- Offer Profile

- WHERE SPECIAL COMES AS STANDARD

Terberg tractors stand out by their robustness, low fuel consumption, easy maintenance and driver comfort. This makes them an efficient option for many operations and although the basic designs are standardised, practically every tractor we deliver is customised.

In addition, we provide a wide range of complementary services directly or via our service network, such as maintenance, spare parts, repair, retrofits, warranty, advice, rental, trade-in, telematics, software updates and training.

We offer solutions from A to Z to maximize the availability of your vehicles, improve efficiency and prevent decapitalization. This allows you to keep your transport and activities operational and up-to-date with optimal investments.

Terberg Special Vehicles

-

Port, Airport, Industry, Steel Construction & Recycling

Terberg Spezialfahrzeuge GmbH is Germany's leading supplier of special vehicles. Since 2007 we have been taking care of sales, rental, maintenance and repair of special vehicles for port logistics, airport logistics, industry, steel construction & recycling. The vehicles we sell are produced in the Netherlands. Terberg has already sold more than 2,500 vehicles in the D-A-CH region.The company also owns the rental car park Terberg Rental with more than 330 vehicles as well as the quality-tested used vehicles of Terberg Used.

Strong partners in the D-A-CH region

Terberg Spezialfahrzeuge GmbH is a subsidiary of the Dutch family-owned Royal Terberg Group. With over 100 employees at currently eight locations, Terberg Spezialfahrzeuge GmbH is the sales and service company responsible for the entire D-A-CH region. The company is headquartered in Hamburg, with additional branches in Bochum and Ulm. In addition, there are currently five service centres with their own technicians throughout Germany. Special Vehicles - Yard Tractors

-

Reliable, powerful, robust: our special vehicles impress with power, efficiency and low maintenance and fuel costs. Sustainability is important to us, which is why some special vehicles are already available as fully electric variants.

Vehicle for port, distribution centres, industry & airport catering vehicle

The new generation Terberg YT193 Yard Tractors are even more durable and easier to service and update. Operators experience the highest level of comfort and ergonomics.

YT193 Yard Tractor

-

The new YT is extremely robust and durable. It has been tested extensively in test labs and on the test track.

- The chassis is anti-corrosion hot dip galvanized.

- The cab has been completely redesigned.

- New fingertip controls are positioned directly next to the seat.

- The cabin suspension is particularly comfortable and similar to that used in road trucks.

- The accessbility of mechanical and electrical components throughout the vehicle has greatly improved.

- The dashboard can be removed and refitted within minutes.

- Also repair is more efficient.

- Covers, bumpers and windows are easy to replace.

- The optional Terberg Connect tractor telematics facilitates proactive maintenance to increase uptime.

YT203-EV Yard Tractor

-

Benefit from high performance, extended range, flexiblity in battery options and worldwide use in warm and cold climates.

- The electric motor performance is comparable to that of a diesel engine.

- You can choose from a number of battery capacity combinations up to 222 kWh, so you can select the option best suited for your operations.

- new battery technology, featuring a thermal management system (TMS),

- extended temperature range and thus can be used worldwide in both very cold and warm climates.

- The new batteries have been thoroughly tested and certified to the ECE-R100 rev. 2 regulation.

- The universal charging connector complies with the CCS2.0 automotive standard.

- The EV drive has regenerative braking to reduce the energy consumption.

- The EV system has fewer moving parts than a diesel engine and the previous EV generation, resulting in low maintenance costs.

Special Vehicles - Body Carriers

-

Robust, agile, efficient. Designed for in-plant logistics, the BC body transfer unit can accommodate all common bodies as well as trailers up to jumbo size. At home in logistics and distribution centres.

- Small turning circle - for optimum manoeuvring even in cramped yards and fast transfer of bodies within the depot.

- Very good all-round visibility and high driving comfort thanks to air-suspended cab and fully hydraulic steering. The handbrake sets automatically when the driver leaves the seat. Low noise level and vibration during driving.

- Particularly low maintenance costs due to fewer moving parts. Also available as a certified electric vehicle with universal charging plug CCS2.0 and long range.

