Dalmec

Videos

Loading the player ...

- Offer Profile

- Dalmec is the world leader in the field of Industrial Manipulators.

60.000 Manipulators are in use throughout the industrialized areas of all five continents.

All processes, from design to production to final testing are carried out exclusively by Dalmec personnel at our Cles plant, which extends over an area of 25,000 square metres, of which 14.000 are under cover. and profitability, Dalmec manipulators are the result of elevated engineering capabilities applied to the study of production processes, and are customized according to the performance required: gripping, moving and positioning. Functional analysis, 3D CAD design, study of the different technical solutions available, simulations, prototype creation are all phases in the production process that Dalmec carries out in close partnership with the client, with continuous controls and review during project development.

Product Portfolio

Dalmec Industrial Manipulators

To lift any product from 6 up to 1500 kg using only compressed air

DALMEC Industrial Manipulators allow the ergonomic, safe and effective handling of any product. We are able to lift every kind of product weighing from 6 up to 1500 kilograms using compressed-air only.

Dalmec is the response to the need to handle loads of different types in enslavement to transport lines, packaging equipment, production processes, etc.

Perfectly balancing the loads, it allows the gripping and handling in a virtually weightless manner in any direction: the operator is able to work effortlessly in maximum safety and ergonomic conditions.

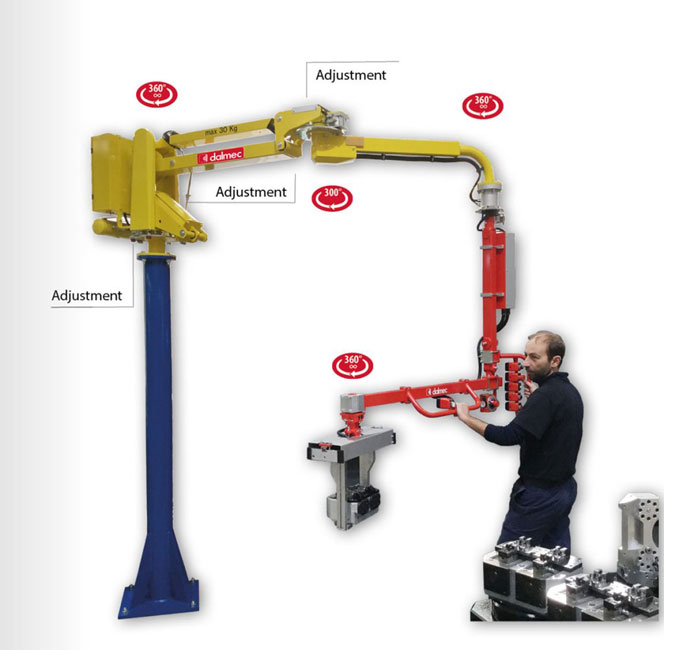

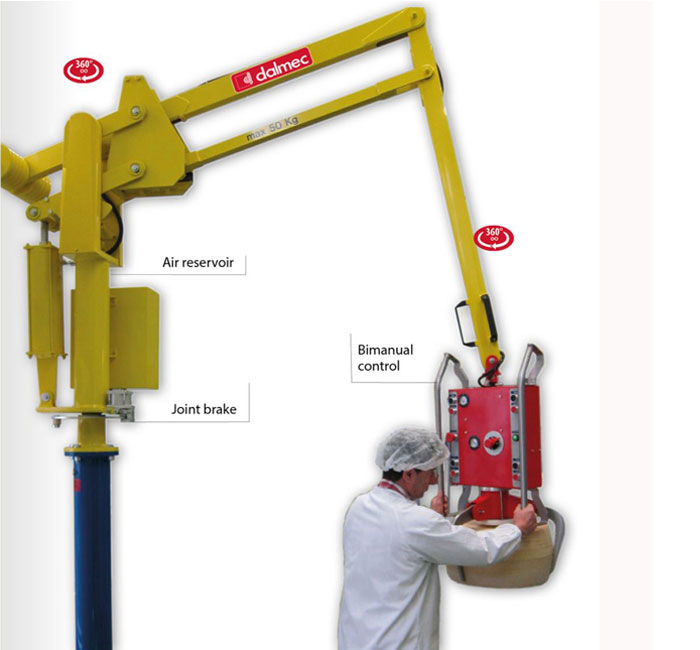

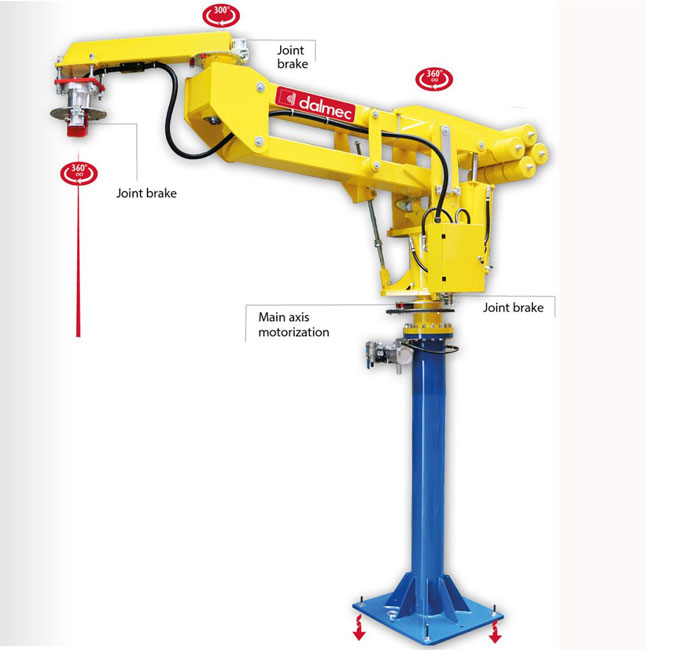

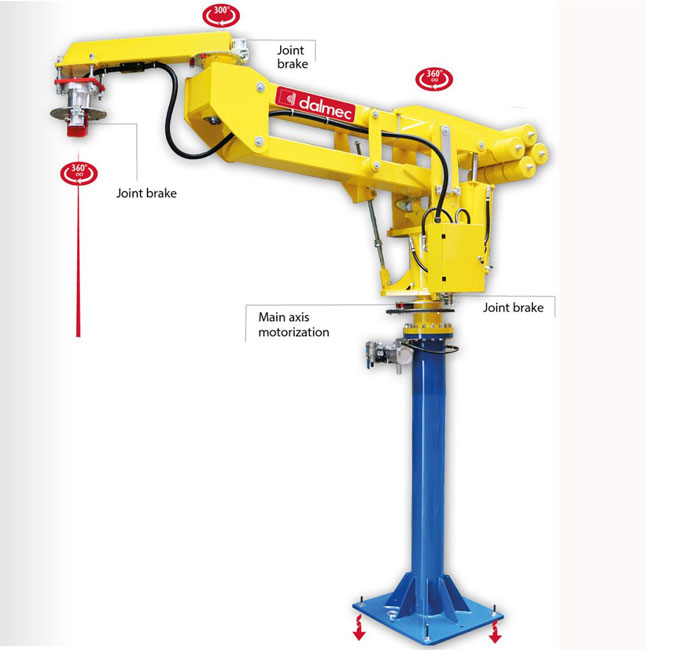

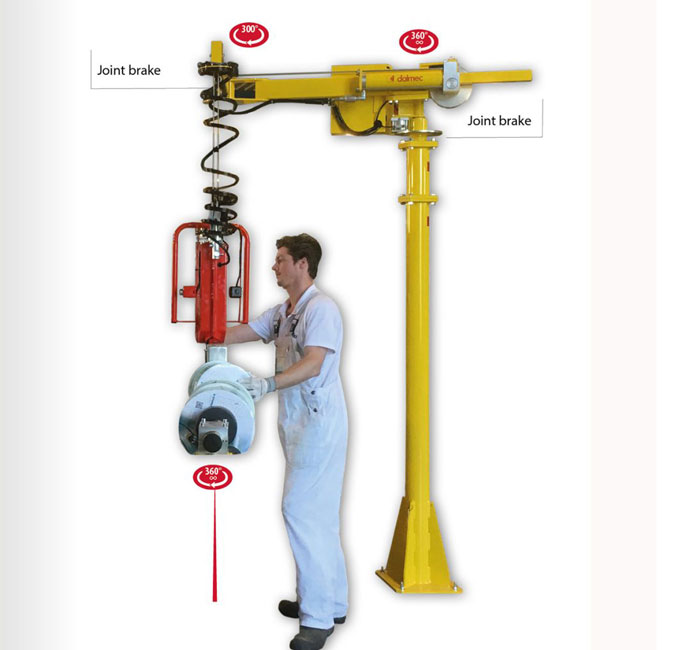

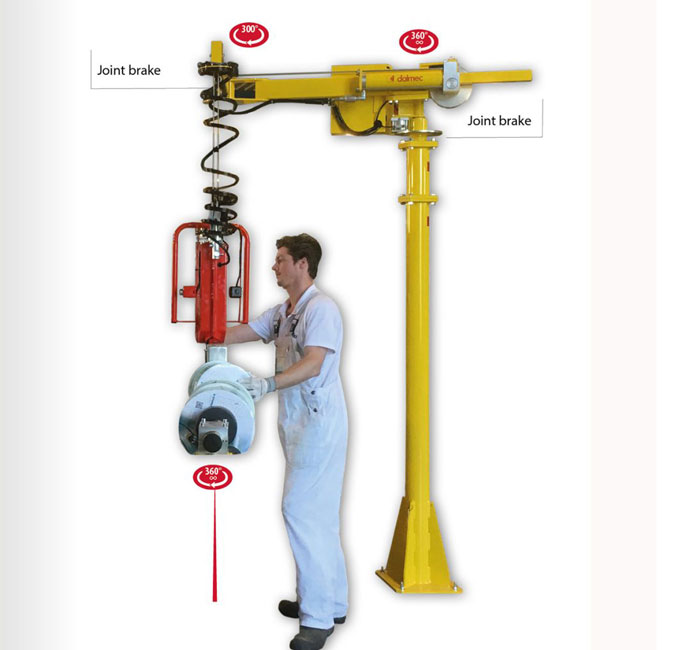

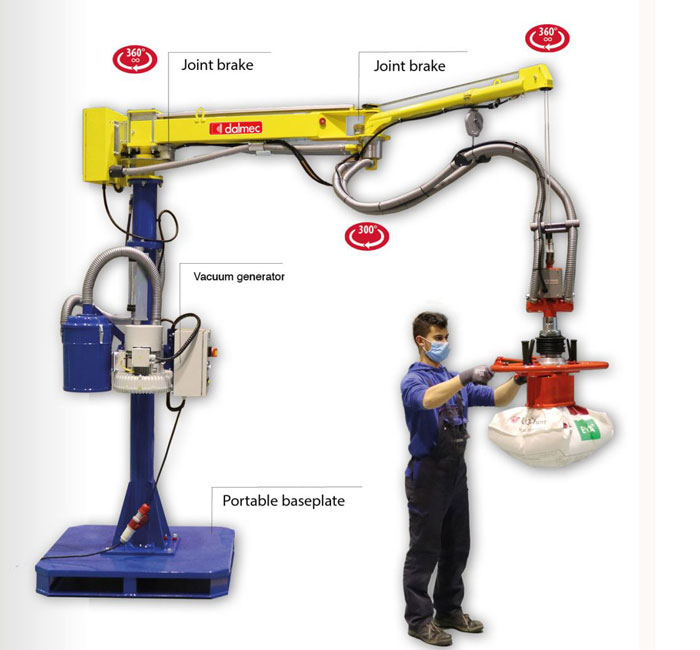

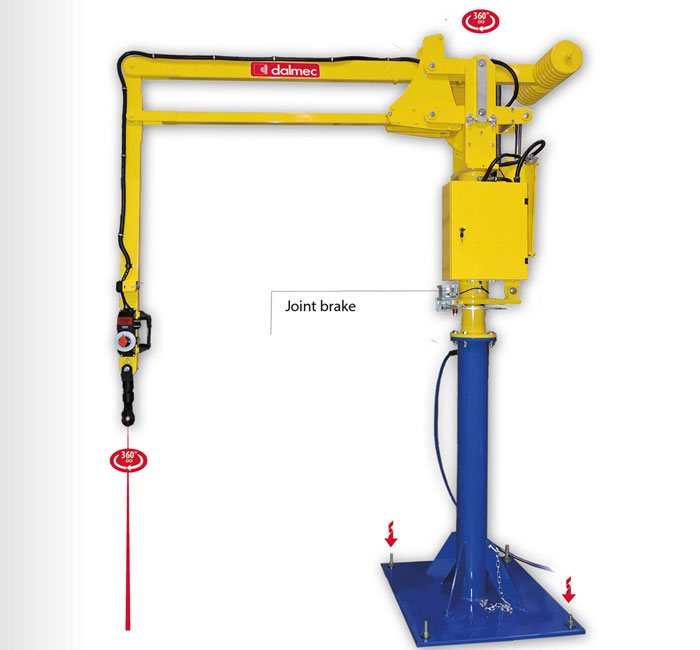

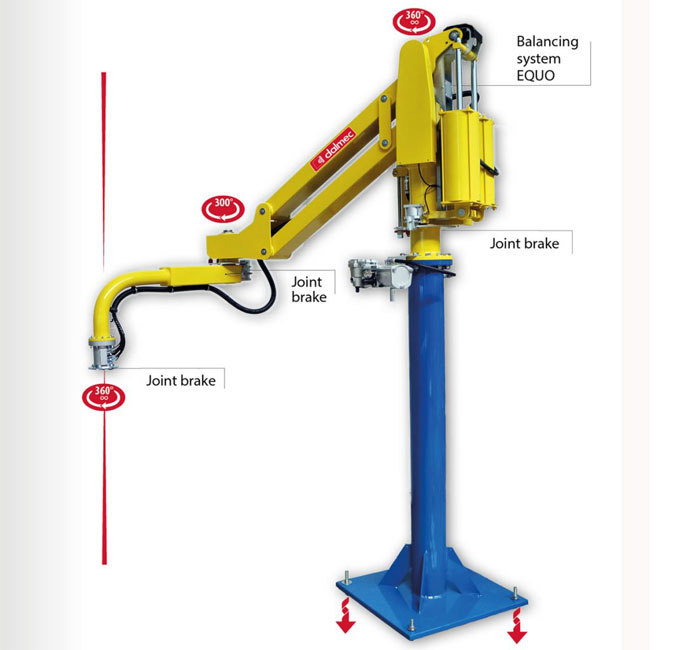

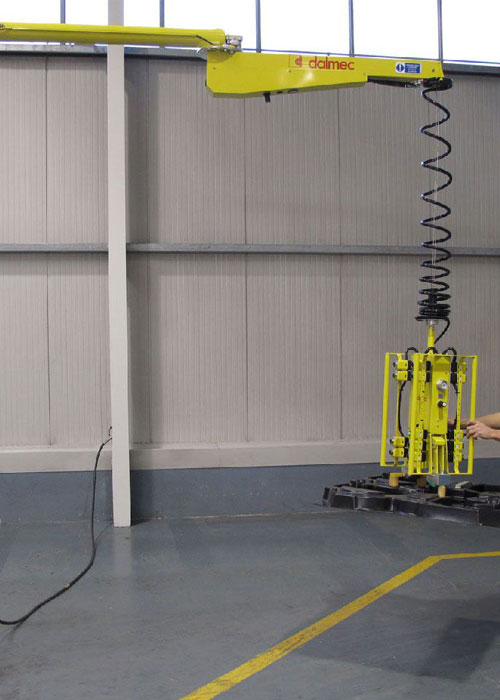

Micropartner

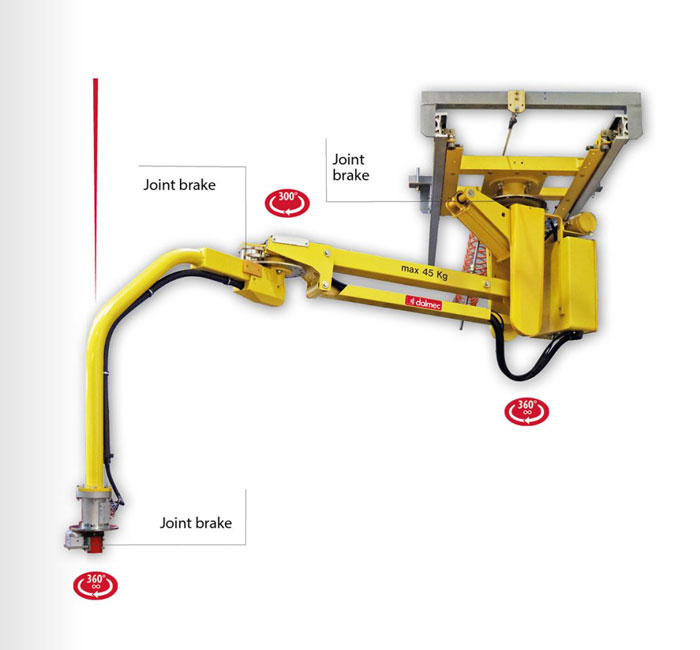

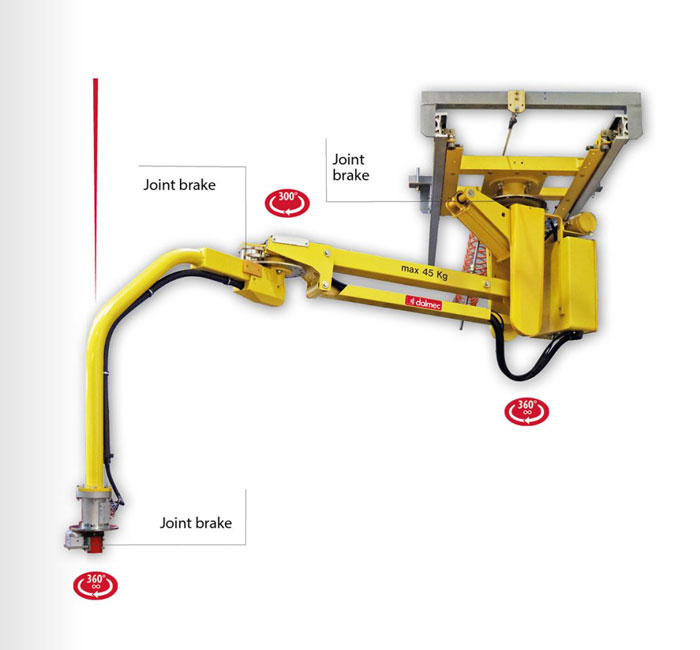

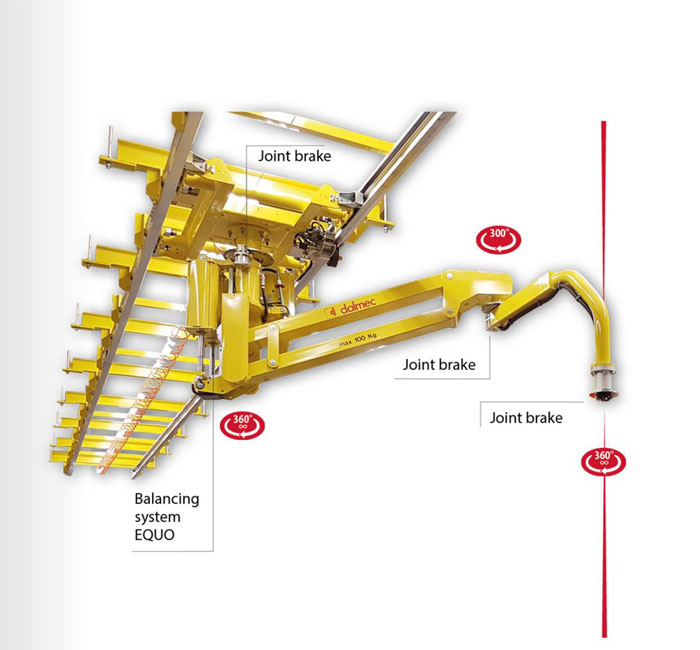

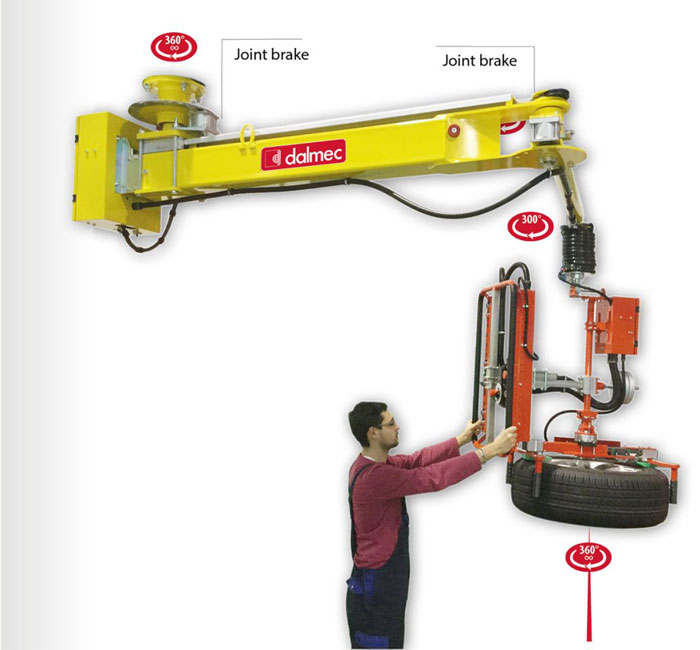

- Manipulator Micropartnert with Articulated Arms

Thanks to the reduced dimensions, the MICROPARTNER MI is a lifting device particularly easy to handle, designed to move in a weightless condition medium-light, center and off-set loads in any direction. Equipped with special gripping tools it allows the operator to work quickly, with precision and without effort, in excellent ergonomic and safety conditions.

Features- Max weight capacity: 125 kg

- Max working radius: 2800 mm

- Vertical lift: 2450 mm Working pressure: 0.7 ÷ 0.8 Mpa

- Control system: solely pneumatic

- Supply: filtrated compressed-air (40 µm), not lubricated

- Noise level:

- Max vertical lifting speed: 0,5 meters/second

- Working temperature: from +0° to +45° C

- Consumption: from 50 Nl ÷ 100 Nl per working cycle

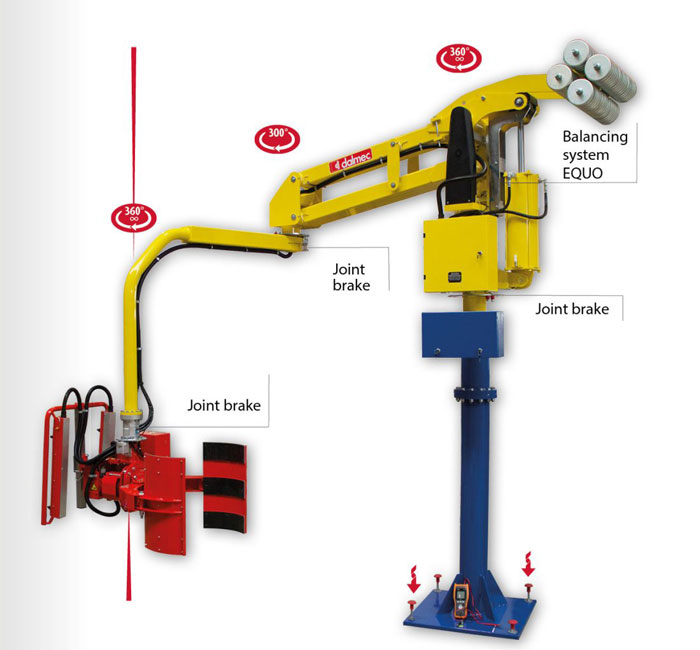

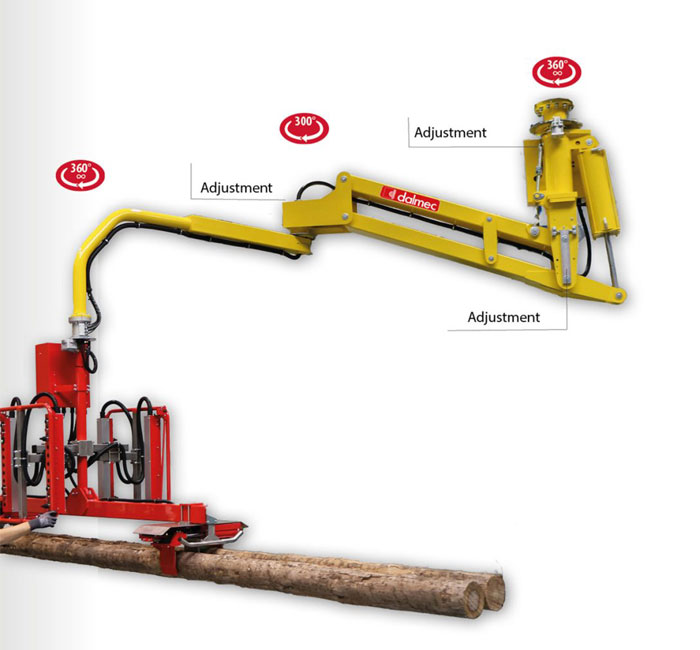

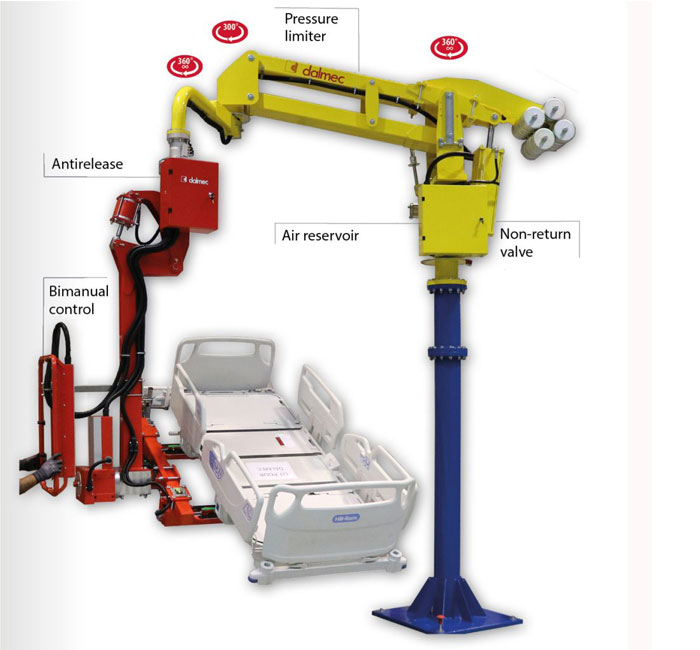

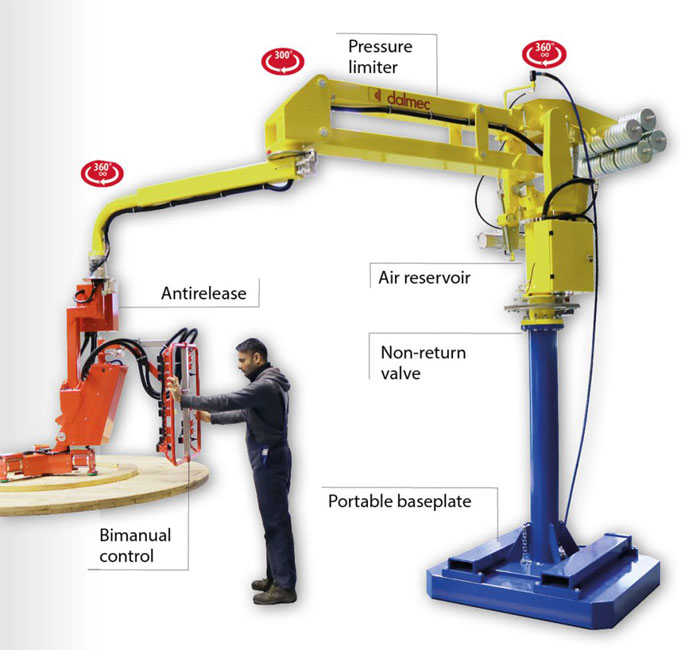

- Rotations: – constant 360° on the column and tooling axis – 300° on the intermediate axis

