- Offer Profile

-

See how we can change your business with innovative 3D technology. Our experts will:

- scan, create a CAD model or carry out quality control of the indicated detail object

- demonstrate application of our 3D scanners on the example objects provided by you

- answer your questions and train your staff

- analyze your needs and prepare the right offer

3D scanning

eviXscan 3D scanners

Professional 3D scanners for use in industry, science, art, medicine and more

eviXscan 3D scanners are designed to meet the growing demands and requirements of the market for reliable, fast and accurate metrology devices used in reverse engineering, contactless quality control, 3D modeling and rapid prototyping. The eviXscan 3D scanner line is designed to provide professional solutions for a different types of implementations.

- 1 to 2 years guarantee

- With 3D software

- Technical support

- Made in Poland

- Designed by Evatronix

- Leasing option

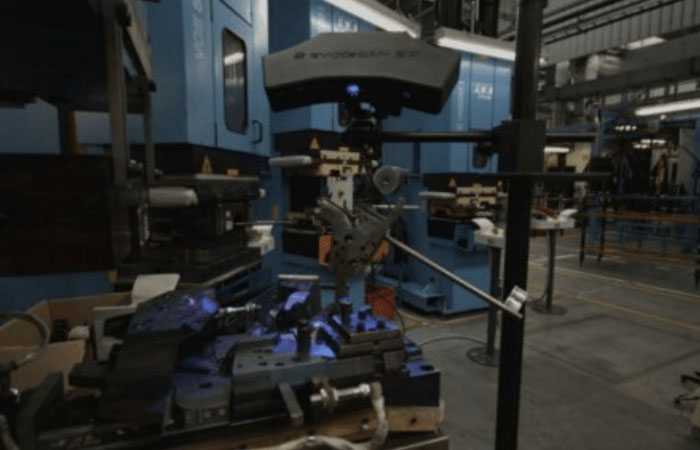

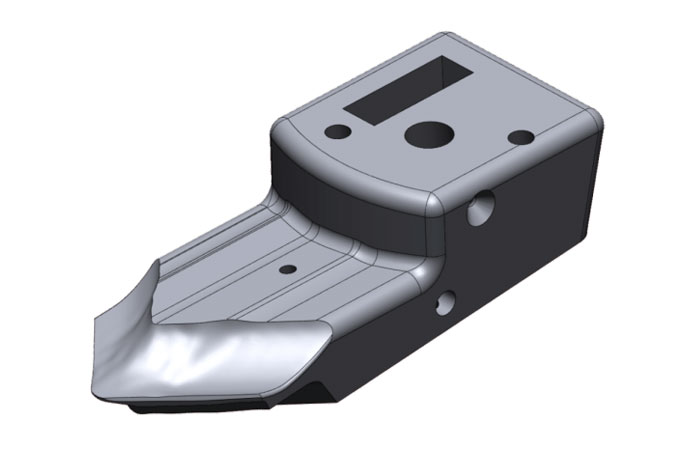

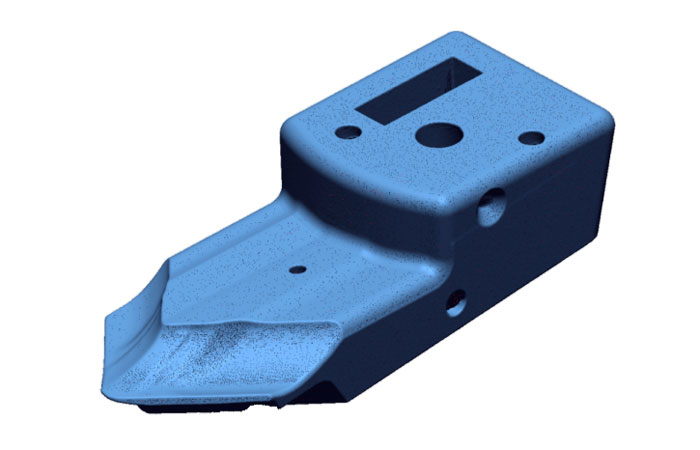

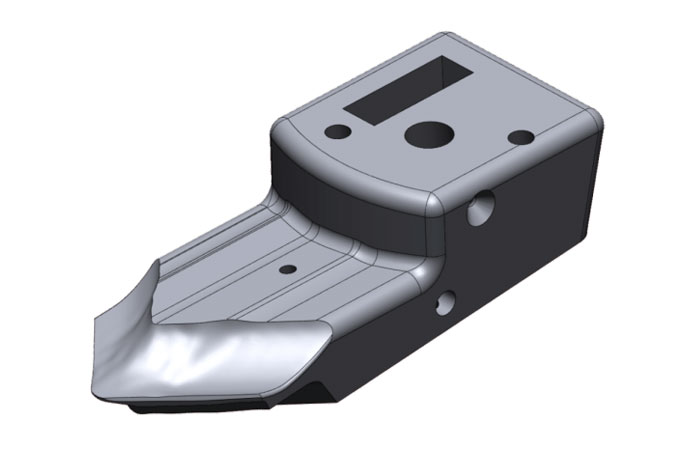

eviXscan 3D Heavy Duty Quadro

- precise 3D scanning in the most difficult conditions

- scanning accuracy up to 0.013 m

eviXscan 3D Heavy Duty Quadro

Breaking all the limits- accuracy certified in accordance with the VDI / VDE standard skanowanie 3D skanery przemysłowe 1

- 4x5 Mpix cameras

- two scanning ranges in one device skanowanie 3D skanery przemysłowe 2

- dust proof device (IP62)

- perfect for: quality control, reverse engineering and rapid prototyping

Heavy Duty Quadro - able to scan in almost any indoor or outdoor conditions

- Produces high precision results in all environmental and atmospheric conditions. Designed for continuous operation in industry and production lines under conditions of varying temperatures and lighting. The blue structured light source enables scanning of dark objects in outdoor lighting environments. The sealed, anodized aluminium housing protects the scanner internals against accidental mechanical damage, moisture and dust.

Two scanning ranges allow measuring the geometry of complex objects of a wide range of sizes. The scanner is compact, rugged and mobile so that it can scan objects in the most challenging locations. The Heavy Duty Quadro 3D scanner is frequently used by heavy industries to increase efficiency when inspecting and reverse engineering objects. Heavy Duty Quadro is a 3D scanner that can be used underground, in foundries, on production lines and in many other places... also in your company.

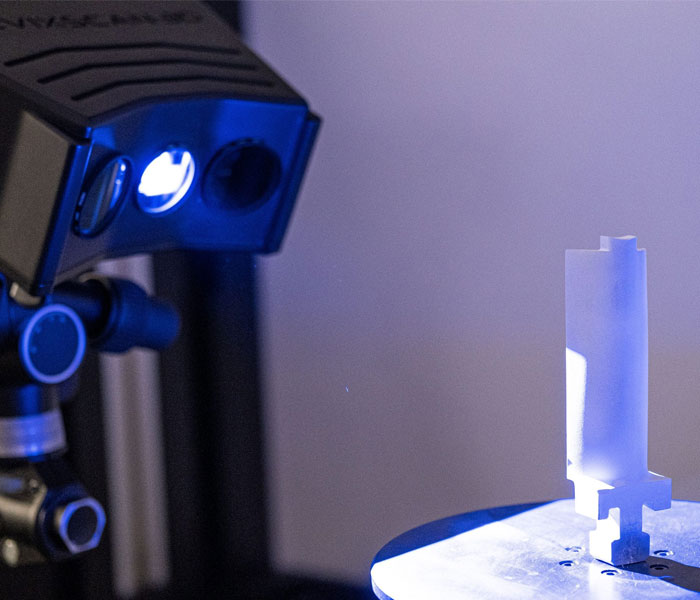

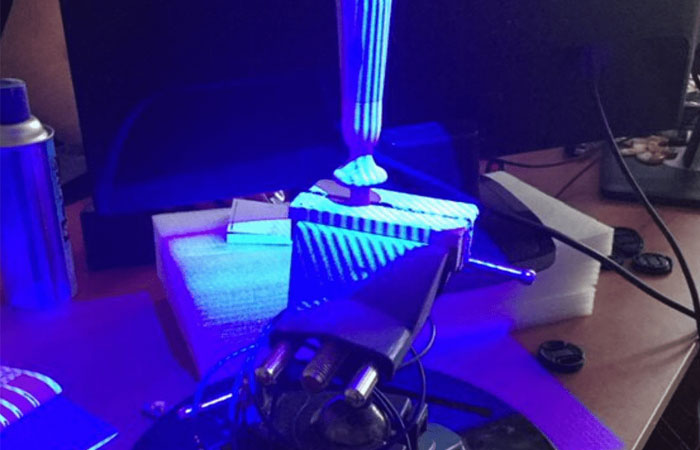

See what makes eviXscan 3D Heavy Duty Quadro so innovative- Blue light source

A high power light source (Power LED) with blue colour enable the scanner to operate with high precision in the most challenging lighting conditions. - Sealed housing

Made of aluminum alloy is resistant (IP62 standard). - Innovative cooling system

The active cooling system allows the device to work in harsh environment and guarantees reproducible results. - Two variable scanning ranges

The ability to scan in two ranges (narrow and wide) allows for precise scanning of small, complex objects and larger objects.

- Blue light source

eviXscan 3D Optima+ M scanner

- optimal solution for the 3D scanning

- scanning accuracy up to 0.009 mm

eviXscan 3D Optima+ M

discover the advantages of the new eviXscan 3D scanner

high-precision 3D scanning- Excellent price/performance ratio

- Powerful blue LED light source with extended lifetime

- Two high quality 7 Mpix cameras

- Accuracy certified in accordance with the VDI / VDE standard

New Optima+ M - optimal scanner

-

Optima+ M provides a high density of scanning points (117 pts/mm2) and high accuracy (declared accuracy up to 0.009 mm according to VDI/VDE p2 Ps). In addition, Optima+ M has a reduced distance between scanner and the object by 230 mm which facilitates the operation of the measuring device during scanning.

Robotized systems are another area where the new Optima+ M scanner can be used. Its lightweight, compact design makes it easy to integrate with a robot. The scanner also has dedicated software for Universal Robots, which guarantees smooth system implementation and easy operation. An additional advantage of Optima+ M is the possibility of cooperation with the entire portfolio of accessories.

