals and plastics, it is also necessary to detach the valuable materials through shredding and classifying out of the composite of different materials, and subsequently feed them into the recycling loop.

Mixed Construction Materials and Bulky Waste

-

Sorting Plants for Mixed Construction Materials and Bulky Waste

The large-volume material mix with a particularly high density requires an especially robust plant construction with high-performance components. In order to satisfy these requirements, STADLER has developed a true powerhouse the ballistic separator STT6000 specifically for this type of plant.

Wood

-

Sorting Plants for Waste Wood

STADLER developed high-throughput wood sorting plants to facilitate recycling as much waste wood as possible the first of several plants to be installed in 2012. The objective: to separate all materials that pose a problem to processing.

Components

-

Components

The performance and efficiency of each sorting system is fully dependent on the performance of the individual components installed.

Whether our particularly robust ballistic separators, torsion-resistant trommel screens made of 10 mm-thick Hardox steel, innovative STADLER conveyors or our new high-performance label remover. STADLER components stand for premium quality Made in Germany.

Intelligent solutions, a particularly solid design and a consistently high level of serviceability as well as a wealth of experience from over 3,000 individual components delivered. This is what our customers all over the world rely on.

STADLER WireX

-

Introducing our new machine

The ultimate solution for bale wire removal: the STADLER WireX

The groundbreaking engineering of this machine takes efficiency in wire removal to a new level. Welcome flawless automation with the state-of-the-art dewiring unit from STADLER.

Ballistic Separators - STT2000

-

Applications

The ballistic separator STT2000 is specially designed for sorting the following feed materials:

- Paper/cardboard

- Films and mixed hollow body products

- Lightweight packaging

- Plastic

- Plastic fraction from domestic waste

Ballistic Separators - PPK2000

-

Applications

The PPK200 ballistic separator is specially designed for separating paper, OCC and cardboard without 3D fractions

Features:

- Paddles

- Maintenance doors

- Shaft quality

- Adjustable outer skin

Ballistic Separators - STT5000

-

Applications

The STT5000 ballistic separator is our all-rounder for separating household waste, mixed commercial waste and bulky waste.

Features:

- Paddles

- Maintenance doors

- Shaft quality

- Adjustable outer skin

- Pivoting frame

- Modular stacking

Ballistic Separators - STT6000

-

Specially designed for large material

Thanks to generously sized material outlets and completely smooth contours in the screen outlet, the STT6000 can sort individual particles that are up to two metres long.

Features:

- Paddles

- Maintenance doors

- Shaft quality

- Adjustable outer skin

- Lubrication

- Protection against wear

Trommel Screens

-

Durable STADLER quality it pays for itself in the long run

The use of 10-mm Hardox steel results in robust and incredibly strong, torsion-resistant trommel screens. What is more, the drive, support and guide wheels feature double bearings for extremely low-vibration operation.

Features:

- Base frame

- transport

- Sizing

- Suspension

- Easy maintenance

Conveyor type GG

-

For flows of light to moderately heavy materials and average centre distances, together with compact design.

- Robust steel table and sliding belt support

- Available with four different side-wall heights and seals

- Robust scraper made of steel or vulcanised rubber depending on the flight design

- Space-saving SEW bevel gear motors

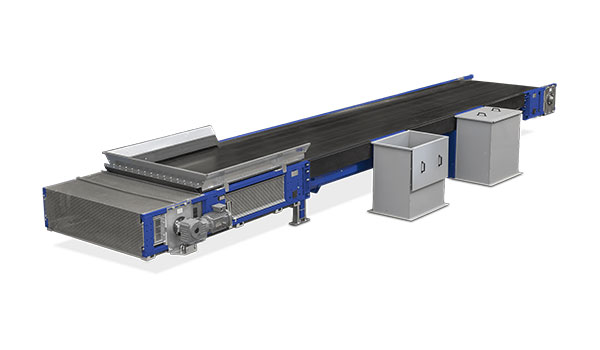

Conveyor type MF

-

For flows of moderately heavy to heavy materials and long centre distances with low drive powers at the same time.

