- Offer Profile

- since almost 30 years HAAS –

a modern family business, – designs innovative machines and plants for the

processing of waste wood and waste.

The highest value at HAAS is placed on quality and customer service! Nearly all HAAS machines are designed and produced in the own production – MADE IN GERMANY.

Recycling-Systems

- We offer individual solution for every mobile and stationary application. HAAS products convince with high performance, efficiency and targeted configuration!

Shredder

- Shredding - Breaking - Chipping

Screening & Separating Technology

- Screening - Sifting - Separating

Loading & Unloading Systems

- Docking - Filling - Emptying

Shredder

TYRON mobile

-

The most powerful pre-shredder in his class

The pre-shredder with the intelligent HAAS Double Shaft System

The HAAS TYRON Double Shaft Slow Speed Shredder convinces due to his strong performance, aggressive infeed, high economic efficiency, and a long lifetime.

The machine with the Viking is due to the “intelligent” HAAS Double Shaft System the perfect solution for the effective shredding of the most difficult materials.

Two independent driven shredding shafts ensure highest flexibility!

Depending on the material, the shaft rotation speed, rotation direction and reversing times can be adjusted at any time by the customer.

The wrapping of wires and long-fibered materials is avoided, the throughput maximized! The unique HAAS Double Shaft System reduces wear and downtime in comparison to synchronously running pre-shredders.

Product advantages- Can be used at any location (comfortable transport measurements)

- Easy and quick positioning thanks to crawler track and radio remote control

- Shreds different materials with just one tool configuration

- High throughput capacity of up to 100 t/h

- Resistant against foreign bodies

- Low wear costs and long lifetime

- Service- und maintenance-friendly

- No wrappings – self-cleaning

- Quiet main drive

TYRON stationary

-

The most powerful pre-shredder in his class

The stationary pre-shredder with the intelligent HAAS Double Shaft System

The HAAS TYRON pre-shredder convinces due to his strong performance, aggressive infeed, high economic efficiency, and a long lifetime.

The machine with the Viking is due to the “intelligent” HAAS Double Shaft System the perfect solution for the effective shredding of the most difficult materials.

Two independent driven shredding shafts ensure highest flexibility!

Depending on the material, the shaft rotation speed, rotation direction and reversing times can be adjusted at any time by the customer

The wrapping of wires and long-fibered materials is avoided, the throughput maximized! The unique HAAS Double Shaft System reduces wear and downtime in comparison to synchronously running pre-shredder.

In stationary plants, the electric Double Shaft Slow Speed Shredder with its optional or separately erectable power unit is often used as the first machine in a recycling line.

Product advantages- Shredding different materials with just one tool configuration

- Main motor control via soft starter instead of star-delta combination (energy saving)

- High throughput capacity from up to 100 t/h

- Resistant against foreign bodies

- Service- und maintenance-friendly

- Very low noise emission

- No wrappings – self-cleaning

ARTHOS mobile

-

the mobile hammermill - ideal combination to our TYRON primary shredder

Let it crack – with our mobile omnivore!

The hammermill will be mobile for the first time, on tracks and will effortlessly perform, even in the most difficult environments.

In the stationary sector, the HAAS ARTHOS hammermill has so far been known as the “HSZ” and has been a popular secondary shredder among connoisseurs for years. The developers at HAAS have now succeeded in ideally adapting the technology of the stationary version to mobile technology.

In the mobile version, impurities in the input material are also automatically separated thanks to the ballistic chute specially developed by HAAS. The system has been in stationary use for several thousand operating hours at many well-known power stations and in the chipboard industry worldwide and has proven itself. The machine does not have to be stopped to remove the impurities, thus downtimes are significantly minimized and costs thereby reduced!

Another highlight of the HAAS hammermill is the very simple screen exchange as the machine can be opened hydraulically. The operator has the possibility to change the screen basket within a very short time and thus to vary the size of the output material.

In combination with the TYRON primary shredder, the new innovation from HAAS thoroughly and quickly shreds wood waste, green waste, RDF and PVC waste to

Product advantages- Resistant against impurities due to flexible swinging hammers.

- Ballistic chute – Impurities will be ejected automatically with the ballistic chute developed by HAAS!

- Easy screen change system – Screen exchange in shortest time due to hydr. openable screen basket.

- Effortless exchange of hammers and hammer shafts

- Special HAAS hammer and counter-knife combinations minimize the fine fraction.

- Sturdy construction - Downtimes will be minimized and costs reduced.