Applications areas for eviXscan 3D scanners

Reverse engineering

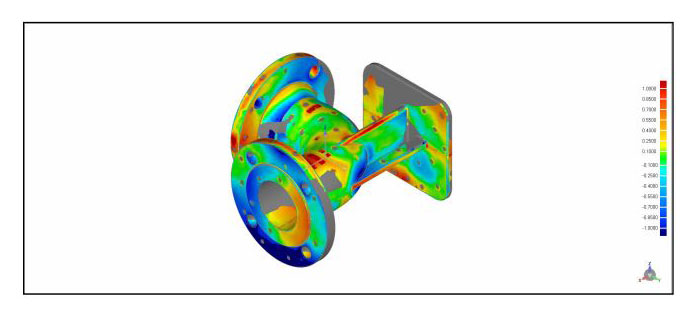

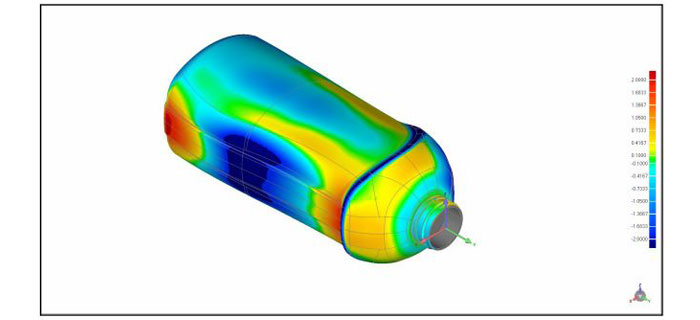

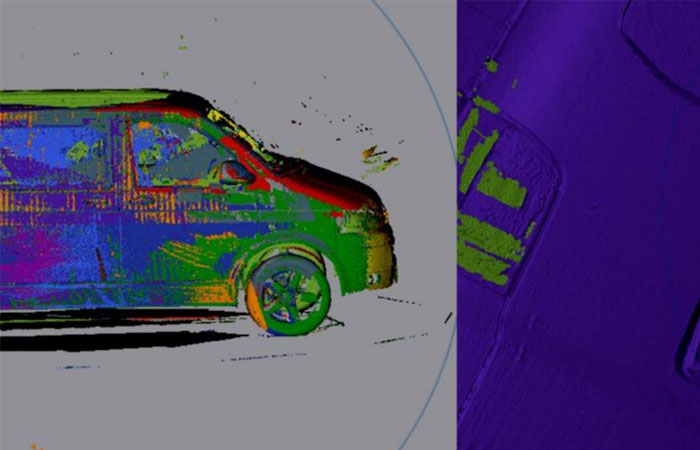

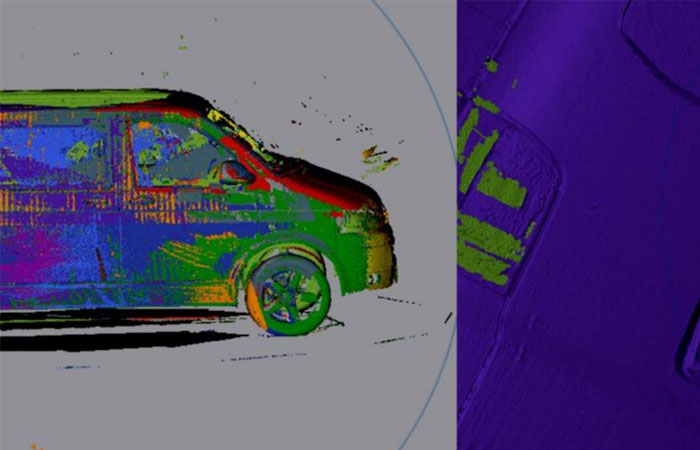

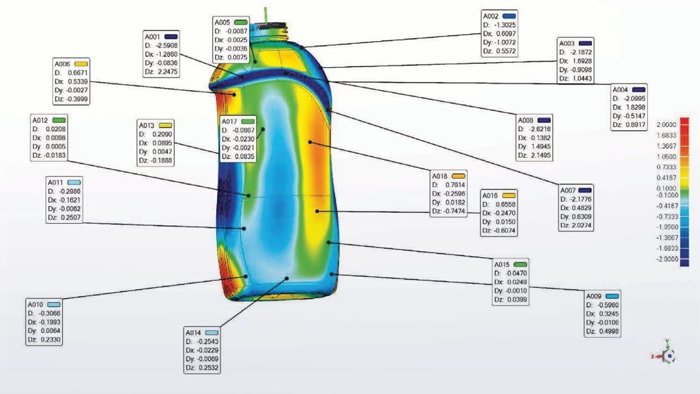

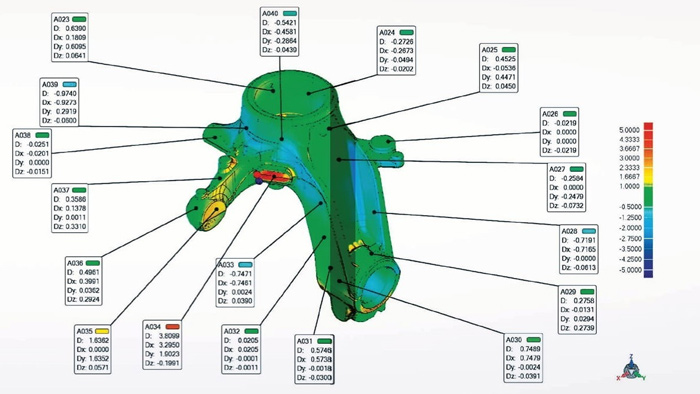

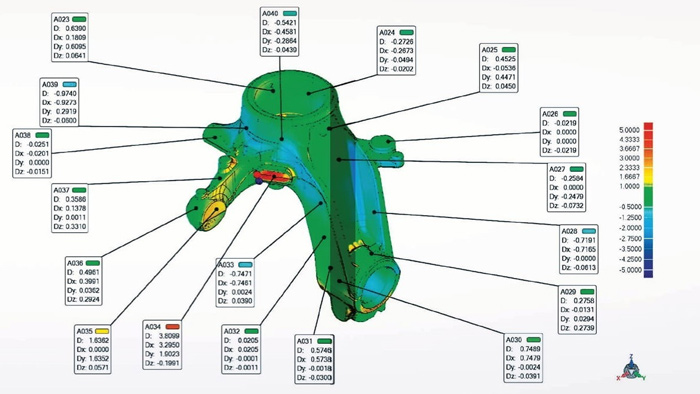

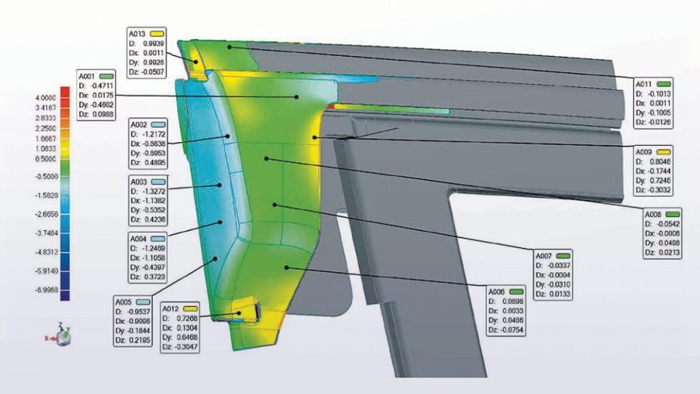

The triangle mesh maps surfaces and forms the basis for creating CAD models of an object. This allows creation of technical documentation for an object. The resulting model can be used to manufacture a replica, or as a starting point for the design of new products or variations.Quality control

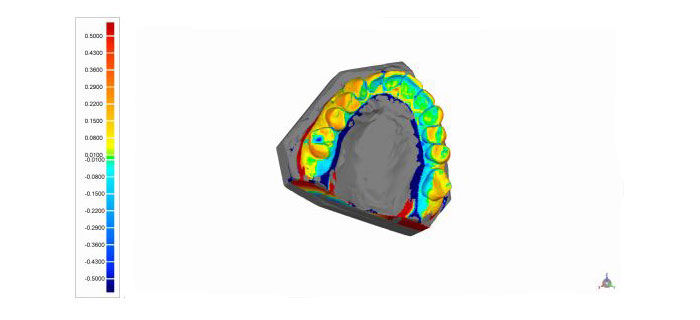

The scanned product is compared with a reference CAD model to create colour deviation maps.This allows accurate verification of tolerances on manufacturing drawings and measurement of elements that are difficult to measure by other methods.Rapid prototyping

Producing prototypes quickly and cheaply is an important strategy for gaining competitive advantage today. A precision 3D scanner, such as eviXscan 3D, is an essential part of the rapid prototyping process.

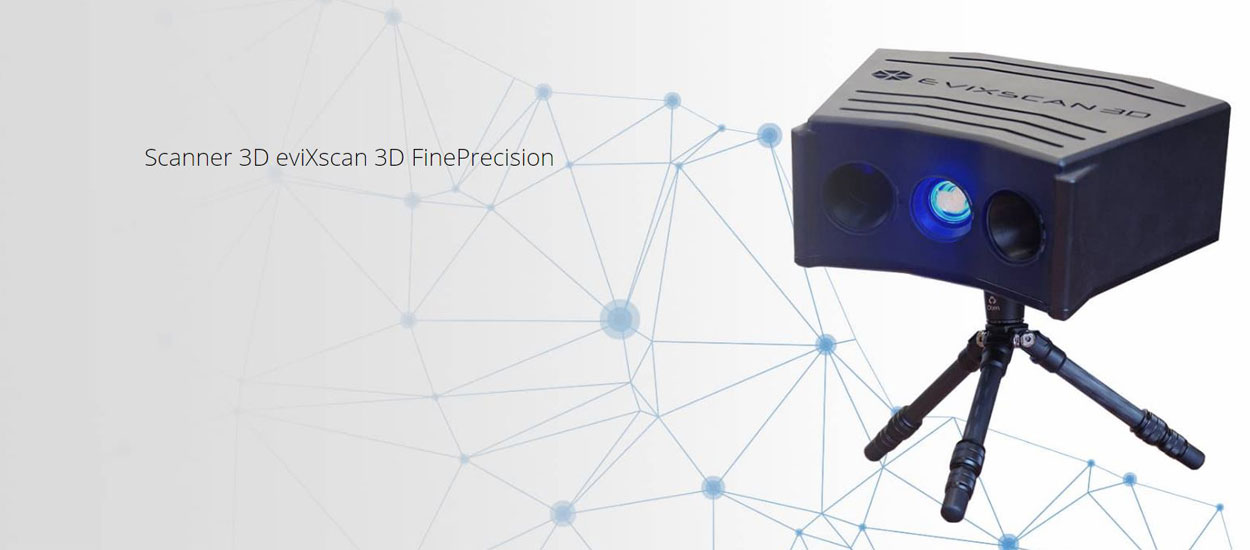

FinePrecision

- precise 3D scanning small sized objects

- scanning accuracy up to 0.006 mm

eviXscan 3D FinePrecision

ensures high precision scanning- accuracy up to 6 µm

- scan time

- ideal for small objects

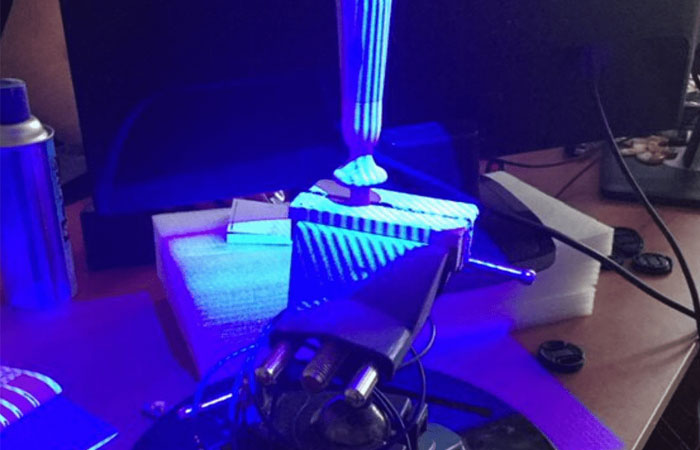

A tiny scanner with great possibilities

- The eviXscan 3D FinePrecision scanner is a device based on the latest generation of high-speed cameras with CMOS sensors and a LED blue light source - the combination of both technologies allows for very accurate reproduction of the scanned surface (accuracy up to 6 µm, resolution 33 µm), even with dark-surface objects.

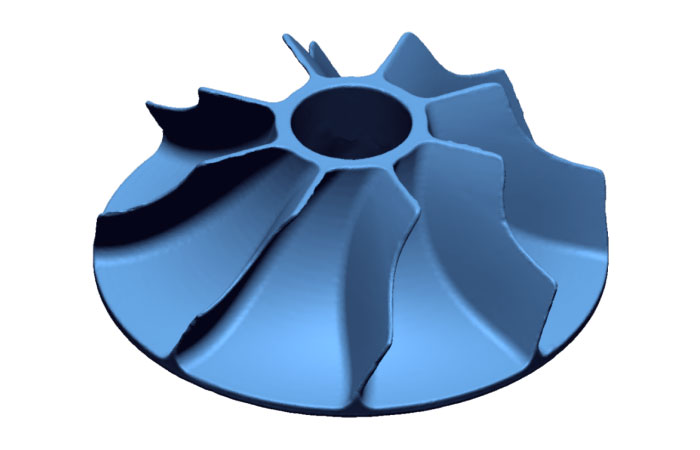

The FinePrecision 3D scanner is perfect as a measuring tool for precision mechanics, especially in areas such as: production of turbine blades, microcircuits, small injection parts, as well as precise numerically processed parts. FinePrecision is also used in scanning implants, in prosthetics, as well as in the watchmaking and jewelry industry. The precision of the scanner also allows it to be used to optimize the 3D printing process.