BC183 Body Carrier

-

The Terberg Body Carrier excels at shunting swap bodies at distribution centres due to its agility and small turning circle. It is also used for applications such as carrying deicing fluid containers at airports.

The design accommodates a range of swap body types and there are several options for locking the bodies to the vehicle. BC units can optionally be fitted with a lifting fifth wheel to handle semitrailers.Specifications:

- Driveline: 4 x 2 GCW: 50 t (depending on operating conditions)

- Engine: Cummins B4.5-173 (Tier 4f/Stage V)

- Transmission: ZF 3WG161 (3F-3R)

- Front axle capacity: 11 t @20 km/h

- Rear axle capacity: 20 t @20 km/h 5th wheel: optional 5th wheel capacity: 15 t (optional)

- Technical lifting frame capacity: 25 t

- Seat position: Forward facing

- Left and right-hand drive

BC202-EV Body Carrier

-

The new generation EV tractor technology introduced in 2020 delivers significant improvements. You can choose from a number of battery capacity combinations and select the option best suited for your operations.

- The performance of the new electric motor is similar to that of a diesel engine, and it does not lead to CO2 and NOx emissions at the point of use.

- In addition the driver experiences hardly any vibrations and noise.

- The new batteries have been thoroughly tested and certified by Millbrook Proving Ground, to the ECE-R100 rev. 2 regulation.

- The universal charging connector complies with the CCS2.0 automotive standard.

- The EV drive has regenerative braking to reduce the energy consumption and this also reduces wear on the brakes.

- The EV system has fewer moving parts than a diesel engine and the previous EV generation, resulting in lower maintenance costs.

Specifications:

- Driveline: 4 x 2

- Battery pack combination options up to 148 kWh

- Batteries and vehicle comply with ECE-R100 rev. 2

- Worldwide use, at high and low temperatures (-30°C up to +50°C*)

- Charger connector complies with CCS2.0 automotive standard

- Traction motor: ZF CeTrax

- Motor performance similar to tractors with a diesel engine

- Regenerative braking

- Front axle capacity: 11t @20 km/h

- Rear axle capacity: 20t @20 km/h

- 5th wheel: optional

- 5th wheel capacity: 15t (optional)

- Technical lifting frame capacity: 25t

- Seat position: Forward facing

- Left and right-hand drive: Low-level cabin with inboard door

- Forward facing

Special Vehicles - Low Entry Distribution Tractors

-

The Terberg DT-series Distribution Tractor is a low entry unit for distribution centres.

The cab floor is only approx. 0.5 m above the ground and the driver can enter or leave the cab on the right or the left. This is a valuable feature for drivers who frequently have to leave the cab to open the trailer doors.

The low entry design, and the low noise and vibration level in the cab, significantly improve the driver’s workplace conditions and also promote efficiency.

DT 183 Low Entry

-

Specifications:

- Driveline: 4 x 2

- GCW: 75 t (DT183-LE) 90 t (DT223-LE) depending on operating conditions

- Engine DT183-LE: Cummins B6.7-129 kW Stage V

- Engine DT223-LE: Cummins B6.7-168 kW Stage V

- Transmission: Allison 3000 (4F/1R)

- Front axle capacity: 11 t @20 km/h

- Rear axle capacity: 30-38 t @20 km/h

- 5th wheel: Terberg cast steel plate 2"

- 5th wheel capacity: 36 t

- 5th wheel lifting capacity: 27 t / 31 t

- Lowest 5th wheel height: 939 mm (27 t) / 1055 mm (31 t)

- Seat position: Forward facing

- Left and right-hand drive: available

Special Vehicles - RT Series

-

Robust, reliable tractor that moves high loads up to 300 t quickly and safely. Vehicle for port, industry, mining, tunnelling and steelworks.

- Multifunctional: Applicable in RoRo and industrial operations. RT tractors form the basis for attachments from all parts of logistics, especially in ports and heavy industry.