- Homogeneous end product and exposure of ferrous and non-ferrous parts like nails and staples

- Very quiet, even with high performance

- Low fuel consumption

ARTHOS stationary

-

Hammermill with saving potential

Let it crack – with our omnivore!

The hammermill ARTHOS shreds thoroughly and quickly waste wood, green waste, substitute fuels and PVC-waste.

Depending on the material and the desired end product special HAAS hammer-, counter knife- and screen basket-systems will be used. With the help of individual matched counter knive- and screen basket-systems the unwanted fine fraction will be reduced to a minimum. HAAS hammermills are immune to interference and low on maintenance!

The special ballistic chute protects the hammermill from wear and machine breakage.

Impurities like ferrous and non-ferrous metals etc., which made it into the hammermill with the material had to be removed manually and very time consuming in the past. “Time is money”, that was the thought of the HAAS-developers und they started to work.

Impurities in the input material are automatically separated. The system has been in stationary use for several thousand operating hours at many well-known power stations and in the chipboard industry worldwide and has proven itself. The machine does not have to be stopped to remove the impurities, thus downtimes are significantly minimized and costs thereby reduced!

Another highlight of the HAAS hammermill is the very simple screen exchange as the machine can be opened hydraulically. The operator has the possibility to change the screen basket within a very short time and thus to vary the size of the output material.

In combination with the TYRON primary shredder, ARTHOS thoroughly and quickly shreds wood waste, green waste, RDF and PVC waste to

In the stationary sector, the HAAS ARTHOS hammermill has so far been known as the “HSZ” and has been a popular secondary shredder among connoisseurs for years. The developers at HAAS have now succeeded in ideally adapting the technology of the stationary version to mobile technology.

Here you get all information about our mobile hammermill

Product advantages- Resistent against foreign objects due to flexible swinging hammers.

- Ballistic chute – Impurities will be ejected automatically with the ballistic chute developed by HAAS!

- Easy screen change system – Screen exchange in shortest time due to hydr. openable screen basket.

- Effortless exchange of hammers and hammer shafts

- Special HAAS hammer- and counter knive-combinations minimize the fine fraction.

- Sturdy construction - Downtimes will be minimized and costs reduced.

- Homogeneous end product; and exposure of ferrous and non-ferrous parts like nails and staples

- Also available ATEX-certified after testing!

Drum Chipper

-

Extremely proven and powerful!

More than 25 years of professional competence practically and reliably implemented!

The versatile drum chippers are exceptional trustworthy and powerful due to 25 years of experience and competence.

To produce wood chips of high quality the drum chippers will be customized for the specific customer requirements.

The material to be processed – trunks, sawmill waste wood or wooden rinds – is fed horizontally to the machine. The infeed is possible via a vibrating infeed as well as a conveyor belt.

The drum chippers and if applicable complemental components like storage- and conveying technology provide economical and efficient solutions for the production of high-quality wood chips for small, middle and high throughputs.

HAAS-drum chippers convince due to their low energy needs, high throughput capacity, minimal maintenance effort, low wear costs and steady, maximum availability.

Product advantages- Highest availability

- Low operational costs

- Maximum throughput capacity

- High-quality consistent end product

- Long-time experience and certified quality

- Single machines for already existing plants or customer-oriented planning of whole plants

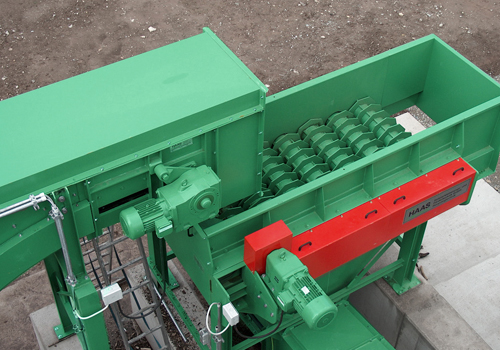

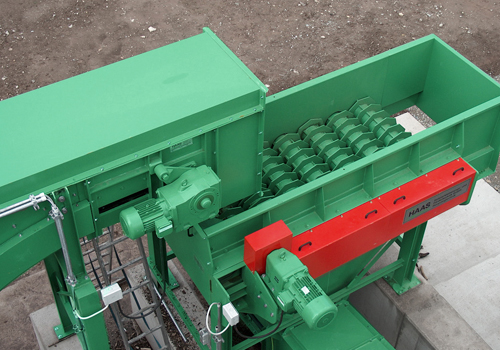

Slow speed drum chipper HAZ

-

Compact and powerful

The HAAS slow speed drum chipper reliably shreds waste wood

The single-shaft shredder of the HAZ-series are mostly used in the wood processing industry for the shredding of waste wood, pallets and packaging woods.