Execution- Atex Column

- Atex Fixed Overhead

- Atex Overhead Running

- Column

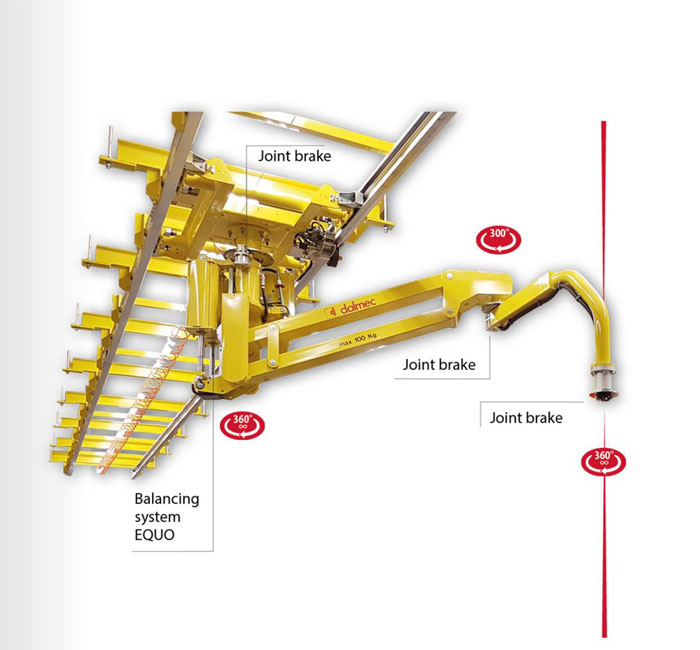

- Fixed Overhead

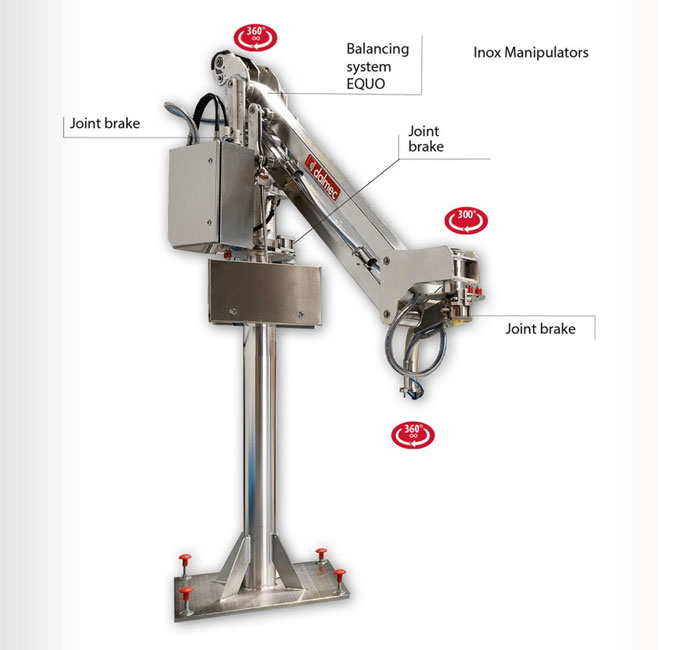

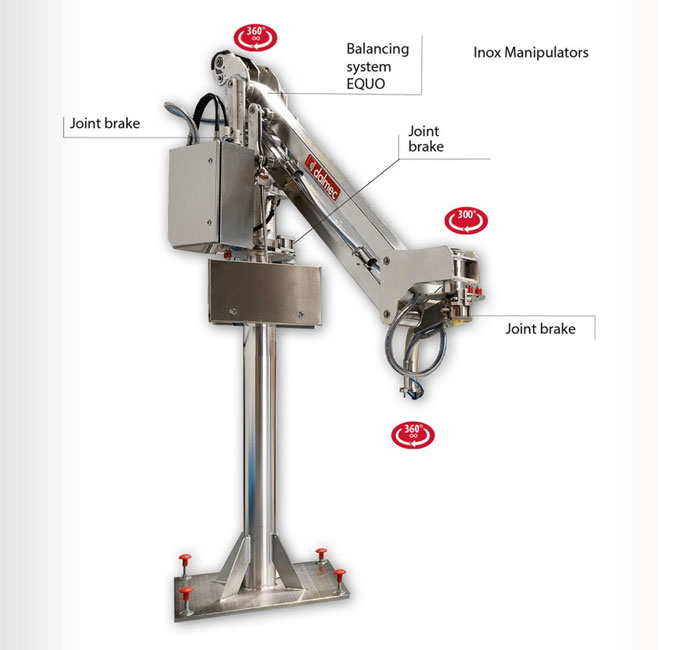

- Inox Column

- Inox Fixed Overhead

- Inox Overhead Running

- Overhead Running

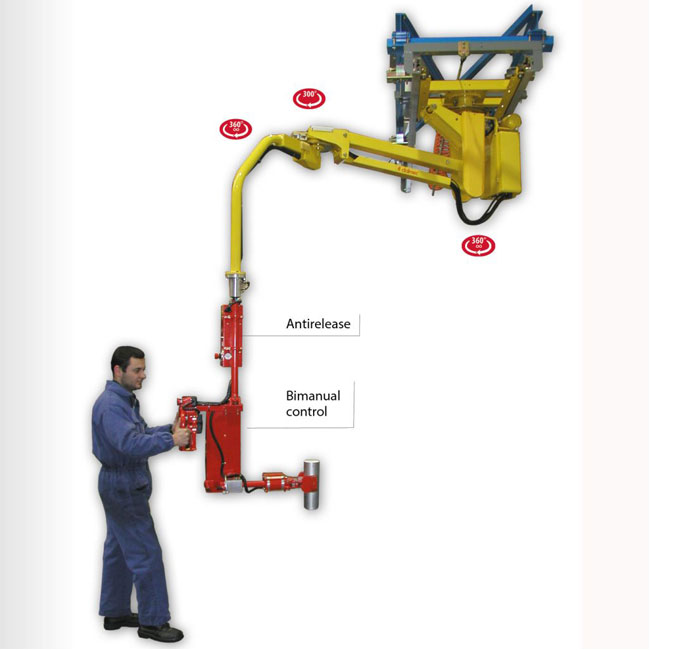

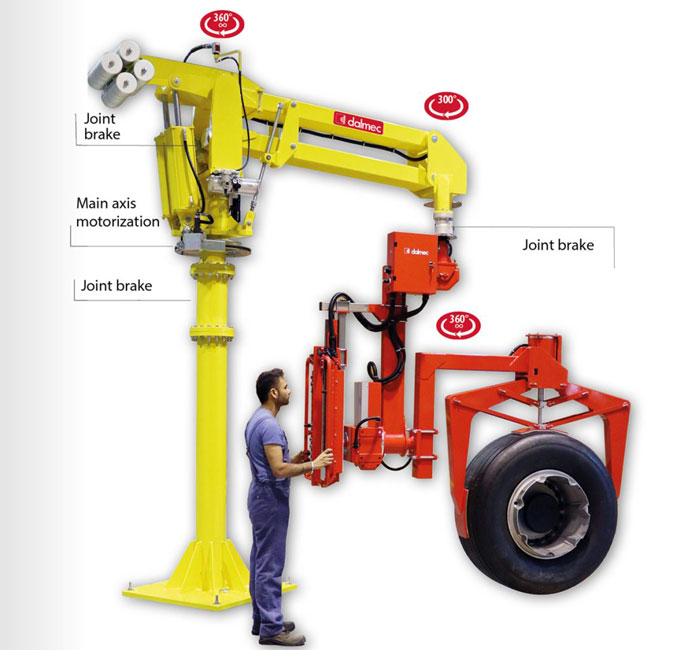

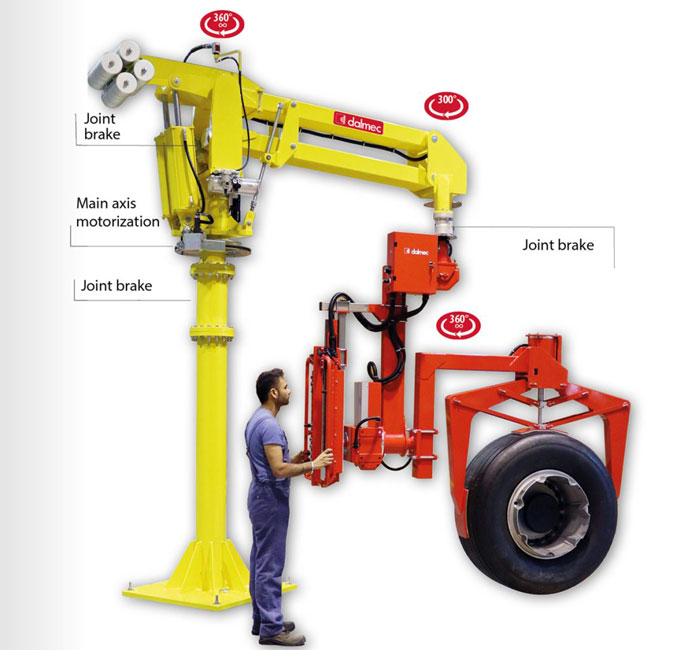

Partner PS

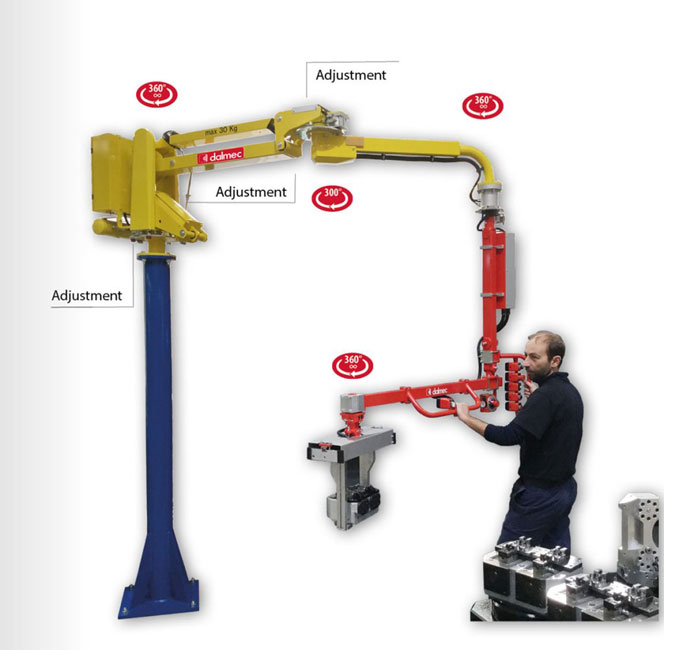

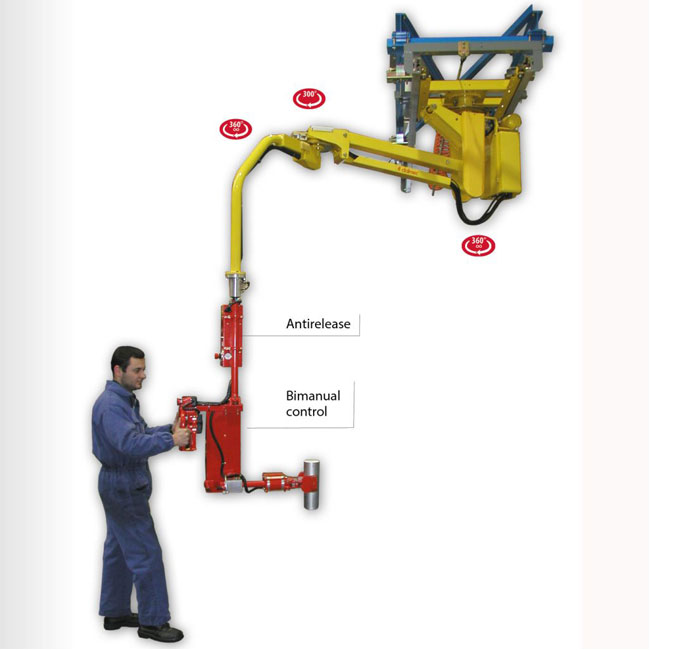

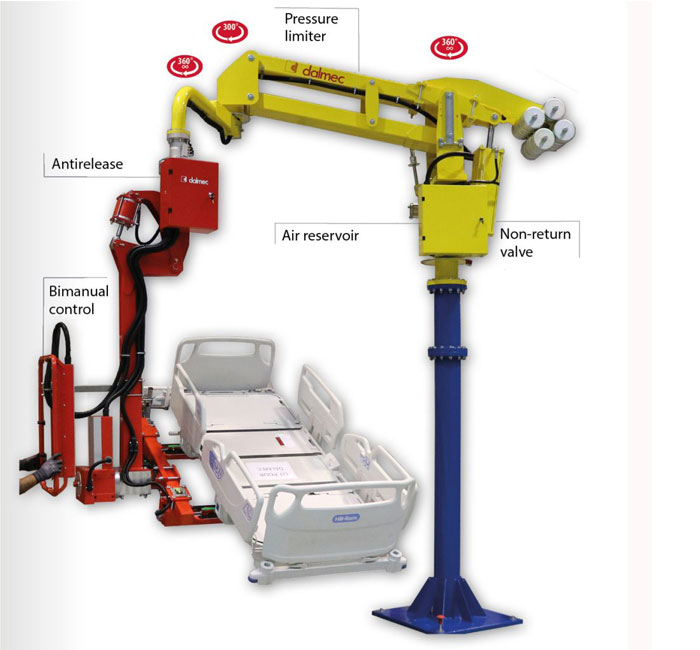

- Industrial Manipulator Partner PS with Articulated Arms

The Manipulator PARTNER PS is a good working assistant for the operator who can work quickly, with precision and without any effort, in excellent ergonomic and safety conditions. Equipped with special gripping tools, it is particularly suitable to manually handle loads in a weightless condition in any direction.

Operating

A pneumatic cylinder fed with compressed-air, combined with a transmission lever system, provides balance to the load weight applied. The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced. The operator can change the load level applying a minimum force on the gripping tool or directly on the load.

Features- Max weight capacity: 250 kg

- Max working radius: 2500 mm

- Max vertical lifting speed: 0,5 meters/second

- Vertical lift: 1900 mm

- Control system: solely pneumatic

- Supply: filtrated compressed-air (40 µm), not lubricated

- Working pressure: 0.7 ÷ 0.8 Mpa

- Working temperature: from +0° to +45° C Noise level:

- Consumption: from 30 Nl ÷ 150 Nl per working cycle

- Rotations: – constant 360° on the column and tooling axis – 300° on the intermediate axis