Precision 3D scanning in the smallest detail

- FinePrecision is an optical measuring device that can be used to collect more than 1200 points per square millimeter of scanned area. A single scan gives the possibility to acquire data in the volume of 120 x 60 x 45 mm3. Thanks to the blue structured light scanning technology the noise on the scans due to ambient light can be significantly minimized. The combination of a new generation of high-speed cameras with the fast frame collection triggered by the projection system allows to reduce the scanning time below 1 second.

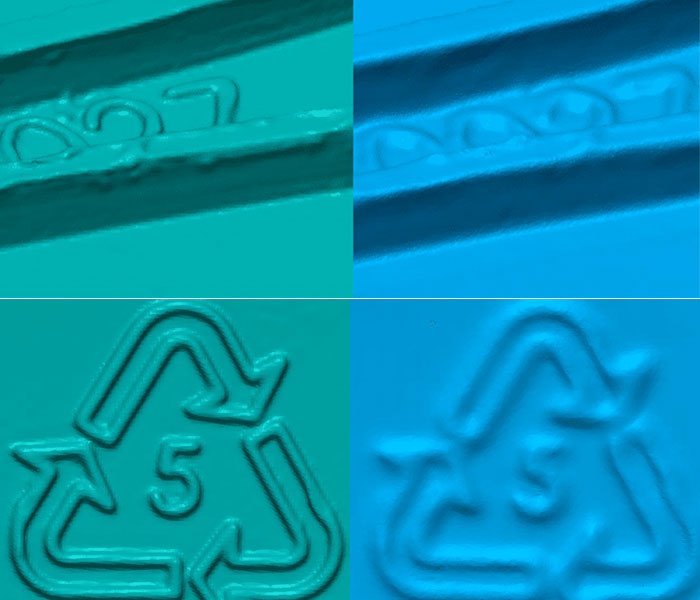

Pictures: Comparison of the details of scans (left: FinePrecision, right: eviXscan 3D scanner with a different design)

High-quality scans of the sharp edge of an object

- The small scanning area in combination with the high-resolution cameras allow for the creation of a scanner with an unsurpassed resolution of 0.02 mm (> 1200 points / mm2). These parameters allow the analysis of surface microdamages, dents occurring during the operation of machines and devices, as well as errors in the production process.

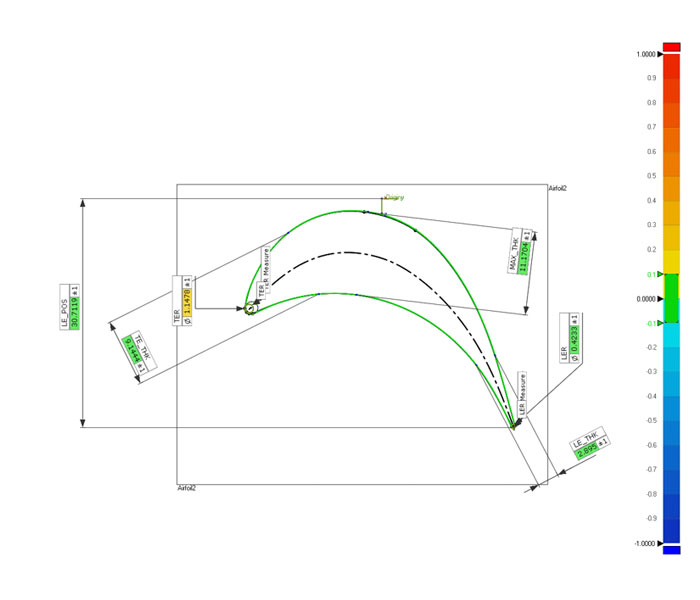

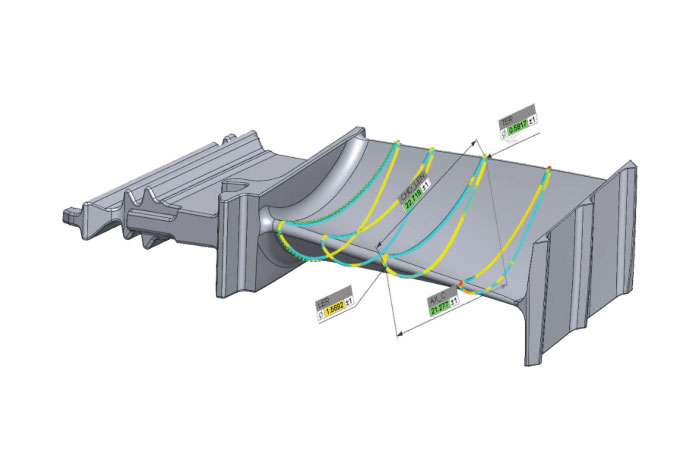

Detailed analysis of turbine blades

- Control the quality of turbines, blisks, blings or blades with the included airfoil analysis tools. Control X automates the measurement of:

- airfoil profiles leading and trailing edge position and thickness

- Camber lines

- chord angles and lengths

- 2D twist analysis

Technical specifications: eviXscan 3D FinePrecision: Light source type Blue LED Number and type of cameras 2 x 8,9Mpix Scanning time 1 second Measuring range 120 x 60 x 45 mm Points density 1233 pt/mm2 Accuracy up to 0,006 mm Computer connection USB 3.0 Export formats stl, ply, obj, asc, bin Hardware requirements Windows 10 (64-bit),32 GB RAM, CPU i77th generation, SSD NVMe 480 GB Software eviXscan 3D Suite

3D Services

We scan products

- Scanning products of various sizes, shapes, made of various materials, including shiny and transparent as glass

- Creating 3D documentation

- Preparation for quality control

- Preparation for the rapid prototyping process

Comprehensive 3D scanning and 3D modeling services

- Our services meet the highest standards of measurement accuracy (accuracy up to 0.013 mm, certified according to VDI/VDE). We operate across the country by scanning at customer locations (our 3D scanners are mobile devices) or by performing services remotely in our testing laboratory.

As part of the services we offer scanning objects of various sizes, shapes and made of various materials.

We specialize in dimensioning elements made of materials impossible to measure by conventional methods. We perform 3D scanning services at our company's headquarters or in the location you specify. Details to be scanned should be sent by courier to the eviXscan 3D measurement department. After the service is completed, the details will be returned to you. For the 3D scanning service at your location, please contact the eviXscan 3D measurement department in advance to arrange the details.

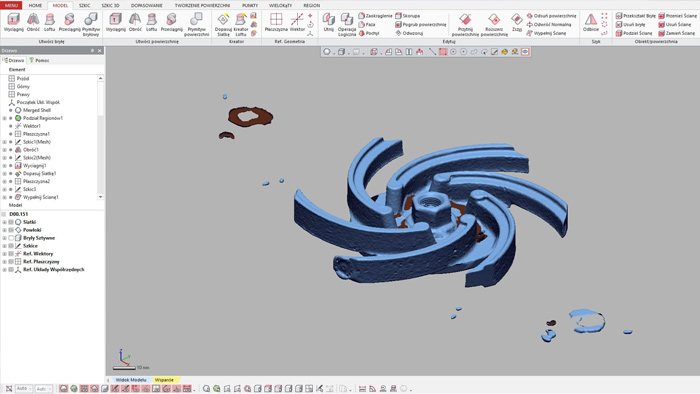

Scanning examples for our clients

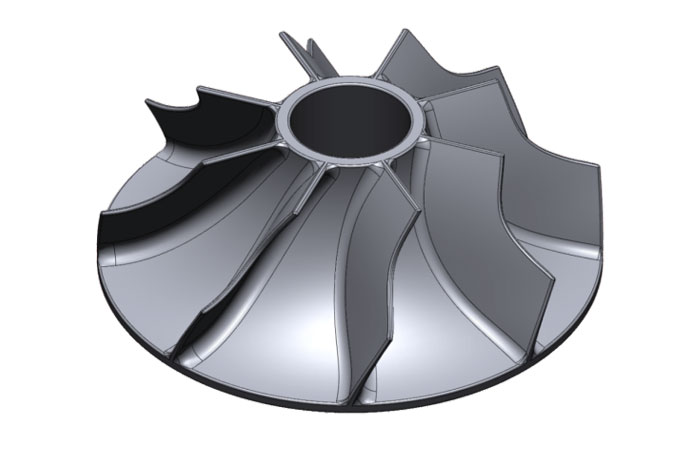

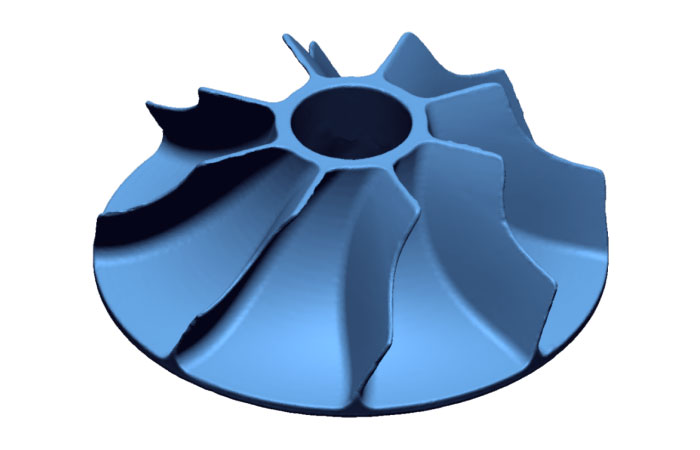

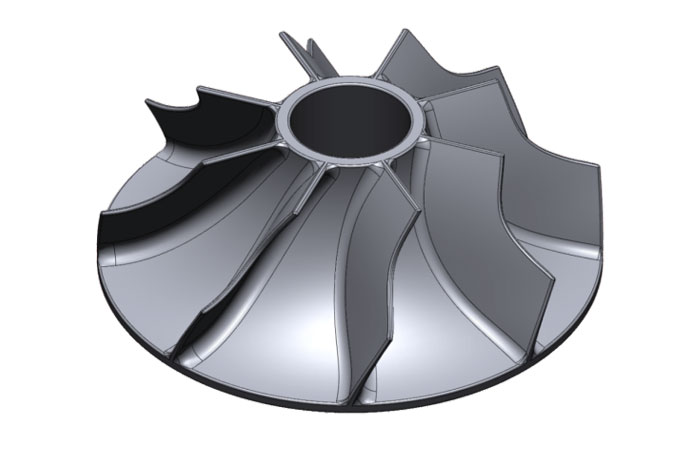

- Perform a 3D scan service of the turbocharger turbine

Based on the data received in the 3D scan process, an STL model was created. Then, the STL model was created by reverse engineering to create a CAD parametric model. So you can make replacements in any technology.

What were the challenges?- complicated shape,

- free surfaces,

- a product which is difficult to measure by conventional methods.