- Rolling belt support on three-part support units

- Available with three different side-wall heights

- Robust scraper made from various steel grades or vulcanised rubber depending on the flight design

- Space-saving SEW bevel gear motors

Conveyor PX

-

The STADLER conveyor PX has been specially designed for use with sensor-based sorting technology.

Thanks to conveyor speeds that can be precisely controlled, it effectively spreads the flow of material. With the stabilizer (optional), the air flow produced by the fans guide the material in a steady way on the belt, regardless of the high speed.

- Special side wall sealing for operation at high conveyor speeds

- Expansion hood with integrated maintenance platform available as an option

- Special support rolls and balanced drums for low-vibration operation

- Higher speeds for film/paper with the use of the optional stabilizer

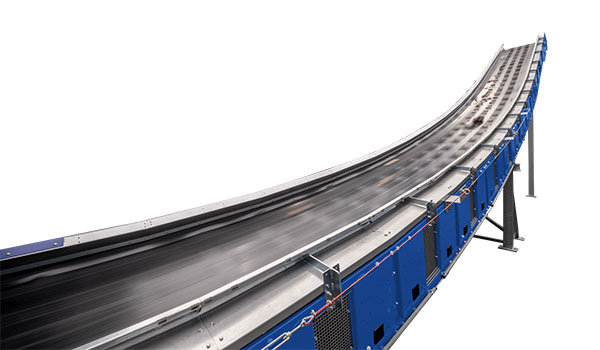

Conveyor type XG

-

For high, voluminous, light to mediumweight materials - can be used outdoors.

- Depending on the desired incline/height difference, the conveyor can be assembled with more or fewer angled elements

- Material can be fed horizontally and then transition to an incline

- No loss of usable width as the belt does not have to be held down

- Rolling belt support on three-part support units

Hood type EH

-

For material and air control in sortingsystems with compressed air discharge of one or two fractions.

- An adjustable separating splitter allows optimisation of the separation precision

- One maintenance access point and one maintenance opening are located on both the left and right side of the hood

- Integrated maintenance platform with fixed position inside the hood

- Different units and conveyors can be connected to the EH via an adapter.

Conveyor type KF

-

Bush conveyor chains allow flows of even heavy and large materials to be transported with ease.

- The use of sturdy lateral sections and various chain and belt designs enables the STADLER chain conveyor to transport whatever material is required

- The KF can be used as an infeed conveyor, a baler feed conveyor or a feed hopper, depending on how the angular sections are positioned

- Space-saving SEW bevel gear motors

- The drive and return shaft can be removed laterally, forwards or backwards.

Conveyor type SO

-

The side wall and belt position have been specially designed to sort material as efficiently as possible directly on the conveyor.

- Discharge chutes that can be flexibly positioned allow sorting of different fractions

- The ergonomic design of the frame enables a comfortable working position

- Adaptable belt speeds for optimum sorting results

- Space-saving SEW bevel gear motors

Conveyor type BU

-

Developed for temporary storage of sorted material fractions, the STADLER storage conveyor has side walls up to 2.5 metres tall.

- Rolling belt support means heavy materials can be accomodated in the storage area

- Thanks to robust doors made of steel segments, the entire storage capacity can always be fully utilised

- Space-saving SEW bevel gear motors

Dosing system type DK

-

The material is evenly distributed and thus ensures a constant feeding of the system and higher purity.

- The system consists of a combination of our DW metering drum and our KF chain conveyor in the bunker version, whereby dosing and storage of the material is made possible

- Reliable material distribution

- Large maintenance opening due to moving unit blockages and wraps can be removed even in the filled state

- The working height of the drum can be adjusted to different heights (100 mm steps)

- Lateral removal of the rotor body possible

Label Remover

- A shining example of German engineering

Our powerful label remover processes up to nine tonnes of plastic bottles per hour – achieving a quality standard of up to 80 per cent of labels removed. It features a robust overall construction and is incredibly resistant to impurities.