Execution- Atex Column

- Atex Fixed Overhead

- Atex Overhead Running

- ColumnFixed Overhead

- Inox Column

- Inox Fixed Overhead

- Inox Overhead Running

- Overhead Running

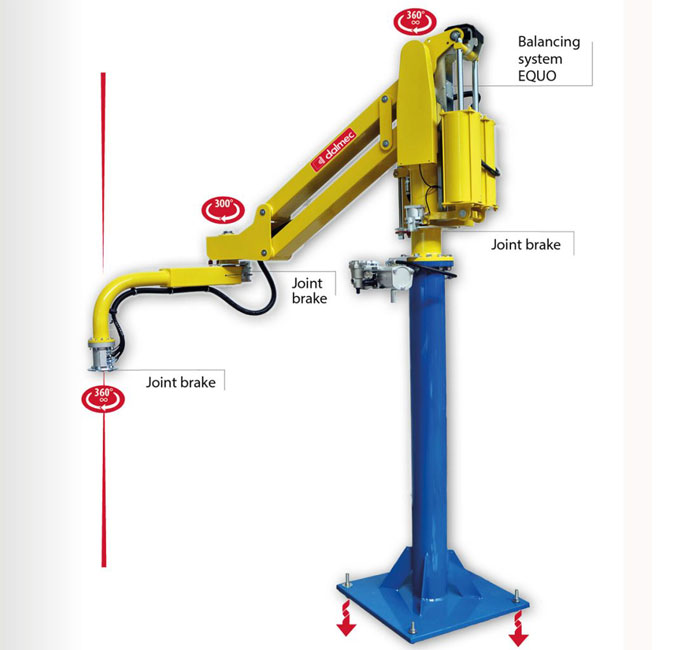

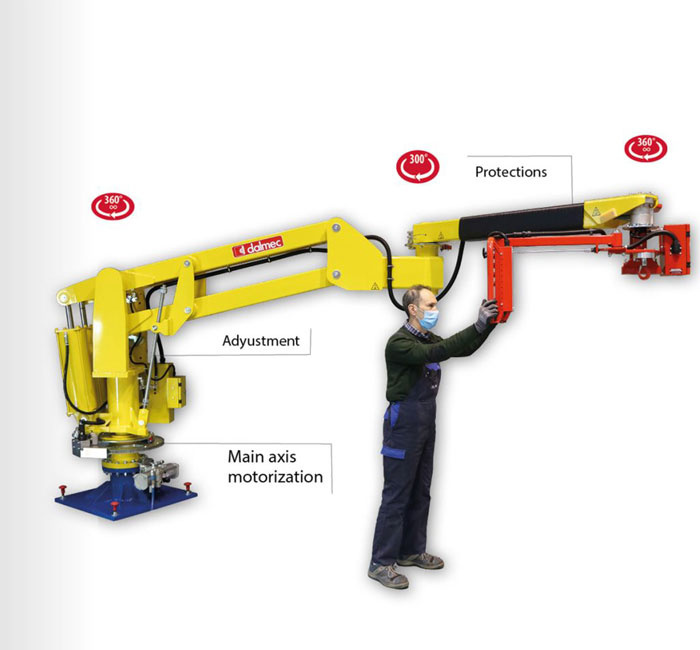

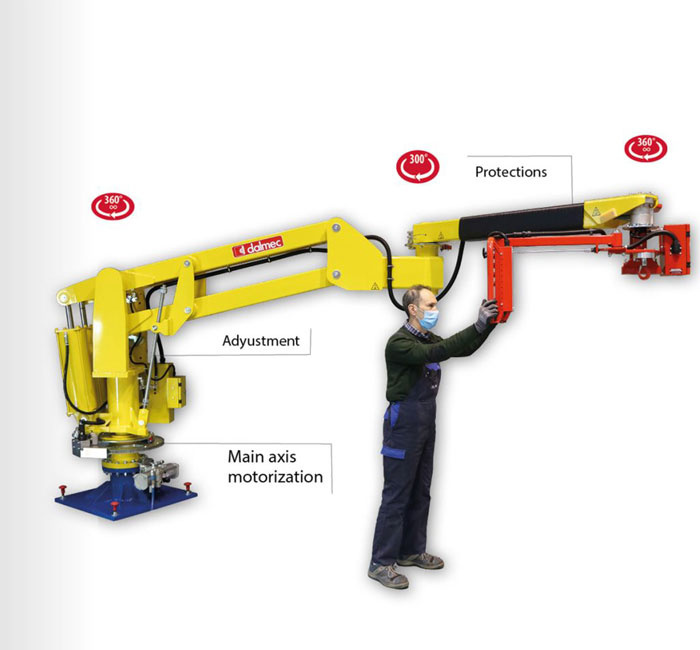

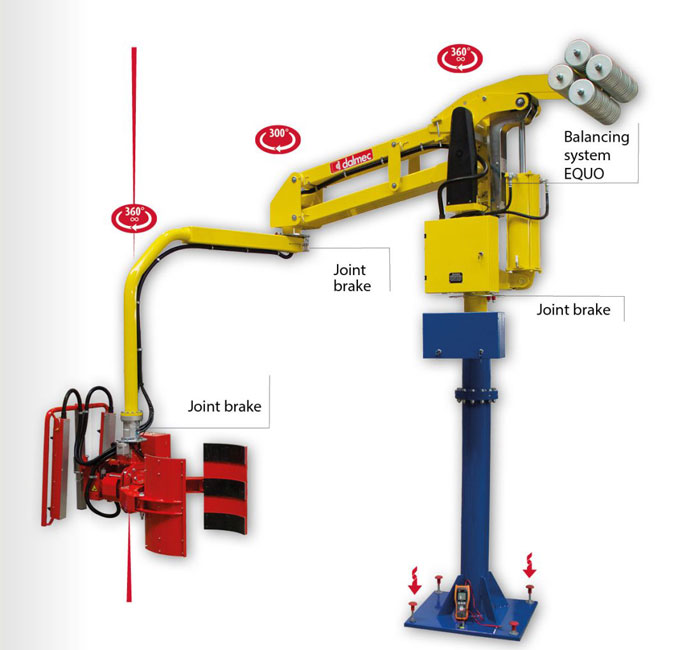

Partner Equo

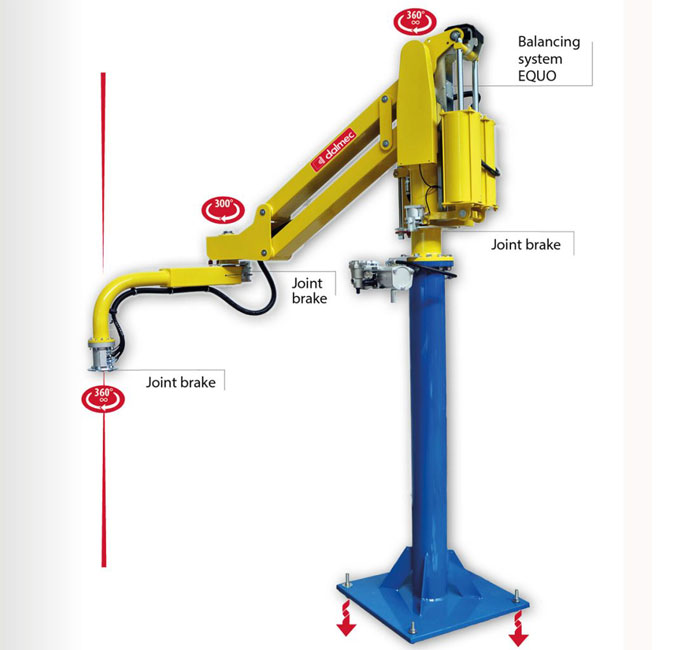

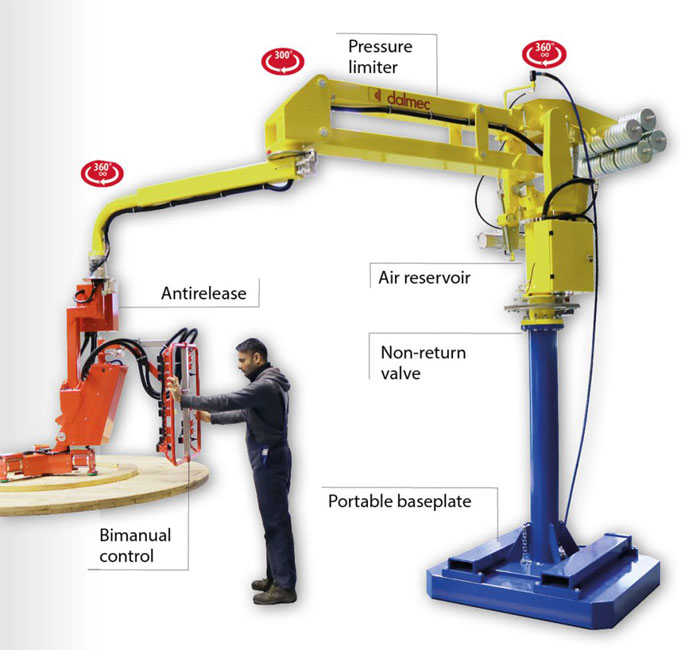

- Industrial Manipulator Partner Equo with Articulated Arms

Pneumatic Manipulator PARTNER EQUO with articulated arms, equipped with special gripping tools, is suitable to handle manufactured products having an off-set centre of mass compared to the vertical axis of the Manipulator arm. Its modular structure has been designed to resist the torsions resulted from this stress. In addition, having the possibility to change the terminal arm shape and dimensions to suit, the manipulator Partner PE can be used in particularly narrow environments.

Operation

A pneumatic cylinder fed with compressed-air, combined with a transmission lever system, provides balance to the load weight applied. The force of the cylinder is controlled by two specially arranged pneumatic circuits: the first keeps the weight of the gripping system always balanced; the second keeps the weight of the load always balanced. The operator can change the load level applying a minimum force on the gripping tool or directly on the load.

Features- Max weight capacity: 500

- Max working radius: 4000 mm

- Vertical lift: 2450 mm

- Working pressure: 0.7 ÷ 0.8 Mpa

- Control system: solely pneumatic

- Supply: filtrated compressed-air (40 µm), not lubricated

- Noise level:

- Max vertical lifting speed: 0,5 meters/second

- Working temperature: from +0° to +45° C

- Consumption: from 50 Nl ÷ 200 Nl per working cycle

- Rotations: – constant 360° on the column and tooling axis – 300° on the intermediate axis

Execution- Atex Column

- Atex Fixed Overhead

- Atex Overhead Running

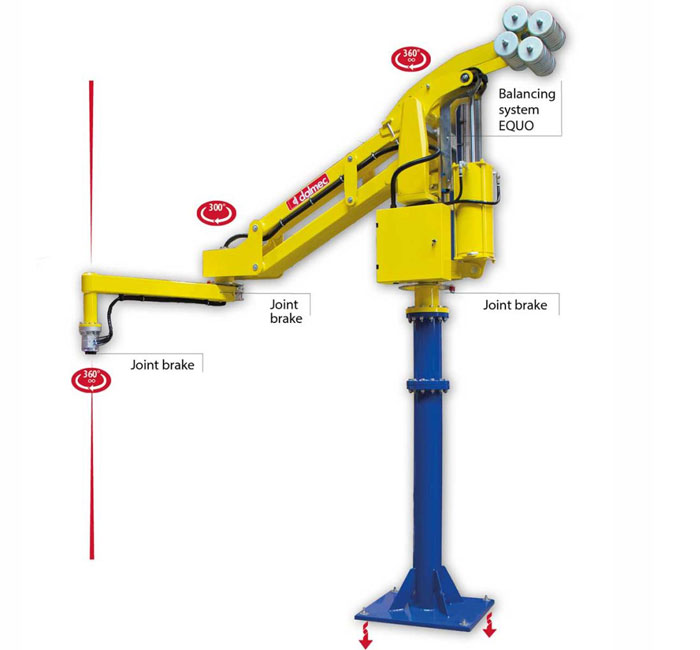

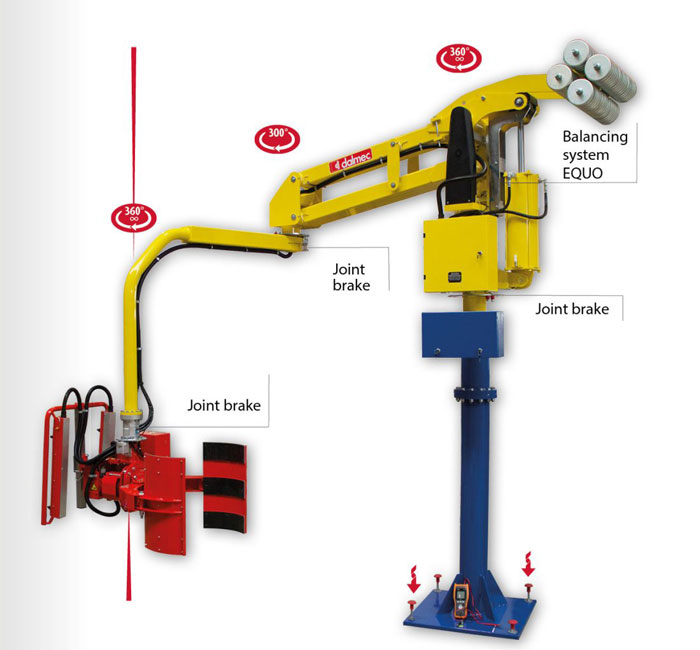

- Column

- Fixed Overhead

- Inox Column

- Inox Fixed Overhead

- Inox Overhead Running

- Overhead Running

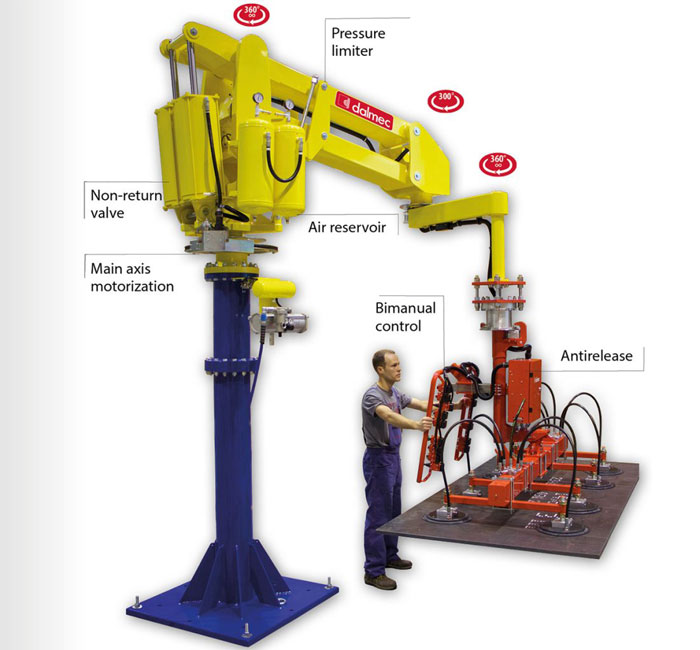

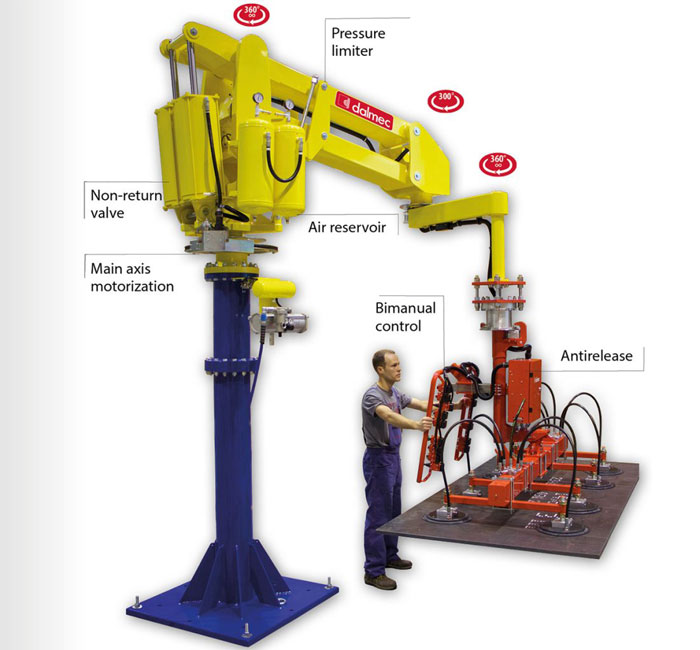

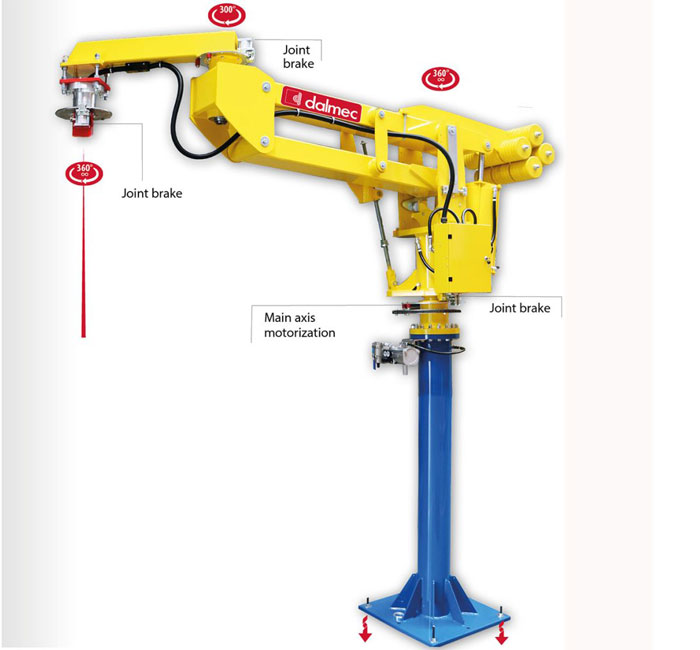

Maxipartner

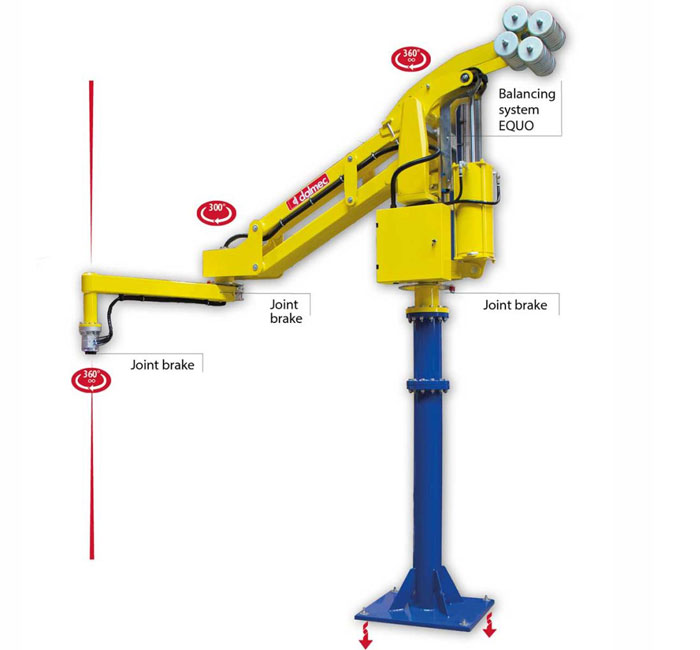

- Manipulator with Articulated Arms Maxipartner Equo Me

Pneumatic Manipulator MAXIPARTNER EQUO ME with articulated arms, equipped with special gripping tools, is suitable to handle heavy (max 900 kg) and also off-set loads, in any direction, allowing the operator to work with the minimum effort in good ergonomic and safety conditions. Its slim and strong structure eliminates the “drifting” effect.

