- Offer Profile

- Axetris AG first started developing and producing micro-technical components in 1998 and has continued to establish and develop its expertise ever since. Axetris is a leading provider of components and modules for gas sensing, gas flow and gas control, powered by Axetris’ proprietary platinum based Pt-microchip technology. All products are manufactured at Axetris’ state-of-the-art micro-technology clean room facilities in the central part of Switzerland.

The product range includes ultra-compact, high-accuracy and fast response mass-flow meters and controllers, rugged infrared light sources for advanced gas sensing applications in mid-IR and high-selectivity laser gas detectors based on tuneable diode laser spectrometry.

Axetris is also a leading provider of micro-optical lenses and diffractive optics and offers MEMS Services for select customers. Axetris engineering and manufacturing teams combine broad experience in design, manufacturing and metrology from the microchip to advanced electronic modules.

Axetris Puts micro-technology to work

- Axetris serves OEM customers with micro technology based (MEMS) infrared light sources, laser gas sensors, gas flow sensors & controllers and micro-optical components used in industrial, telecom, environmental, medical and automotive applications.

Our multi-disciplinary and highly skilled engineering and manufacturing teams combine broad experience in design, manufacturing and metrology from MEMS components to advanced optical and electronic sensor modules. Axetris supports its customers with in-depth application know-how. Customers benefit from excellent product value, consistent high product quality and outstanding customer support. OEMs rely on Axetris worldwide as a competent partner for customer-specific solutions from concept to volume production. Axetris is ISO 9001:2015 certified and operates its own 6-inch to 8-inch wafer MEMS foundry for its own products and contract manufacturing for external customers. A wafer back end, a sensor assembly and calibration facility under clean room conditions completes the manufacturing infrastructure of Axetris.

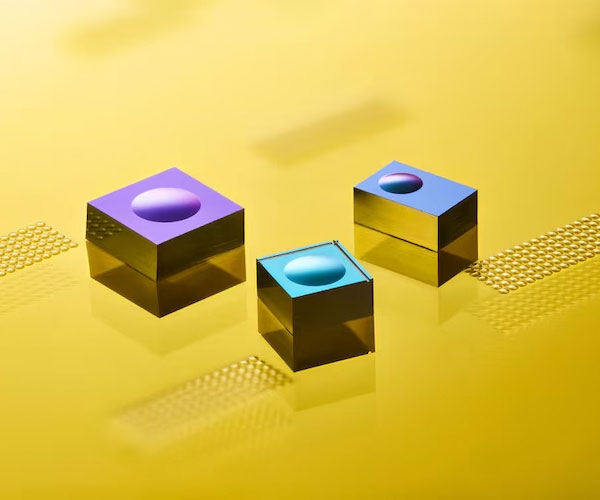

Micro-Optics Products

-

Axetris offers high quality refractive microlenses and lens-arrays as well as diffractive optical elements (DOEs) in silicon and fused silica, covering the entire wavelength range from UV to IR. Axetris supports OEM customers from prototyping to volume production to meet their specific design requirements in various industries such as communications, industrial, medical, automotive, and consumer.

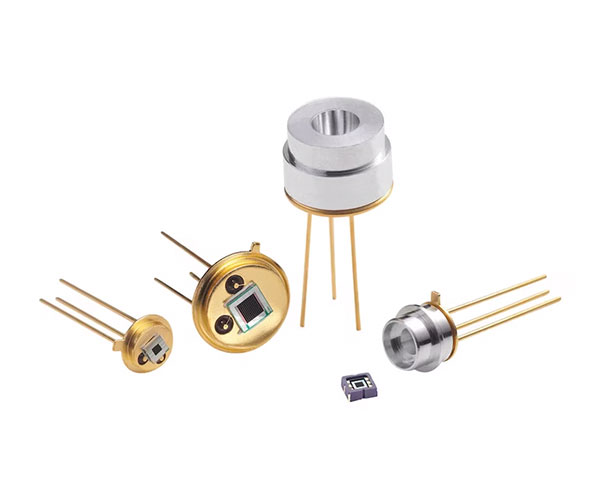

Infrared Sources

- Axetris MEMS-based infrared sources guarantee precise measurement results in optical gas sensing. Their modular design allows tuned configurations for efficient and straightforward integration. In addition, the technology allows electrically modulated operation in combination with true blackbody radiation, low power consumption, high emission and long lifetime.