- Manoeuvrable: Perfectly manoeuvrable in confined yards and equally fast forwards and backwards: thanks to the 180-degree swivel seat with logical steering changeover and the same number of gears for driving forwards and backwards.

- Clearly arranged: The drivers are always seated at the window when driving forwards and backwards and thus have an optimal overview at all times.

RT 223, 283, 323 Industrial Tractor

-

The 4x4 drive Terberg RoRo yard tractors with Ergoturn® 180° swivelling seat are designed for operating in RoRo vessels with steep ramps and in industrial yards because of their robust design and powerful driveline.

A 4x2 drive model (TT223) is available for applications that do not require 4x4 drive and do require a 180° swivelling seat.

Specifications:

- Driveline: 4 x 4

- GCW: 150 t (RT223) 165 t (RT283/323) depending on operating conditions

- Engine RT223: Volvo TAD880VE-160 kW Stage V

- Engine RT283: Volvo TAD882VE 210 kW Stage V

- Engine RT323: Volvo TAD883VE-235 kW Stage V

- Transmission: ZF 6WG211 (6F-3R)

- Front axle capacity: 16 t @20 km/h

- Rear axle capacity: 38 t @20 km/h

- 5th wheel: Terberg cast steel plate 2"

- 5th wheel capacity: 36 t

- 5th wheel lifting capacity: up to 35 t

- Lowest 5th wheel height: 962 mm

- Ergoturn® 180° swivelling seat

- Left and right-hand drive available

RT403 Heavy Duty Industrial Tractor

-

The Terberg RT403 industrial tractor is designed for extremely demanding yard and shunting operations in steelworks and other industrial plants. Its fifth wheel lifting capacity of 45 tonnes and heavy-duty chassis and power train design make the RT403 the perfect choice for the steel industry, extremely heavy RoRo operations and handling MTS trains.

Depending on the application and operating environment, the GCW can reach up to 375 tonnes.

Specifications:

- Driveline: 4 x 4

- GCW: 200 t depending on operating conditions

- Engine: Volvo TAD1183VE-315kW Stage V

- Transmission: ZF 6WG310 (6F-3R)

- Front axle capacity: 20 t @ 20 km/h / 25 t @ 10 km/h

- Rear axle capacity: 45 t @ 20 km/h / 48 t @ 10 km/h

- 5th wheel: 2" Cardanic cast steel plate

- 5th wheel capacity: 45 t

- 5th wheel lifting capacity: up to 45 t

- Lowest 5th wheel height: 1,335 mm

- Ergoturn® 180° swivelling seat

- Left and right-hand drive: available

Special Vehicle for Recycling - CC Series

-

CC Container Carrier: Robust basic vehicle based on YT or TT.

- Robust: Top performance at high transfer speeds: Thanks to the reinforced hook lift system with up to 30 t payload. Another plus: low wear even with frequent rolling and tipping operations.

- Safe: Ergonomically designed with excellent all-round visibility and safety equipment in accordance with EC machinery directives/UVV. Scores points with air-sprung cab suspension and the high-quality driver's seat as well as a reversing camera system with view to the pick-up hook.

- Solution-oriented: Easy handling of open-top and ACTS containers - can also be used for internal transport without a CE driving licence. Optionally, there is the possibility of StVZO approval.

THE 5 ADVANTAGES OF TERBERG CONTAINER CARRIERS

(compared to highway trucks)- Rear axle with a capacity of 38 tonnes (at 20 km/h)

- Greatly reduced risk of damage due to the excellent view in all directions

- Two axles are cheaper to maintain than four

- There are no tandem tyres which suffer from friction

- Wear of the suspension system is greatly reduced due to lower tyre friction

YT222CC Container Carrier

-

The perfect tool for handling heavy containers in crowded yards.