For heavy-duty and reliability in continuous operation when shredding waste wood and other materials in industrial companies we recommend you the HAAS slow speed drum chipper!

The material discharge is carried out via screw conveyor, suction system or belt or chain conveyor. A following optional FE-separation is possible.

Product advantages- Big infeed hopper for easy infeed

- Automatic shutdown as soon as the infeed hopper is empty

- Nails and simple fittings are no problem and can be separated after the shredding

TYRON hybrid mobile

-

Choose our hybrid technology and reduce your CO2 emissions

The new hybrid version of the TYRON primary shredder complements the HAAS product range with a mobile, electric version. The robust twin-shaft primary shredder TYRON 2000 XL 2.0 hybrid features a main drive with 280 kW for the shredding process. The diesel generator provides 43 kW for moving the crawler track.

As at the mobile and the stationary version, two shredding shafts are driven independently of each other. Shaft speed, direction of rotation and reversing times can be easily adjusted at any time depending on the material.

The throughput is maximised because the winding of wires and long-fibre materials is avoided.The hybrid Viking is designed for maximum shredding performance. Due to its high efficiency, the electric motor has a significant advantage in energy efficiency, compared to the diesel engine. Up to 70 % energy costs can be saved compared to diesel-hydraulic.

- No exhaust emissions during operation.

- High energy efficiency.

- Low energy costs, minimal maintenance.

- Significant CO2 reduction.

Screening & Separating Technology

Drum screen

-

Excellent screening of a wide range of materials

The new Siebo drum screen is designed for the use on recycling and waste disposal sites. The screening machine is characterised by its robust construction and high-performance components. It is mobile and very easy to operate by one person.

Even the standard version of the Siebo is packed with many options and features. The machine can be customised according to your specific needs. For example with coarse material separator, magnetic drums, etc. Turn your 2-fraction drum screening machine easily into a 5-fraction machine!

The rotating screening drum is able to screen the most difficult materials. The machine reliably screens household and industrial waste, compost, bark, wood chips, bulk materials or excavated earth, the load-dependent controlled material feed ensures the best possible usage of the large screening area. The screening drum, which is quietly driven by a grip belt and chain, can be replaced very easily.

Product advantages

- latest engine generation, compliance with the stage V emissions standard without AdBlue

- large approx. 6.0 m³ or 6,5 m³ feed hopper with only 2.9 m loading height

- in standard 7.2 m long discharge belt with 3.5 m discharge height

- Generous access and large service doors for easy maintenance

- fast, easy drum exchange

- hydraulically foldable cleaning brush

- extensive standard basic equipment

Flat screen

-

Swing screen for the separation of waste wood shavings and wood chips

Up to 5 fractions in just one work process

The Haas flat screen type HPS allows a separation of fine fraction, useful fraction and oversizes in just one work process. In addition, up to two middle fractions can be separated.

Product advantages- Different fractions in just one work process with minimum space requirement

- High screening capacity

- Sturdy reliability with low energy consumption

- Can be integrated in already existing plants

- Long durability due to high qualitiy swinging elements

- Exchangable screen decks

- Nearly maintenance-free

Disk screen

-

Sophisticated Disk screen solution for highest performance

Efficient separation of oversizes in sturdy structure

The HAAS disk screen is ideal for the separation of oversizes in areas of application with high throughputs. Due to the sturdy structure HAAS disk screens are extremely insensitive and guarantees highest availability.

Product advantages- is ideal for the separation of oversizes

- Highest capacity at minimum space requirement

- Different speed due to a frequency converter

- Sturdy design with low maintenance costs

- Shaft drive with a sturdy duplex chain

ALVA - Mobile Starscreen

-

Exploit the full potential of your production with the HAAS ALVA screening machine. Screen a precisely defined, valuable fraction and seamlessly feed the useful oversize back into the shredder.

The stationary version of the ALVA screen is already impressive in countless applications – now the technology is going mobile!

The oversize material is discharged from the screen deck via a funnel-shaped chute onto the return conveyor. This can be pivoted by 200 degrees. With a discharge height of up to 5 metres, the oversize material can be automatically fed back into the shredder or optionally discharged as a second finished fraction.

ALVA is compact and impresses with an outstanding screening capacity (200 m3/h). The assembly on a hook-lift frame provides flexibility. The electric drive and the wear-

resistant, crew conveyor guarantee maximum efficiency.- 2-fraction, mobile star screen with oversize return conveyor on a hook-lift frame

- large feed hopper with metering drum

- excellent screening capacity of up to 200 m³/h

- integrated screw conveyor

- fully electric driven

- service access

Loading & Unloading Systems

Containerloading & Truck-loading

-

Save time and money - work efficient!