Laser Gas Detection

- Laser Gas Detection (LGD), based on Tunable Diode Laser Spectroscopy (TDLS), provides a solution to many gas detection challenges in emission monitoring and process control. The technology offers unique advantages like precise optical and contactless measurement, excellent target gas selectivity and sub ppm-level detectivity.

Mass Flow Devices

- Axetris offers OEM mass flow meters (MFM), mass flow controllers (MFC) and manifolds for gases with outstanding benefits for its worldwide customers. The platinum-based MEMS thermal mass flow technology guarantees excellent accuracy and repeatability combined with high speed and unsurpassed dynamics.

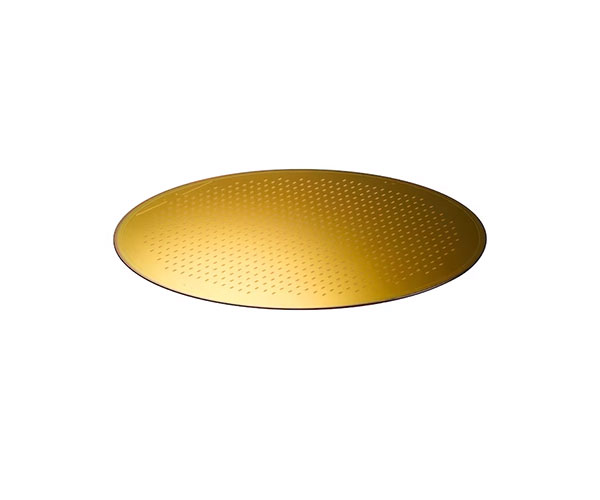

Wafer Processing Services

- Axetris offers in-house wafer processing services and post-processing on customer wafers in the only MEMS foundry in Central Switzerland. The facilities include a class 1000 clean room environment, lithography, thin film as well as dry and wet etching processes for 150 and 200mm wafers. ISO 9001 certification and ISO TS16949 compliance ensures the highest level of quality and customer support.

Micro-Optics Products

Microlens Arrays

-

Axetris manufactures custom silicon and fused silica microlens arrays on 150mm and 200mm wafers. The silicon-based lenses are particularly effective in high numerical aperture (NA) applications in the near-infrared region. Quartz-based products extend the portfolio in the visible wavelength range. Axetris microlens arrays offer high pitch accuracies as well as uniformities and enable high coupling efficiencies with fiber, waveguide or photodiode arrays.

Typically, microlens arrays are used in wavelength selective switches (WSS) or high-speed components such as transceivers (the word transceiver is a combination of "transmitter" and "receiver".).

- High pitch accuracy

- High material and surface quality (silicon and fused silica)

- Optimized custom designs

- Cost-effective wafer level manufacturing

Refractive Microlenses

-

Axetris manufactures customized micro-lenses in silicon and fused silica on 150 and 200mm wafers. The silicon-based lenses are especially effective for high NA applications in the near-infrared range. Fused silica-based products extend the portfolio into the visible wavelength range. Axetris micro-lenses allow high coupling efficiencies (high NA and aspherical shape control) and tight integration due to their small size.

Axetris lenses are perfectly suited for optical sub-assemblies (TOSA/ROSAs) and direct integration in high speed components. No matter whether the assembly is solely optical or combined with integrated photonic integrated circuits.

- Precise lens profile (spherical and aspherical)

- High NA for laser or waveguide coupling

- Ultra compact size for high integration

- Glue-stop, solder pads and more

Diffractive Optical Elements (DOE)

-

Axetris manufactures customized diffractive optical elements (DOEs) with up to 16 levels in silicon and fused silica on 150 and 200mm wafers. Both materials may be used in transmission and reflection, the latter usually requiring the application of surface metallization. The Axetris DOE portfolio covers single chips typically sized in the millimeter range as well as undiced post-processed customer wafers.