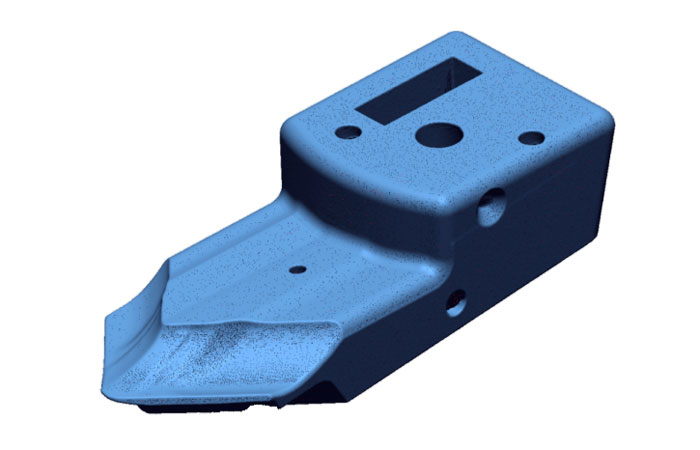

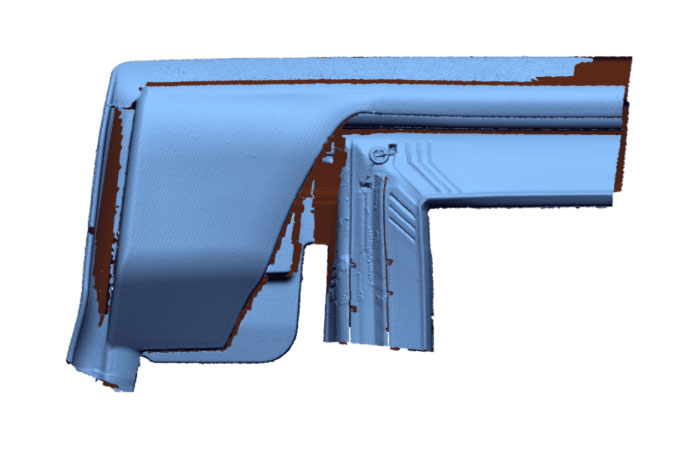

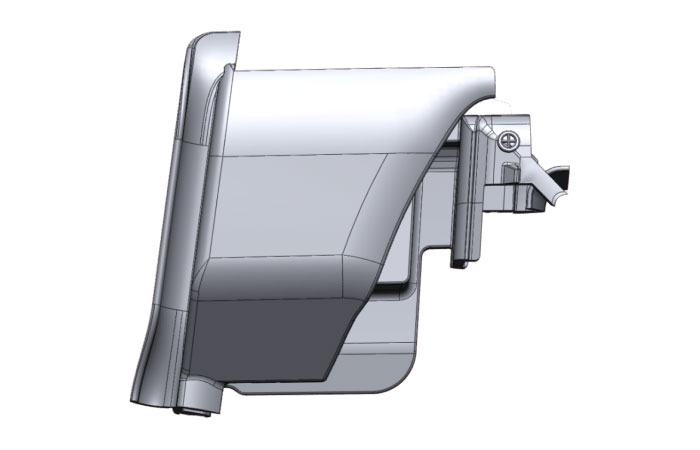

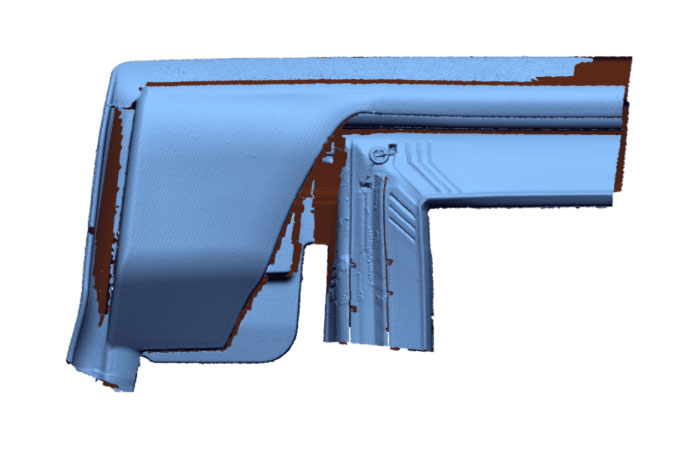

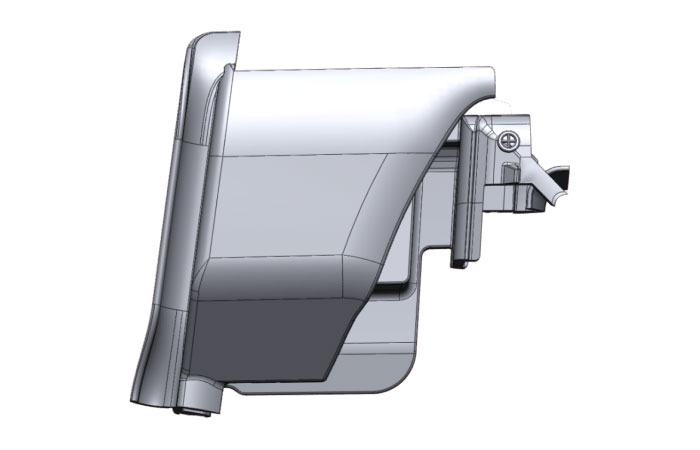

Design of the CAD model of the injection mold used

- Customer Cooper Standard has commissioned our engineers to make a CAD model of the injection mold. The STL model was created in the 3D scanning process. Based on this, the 3D Service engineers produced a CAD parametric model. The requisitioner performs part replacements in CNC machining technology.

What were the challenges?- complicated shape,

- free surfaces of the front part,

- an element that is difficult to measure by conventional methods.

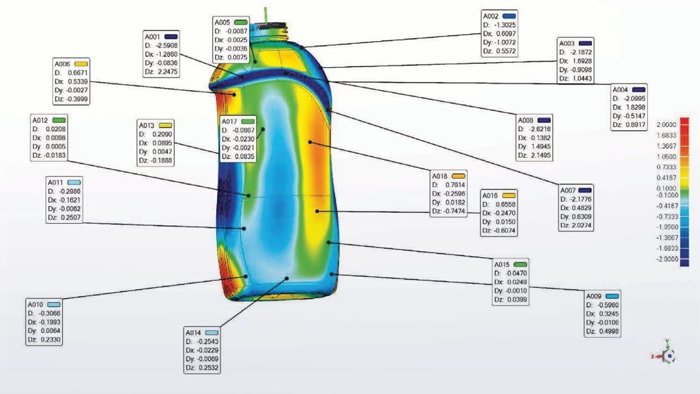

Performing reverse engineering service

- For our customer, the leader in plastic packaging production, we have developed a reverse engineering service. In the 3D scanning process of the supplied PET bottle, our engineers have made the CAD model. Based on this, our customer could make injection molds in mass production.

What were the challenges?- complicated shape,

- free surfaces,

- an element that is difficult to measure by conventional methods because of its flexibility.

Performance of the 3D scanning service of the rubber seal provided

- For our customer, the leader in the manufacturing of automotive bodywork seals, we have performed a 3D scanning service for the supplied rubber seal. Based on the data obtained as a result of the 3D scanning process, our engineers made a CAD model that was used by our client to make the injection mold.

What were the challenges?- complicated shape,

- free surfaces,

- an element that is difficult to measure by conventional methods because of its flexibility.

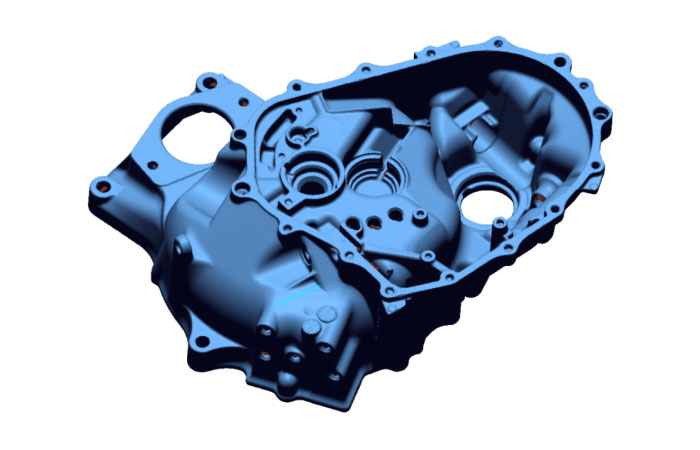

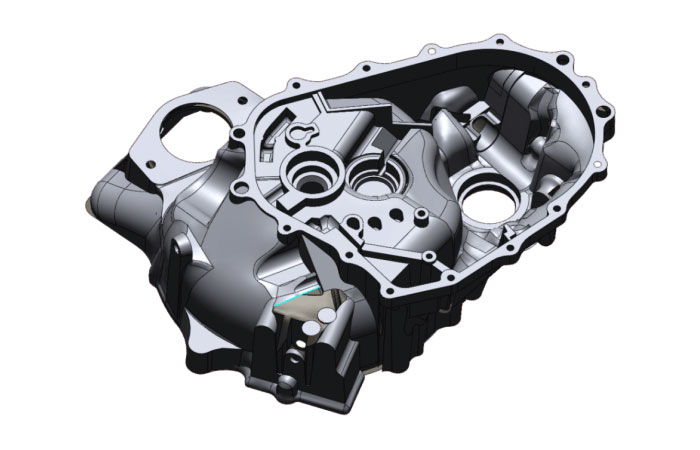

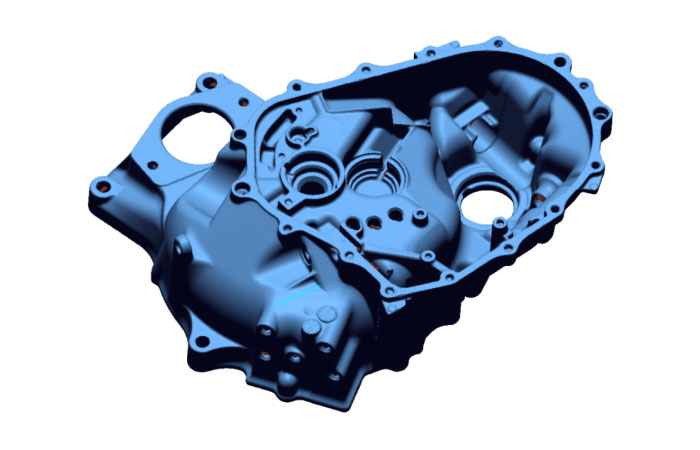

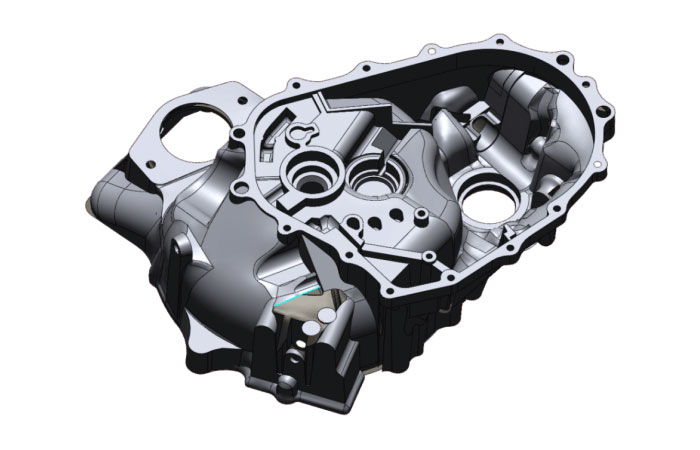

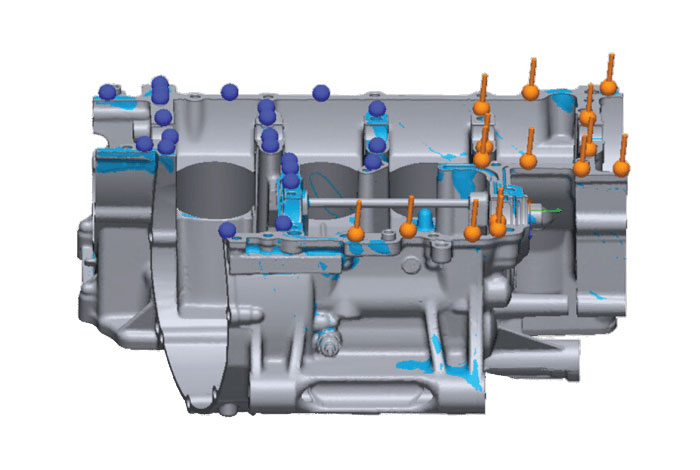

Perform 3D scan of the transmission housing

- For our client from the automotive industry we have performed 3D scanning service of the gearbox housing. The 3D scan process results in an STL model that is sufficient to reproduce the element only in the 3D printing process. Our engineers based on the STL model have conducted a 3D modeling process that results in a parametric CAD model.

3D modeling services

- We provide 3D modeling services. We support our clients in the process of full reconstruction of damaged or worn out components.