Sophisticated technique for dust-free loading of bulk materials into trucks and containers.

Proper loading and unloading processes help to increase the efficiency in the loading zone!

A crane system automatically lifts and lowers the loading unit. A special sealing of the filling system to the trailer or container ensures a dust-free loading.

The automatic switch-off device with full detection ensures the ideal filling and highest workload of your containers or trucks. HAAS-Systems are always individually adjusted for your specific trailer and container sizes.

Conveying systems like chain conveyors or screw conveyors are the ideal addition to our loading and unloading stations. We would be happy to advise you in detail.

Product advantages- Material handling without wheel loader etc.

- Short truck downtimes for loading

- Low-dust loading

- Low wear costs and high availability

- Easy to use

Loading / unloading conveyor

-

Efficient filling and emptying of boxes

Filling and emptying, fully automatic with highest capacities!

Loading and unloading conveyors, also called lifting and lowering conveyors, are used in storage boxes and halls. The special feature of the conveyors is the suitability for filling and emptying bulk materials such as wood chips, wood chips, substitute fuels, biomass and plastic / PVC.

A loading and unloading conveyor consists of a chain conveyor which can be driven up and down by a lifting device. This enables uniform filling and emptying of storage boxes and halls.

The individual work steps are processed fully automatically by a programmable controller.

The standard version of the loading and unloading conveyor operates in a box. If several boxes are next to each other, it is possible to move the loading and unloading conveyor to the other boxes in order to fill and empty them as well.

Product advantages- Modular construction system

- One unit can be used for different boxes

- Compact and robust design

- Wide range of applications

- Low investment and wear costs

- Long service life

- High storage capacity

Truck-Loading

-

Proper loading and unloading processes help to increase the efficiency in the loading zone!

A crane system automatically lifts and lowers the loading unit. A special sealing of the filling system to the trailer or container ensures a dust-free loading.

The automatic switch-off device with full detection ensures the ideal filling and highest workload of your containers or trucks. HAAS-Systems are always individually adjusted for your specific trailer and container sizes.

Conveying systems like chain conveyors or screw conveyors are the ideal addition to our loading and unloading stations. We would be happy to advise you in detail.

- Material handling without wheel loader etc.

- Short truck downtimes for loading

- Low-dust loading

- Low wear costs and high availability

- Easy to use

Complete Installations - HAAS plant engineering for more than 30 years

Customized solutions and efficiency improvement for already existing plants

Benefit from our Know-how in the conception, planning, development/production, delivery, mounting and start-up of overall solutions and the expansion of already existing plants.

With a HAAS-Plant you receive a customized solution, adjusted for your personal needs and requirements. From the shredder over screening or separation to bale wrapper and bunker storage, you will receive a suitable solution for every plant section. We also offer you the best problem solution for high demands, for example: for architectural, confined area sizes.

With our After-Sales service we will completely take care of you even after the project has been implemented. This ensures you our high quality standards on a long-lasting term.

Our mobile technicians carry out all maintenance works and repairs at your site. Via the modem help the support for electronic adjustment is possible

Our comprehensive spare part storage ensures you shortest down times and outstanding quality.

Your benefits

Even in the case of a warranty we promise you an uncomplicated and quick settlement.- Consulting and delivery of complete installations and single components.

- With us you are in personal contact! From the preliminary design to the turnkey handover of your project your designated contact is always up to date and you donÂt have to explain your self over and over again. That continuously ensures a fast and flexible action.

- Assistance with applications for approval procedures

- Training and briefing of your operating staff

- ATEX-certified products can be applied depending on testing

Waste Wood & Biomass

- 3.257.200 tons of waste wood pear year with HAAS plants

Waste & RDF

- Valuable raw materials thanks to waste processing plants

PVC & Plastics

- PVC from old windows can be recycled at least seven times while maintaining the same quality and weather resistance

Sawmill & Residual wood

- Knowledge & Experience since 1989

The construction and manufacture of stationary machines such as chippers, screens, conveyors and bunkers for the equipment of complete sawmill plants and for the wood industry has been the basis of HAAS since the foundation of the company in 1989. HAAS has made a name for itself in the industry over the past 30 years and has been able to impress with its wealth of experience ever since! Today HAAS has installed sawmill systems all over the world. The original product range for waste wood disposal for the sawmill industry has been continuously expanded.