Typical applications are beam shapers in high power laser applications or pattern generators for medical applications. Besides metallization, anti-reflective coatings can be applied, covering the desired wavelength range. Although Axetris' philosophy is to ship 100% inspected, good parts only, our customers may choose to be supplied with undiced wafers including a wafer map.

- Binary and multi-level DOEs

- Phase and amplitude DOEs

- Transmissive and reflective DOEs

- Controlled zeroth order

Infrared Sources

-

Axetris MEMS-based infrared sources guarantee precise measurement results in optical gas sensing. Their modular design allows tuned configurations for efficient and straightforward integration. In addition, the technology allows electrically modulated operation in combination with true blackbody radiation, low power consumption, high emission and long lifetime.

EMIRS200

-

The Axetris EMIRS200 infrared source is available in different versions and is suitable for various sensor principles: For example, non-dispersive infrared spectroscopy (NDIR), photoacoustic spectroscopy (PAS), and attenuated total reflection spectroscopy (ATR). Common applications are environmental measurement, medical diagnostics, and safety applications in industry.

The collimation properties of Axetris infrared sources are well-suited to many optical designs and detector characteristics in terms of the angular distribution of radiation. Their compact size makes them easy to integrate into most solutions. EMIRS200 infrared sources are available and compatible with a variety of broadband optical filters.

- True black body radiation

- High modulation depth

- High electrical-optical efficiency

- Long lifetime

EMIRS50

-

Axetris EMIRS50 infrared sources are optimized for miniaturized sensor technology. Like non-dispersive infrared (NDIR) sensors, photoacoustic spectroscopy (PAS) or attenuated total reflection (ATR) spectroscopy. The sources are particularly well-suited to size-optimized and battery-powered sensor solutions in medicine as well as in numerous environmental and industrial applications. Thanks to the low thermal mass of the chip, modulation frequencies of 100 Hz are guaranteed, allowing high sampling rates.

The efficient collimation of the available reflectors is achieved by optimized Winston-Cone geometry and mirror-like surfaces. As a result, Axetris EMIRS50 infrared sources offer maximum efficiency.

- True black body radiation

- High modulation depth

- Low power consumption

- Long lifetime

EMIRS200 Custom

-

The Axetris EMIRS200 infrared source is available in customized versions. Our application specialists support you with the adaption of our tried and tested technology to your individual OEM requirements. As a result, installation-relevant specifications are met and optimal coupling of the optical signal is achieved. Customer-specific solutions are built on a broad, modular product portfolio of implemented components and adapted and extended according to individual requirements.

- Custom reflector properties for maximum efficiency

- Customized casing for a perfect fit

- Custom interface for simplified integration

IRS LabKit

-

The Axetris IRS LabKit is perfectly suited for testing and evaluating EMIRS infrared sources. Multiple sources can be purchased and characterized with the LabKit. This allows for quick testing when electronics are not yet available. In combination with the detector, the optimal drive parameters for the entire EMIRS portfolio can be selected. Continuous data recording allows analysis and optimization of the IR source's behaviour and the over Using the LabKit allows for a more efficient development phase prior to the market launch. This saves valuable time even before the prototype is built.

EMIRS50 Custom

-

Axetris offers customized versions of the EMIRS50 infrared source. The housing, reflector design, and broadband filters are configurable to meet specific product requirements. The size and collimation characteristics of the reflector can be matched to the absorption cell and detector configuration. This results in a maximized optical signal and optimized angular distribution of the radiation. We also support efficient and economical implementation through ray-tracing simulations and finite element analysis.

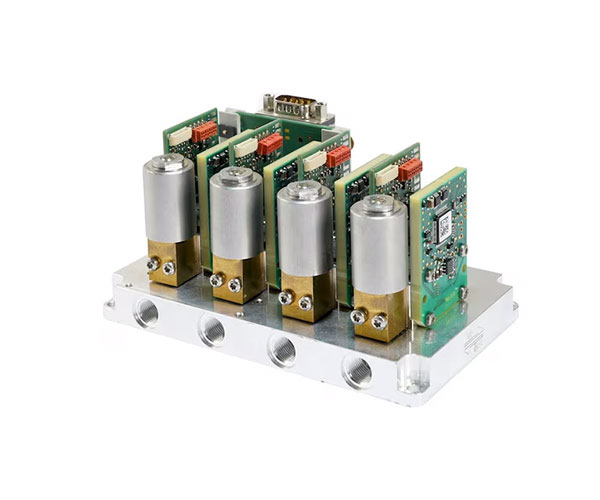

Mass Flow Devices

- Axetris offers OEM mass flow meters (MFM), mass flow controllers (MFC) and manifolds for gases with outstanding benefits for its worldwide customers. The platinum-based MEMS thermal mass flow technology guarantees excellent accuracy and repeatability combined with high speed and unsurpassed dynamics.