We perform 3D CAD model reconstruction based on:

- traditional measurement of damaged or worn out part

- available model or 3D scanning of it fragments

- the technical documentation available on paper or electronically

- combination of the mentioned possibilities

3D modeling services

- As part of the ongoing project, we provide full consultative support to our team of designers and constructors. Moreover, as part of the project our designers and constructors provide full consultation support. We guarantee that our projects are fully optimized in terms of design, utility and production costs.

We design additional elements compatible with the existing CAD model. We realize this services based on:- customer’s guidelines,

- available CAD documentation of the base element,

- 3D scanning of prototypes or based model,

- the technical documentation available on paper or electronically.

Modification / improvement of the existing CAD model we perform based on:- customer’s guidelines,

- available CAD documentation of the base element.

3D modeling services

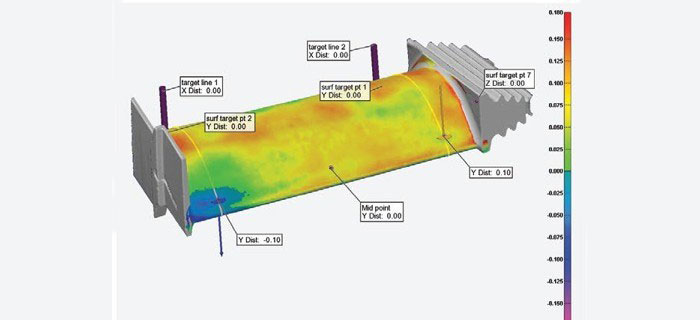

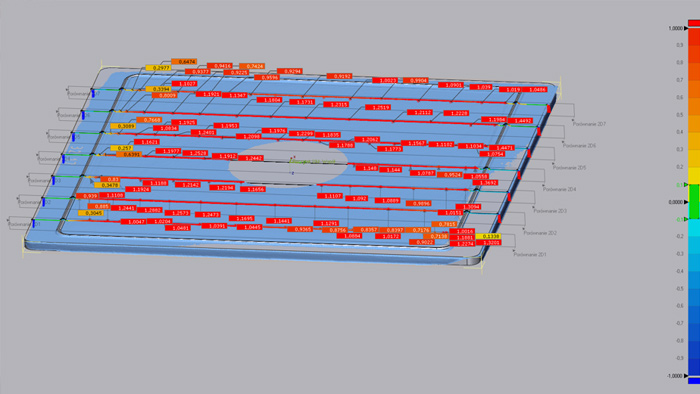

Quality control under laboratory or field conditions (at the eviXscan 3D Control Center) or at the location indicated by the ordering authority:

- full 3D analysis, free definition of tolerance

- wear analysis

- visual 3D reports, profile deviation color mapping, 2D sections analysis, boundary analysis

Quality Control – Area measuring and inspection

Precision is a guarantee of success! NOur engineers are a team of experienced metrology and quality control professionals. Thanks to the experience and use of the latest measuring tools such as professional 3D scanners of our own production, you are guaranteed the highest quality of service.

All 3D scanners from eviXscan 3D are certified to VDI/VDE.

Independant and non-invasive device control (optical quality control based on 3D scanning technology – non-invasive metrology).Sample quality accounts reports

- Quality Control reports customized to client’s needs and standards:

- point cloud and polygon mesh analysis,

- comprehensive probing support,

- airfoil analysis,

- state-of-the-art GD&T functions,

- intelligent reference geometry recognition,

- platform automation and scripting,

- 3D PDF reporting tools,

- advanced Reporting Toolse,

- automatic alignment based on feature recognition,

- inspection without a CAD nominal,

- interactive guided inspections,

- 2D and 3D dimensioning, iimport and support of key native MCAD formats with PMI.

3D software

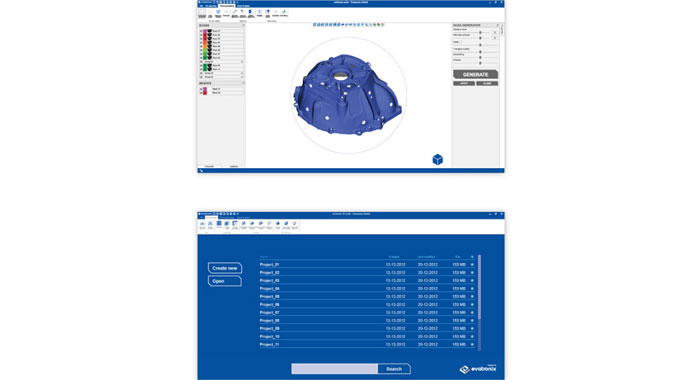

eviXscan 3D Suite

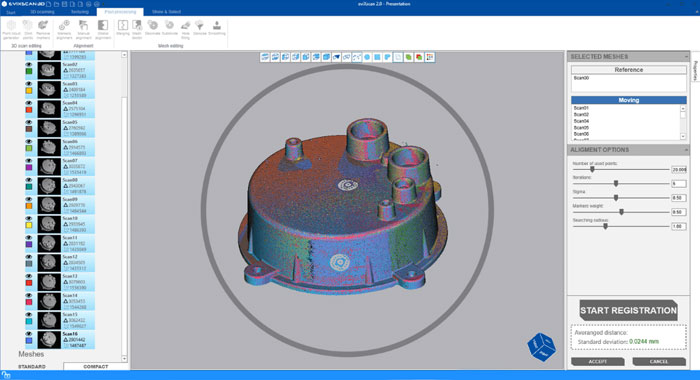

- The latest eviXscan 3D Suite 2.8 software package improves

the speed and quality of the eviXscan 3D scannersExplore the eviXscan 3D Suite 2.8

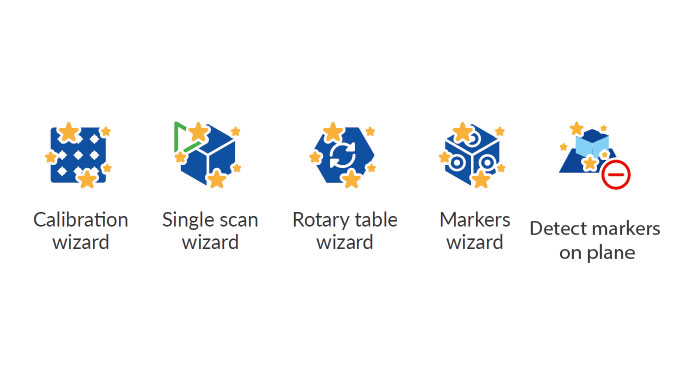

Comprehensive and user-friendly software for 3D scanning and triangle mesh processing. Key features and functions of the eviXscan 3D Suite 2.8:

- improved scanning performance, especially with older generation eviXscan 3D scanners functions

- possibility to control the robot without external plugins

- new version of the point cloud generator

- innovative ways of hole filling

- better merging quality

Wide range of functions combined with ease of use

- To answer the needs of our customers and partners, the latest version of eviXscan 3D Suite has been enriched with tools increasing the use comfort of the 3D scanning process (autoexposure, automatic removal of markers (targets) during the scanning, removal of rotary table surface and areas outside of the scanned object), the scans processing and evaluation capabilities (3D Scan Viewer improved). In addition, the algorithms for aligning scans using unique coded markers, reducing significantly the scan detection and matching errors have been refined and improved, which directly translates to increased accuracy of the resulted 3D scans.

The software is compatible with the following models of eviXscan 3D scanners: Loupe+, Pro+, HD Quadro, HD Optima and HD Basic. Owners of previous versions 1.3 and 2.0, in addition to the above described new functionnalities, will gain access to a number of other features implemented in version 2.5.

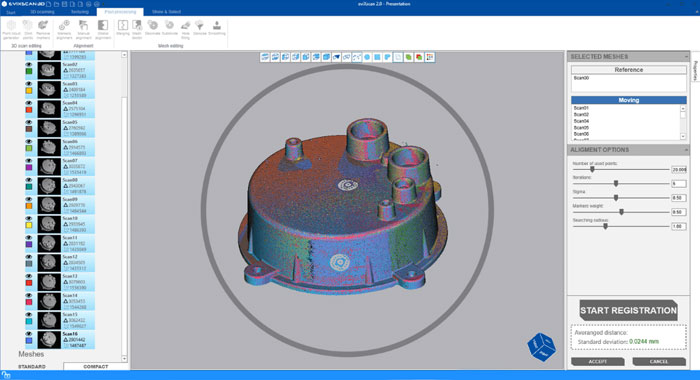

Learn about the features that make your 3D scanner more efficient

- Automatically set scan parameters

Setting the projector brightness and exposure time has never been easier. Clicking on the camera preview area allows to indicate where the optimal scanning parameters are to be selected. The algorithms will automatically estimate the brightness of the projector and the required exposure times.

New marker adjustment algorithm

- The implementation of a new matching algorithm for unique markers has reduced the scan adjustment error by up to five times, resulting in more accurate and faster global scan registration.

More efficient graphics engine

- It is possible to display hundreds of millions of triangles without slowing down the visualization. The optimization of the 3D Viewer resulted in a five fold increase in the number of frames per second displayed when the view is dynamically changed. In addition, the support for integrated Intel graphics cards has been implemented, so that the eviXscan 3D Suite software can be run on computers with limited hardware resources.

Automatically markers removal at the scan generation level

- The rewritten point cloud generator gives you the ability to automatically clean the scan from captured 3D markers, which significantly improves the comfort of further processing steps to obtain the final STL model.

New ways to display scans in the 3D preview

- Modified software graphics engine of eviXscan 3D Suite has introduced revised surface display methods to visualize even the smallest details on a 3D scan. Additionally, a surface view is enhanced with an overlaid mesh of triangles for better analysis of surface topology.

New functionality for determining the cut-off plane of the rotary table

- The new functionality of removing the scanned background when scanning with a table allows to easily and intuitively determine the plane which is the limit of the scans generated, which significantly accelerates the further processing of scans: this allows to skip the tedious process of cutting out unwanted scanned areas.

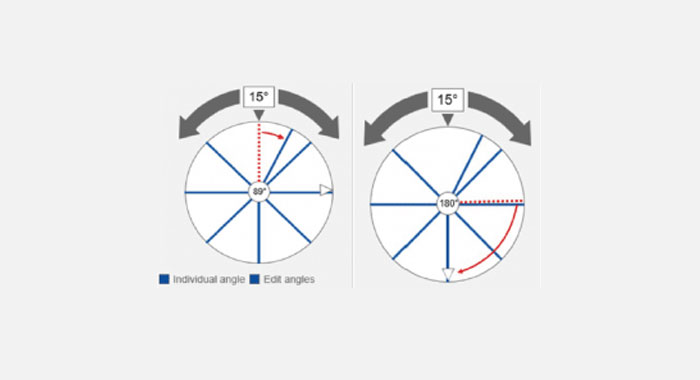

Tool for defining variable steps of the rotary table

- The new rotary table management module allows to define in an easy way the variable steps of the table.