More effective recycling requires sorting and processing at waste handling plants. Terberg tractors provide an efficient solution for handling open-top and ACTS containers at these facilities.Specifications:

- Driveline: 4 x 2

- GCW: 40t depending on operating conditions

- Engine Cummins: B6.7-129 kW Stage V

- Transmission: Allison 3000 (4/5F-1R)

- Front axle capacity: 11t @20 km/h

- Rear axle capacity: 30t @20 km/h

- Seat forward facing

- Left and right-hand drive available

TT223CC Container Carrier

-

If you need an 4x4, 4x6 or even a 6x6 driveline, more power and/or Ergoturn® 180° swivelling seat you can opt for a TT or RT Container Carrier.

Specifications:

- Driveline: 4 x 2

- GCW: 40 t depending on operating conditions

- Engine: Volvo TAD880VE -160 Stage V

- Transmission: ZF 3WG171 (3F-3R)

- Front axle capacity: 11t @20 km/h

- Rear axle capacity: 30t @20 km/h

- Ergoturn® 180° swivelling seat

- Left and right-hand drive available

Special Vehicles Road Rail Tractor - RR283

-

The RR Road/Rail tractors were developed together with Zagro - a perfect example of joint development by companies with complementary expertise. These units can be supplied for track gauges from 1.435 to 1.676 metres. Some of their advantages include the good availability of spares, tight turning circle on roads and a high GCW.

- Can be used on rail and road: Switching from road to rail mode takes only a few minutes.

- Full power with low fuel consumption: gross train weight for semi-trailers up to 100 t, for rail wagons up to 1,000 t.

- At home in the world: A worldwide distribution system with service and spare parts is available for the RR two-way vehicle.

If the rail tracks are set into a paved surface on your site then our conventional tractors can also be used for shunting rail wagons.

RR283 Road Rail Tractor

-

Specifications:

- Driveline: 6 x 4

- GCW: 2,800 t depending on operating conditions

- Engine Mercedes OM936LA-210 kW Tier4f / Stage4

- Transmission: ZF 6WG211 (6F-3R)

- Front axle capacity: 10 t @20 km/h

- Rear axle capacity: 15 t each @20 km/h

- Track gauge: 1,435 to 1,676 mm

- Turning circle: 14,3 m

- Forward-facing, rear centre door, 2 seats facing in opposite directions

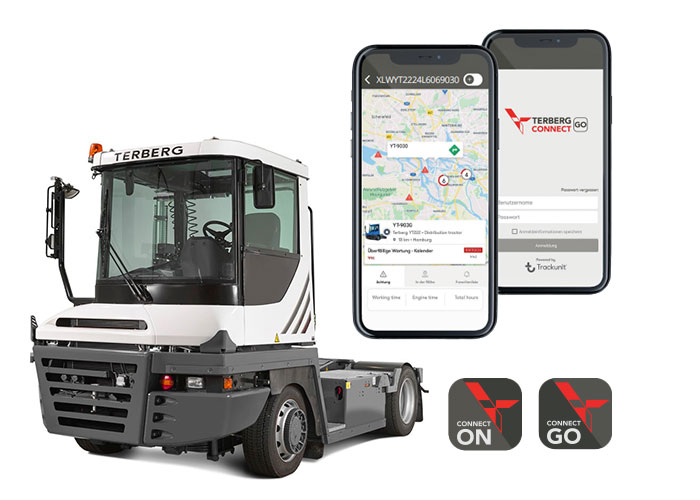

Terberg Connect - Our telematics solution for your fleet management

-

Optimise your fleet management. Terberg Connect is our telematics solution that gives you full transparency over your entire fleet at all times.

your entire fleet at all times. Use your data to keep your fleet management up to date at all times.Fleet management at a glance

The Terberg Connect Manager supports you with daily updated vehicle operating data in improving the efficiency and monitoring of your fleet.

You gain insight into operating and idling hours, distances travelled, fuel consumption, CAN bus data and many

other data records.Maintenance and service at the click of a button

Upcoming maintenance based on the operating hours and legally prescribed inspections such as UVV and HU can be conveniently scheduled with a predefined service reminder. Prevent defects and simplify the maintenance process.

the maintenance procedure. Terberg Connect

- Terberg Connect is our telematics solution that gives you full transparency over your entire fleet at all times. Use your data to keep your fleet management up to date at all times.