Mass Flow Controller Standalone

-

MEMS-based standalone mass flow controller (MFC) designed for OEM applications, where shielding and IP40 protection are required. The platinum-based MEMS chip technology guarantees excellent stability and repeatability over the whole flow range. Due to their unmatched dynamic range and multi-gas capability, Axetris MFC modules can replace several conventional mass flow controllers with a single unit.

The compact and robust design makes it also an ideal choice for portable applications as for example leak testing devices or any other handheld systems.

- Fast settling time <150 ms

- Excellent repeatability and accuracy

- High turn-down ratio >1000:1

- Rigid stable design IP 40

Mass Flow Controller OEM

-

The Axetris mass flow controller OEM-module (MFC) with platinum-based MEMS chip technology guarantees excellent stability and repeatability over the whole flow range. Due to their unmatched dynamic range and multi-gas capability, the MFC modules can replace several conventional mass flow controllers with a single unit. Target gases for this module are N2, Air, O2, CO2, Ar, He, and H2.

The compact and robust design makes it also an ideal choice for portable applications like for example leak testing devices or handheld systems. The OEM mass flow controller OEM-module is currently available in different variations communicating over RS232 TTL or EIA, RS485 half duplex or full duplex and with analog signal (0-5V or 4-20mA).

- Ultra compact size

- Fast settling time <150 ms

- Excellent repeatability and accuracy

- High turn-down ratio >1000:1

- High long-term stability

Mass Flow Manifold

-

Axetris mass flow manifolds consist of multiple mass flow meters or controllers on a single mixer or splitter block. This product is available both as a custom solution, tailor-made for specific customer needs, or as a standard platform with up to four mass flow controllers or mass flow meters respectively in mixer or splitter configurations.

- Compact systems to save space

- Easy “Plug-and-Play” integration

- Complete solution

Mass Flow Meter OEM

-

The Axetris mass flow meter OEM-module (MFM) offers outstanding value to the customer. Platinum-based MEMS chip technology guarantees excellent stability and repeatability over the whole flow range. The high speed of MEMS technology combined with smart software processing along with rigid and robust packaging makes the MFM series an ideal choice for applications requiring small size, high stability, and fast response time.

The product is currently available for communications over RS232 TTL or EIA, RS485 half duplex or full duplex and with analog signal (0-5V or 4-20mA).

- Extra compact size

- Fast response time

- Excellent repeatability and accuracy

- High turn-down ratio >1000:1

- High long-term stability

Mass Flow Meter Standalone

-

The MEMS-based standalone mass flow meter (MFM) by Axetris is designed for OEM applications requiring both shielding and IP40 protection. Platinum-based MEMS chip technology guarantees excellent stability and repeatability over the whole flow range. In addition, the high speed of MEMS technology combined with smart software processing makes the MFM Standalone series an ideal choice for applications requiring small size, high stability, and fast response time.

On top of that, the MFM standalone series is an ideal choice for all applications that require small sizes, high stability and quick response times due to its highspeed MEMS-technology and intelligent softwareprocessing. The rigid and robust casing of the compact mass flow meter adds to that. The product comes in various variations communicating with RS232 EIA, RS485 half or full duplex, PROFINET or EtherCAT.

- Speedy response time

- Reliable and accurate

- Excellent turn-down ratio >1000:1

- Long-term stability

- Rigid stable design IP 40

Laser Gas Detection

- Laser gas detection (LGD) is based on TDLS technology: Spectroscopy with tunable diode lasers. Laser beams scan across absorption lines of target gases, enabling high-resolution absorption measurement. This technology has unique advantages: Precise optical, non-contact measurements, excellent selectivity of target gases and detectivity in the sub-ppm range.