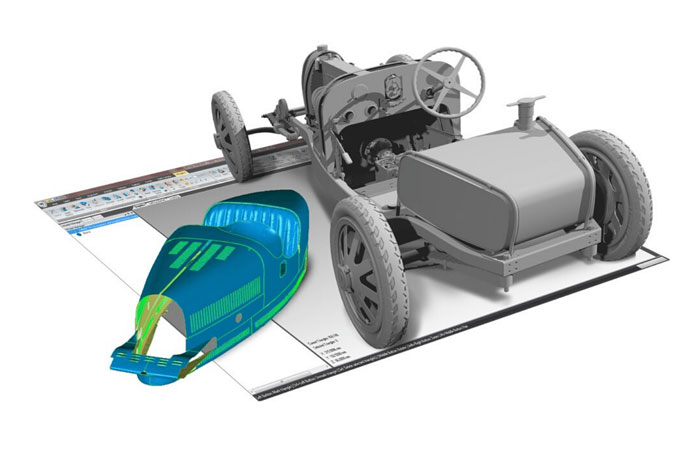

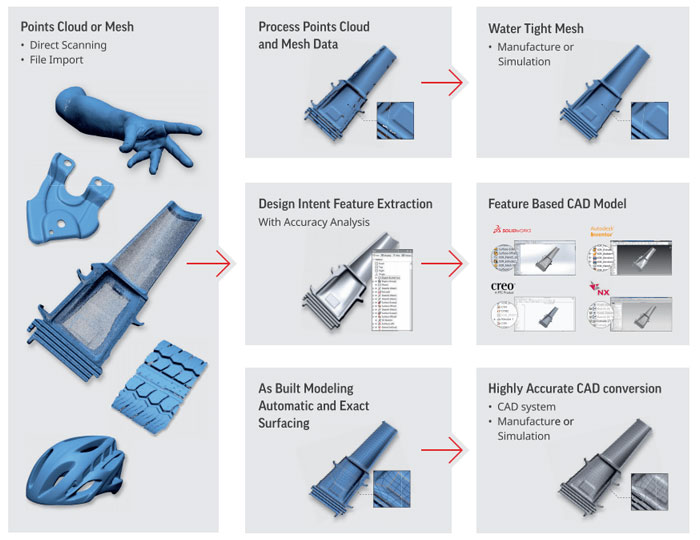

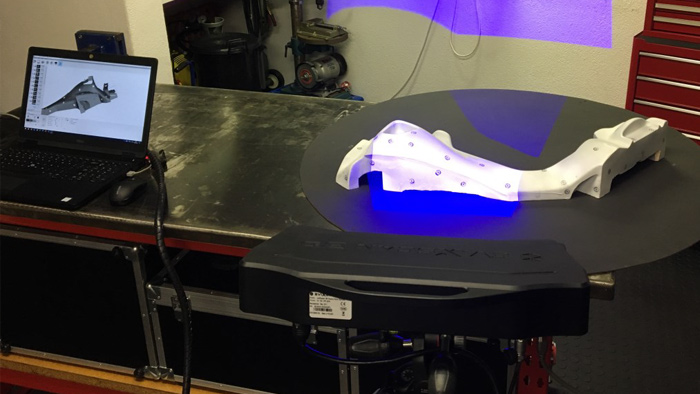

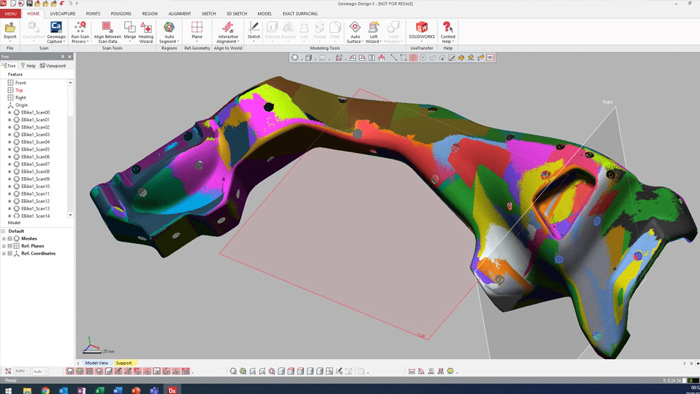

Geomagic Design X

Geomagic Designe X combines 3D modeling as in CAD software with the processing of scanned data. This solution enables users to create fully parametric and editable models in a format compatible with their CAD software based on data obtained from the eviXscan 3D scanner.

- Design using 3D scanning capabilities

Instead of starting with a "blank screen", start by editing data collected from already existing objects – Integrating 3D scans into the engineering design process. Geomagic Design X is the easiest way to create fully editable and functional CAD models based on STL files. - Reduce time-to-market

From the appearance of an idea to the creation of a ready-made project and production launch, you are only days away, not weeks or even months. All thanks to Geomagic Design X. Scan prototypes, existing parts, tools, and other related objects to create a CAD design for the finished product - up to eight times faster than manual modeling from scratch. - Reduce design and production costs

A definite end to wasting time and money during design and production. Tightly match the CAD model to the scanned model of the finished object already at the design stage. You will reduce production costs, avoid costly errors associated with inappropriate matching of the prototype with other elements.

CAD modeling has never been so easy! Enjoy innovative 3D technology

- Multiply your CAD capabilities

Act faster and more widely by using 3D scans in the design process. Geomagic Design X is compatible with the most popular CAD environments: Autodesk Inventor, SolidWorks, Siemens NX®, Solid Edge, PTC Creo® and Pro / ENGINEER. - Improve existing solutions

Many new, creative projects are inspired by existing solutions. Scan an object and enter it into your CAD project easily and quickly. Get to know its structure and dimensions. Modify it according to your needs and current project assumptions. Create CAD documentation for objects without it. - Make the impossible

Create products that could not be designed without reverse engineering. Design implants that require a perfect fit to the human body. Create elements that connect perfectly with existing products. Recreate the geometry of objects that cannot be measured in the traditional way.

- Design using 3D scanning capabilities

Learn more about software

- Works with the most popular CAD systems

Geomagic Design X is fully compatible with the leading CAD programs, including the one with: SolidWorks, Siemens NX®, Solid Edge, Autodesk Inventor and PTC Creo®. The use of the unique LiveTransfer technology enables the export of complete models together with the history tree, which significantly accelerates the design process, reducing the time needed to start production.

A tool designed for demanding projects

Geomagic Design X has a unique combination of functions, which is a part of the design process of demanding models – a completely new quality of efficiency. The software supports billions of scan points, which, combined with data troubleshooting features, allows you to skip clean-up scans and start creating CAD models immediately.

Robust and flexible software

Geomagic Design X is designed for the most efficient processing of 3D scanning data into functional CAD models. This is due to the unique combination of innovative software features: Precise surface mapping, automatic merging into a CAD model, point cloud processing and triangle grid editing. In practice, thanks to these solutions, the designer can make the final production model based on almost any scan.

Work as in CAD software

If you design in CAD software, the support of Geomagic Design X 2016 will not be a challenge for you. The reworked and refreshed user interface and a wide range of tools make creating CAD models from scratch or using 3D scanner data has never been so easy and fast.

Operating diagram of Geomagic Design X

- Supports the world's leading 3D scanners.

- Enables the import of more than 60 file formats, including polygons, point clouds and CAD.

- Professionally processes, merges and reconstructs point clouds and triangle nets.

- Intelligent and easy-to-use tools such as hole filling, smoothing and surface improvement enable fast machining of point clouds and triangle meshes.

- The automatic surface creation function based on 3D scanner data significantly accelerates the process of CAD model design.

- A tool for automatic comparison of designed surfaces and solids with data obtained from the 3D scanning process ensures the precision of the project.

- The Live Transfer™ tool enables full data export to the most popular CAD systems.

- The function of precise free form surface mapping accelerates the creation of CAD models.

- Allows you to create professional visualization in cooperation with KeyShot software.

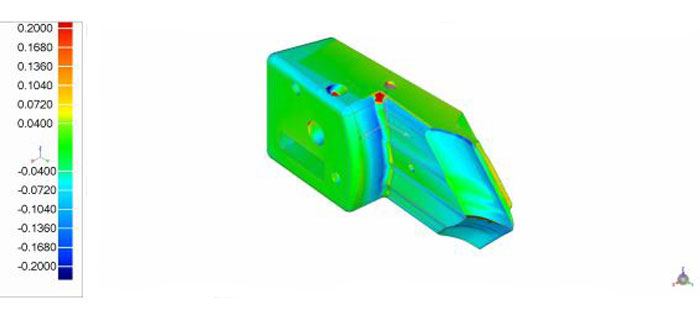

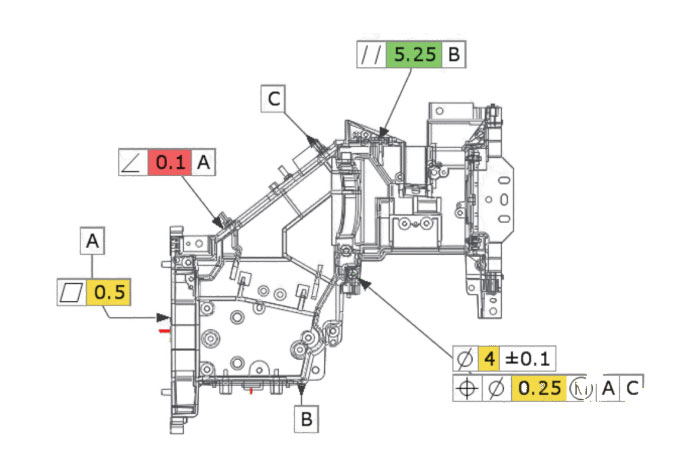

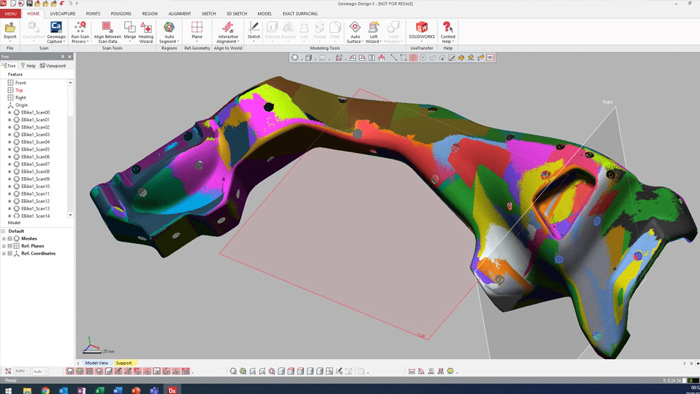

Geomagic Control X

The combination of the advantages of touch and non-contact measurement with CAD software technology enables fast and accurate inspection of components. The technology of intelligent model feature detection enables defining model orientation, dimensions, tolerances, and the end result is a detailed report with colorful deviation maps.

- Gurantee high quality

Take advantage of 3D scanning-based control for more people in more places. The software makes it easy to capture and interpret scanned data even in automatic mode (Automation Server). - Better insight into success and failure

3D scanners capture much more information than a handheld tool or CMM. Control X allows you to use the collected data and understand why parts are within or outside tolerance. - Optimalise production process

The insights gained by comparing scanned parts to CAD models or master parts in Control X allow employees to recognize and solve problems faster than ever before.

7 times quickly

Quality control with 3D scanning and Control X is up to 7 times faster than with a CMM

costs lower up to 80%

Control X users report up to 80% lower control costs based on time and labour savingsExplore the advantages of Geomagic Control X software

- Easy, intuitive and quick to learn

No time to become a software expert? No need, Control X is easy to use it after a short training course organized by our company. - fast during the user's work

The software is flexible - it follows your work pace, not the other way around, and native scan algorithms built on a CAD kernel make handling large files fast and easy. - All possibilities in one place

Control X contains everything you need for professional control. You don't pay extra for CAD software, scanning tools or statistical analysis capabilities. - Created to work with a 3D scanner

Make the most of your 3D scanner with software that is specifically designed to work with it. Control X works with any 3D scanner, so you can use multiple devices at once.

Find out more about the program

Use any 3D scanner

Control X can work with data from any 3D scanner. Direct plugins to many of the most popular systems have been developed. So you are ready for the future - you can add any 3D scanner at any time, without having to learn the new software interface.

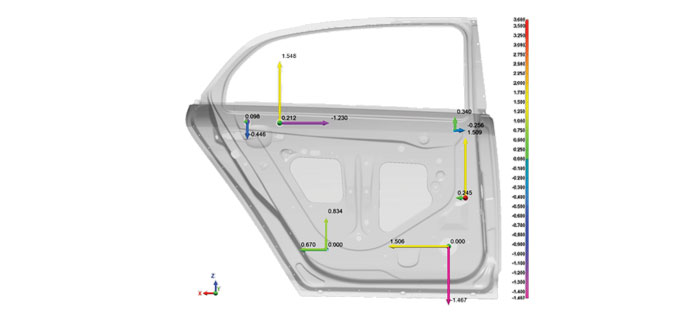

Compare scans with CAD

Beautiful, intuitive color maps show what fits in and out of tolerance and what the difference is. Control X supports countless comparison techniques, including 2D and 3D cross-sections. You get native interfaces with PMI for all major CAD systems: DS SOLIDWORKS, DS CATiA, CREO, AUTODESK INVENTOR, NX SIEMENS.