Operation

A pneumatic cylinder fed with compressed-air, combined with a transmission lever system, provides balance to the load weight applied. The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced. The operator can change the load level simply operating a pneumatic control lever.

Features- Max weight capacity: 900

- Max working radius: 4500 mm

- Vertical lift: 2200 mm

- Working pressure: 0.7 ÷ 0.8 Mpa

- Control system: solely pneumatic

- Supply: filtrated compressed-air (40 µm), not lubricated

- Max vertical lifting speed: 0,5 meters/second

- Working temperature: from +0° to +45° C

- Noise level:

- Consumption: from 100 Nl ÷ 400 Nl per working cycle

- Rotations: – constant 360° on the column and tooling axis – 300° on the intermediate axis

Execution- Atex Column

- Atex Fixed Overhead

- Atex Overhead Running

- Column

- Fixed Overhead

Megapartner

- Manipulator with Articulated Arms Megapartner MG

Pneumatic Manipulator MEGAPARTNER MG with articulated arms, equipped with special gripping tools, is suitable to handle heavy (max 1500 kg) and also off-set loads, in any direction, allowing the operator to work with the minimum effort in good ergonomic and safety conditions.

Features- Max weight capacity: 1500 kg

- Max working radius: 5000 mm

- Vertical lift: 3050 mm

- Working pressure: 0.7 ÷ 0.8 Mpa

- Control system: solely pneumatic

- Supply: filtrated compressed-air (40 µm), not lubricated

- Max vertical lifting speed: 0,5 meters/second

- Working temperature: from +0° to +45° C

- Noise level:

- Consumption: from 100 Nl ÷ 600 Nl per working cycle

- Rotations: – constant 360° on the column and tooling axis – 300° on the intermediate axis

Executions- Atex Column

- Atex Fixed Overhead

- Column

- Fixed Overhead

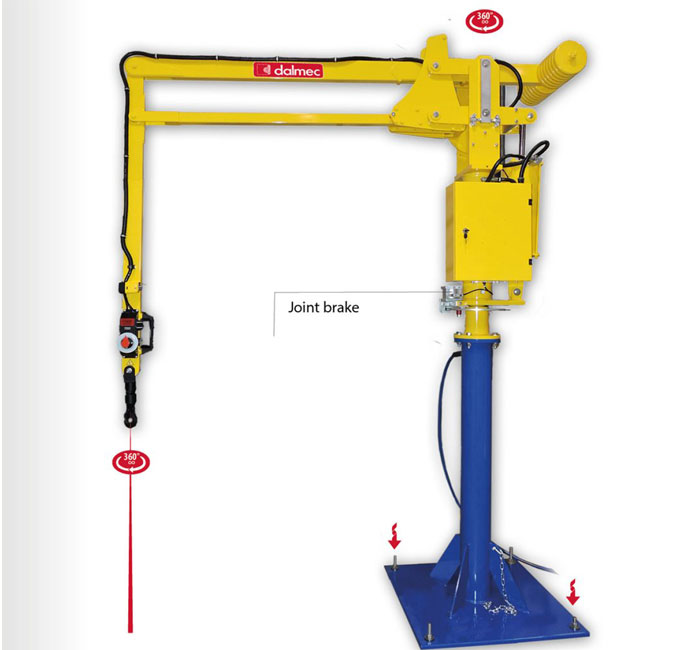

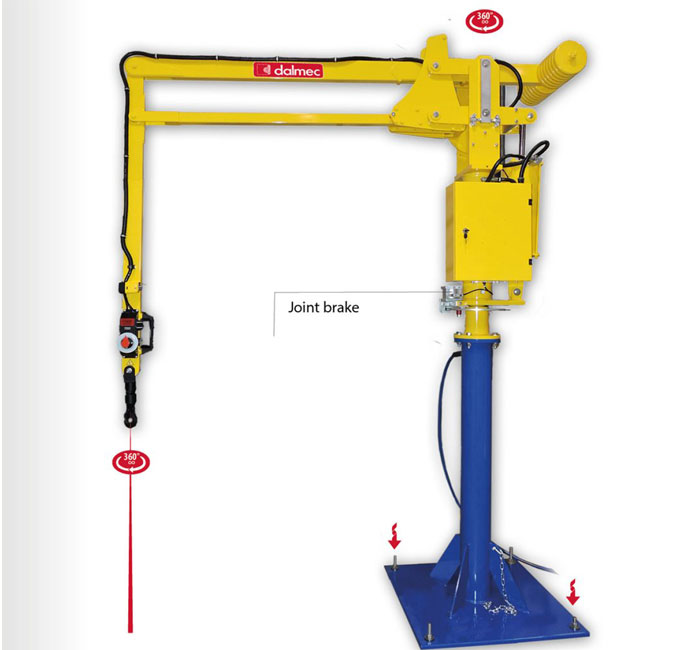

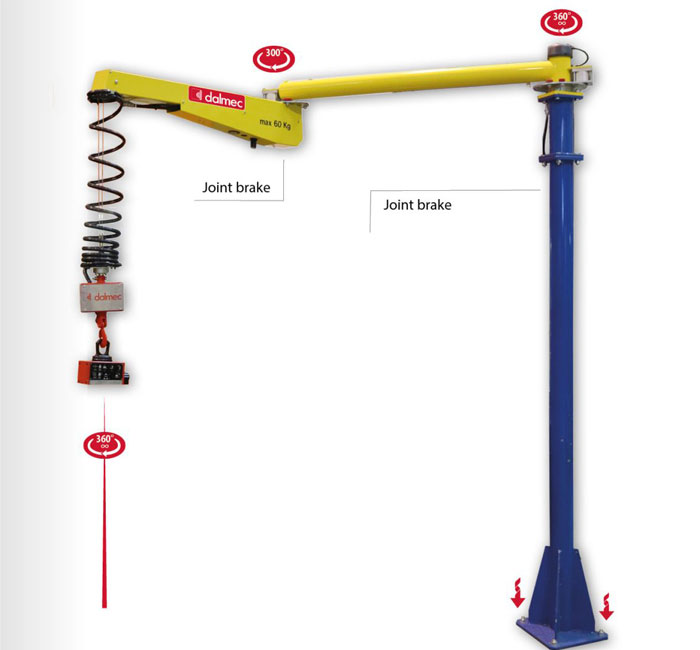

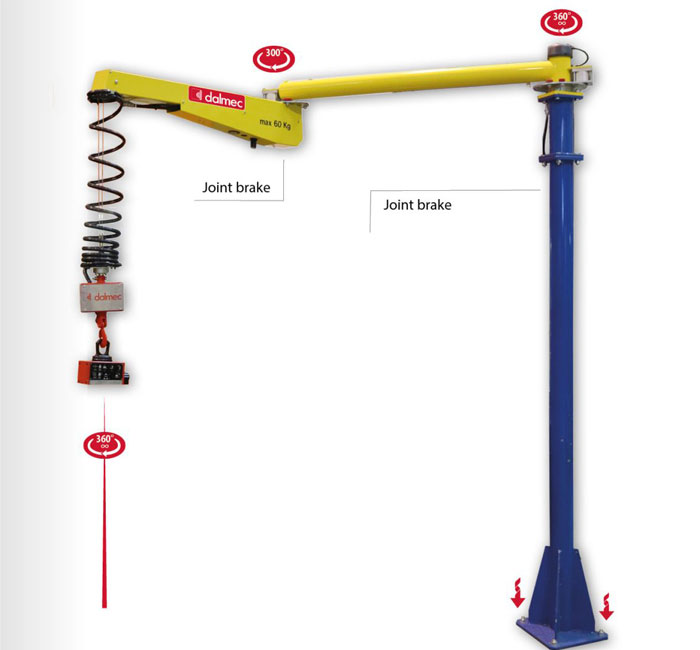

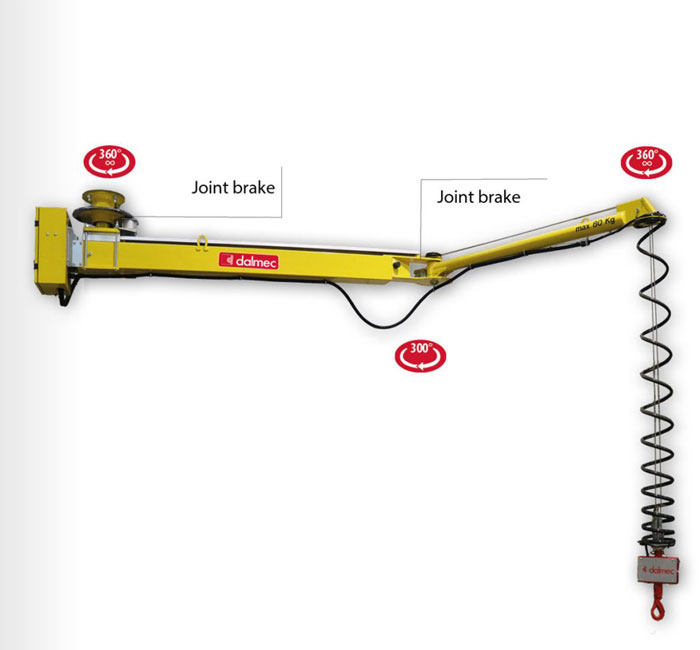

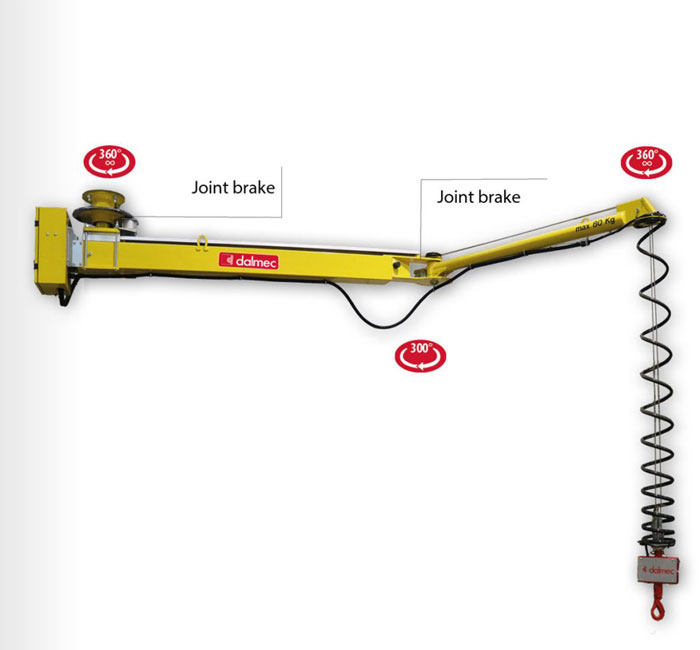

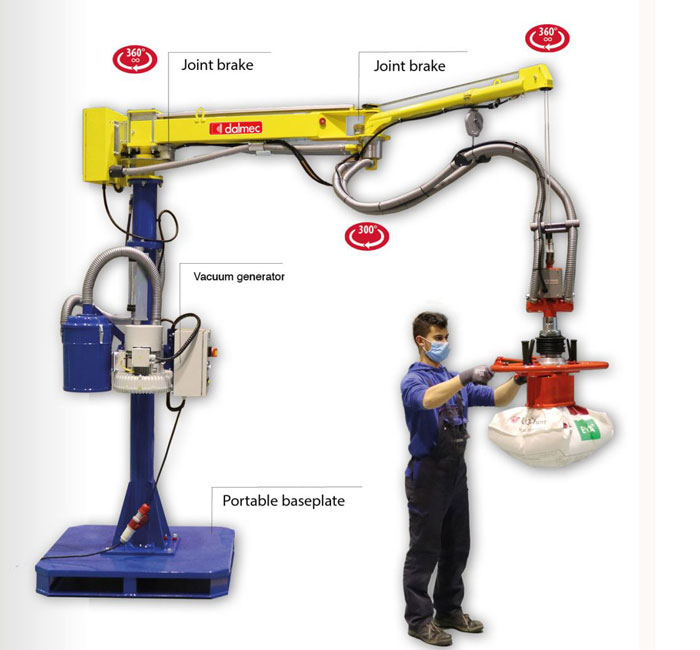

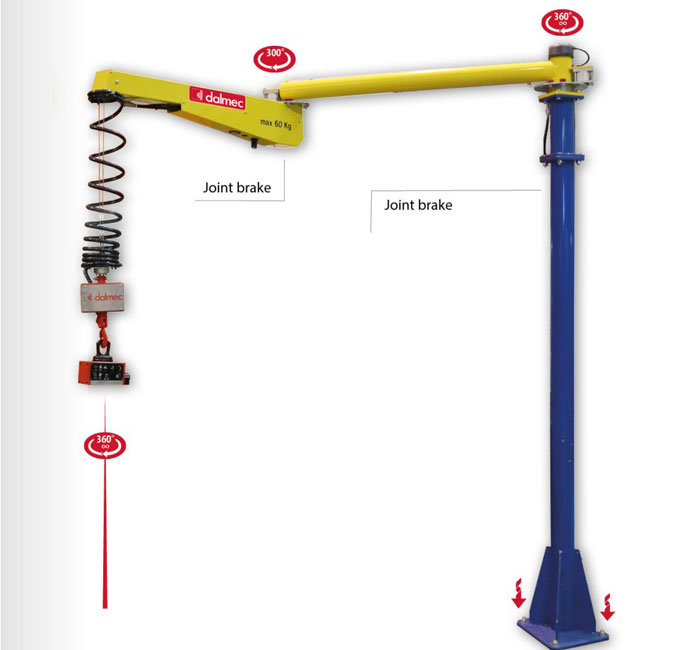

Posivel

- Manipulator with Double Cable Posivel PV

POSIVEL PV, generally realized with hook, can be equipped with simple gripping tools to allow the handling of light loads in a weightless condition in any direction. The particular double arm structure and medium joint makes it easy to handle and precise throughout the working area.

Operation

A pneumatic cylinder fed with compressed-air, combined with a transmission cables system provides balance to the load weight applied. The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced. The operator can change the load level applying a minimum force on the gripping tool or directly on the load.