LGD Compact-A CH4

-

In the context of climate change, methane is becoming increasingly significant because it has a greenhouse potential many times higher than carbon dioxide. The Axetris LGD Compact-A CH4 laser gas detection OEM module detects methane down to the sub-ppm range. And due to the LGD Compact's small-volume multipass cell, real-time measurements are possible.

The robust and compact design allows both easy integration and mobile use for a wide range of methane measurement applications. Thanks to patented, modulation-based noise suppression, the Axetris LGD Compact-A CH4 ensures high performance over a long period of time. This means low maintenance effort and calibration for users.

- Lightweight and compact for portable application

- Fast response time for real-time measurement

- Sub-ppm detection limit

- Long-lasting stability

LGD F200P2-H NH3/H2O

-

Urea or ammonia (NH3) is often used in the reduction of nitrogen oxides from combustion processes. In the process known as selective catalytic reduction, ammonia must be dosed very precisely in order to achieve the desired conversion to nitrogen with the highest possible efficiency. The Axetris LGD F200P2-H NH3/H2O laser gas detection OEM module detects ammonia down to the sub-ppm range, ensuring stable processes.

Thanks to the high selectivity of TDLS technology, it is possible to measure moisture in the process gas as well. This means an additional water vapor sensor is no longer required for continuous emission monitoring, where the gas concentration must be reported to the authorities based on dry values.

- Direct measurement of NH3 in humid gas matrix

- Long-term stability

- Sub-ppm detection

- Dual gas measurement

LGD Compact-A NH3/H2O

-

Ammonia (NH₃) is often forgotten as an environmentally harmful gas, but plays an enormously important role in many processes in our world today. The TDLS technology in the Axetris LGD Compact-A NH3/H2O laser gas detection OEM module detects ammonia down to the sub-ppm range and does so without cross interference from other gases. Its robust design is specifically developed for harsh environmental conditions. In addition, the LGD module scores with maintenance requirements close to none.

By measuring very small concentrations of ammonia, their sources can be identified and the release prevented. Especially in agriculture, a lot of ammonia is released by livestock and soil cultivation. Ammonia is discussed as a promising energy carrier in the global energy transition. However, if this gas ends up in the air, it damages plants and ecosystems and, as a precursor of particulate matter, contributes to poor air quality.

- High dynamic range

- Low maintenance

- Rugged design for rough environments

LGD Compact-A CH4/CO2

-

In medical diagnostics, there are several applications in which respiratory gases allow us to draw conclusions about diseases. The combination of methane (CH4) and carbon dioxide (CO2) is used, for example, in lactose and glucose intolerance tests. The high reproducibility of measurement results makes the Axetris LGD Compact-A CH4/CO2 laser gas detection OEM module perfect for this purpose.

Both gases can be detected simultaneously and without interference to other gases. The ease of use and integration of the LGD Compact OEM module makes it possible to develop end devices that stand out for their user-friendliness and durability.

- Multigas measurement

- High reproducibility

- Easy integration and operation

LGD Compact-A CH4/C2H6

-

Leaks in natural gas pipelines occur frequently due to age and wear and tear. They contribute to enormous methane emissions. The Axetris LGD Compact-A CH4/C2H6 laser gas detection OEM module measures methane and ethane - two major components in natural gas.

The TDLS technology uses a narrow-band diode laser that scans each gas line separately, eliminating cross interference from other gases. Thanks to the robust and compact design of the LGD Compact-A CH4/C2H6, it is also perfectly suited for mobile use in urban areas. Detected methane occurrences can be checked for their origin within seconds through ethane measurement.

- Dual gas measurement in a single device

- Lightweight and compact for portable application

- High selectivity

- Calibration free

LGD F200P2-H H2O

-

The pollutant gases specified in industrial regulations must always be reported to the authorities on a dry basis. However, these gases are measured in humid process gas. Therefore, it is important to determine the exact moisture content. The Axetris LGD F200P2-H H2O laser gas detection OEM module reliably measures absolute humidity up to 30% in the process gas without the need for regular calibrations. In addition, the robust design of the LGD module reduces maintenance to a minimum.