Equipped with blades made from high-tensile steel that are attached to the rotor at one end so they can oscillate freely, and to the housing’s inner wall at the other, the label remover processes a mass flow of up to nine tons per hour depending on the particle size and material composition.

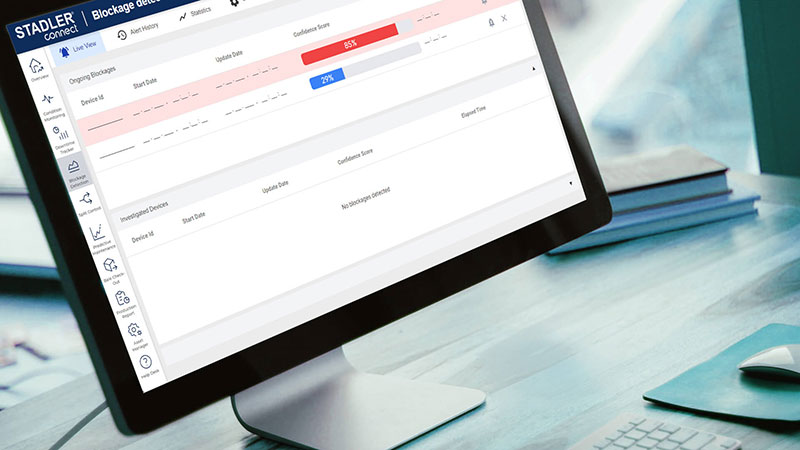

STADLERconnect

-

Digital solutions to enhance plant performance

STADLERconnect leverages both machine data and material data to optimize the performance of your sorting plant. Powered by real-time plant data and AI, our comprehensive platform focuses on two key areas, providing tailored solutions to boost operational efficiency.

Digital Maintenance

-

By analyzing and evaluating your plant's machine data, STADLERconnect offers a range of innovative solutions designed to optimize plant performance. Utilizing advanced sensors and AI-powered analytics, our Digital Maintenance modules help to reduce unplanned downtime and minimize maintenance costs, ensuring a more efficient and cost-effective operation.

- Predictive Maintenance

- Blockage Detection

- Downtime Tracker

- Support Portal

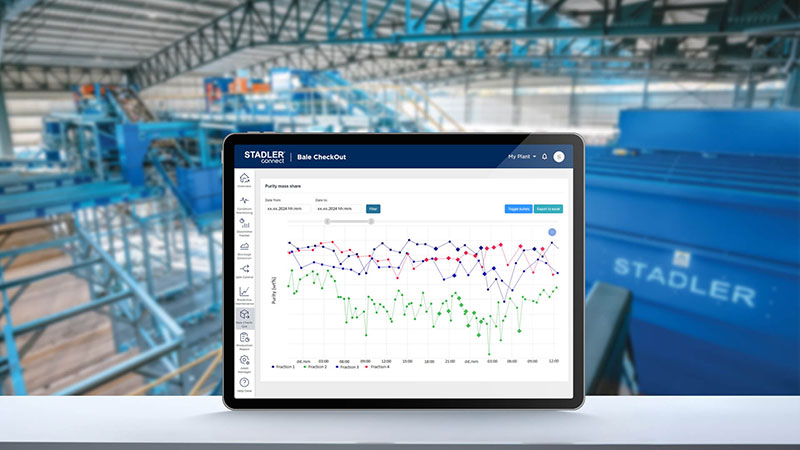

Automation & Material Analysis

-

Our Automation and Material Analysis modules analyze valuable material data, delivering enhanced sorting performance process and reduced operational costs. By combining advanced inline sensor technologies and AI models with the expertise of our highly skilled engineering teams, we achieve superior plant performance and efficiency.

- Production Report

- Bale Check

- Adaptive Material Split Control

- Adaptive Screen Cut Control

- Volume Flow