Features- Max weight capacity: 60

- Max working radius: 2600 mm

- Vertical lift: 1700 mm

- Working pressure: 0.7 ÷ 0.8 Mpa

- Control system: solely pneumatic

- Supply: filtrated compressed-air (40 µm), not lubricated

- Noise level:

- Max vertical lifting speed: 0,5 meters/second

- Working temperature: from +0° to +45° C

- Consumption: from 10 Nl ÷ 50 Nl per working cycle

- Rotations: – constant 360° on the column and tooling axis - 300° on the intermediate axis

Execution- Atex Column

- Atex Fixed Overhead

- Atex Overhead Running

- Column

- Fixed Overhead

- Inox Column

- Inox Fixed Overhead

- Inox Overhead Running

- Overhead Running

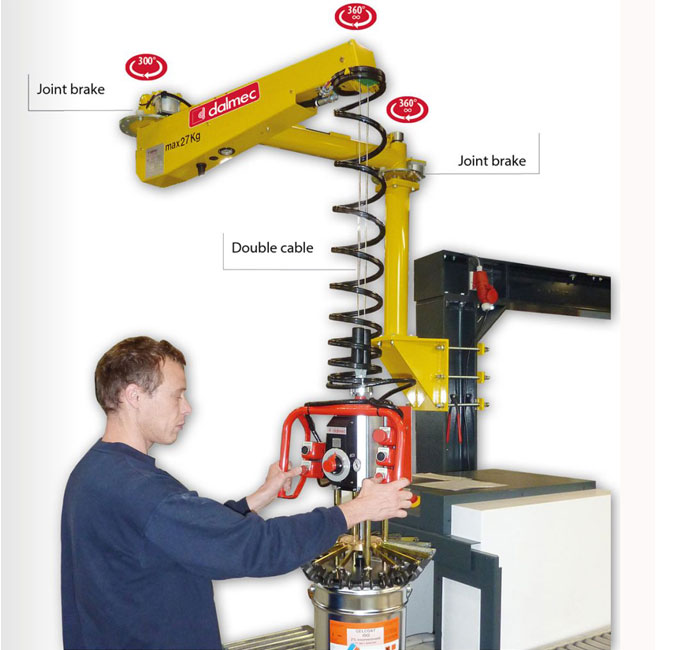

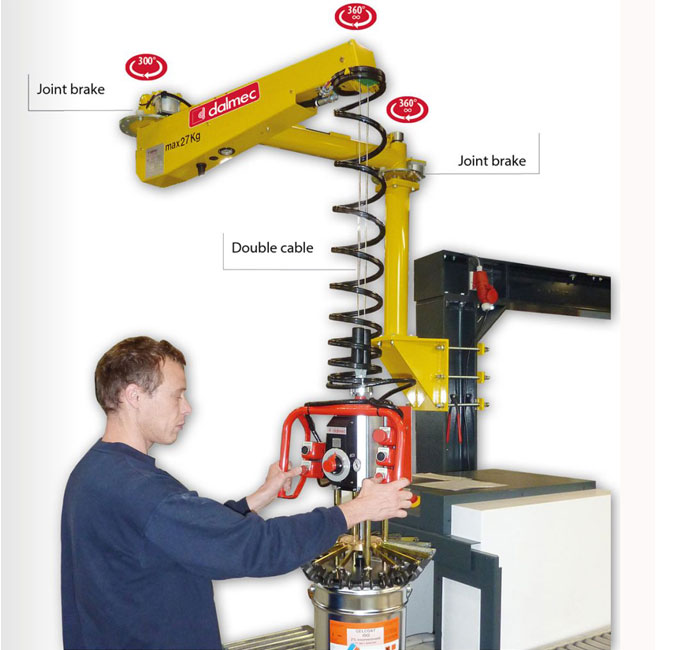

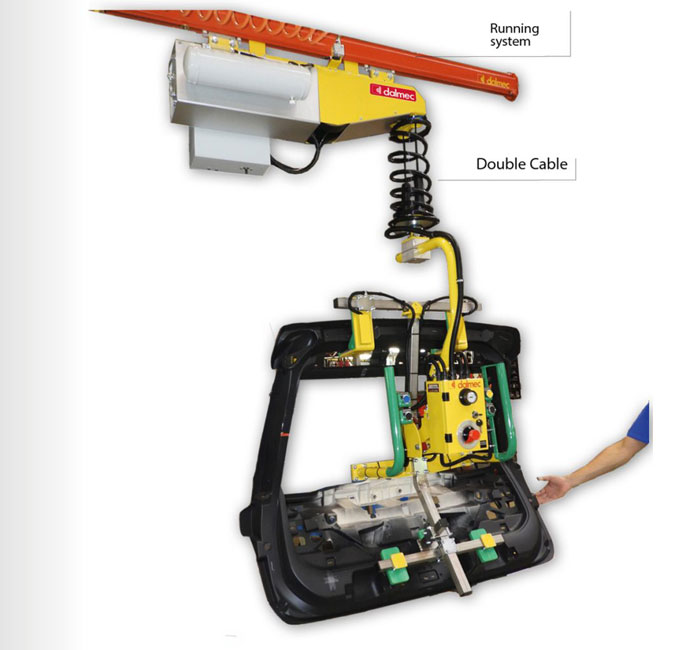

Speedyfil

-

Manipulator with Double Cable Speedyfil - Cable Balancer

Pneumatic Manipulator Speedyfil SP with double cable equipped with simple gripping tools, allows the handling of light loads in a weightless condition, throughout the working area. The gripping tool is connected to the balancing group by two independent steel cables to guarantee max safety. The particular double arm structure and middle joint makes it easy to operate within the entire working area.

Operation

A pneumatic cylinder fed with compressed-air, combined with a transmission cables system provides balance to the load weight applied. The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced. The operator can change the load level applying a minimum force on the gripping tool or directly on the load.

Features- Max weight capacity: 80 kg

- Max working radius: 2000 mm

- Vertical lift: 2150 mm

- Working pressure: 0.7 ÷ 0.8 Mpa

- Control system: solely pneumatic

- Supply: filtrated compressed-air (40 µm), not lubricated

- Noise level:

- Max vertical lifting speed: 0,5 meters/second

- Working temperature: from +0° to +45° C

- Consumption: from 5 Nl ÷ 30 Nl per working cycle

- Rotations: – constant 360° on the column and tooling axis - 300° on the intermediate axis

Execution- Atex Fixed Overhead

- Fixed Overhead

- Atex Overhead Running

- Overhead Running

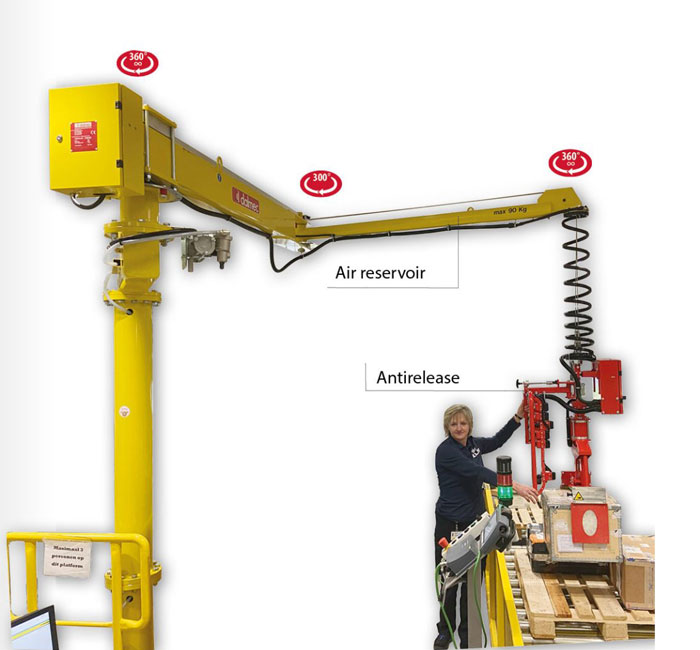

Posifil

- Manipulator with Double Cable Posifil PF - Cable Balancer

Pneumatic Manipulator POSIFIL PF with double cable equipped with simple gripping tools, allows the handling of light loads in a weightless condition, throughout the working area. The gripping tool is connected to the balancing group by two independent steel cables to guarantee max safety. The particular double arm structure and middle joint makes it easy to operate within the entire working area.

Operation

A pneumatic cylinder fed with compressed-air, combined with a transmission cables system provides balance to the load weight applied. The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced. The operator can change the load level applying a minimum force on the gripping tool or directly on the load.

Features- Max weight capacity: 140

- Max working radius: 3000 mm

- Vertical lift: 1800 mm

- Working pressure: 0.7 ÷ 0.8 Mpa

- Control system: solely pneumatic

- Supply: filtrated compressed-air (40 µm), not lubricated

- Noise level:

- Max vertical lifting speed: 0,5 meters/second

- Working temperature: from +0° to +45° C

- Consumption: from 20 Nl ÷ 100 Nl per working cycle

- Rotations: – constant 360° on the column and tooling axis - 300° on the intermediate axis

Execution- Atex Column

- Atex Fixed Overhead

- Atex Overhead Running

- Column

- Fixed Overhead

- Inox Column

- Inox Fixed Overhead

- Inox Overhead Running

- Overhead Running

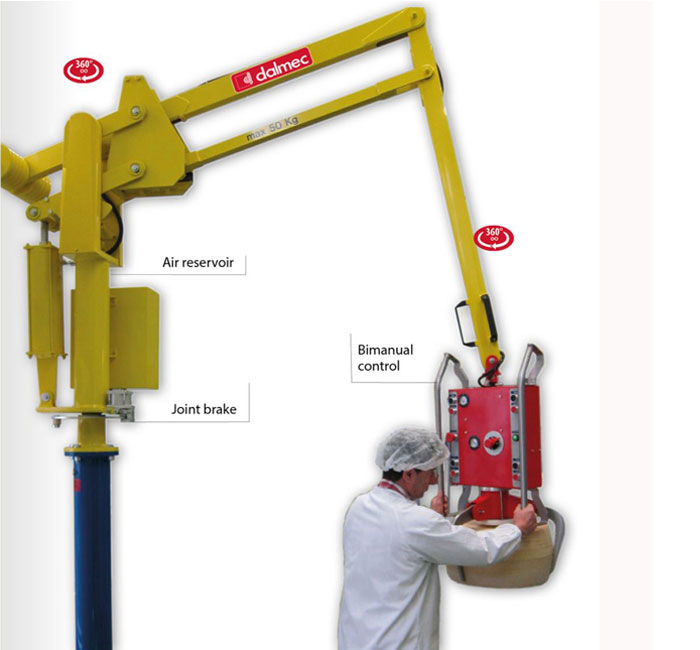

Posifil bags

- Rope manipulator Posifil for bags, cartons, drums.

The POSIFIL Manipulator, equipped with electrical turbine vacuum pump, allows the handling of paper and plastic bags, cardboard boxes, rubber bales, drums etc., using standard or customized suction cups according to the applications.

This new vacuum integration on board the Posifil, allows to obtain extraordinary ergonomic benefits when handling bags in working environments with low ceiling heights, allowing the operator to use the Manipulator freely, in the available workspace.

Features- Max weight capacity: 50 kg

- Max working radius: 5000 mm

- Vertical lift: 1800 mm

- Working pressure: 0.7 ÷ 0.8 Mpa

- Control system: pneumatic and electric

- Supply: filtrated compressed-air (40 µm), not lubricated

- Noise level:

- Max vertical lifting speed: 0,5 meters/second

- Working temperature: from +0° to +45° C

- Consumption: from 20 Nl ÷ 100 Nl per working cycle

- Rotations: – constant 360° on the column and tooling axis - 300° on the intermediate axis

Execution- Atex Column

- Atex Fixed Overhead

- Column

- Fixed Overhead

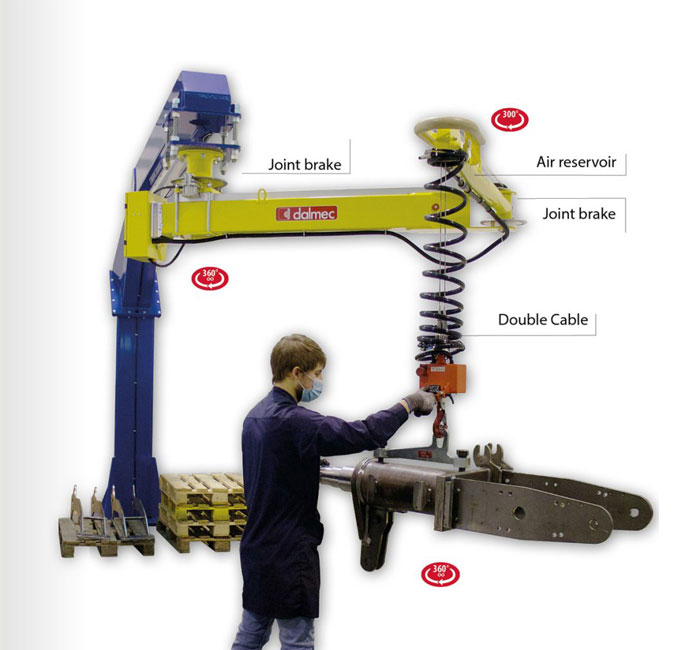

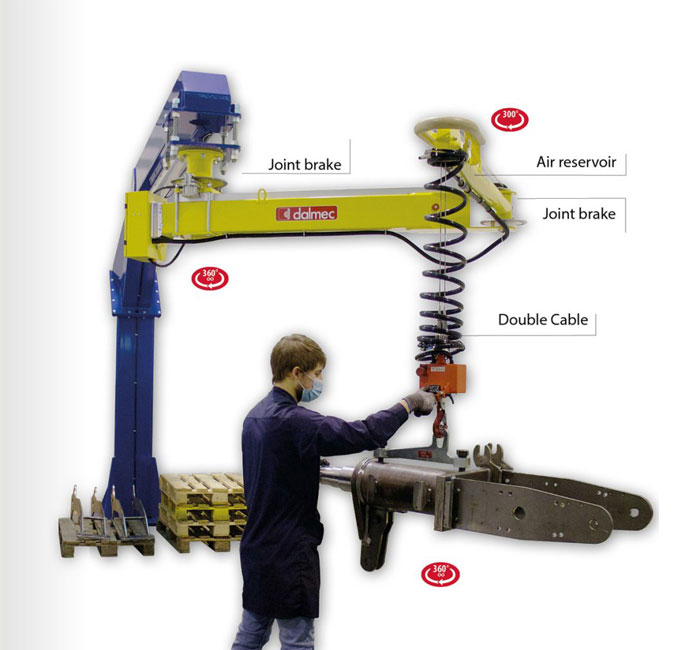

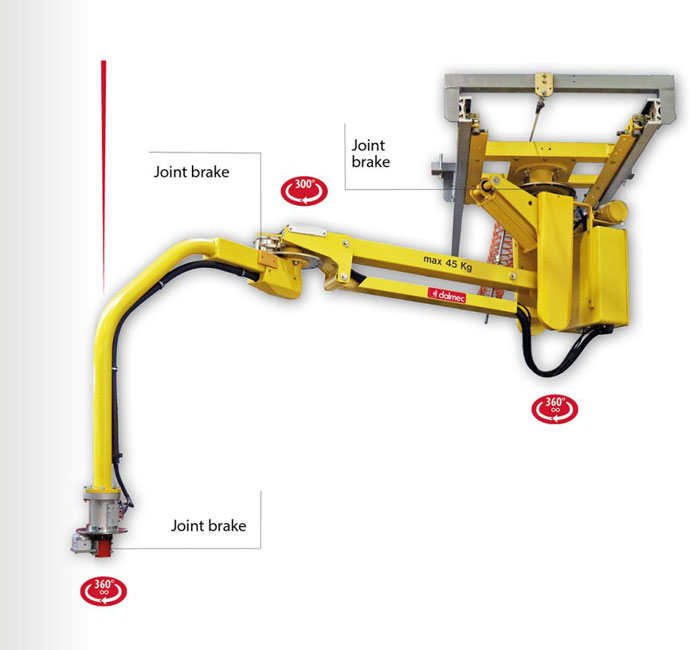

Posiplus

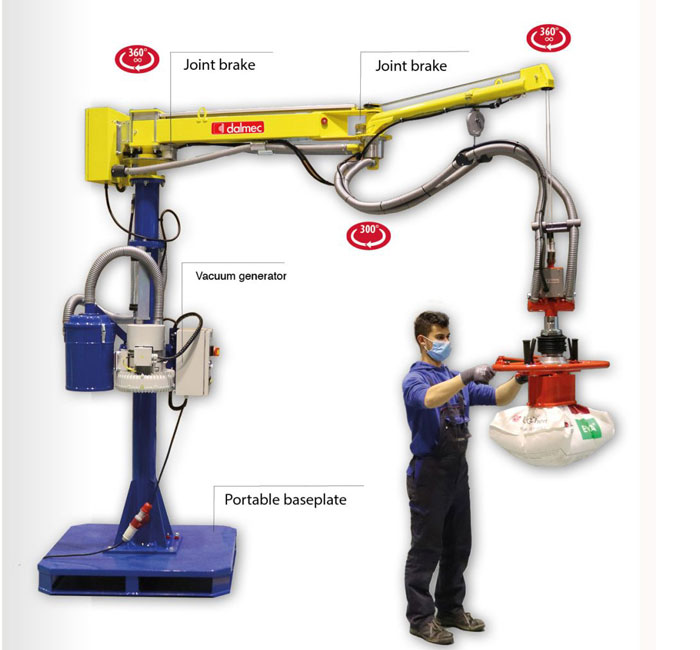

- Pneumatic Manipulator Posiplus PP with Double Cable

POSIPLUS PP is a double cable manipulator with high load capacities, capable of handling loads up to 200 kg and reaching working radii up to 4500 mm. The gripping tooling is connected to the balancing group through two independent steel cables to ensure maximum safety. The particular double-arm structure with intermediate joint makes it easy to operate within the entire working area. Specific brakes mounted on the main joints guarantee control of drift movements.