- Measurement of high moisture contents

- No calibration necessary

- Low operating costs

LGD F200P2-H HCl/H2O

-

In many industries, the regulations for permitted limits for gas emissions are constantly being tightened. For example, hydrogen chloride (HCl) is one of the gases that must be measured and reported by means of continuous emission monitoring. Thanks to its perfect selectivity for this harmful gas and its long-term stable performance, the Axetris LGD F200P2-H HCl/H2O laser gas detection OEM module is ideally suited to meet the requirements of these regulations.

This is because its heated gas cell allows to measure hydrogen chloride extractively in the hot and humid gas stream. Its robust design is perfectly suited for harsh environmental conditions such as those encountered in waste incineration. Thanks to the modular design, maintenance can be carried out easily and quickly, which prevents prolonged downtimes.

- Hot-wet gas measurement

- Easily integrated

- High selectivity

- Rugged design for industrial applications

LGD Compact-A C2H2/H2O

-

Acetylene (C2H2) plays an important role in many processes in the manufacturing industry. Acetylene is also measured in oil and gas analysis as well as in medical diagnostics. Thanks to the versatility of the Axetris LGD Compact-A C2H2/H2O laser gas detection OEM module, it is suitable for almost any acetylene application. Due to the TDLS technology used, it measures acetylene even in a complex gas matrix without cross interference from other gases. Its rugged design and patented modulation-based noise reduction ensure long-term stable performance even in harsh industrial environments.

- No cross-sensitivity to other gases

- Long-term stability

- Robust for industrial environments

Wafer Processing Services

- Axetris offers in-house wafer processing services and post-processing on customer wafers in the only MEMS foundry in Central Switzerland. The facilities include a class 1000 clean room environment, lithography, thin film as well as dry and wet etching processes for 150 and 200mm wafers. ISO 9001 certification and ISO TS16949 compliance ensures the highest level of quality and customer support.

Post-processing on customer wafers

-

Axetris offers processing services on customer supplied and pre-processed 150 and 200mm wafers. Processes include patterning of silicon or glass substrates by wet- and/or dry etching, including membranes or cavities, as well as metal or dielectric coating deposition and patterning. A wide range of metrology, characterisation and inspection can be provided, as well as dicing and die sorting.

- 150 & 200mm wafer sizes

- Processing on existing topographies

- Processing on fragile structures (e.g. membranes)

- Non-standard or customer specific processes

Micro-structured parts

-

Axetris offers customized micro-structured parts in silicon and fused silica on 150 and 200mm wafers. Mechanical features are obtained by lithography and either dry- or wet-etching. Additional features such as patterned metalizations can be applied, for example as fiducial marks, but also solder frames. The high accuracy and small form factor allows for highly precise components such as submounts or optical benches.

- Submounts, optical benches etc.

- Lithographic accuracy

- Alignment & assembly features

- Membranes, microfluidics structures etc

Patterned metallizations

-

Axetris offers customized patterned metallization on 150 and 200mm wafers. They can be applied to either silicon or fused wafers, or onto supplied and pre-processed customer wafers. The lithographic accuracy and high-quality metal layer depositions are an ideal match for high-accuracy noble-metal electrodes or solder frames (e.g. hermetic packaging). They are delivered as singulated chips or whole wafers, for further processing or wafer-level assembly.

- Electrodes, bond- or solder pads & frames etc.

- Noble metals for harsh environment

- Double-sided processing possible

- Full metrology & inspection

Applications

Measuring gases - OEM Solutions for your Market

Infrared Sources for Medical Applications

Anesthesia Monitoring

-

Monitoring the patient during anesthesia is now a standard part of any surgical procedure. This not only ensures patient safety, but also protects medical staff in the event of emissions of anesthetic gases. The number of surgeries performed is steadily increasing with each passing year. The WHO estimates that more than 300 million operations were performed worldwide in 2012, an increase of more than 38% compared to 2004.

The reasons for this are manifold: from improved treatment options for diseases to financial incentives in the accounting system in certain countries. Regardless of the reasons the safety of patients and medical staff is paramount. To guarantee a safe environment it is important to be able to dose anesthetic agents precisely, monitor them and adjust them according to the situation.