Fit as you wish

Control X has improved the fitting techniques to accommodate every control scenario: - Function-based Automatic Fit (Best Fit) - Best fit with constraint options - RPS, after features and 3-2-1 fit - Adaptive and based on.

Check for damage or surface wear

Control X can automatically estimate what is the ideal shape of the scanned object and measure the deviation to determine even small surface imperfections.

Compare scans with reference elements

You can scan the reference elements and use them for comparison as nominal models. Control X treats the scanned nominal as a CAD model because it automatically adds intelligence to each scan (for example, it knows that a plane is a plane).

Repeat and investigate to better understand

You can make changes in any part of the control process at any time. Try different alignments, different measurements, and Control X will recalculate the entire inspection process and display updated results immediately.- Gurantee high quality

Immediate dimensioning

- Because Control X automatically recognizes functions in the nominal models (regardless of whether they are CAD models or part of the reference elements), measuring dimensions in 2D or 3D is extremely fast and easy.

2D i 3D GD & T

- Advanced geometric dimensioning and tolerance tools allow to analyze the size, form, orientation and location of objects according to ASME Y14.5M standard. Geomagic Control X measures: - Lines, angles, radii, ellipses, hole depth, hole and thickness. - Straightness, flatness, roundness, cylindricity, parallelism, perpendicularity, angularity, position, concentricity, symmetry, line profile, surface profile, catwalk and total catwalk.

Clear, interactive 3D reports for everyone

Create reports the way you want them, using templates. And don't worry if you decide to change or add something later - reports update automatically. Monitor changes over time through trend analysis. Share reports using 3D PDF so everyone can view them on their PC, Mac or phone - no special software is required.

automate the entire process

Every aspect of project control is saved in the Control X model manager. Additional parts can be checked with a few clicks with the included batch processing application, which can run simultaneously on multiple computers.

Analyse the airflakes

- Control the quality of turbines or blades with the included airframe analysis tools. Control X automates the measurement of: - Airframe profiles - Position and thickness of guide and end edges - Angles and chord lengths - 2D steering analysis.

PolyWorks Inspector

Universal 3D measurement process

- Perform all measurement tasks using a common process

Improved alignment toolkit

PolyWorks 2018's alignment techniques for dimensional reference points and dimensional base targets are more versatile and complete than ever: balancing of deviations for parts with integrated iterative alignment functions with assigning target reference points to features of the constructed component.

User Experience

Improved detection features, ease of use and improved tool performance in PolyWorks 2018 provide valuable benefits from a user productivity perspective:- Simplified icons speed up the recognition of options, while preserving the original icon concepts.

- Colors attract attention in the right places and communicate results more clearly.

- Intuitive tools for positioning and annotation editing directly in 3D view.

Main Features

-

- 1.A universal measuring platform that works with the whole range of measuring devices, such as measuring arms and manual measuring devices, devices using photogrammetry, laser tracers and manual CMM. All plugs for operating the measuring devices are available at no extra charge.

- 2.A universal approach to all measurement tasks.

- 3.Parametric, traceable and upgradeable solution, that automatically records the operator's intentions and ensures that changes made to measurement projects are automatically duplicated in all objects and reports in the project.

- 4.The integrated Play Inspection function allows you to measure the next part without having to learn or write scripts.

- 5.The largest range of dimensional inspection functions on the market for complete analysis of surface, edge and section deviations, dimensioning of geometric features, flush & gap analysis, profile radii, blade dimensioning and many more.

- 6.GD&T™ analysis ased on the algorithms described in ASME and ISO standards, advanced capabilities of dimensional base frame definition (support for base feature arrays, complex bases and partial bases), support for base modifiers and tolerance zones, radial and rectangular tolerance zones and many others.

- 7.The position control mode allows for precise positioning of parts relative to selected objects, control of deviations in X, Y, Z and 3D, visual and audible operator guidance, automatic reference object detection and much more.

- 8.Best-in-class solution for managing multiple measuring device positions, with automatic adjustment of device positional transfer points, point analysis tools.

- 9.A powerful set of functions to align measurement data to CAD references, including the use of measured geometric features, reference points, surface points, best fit for surface points or sections, and much more.

- 10.Ability to work with multiple coordinate systems and multiple alignments within one project.

- 11.Extended reporting capabilities, including configurable templates, automatic report generation and export to Adobe PDF.

- 12.Integrated set of tools for statistical process control (SPC).

- 13.User-friendly macro programming language for advanced process customization.

- 14.Full compatibility with the Polyworks|Inspector™ point cloud metrology platform.

- 15.The free Polyworks|Reviewer™ allows anyone interested to view 3D measurement results.

Create and insert short macro scripts directly into measuring objects to:- Integrate your own internal measurement techniques as native PolyWorks|Inspector™ measurement methods.

- Integrate additional measuring devices such as digital meters and indicators.

- Gain additional measurement instructions and better feedback for quality control personnel.

- Use the standard measurement workflow by relying on efficient and reliable PolyWorks |Inspector standard components to guide operators, perform inspections, update designs and report results.

Build a library of your own measuring methods tailored to each production requirement and share them with colleagues.

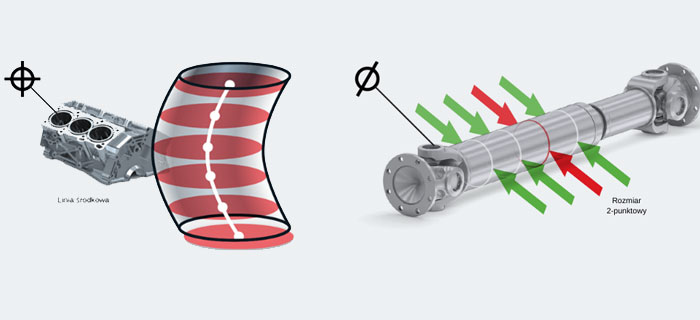

Check GD&T requirements

- Perform more thorough inspections with the improved GD&T PolyWorks|Inspector™ toolkit, which is now compatible with the latest versions of the ISO GPS and ASME GD&T standards. Now you can use the new axle and 2-point dimension calculations together with the associated dimensional checks for quality control of components such as holes in car engines and drive shafts.

Create and edit control views easily

Intuitively create control views by displaying desired objects and their descriptions in 3D view. Use the improved control results viewer to edit and improve control views.- Easily add controls or objects to or remove them from control views.

- Add custom measurements to control views to manage process information.

Accurately analyze feature deviations

- Use the maximum and minimum deviations of the measuring points of the matched feature, as well as the direction and magnitude of the deviations of the midpoint, to analyze the measured features more effectively.

Case Studies

Maritime sector: MAEM

-

Application of eviXscan 3D Heavy Duty Optima scanner in MAEM

MAEM is a manufacturer of spare parts for various equipment in ship engine rooms. Known on the world's waters, the company from Kraków, Poland, implemented eviXscan 3D solutions in its operations.

Advantages of using eviXscan 3D Heavy Duty Optima scanner

MAEM uses eviXscan 3D scanner for reverse engineering tasks. The measuring device, produced by Evatronix, supports and accelerates the process of designing solids. Its work is essential in case of difficult to measure details, whose shape influences devices' parameters and the quality of the offered product.An added value of implementing the eviXscan 3D Heavy Duty Optima scanner is the technical support and assistance offered by Evatronix specialists.

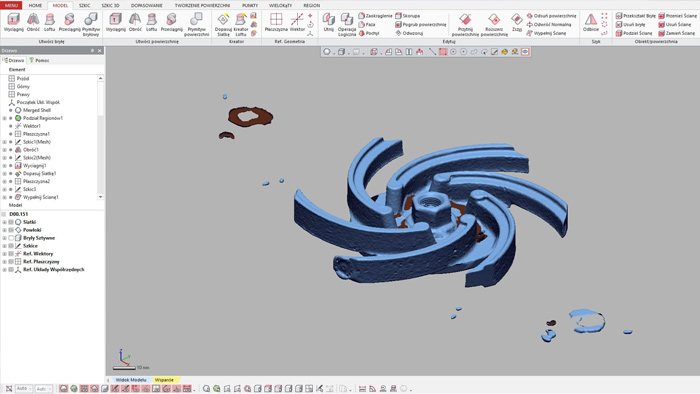

Automotive: 3DWORX

-

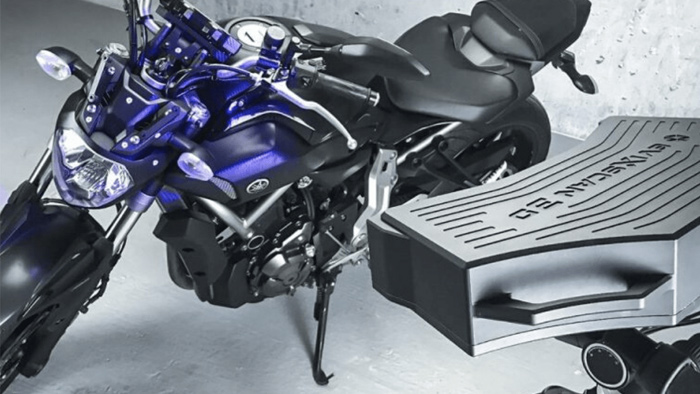

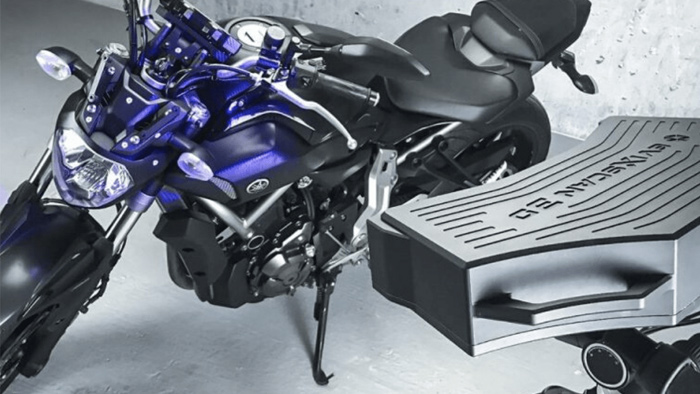

3DWORX – use of eviXscan 3D Heavy Duty Optima scanner in the Blackstone Tek Hypertek Electronic Motorcycle development project

3DWORX (www.3dworx.co.za) is the sub-Saharan distributor for eviXscan 3D scanners manufactured by Evatronix in Poland. A company from South Africa offers services in the field of high-precision 3D scanning, CAD design, reverse engineering, and 3D printing.

Blackstone Tek (BST) is an innovative company that builds carbon fiber performance products. It is a combination of the business profile and a love for racing which enables them to create exceedingly strong but still lightweight wheels, and fuel tanks, swingarms, fairings and custom-built components for iconic motorcycle and automotive brands.

Challenge

Design the most innovative electric motorcycle using CAD, but also hand-sculpting some prototype parts is the essence of the work to achieve an original organic aesthetic. The Master designer is Pierre Terblanche, responsible for the following styling motorcycles: Ducati 999, the HyperMotard and the SuperMono.

One of the challenges in this project was to digitize the compound curved components that were hand sculped into CAD models so that moulds can be manufactured for production lay-up of the carbon fiber parts.

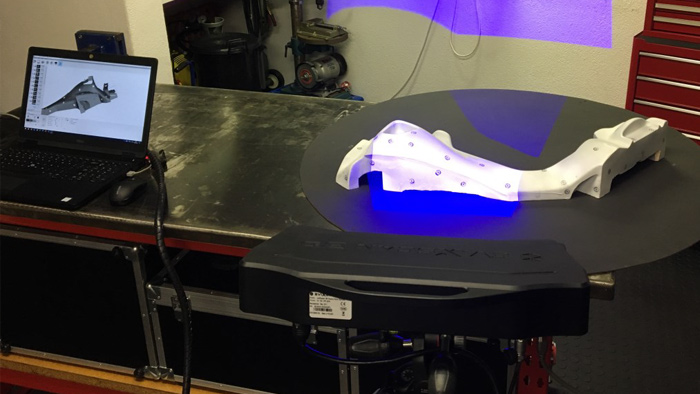

Solution

The solution used by 3DWORX is to combine CAD modeling with 3D scanning. The entire motorcycle design can be represented in CAD thanks to the application of eviXscan 3D Heavy Duty Optima scanner, the eviXscan Suite 3D scanning software and the 3D Systems Geomagic Design X software for reverse engineering.