Operation

A pneumatic cylinder fed with compressed-air, combined with a transmission cables system provides balance to the load weight applied. The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced. The operator can change the load level applying a minimum force on the gripping tool or directly on the load.

Features- Max weight capacity: 200 kg

- Max working radius: 4500 mm

- Vertical lift: 1900 mm

- Working pressure: 0.7 ÷ 0.8 Mpa

- Control system: solely pneumatic

- Supply: filtrated compressed-air (40 µm), not lubricated

- Noise level:

- Max vertical lifting speed: 0,5 meters/second

- Working temperature: from +0° to +45° C

- Consumption: from 40 Nl ÷ 120 Nl per working cycle

- Rotations: – constant 360° on the column and tooling axis - 315° on the intermediate axis

Execution- Atex Column

- Atex Fixed Overhead

- Atex Overhead Running

- Column

- Fixed Overhead

- Inox Column

- Inox Fixed Overhead

- Inox Overhead Running

- Overhead Running

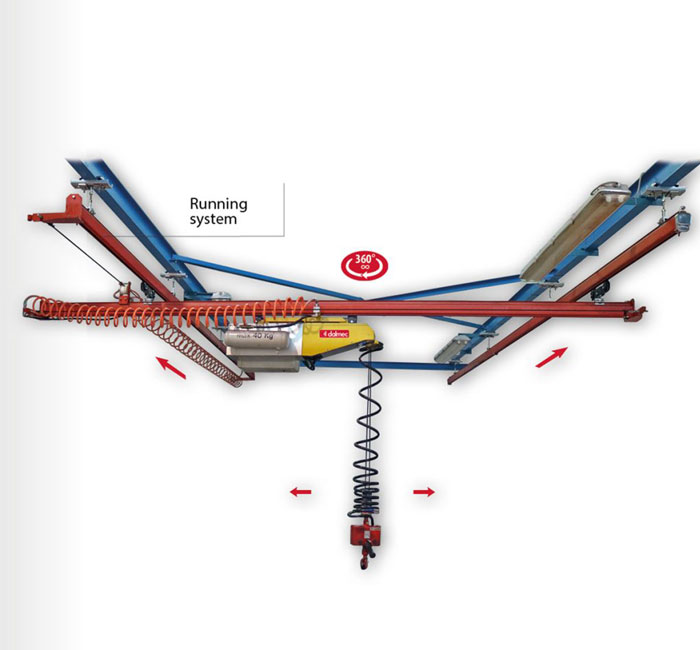

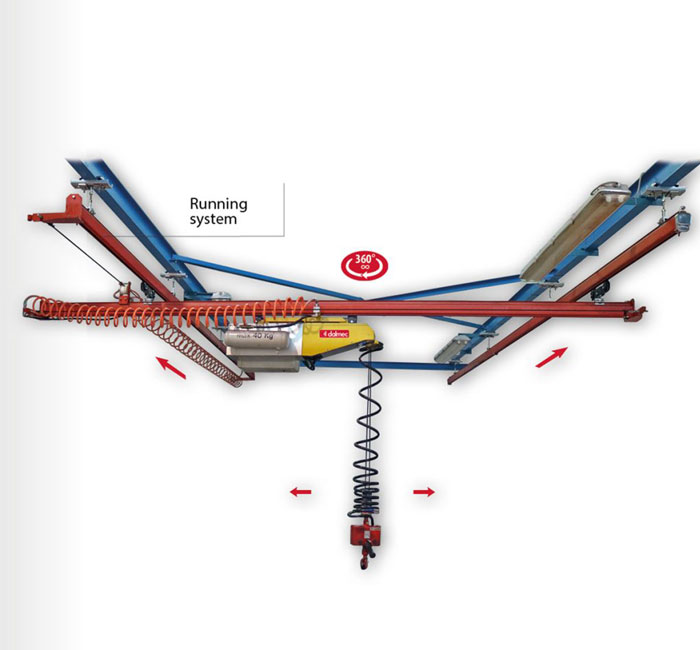

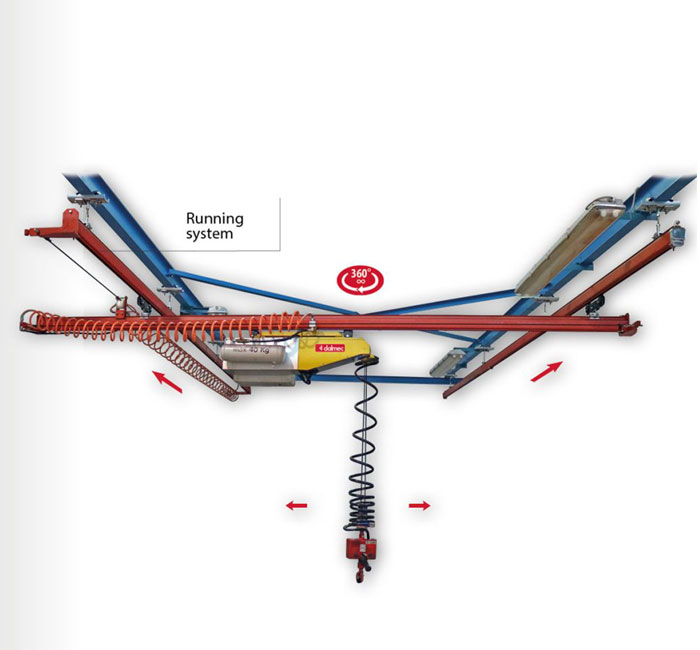

Minipartner

- Manipulator Minipartner with Double Cable

Pneumatic Manipulator MINIPARTNER with double cable equipped with simple gripping tools, allows the handling of light loads in a weightless condition, throughout the working area. The gripping tool is connected to the balancing group by two independent steel cables to guarantee max safety. Generally overhead mounted with double track system, it offers an easy translation in order to cover a long working area.

Operation

A pneumatic cylinder fed with compressed-air, combined with a transmission cables system provides balance to the load weight applied. The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced. The operator can change the load level applying a minimum force on the gripping tool or directly on the load.

Features- Max weight capacity: 80 kg

- Vertical lift: 1800 mm

- Working pressure: 0.7 ÷ 0.8 Mpa

- Control system: solely pneumatic

- Supply: filtrated compressed-air (40 µm), not lubricated

- Noise level:

- Max vertical lifting speed: 0,5 meters/second

- Working temperature: from +0° to +45° C

- Consumption: from 10 Nl ÷ 20 Nl per working cycle

- Rotation: 360° on tooling axis

Execution- Atex Fixed Overhead

- Fixed Overhead

- Atex Overhead Running

- Overhead Running

Industrial Manipulators

- DALMEC Industrial Manipulators allow the ergonomic, safe and effective handling of any product. We are able to lift every kind of product weighing from 6 up to 1500 kilograms using compressed-air only.

PARTNER STANDARD

- Versions PSC – PSF – PSS

- Weight capacity 300 Kg

- Radius max 2900 mm

- Vertical lift 1900 mm

- Rotation axes 2

- Misaligned loads NO

MICROPARTNER

- Versions MIC – MIF – MIS

- Weight capacity 125 Kg

- Radius max 2800 mm

- Vertical lift 1400 mm

- Rotation axes 3

- Misaligned loads SI

PARTNER EQUO

- Versions PEC – PEF – PES

- Weight capacity 550 Kg

- Radius max 4000 mm

- Vertical lift 2450 mm

- Rotation axes 3

- Misaligned loads SI

MAXIPARTNER EQUO

- Versions MEC – MEF – MES

- Weight capacity 900 Kg

- Radius max 4500 mm

- Vertical lift 2200 mm

- Rotation axes 3

- Misaligned loads SI

MEGAPARTNER

- Versions MGC

- Weight capacity max 1500 Kg

- Radius max 5000 mm

- Vertical lift 3050 mm

- Rotation axes 3

- Misaligned loads SI

Dalmec Industrial Manipulators with Cable

- DALMEC Industrial Manipulators with double cable, equipped with simple gripping tools, allow the handling of light loads in a weightless condition, throughout the working area. The gripping tool is connected to the balancing group by two independent steel cables to guarantee max safety. The particular double arm structure and middle joint makes it easy to operate within the entire working area.

POSIVEL

- Versions PVC – PVF – PVS

- Weight capacity max 60 Kg

- Radius max 3400 mm

- Vertical lift 1700 mm

- Rotation axes 3

- Misaligned loads NO

POSIFIL

- Versions PFC – PFF – PFS

- Weight capacity max 140 Kg

- Radius max 5000 mm

- Vertical lift 1800 mm

- Rotation axes 3

- Misaligned loads NO

POSIFIL SACCHI

- Versions PFC – PFF – PFS

- Weight capacity max 50 Kg

- Radius max 5000 mm

- Vertical lift 1800 mm

- Rotation axes 3

- Misaligned loads NO

POSIPLUS

- Versions PPC – PPS

- Weight capacity max 200 Kg

- Radius max 4500 mm

- Vertical lift 1900 mm

- Rotation axes 3

- Misaligned loads NO

SPEEDYFIL

- Versions SPC – SPF – SPS

- Weight capacity max 80 Kg

- Radius max 2000 mm

- Vertical lift 2150 mm

- Rotation axes 3

- Misaligned loads NO

MINIPARTNER

- Versions MPC – MPF – MPS

- Weight capacity max 80 Kg

- Vertical lift 1800 mm

- Rotation axes 1

- Misaligned loads NO

Commodity Sector

Aerial Naval

Dalmec industrial manipulators for the aviation and naval sector

Well-trained design staff are able to develop state-of-the-art equipment, which ensure the operators ergonomic use of the Manipulators.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

Mooring chain rings

- Balancer for rings of mooring chains.

Pinch jaws gripping tooling with cooling system combined to the manipulator Maxipartner type, column mounted, especially designed for the handling of rings of mooring chains.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

Hundreds of Dalmec manipulators are used in the leading industries all over the world. Our balancers are equipped with different types of gripping devices able to lift, rotate, tilt loads of all sizes and materials with a weight from 5 Kg to 900 Kg. DALMEC continuously strives to find the best solution to allow the handling of loads without any effort in accordance with the ergonomic criteria.

Safety is a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings.

Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client.

Parts of aircraft turbine

- Manipulator for parts of aircraft turbine.

Manipulator Maxipartner, column version, equipped with pinch jaws tooling for handling parts of aircraft turbine.

The device is suitable for the handling of the part during the processing phases on the machine tools. The gripping tooling is equipped with a pneumatic inclination group and allows the gripping of parts having different sizes.

Every project is developed according to the instructions given by the Directive 2006/42/EC on machinery and after a careful and a methodical analysis of the risks.

Safety is a matter of utmost importance and a fundamental component common to all our products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Auto Motorbike - Industrial Vehicles

- Dalmec has faced and solved all the handling problems in the auto – industrial vehicles sector; many are the installations all over the world.

Dalmec Manipulators meet the need to handle loads of different kind in enslavement to transport lines, packaging lines, production processes, etc.

Perfectly balancing the loads, Dalmec handling systems allow the gripping and handling of loads in a “weightless” condition in any direction of the workspace: the operator works effortlessly in the safest conditions.

The ergonomic concept of PARTNER®, aimed at reducing physical stress during manual handling of loads, helps to comply with the EU directives.

Batteries

- Dalmec manipulators equipped with gripping devices for the handling of automotive batteries.

Dalmec is specialized in handling loads Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Manipulator Micropartner type, equipped with suction cups tooling for gripping, handling and positioning of batteries into car baggage car.

Dalmec industrial manipulators for batteries are custom-built, with specially adapted design, dimensions and picking systems to suit the specific requirements of the users and the various environmental conditions available.

Bodywork

- Gripping systems for bodywork products.

Dalmec is specialized in handling loads. Dalmec is present in companies all over the world.

Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Partner type Manipulator, column mounted version, equipped with suction cups tooling for gripping and handling car door frames. The gripping system enable to tilt the load.

Dalmec Manipulators are custom-built, with specially adapted design, dimensions and picking systems to suit the specific requirements of the users and the various environmental conditions available.

Car components handling – Bonnets

- Car components handling – Bonnets

Partner Manipulator, fixed overhead, equipped with a suction cups tooling for gripping, handling and installation of front bonnets.

The pneumatic manipulator Partner PE fixed overhead version allows to eliminate any floor obstructions.

The flange of the Manipulator is supplied with holes for the anchoring with screws to a strong plate to the ceiling or to a shelf.

All movements are free and are obtained with minimum effort by the direct action of the operator on the gripping tooling or on the load.

The main purpose of DALMEC manipulators is to assist the customer and give him support to reduce the weight of his workload and to enable him to work safely, efficiently and precisely. DALMEC continuously strives every day to find the best solution to allow the handling of any kind of product without any effort in accordance with the ergonomic criteria.

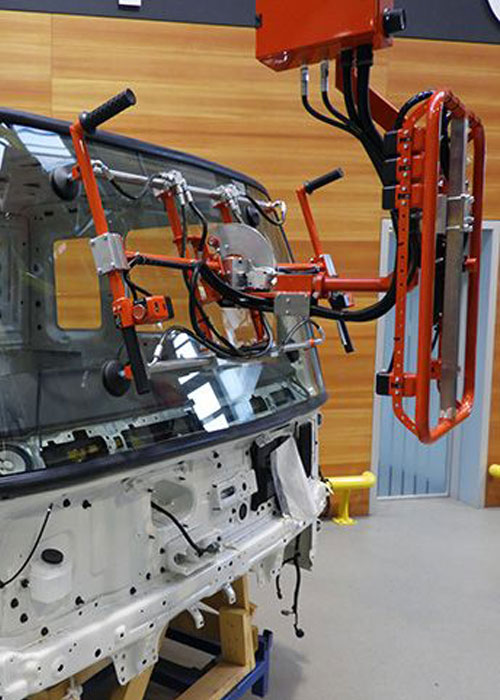

Car glasses

- Gripping solutions – Manipulators equipped with gripping devices for handling car glasses.

Dalmec offers custom-built gripping solutions for handling car glasses, as windshields, moonroofs, rearglasses and so on. Dalmec is present in the main companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

Safety is a matter of utmost importance for us and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Manipulator Partner type equipped with gripping unit with pins references and mechanical coupling devices for handling and positioning of sunroofs on the vehicle.

Dalmec gripping solutions have a specially adapted design, dimensions and picking systems to suit the specific requirements of the users and the various environmental conditions available.

Crankcases

- Hoist for handling crankcases.

Pinch jaws gripping system coupled to Dalmec hoist type Posivel double rope, column mounted version, for lifting and handling crankcases.

Dalmec presents a wide range of versatile solutions to allow the lifting of products weighing from 10 up to 900 kilograms.

DALMEC hoists are able to ensure safe and continuous operation. Manipulators are customized and designed bearing in mind specific movements, operations and requirements of the production processes of every single customer.