Capnography

-

Capnography is a non-invasive method that measures the concentration of carbon dioxide during expiration (EtCO2). Initially used in hospital surveillance and emergency care, capnography is rapidly becoming popular in medical practices and homecare medicine.

The trend to miniaturize CO2 sensor modules emphasizes the advantages of MEMS-based broadband infrared (IR) sources for NDIR gas detection. Axetris provides a portfolio of such IR Sources with adapted reflectors and optionally mounted optical windows. The newly released EMIRS50 is specifically developed for high-quality CO2 monitoring, supporting compact NDIR capnography sensors for high-quality.

Blood Gas Analysis

-

Blood gas analysis determines the partial pressure of carbon dioxide and oxygen (pCO2 and pO2) as well as pH and acid-base balance. This procedure is often used in monitoring patients with oxygen deficiency caused by lung diseases. Blood gas analysis requires an arterial blood sample. Although venous blood is easier to collect, it is too dependent on local perfusion. The blood sample is then analyzed in the laboratory using various parameters. Collection and analysis requires staff and time.

To safe ressources, recent developments perform blood gas analysis non-invasively via the skin. In addition to generally improving patient comfort and saving time, this also makes real-time monitoring possible.

Infrared Sources for Industrial and Safety Applications

Combustible and Toxic Gas Detection

-

In most cases, gases are not perceptible to us, yet it is impossible to imagine our everyday lives without them. Oxygen, for example, is the basis for all life, while other gases can be lethal within a very short time.

In addition to solid or liquid state, chemical substances can also assume a gaseous state, in which case the molecules contained therein move at a large distance from one another. As a result, gases can occupy a space up to 1000 times larger than solid or liquid substances. Gases are classified into different groups based on their properties. These may be based on their reactivity, flammability, toxicity or explosiveness. Some of them are influenced by temperature and pressure on top of that. However, gases that are dangerous to humans or the environment must be monitored in any case to prevent damage or accidents.

Refrigerant Monitoring

-

The first synthetic refrigerants hit the market in the 1950s. Unlike their predecessors, they were non-flammable and non-toxic, which made them much more popular to use.

On May 16, 1985, scientists Joe Farman, Brian Gardiner and Jonathan Shanklin published their findings on the discovery of the first hole in the ozone layer over Antarctica. Around the same time, people became aware of the climate-damaging potential of refrigerants. In the Montreal Protocol of 1987, all 197 member states of the United Nations finally committed themselves to reducing the number of substances that are harmful to the climate. Among other things, they agreed to halve production and consumption of the refrigerant CFC within 13 years. Today's regulations go much further, banning previously widely used refrigerants and switching to more climate-friendly ones.

SF6 Monitoring

- Carbon dioxide (CO2) and methane (CH4) immediately come to mind when we think of greenhouse gases- after all, they are the talk of the town. Sulfur hexafluoride (SF6) and its harmful effect on the climate, on the other hand, is rather unknown to many. Sulfur hexafluoride is a colorless and odorless gas that is not toxic to humans. Since it does not react with other gases, it is very popular as a tracer gas, e.g. in medicine. If it enters the atmosphere, however, it is very persistent and contributes significantly to the greenhouse effect. Although it occurs in the atmosphere in much lower concentrations than CO2, its greenhouse potential is 24,000 times higher than that of CO2. This is why it was included in the Kyoto Protocol as one of the six gases that are harmful to the climate in order to reduce these gas emissions.

Fruit Ripening Monitoring

-

More than half of the European population consumes fruit or vegetables daily. Consumers consider them healthy sources of vitamins and fiber. How our fruit and vegetables get into the supermarkets ripe and ready to eat, however, is rarely discussed. Besides quality, the freshness, color and taste of fruits and vegetables are the main criteria for purchase.

An appropriate degree of ripeness plays an essential role: If the fruit is not yet ripe enough for consumption, the buyer has to ripen it at home for a few more days. If the fruit is already overripe, both the appearance and the taste are impaired. With the right degree of ripeness at the time of sale, unnecessary food waste can be avoided. In times of climate change, avoiding overproduction and food waste is of great importance.