Automotive: NGK Ceramics

-

NGK Ceramics – use of eviXscan 3D scanner

NGK Ceramics Poland is a producing plant that specializes in the production of DPF - ceramic particulate filters for diesel engines, designed to remove soot particles and other components form the axhaust gas, making them safer for the environment and people.

In addition to the main DPF business, for several years the plant also been successfully producing GPF filters – for gasoline engines, as well as LSH large-size ceramic substrates, which are used as catalytic converters in diesel engines.

Advantages of use eviXscan 3D Heavy Duty Quadro scanner

Manufactured components require accurate deformations control after heat treatment which is very difficult to perform by standard methods. The EviXscan 3D Heavy Duty Quadro scanner allows quick and exact quality control of production/execution.

In combination with dedicated software, the scanner is used to support solutions to production process issues.

Rapid Prototyping and Creating of CAD documentation

A team of engineers, who deal with new innovative applications, use scanning in Rapid Prototyping issues. Captured scans become the basis for the design of improved versions of manufactured components.

Plastics industry: Rosiński

-

Rosinski Packaging manufactures polypropylene and polyethylene packaging for household chemicals, parapharmaceutical products and cosmetics. Our client’s product portfolio is continuously updated with new designs of bottles and caps according to the latest technological solutions and customer requirements.

Reverse engineering

With implementation of an eviXscan 3D solution the company has gained a tool that provides support to orders that they previously could not accept due to lack of the technical documentation from the customer. A reference product is provided by the customer, scanned, a CAD model is made from the scans and finally, a production mold is prepared. The use of 3D scanning technology significantly reduced preparation time of molds and tools necessary in production.

Quality control

The use of eviXscan 3D Pro+ scanner in the quality control department allows for precise control of the quality of finished products by comparing them to original CAD models supplied by customers. This allows the company to be confident that products meet the expectations of the contracting customers. Implementation of eviXscan 3D solutions enabled precise quality control of finished products and shortened time to production.

Automotive: LOSTER

-

The Loster company specializes in the design and production of windshields and tuning components for a wide spectrum of motorcycles. The company successfully uses the eviXscan 3D scanner to design new components, which supports the entire production process.

Reverse engineering

Our partner uses an eviXscan 3D scanner to design new components for motorcycles (tuning). The scanning process significantly optimizes the design phase and guarantees the company’s products are always compatible with the base product. Developing a portfolio of new products begins with scanning the original element. Then, based on the scan, the company creates a 3D CAD model, which is modified according to the guidelines of the customer or Loster designer’s.

Rapid prototyping

Directly from the CAD file, the company makes a prototype using a 3D printer, which significantly speeds up the production process and reduces its cost.

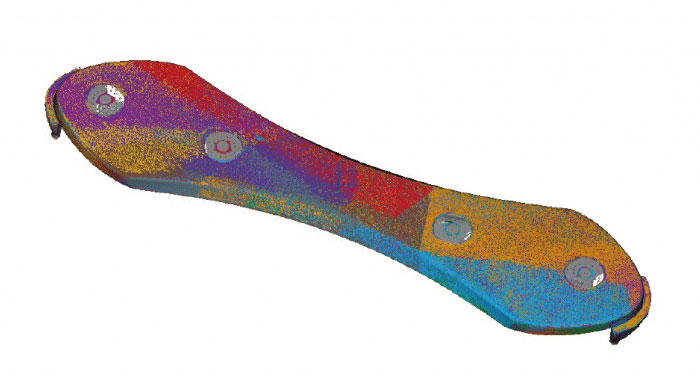

Metallurgy industry: Krosno Glass

-

Krosno Glass is a company that has been on the market for almost a century and one of the largest producers of useful glass in Poland, but also in the world. The glass produced by the Krosno brand is characterized by high durability, crystallinity and unique design. The Polish leader creates its products in the glassworks using mechanical methods but it is also a handmade work, by talented glasswork artists.

Advantages of use eviXscan 3D Heavy Duty Quadro

Krosno Glass creates products with very high precision every day. To make production process easier, the company bought the eviXscan 3D scanner. The equipping's 3D scanner has reduced the time it takes for the company to deliver the component to an external contractor. The in-house 3D scanning process also enables close cooperation at every stage of the process between all departments within company. Krosno Glass employees also noticed a lowered costs of production. Internal processes allows to reduce the costs before allocated to external services, and the number of people involved in the entire workflow has decreased significantly.

3D scanning of glassware to verify the manufacturing process

Our customer uses the eviXscan 3D scanner to check the dimensions and geometry of the products for: quality control process as well as for preparation of the tools to perform the process. Making a right tool without the need for multiple iterations improves production significantly. This is especially helpful due to the features of the processes related with glass processing. The high accuracy of surface mapping obtained from a 3D scan results in high-quality tooling and improved productivity.3D scanning of glassware to verify the manufacturing process

Our customer uses the eviXscan 3D scanner to check the dimensions and geometry of the products for: quality control process as well as for preparation of the tools to perform the process. Making a right tool without the need for multiple iterations improves production significantly. This is especially helpful due to the features of the processes related with glass processing. The high accuracy of surface mapping obtained from a 3D scan results in high-quality tooling and improved productivity.

Metallurgy industry: Metalpol

-

Metalpol, the oldest foundry in Poland fulfilling orders for clients in Europe and Asia, implemented an eviXscan 3D solution in the area of quality control and reverse engineering.

Quality control

eviXscan 3D solutions have been implemented in the quality control department. 3D scanning has enabled very high quality control of produced castings.

By using an automated 3D scanning system which consists of the eviXscan 3D Pro+ scanner and a rotary table with a capacity of up to 200 kg, scanning of large size and heavy castings is done very quickly. Thanks to strict quality control, our client has the ability to evaluate a trial casting by comparing it to a CAD model supplied by the customer.

When the trial casting is approved by the QC department, a full quality control report is sent to the client and, based on it, the client approves the start of commercial production of the ordered products.

Reverse engineering

Using 3D scanning increased Metalpol’s competitiveness by allowing them to serve customers who do not have the technical documentation for the products they want to order. The company uses an eviXscan 3D scanner to build a CAD model of the customer’s product. A prototype is produced from this CAD model. After approval of the prototype, commercial space production begins. The sawings are clear – Metalpol generates an additional profit and acquires more new clients annually.

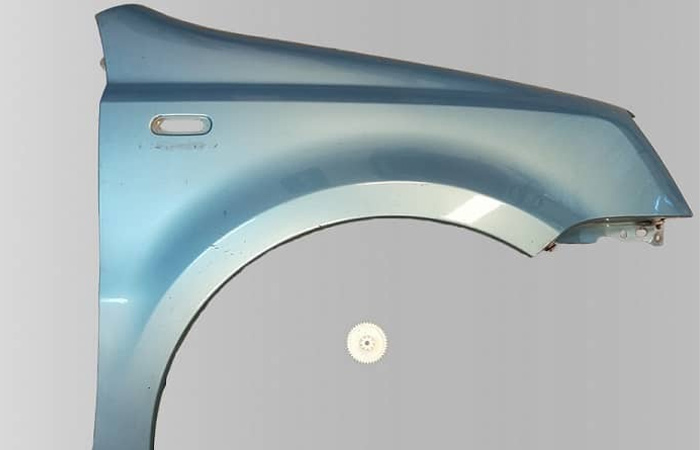

Automotive: Shapers Advanced Design Studio

-

Automotive – Shapers Advanced Design Studio – Lamborghini

3D scanning and reverse engineering services are used by people who design products and customize them. In the automotive industry, automotive component manufacturers place very high demands on measurement system suppliers in terms of accuracy and measurement speed. EviXscan 3D scanners handle this perfectly.

– The 3D scanning process opens up new possibilities for car part designers – said Jesuan Reis from Shapers Advanced Design Studio. – Through the use of 3D scanners, we have full control over the quality of both the entire scanning process and the final product. 3D scanning significantly reduces costs and shortens the time of the design process.

The main application areas for 3D scanning in the automotive industry are reverse engineering and quality control reports. Our diverse range of scanners allows us to scan and control the quality of both small and large items such as car bodies. In reverse engineering, 3D scanning allows the reconstruction of hard-to-reach or very expensive car parts," says Kamil Piasecki, application engineer at Evatronix S.A.

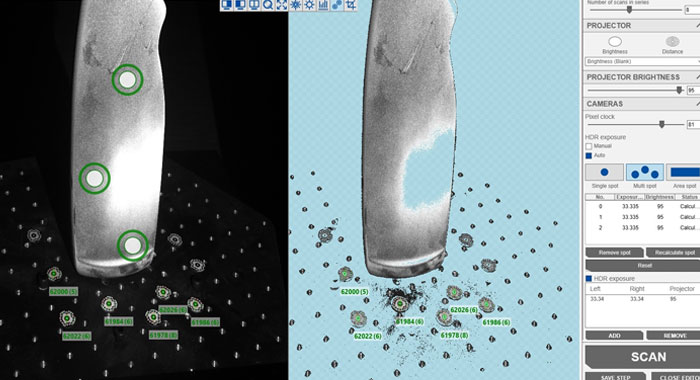

Process:

1. Raw scans – combining by unique markers.

2. Scanning and preparation for modeling.

3. CAD surface model.

Automotive: Cooper Standard Automotive

-

Cooper Standard Automotive is one of the leading suppliers of plastic and rubber components for the automotive industry. This global leader specializes in the production of car body seals, braking systems, fuel hoses, and air-conditioning systems for a wide portfolio of automotive brands.

Reverse engineering

Cooper Standard based in Bielsko-Biała (Poland) introduced an eviXscan 3D solution into their maintenance section. The use of 3D scanning enabled restoration of technical documentation of molds used in production. Now, preparation of new forms and tools is not only faster, but above all, much less expensive by producing them in their factory tooling department or outsourcing their production to external suppliers. As a result of implementing an eviXscan 3D solution, Cooper Standard has shortened production time of such elements and lowered costs generating savings.

Quality control

The use of 3D scanning in the quality control department ensures the highest quality of no finished products by comparing them to the CAD models supplied by the customer. Our customer thanks to the use of 3D scanning has the full confidence that their products meet the highest standards of the automotive industry, and that the product quality is in line with the expectations of their customer. Implementation of an eviXscan 3D solution enabled precise quality control of no finished rubber products, and shortened the measuring time.

3D scanning in art

-

3D scanning in art - Recreating the sculpture of Madonna from Krużlowa

uliusz Słowacki Theatre is a unique cultural institution in Krakow. In addition to talented actors, an important element of their performances is also the stage design that completes each performance. To create a new decoration component and thus support artistic scenery, this theater used 3D scanning services using the eviXscan 3D Heavy Duty Quadro scanner.

Creating a copy of the object in the process of rapid prototyping

The management of the Krakow theater asked us to make a copy of the sculpture of the Madonna of Krużlowa, which was to be part of the stage decor in the show "Name of the Rose". Using the eviXscan 3D Heavy Duty Quadro scanner and using rapid prototyping, the desired effect was added to the scenery.

Precise reproduction of such a complicated geometry of the original object is possible only thanks to the use of a 3D scanner. Compared to traditional methods of reproducing works of art, 3D scanning is a much cheaper, faster, simpler and - most importantly non-invasive method. Sculpture scans were developed by engineers and placed in an STL file, in which the object was enlarged to the appropriate dimensions, and then printed in 3D.

The resulting print accurately reproduced the surface condition of the original sculpture, which allowed the discovery of previously unnoticeable details.