The main purpose of DALMEC manipulators is to assist the customer and give him support to reduce the weight of his workload and to enable him to work safely, efficiently and precisely.

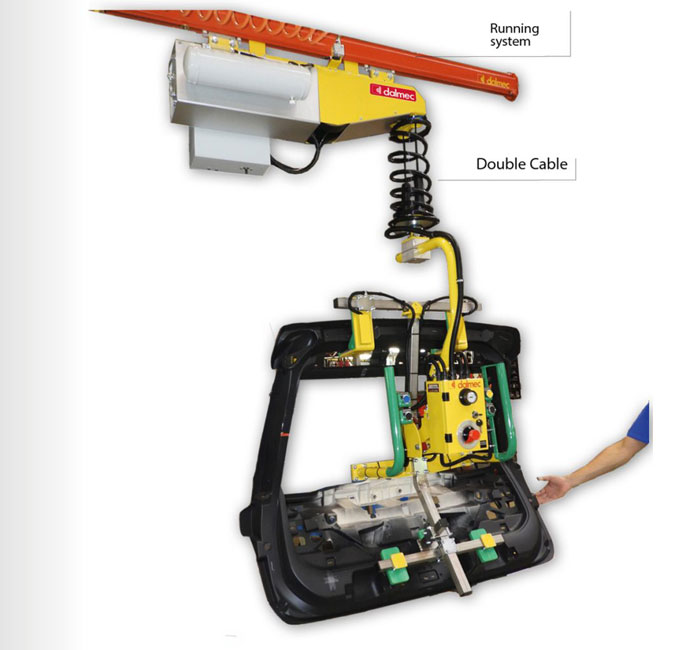

Dashboards and windscreens assembly plant

- Inauguration of a new plant for dashboards and windscreens assembly at ISUZU Kenya

In fifty years of activity we have created plants of all kinds, always custom-designed in accordance with the single industrial situation, to ensure the highest level of quality and operation.

We have tackled and successfully solved every type of problem in the field of manual handling of loads, creating new plants and specializing in finding efficient and ergonomic solutions.

Every time we deliver a new plant is as if it were the first: the Customer and operators satisfaction is our best reward.

In this specific project we have manufactured a system composed of two manipulators Partner PE type overhead running version, for the fitting out of an industrial vehicle.

The first manipulator is equipped with a pinch jaws device designed for the gripping of the dashboard from special supports and allows the insertion and installation of the same inside the vehicle cabin; the second manipulator is equipped with a suction cups device for the installation of the windscreen.

The installation is complete with an overhead running system with pneumatic motorization to facilitate the sliding in the tracks, composed of two opposite aluminium U-shaped profiles with connecting and stiffening ribs, complete with attachment points for an overhead suspension and end buffers. The various parts are jointed with screws.

Dashboards

- Dalmec manipulators equipped with gripping devices for handling automotive dashboards.

Dalmec is specialized in handling loads Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Manipulator Micropartner equipped with gripping unit with pins references and mechanical coupling devices for the handling and positioning of dashboards inside the vehicle.

Dalmec lifting arms – manipulators for the car-motorcycle industry are custom-built, with specially adapted design, dimensions and picking systems to suit the specific requirements of the users and the various environmental conditions available.

Doors

- Gripping systems for car doors.

Dalmec is specialized in handling loads Dalmec is present in companies all over the world.

Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Pneumatic Manipulator Micropartner for handling car doors.

Micropartner overhead trolley mounted version, equipped with a suction cups device for gripping and handling of car doors.

Dalmec industrial Manipulators for the car-motorcycle industry are custom-built, with specially adapted design, dimensions and picking systems to suit the specific requirements of the users and the various environmental conditions available.

Drive shafts

- Balancer for handling drive shafts.

Dalmec pinch jaws gripping device mounted on the balancer Partner type, column mounted version, designed for the horizontal gripping of drive shafts.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Handling of crankcases.

Pinch jaws gripping system Dalmec mounted on balancer Partner Equo, column mounted version, designed for lifting and handling of crankshafts.

Each balancer is a guarantee. Both from the functioning and the safety point of view.

Dalmec balancers – Manipulators are custom-built, with specially adapted design, dimensions and picking systems to suit the specific requirements of the users and the various environmental conditions available.

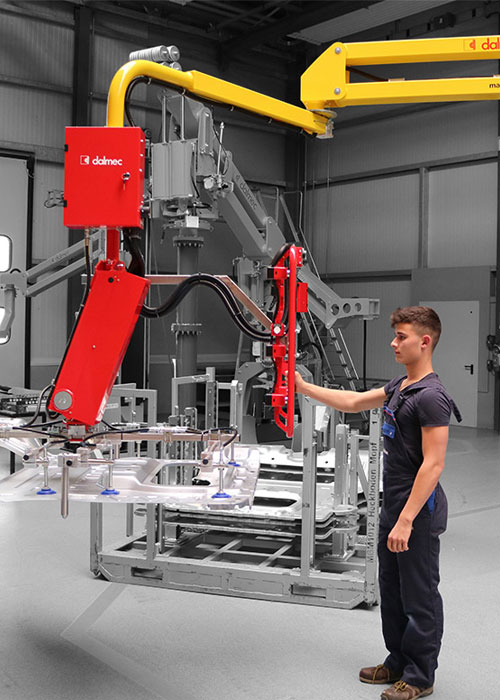

Positioner floor pans – metal sheets

- Positioner for floor pans – metal sheets

Dalmec gripping system with a suction cups device applied to Partner Equo Manipulator for the lifting and handling of metal sheet floor pans for vehicles.

The gripping device allows the picking of the floor pan positioned horizontally and after a pneumatic inclination of 90° its positioning in vertical in special containers.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

Manipulator with suction cups for glasses

- Manipulator for the handling of glasses.

Manipulator, column mounted version, equipped with Dalmec suction cups gripping system for the lifting and handling of plate glasses – vehicles.

The gripping device allows the picking of the glass positioned horizontally and after a pneumatic inclination of 90° its positioning in vertical in special containers. The suction cups are adjustable in order to allow the gripping of glasses having variable dimensions.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Lifter for glasses

Dalmec gripping system with a suction cups device applied to Partner Equo Manipulator, column mounted version, for the lifting, handling and positioning of windscreens for vehicles.

Simple to use, these lifters allow the operator to move loads of all kin ds throughout the working area quickly, accurately and safely.

Our Manipulators are custom-built, with specially adapted design, dimensions and picking systems to suit the specific requirements of the users and the various environmental conditions available.

Mechanics

- Dalmec gripping solutions for the handling of various

mechanical parts of motor vehicles.

Dalmec is specialised in handling loads of all sizes and materials with a weight from 5 Kg to 900 Kg. Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new gripping solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Partner type manipulator, column mounted version, equipped with pneumatic gripping system for the handling, inclination and servo-assisted rotation of crankcases from a conveyor to a molding machines.

Dalmec Manipulators are custom-built, with specially adapted design, dimensions and gripping solutions to suit the specific requirements of the users and the various environmental conditions available.

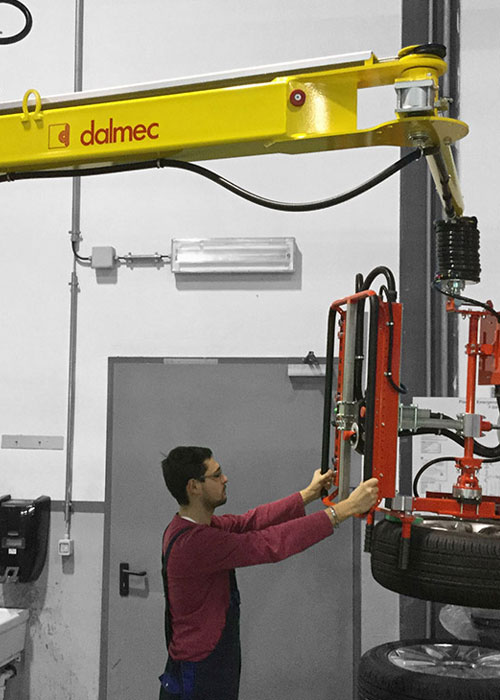

Positioner rubber wheels – raw tyres

- Positioner for rubber wheels

Manipulator, Posifil type, fixed overhead version, equipped with a gripping device with concentric jaws suitable for the gripping and handling of rubber wheels – raw tyres

Dalmec is specialized in handling loads Dalmec is present in the major car companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Balancing device for mounting seats

- Balancing device for mounting seats with variable shapes and sizes.

Manipulator Partner Equo, overhead trolley mounted version equipped with pinch jaws tooling for handling and installation of bus seats with variable shapes and types.

The tooling is able to grip the seats positioned flat, to tilt them by 90° with a pneumatic device and release them in a vertical position inside the bus, thanks to a telescopic arm and a particular shaping of the terminal arm.

The Manipulator is supplied complete with an overhead trolley to run in a tracking system, composed of two opposite aluminium U sections with connecting and stiffening ribs,complete with attachment points for an overhead suspension and end buffers. The junction between the various parts is done with screws.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Dalmec in the industrial vehicles sector

- Dalmec Manipulators at work in some of the most prestigious automotive industries in the world.

Dalmec has faced and solved all the handling problems in the auto – industrial vehicles sector; many are the installations all over the world.

Dalmec manipulators are flexible and adaptable – a perfect tool not only for controlling production processes and increasing productivity but also for resolving problems related to the movement of products in logistics. Thanks to the uniquely customer-focused approach, from functional analysis and designing to manufacturing, Dalmec manipulators are applied with maximum advantage in the most various sectors from mechanical, chemical and food industry to the building sector and manufacturing in general.

The key to success lies in the simplicity of the approach, the high-quality standards, the capability and engineering know-how, but above all in the strength and consistency applied to a simple, initial idea – help a man perform his job as effortlessly as possible.

Building

- Dalmec has produced many Industrial Manipulators used in the building sector for the handling of paving tiles – sanitaries – cement products – isolating materials etc.

Bags

- Handling of bags – Industrial Manipulators Dalmec for gripping, lifting and emptying bags of different weights and materials.

Well-trained design staff are able to develop state-of-the-art equipment, which ensure the operators ergonomic use of the Manipulators.

Every project is developed according to the instructions given by the Directive 2006/42/EC on machinery and after a careful and a methodical analysis of the risks.

Each manipulator ensures security and safety of operation.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development. .

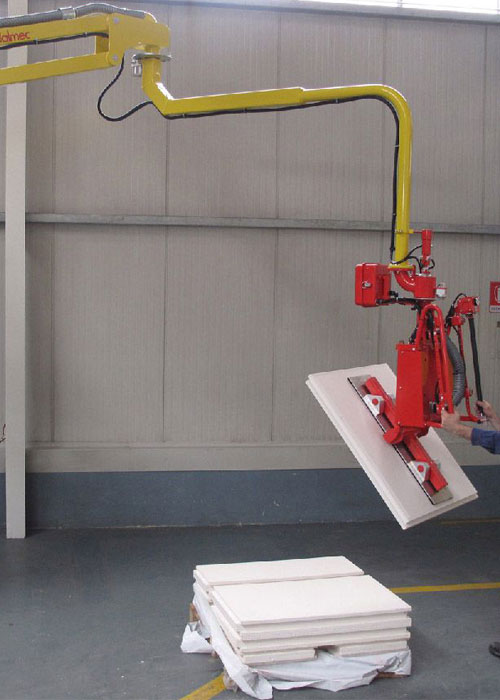

Building insulation materials

- Insulation material handling – Dalmec Industrial Manipulators for the building sector.

Well-trained design staff are able to develop state-of-the-art equipment, which ensure the operators ergonomic use of the ManipulatorsWe consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Every project is developed according to the instructions given by the Directive 2006/42/EC on machinery and after a careful and a methodical analysis of the risks.

Each manipulator ensures security and safety of operation.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

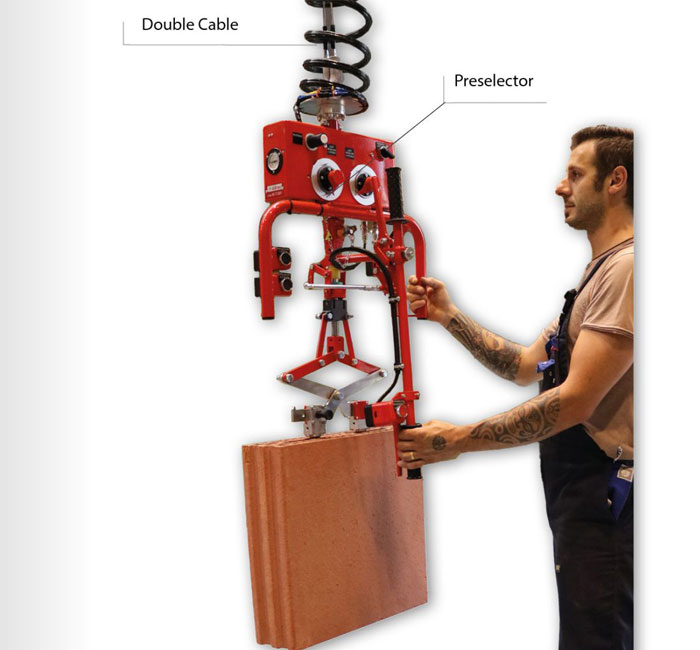

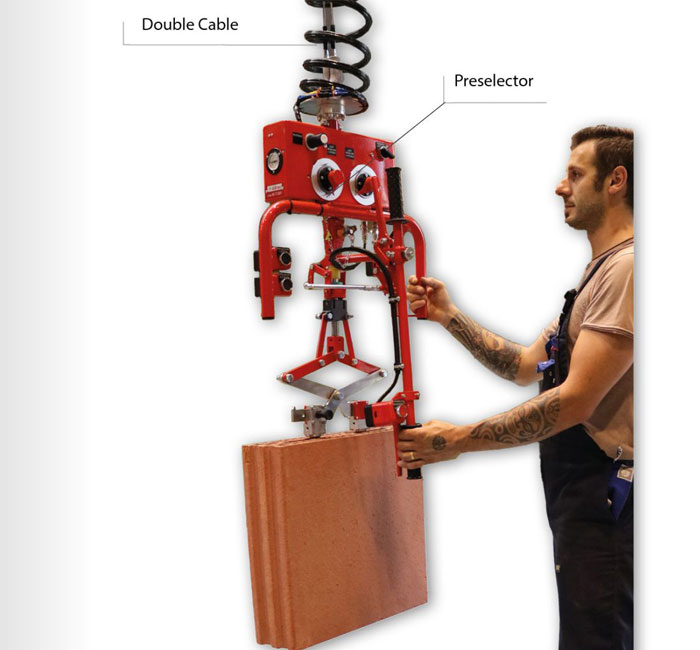

Cement products

- Handling of cement products – Industrial Manipulators Dalmec for the building sector.

Dalmec Manipulators are custom-built, with specially adapted design, dimensions and picking systems to suit the specific requirements of the users and the various environmental conditions available.

Well-trained design staff are able to develop state-of-the-art equipment, which ensure the operators ergonomic use of Dalmec handlers.

Every project is developed according to the instructions given by the Directive 2006/42/EC on machinery and after a careful and a methodical analysis of the risks.

Each manipulator ensures security and safety of operation.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Door and window frames handling

- Door and window frames handling – Maxipartner Manipulator column mounted version.

Dalmec gripping system with a suction cups device applied to Maxipartner Manipulator for the lifting and handling of door and window frames.

The gripping device allows the picking of door and window frames having different forms and dimensions, positioned horizontally and after a pneumatic rotation of 180° their positioning in vertical in special containers.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Glass

- Handling of glass products – Industrial Manipulators Dalmec for the building industry.

DALMEC has been able to offer solutions that allow continuous operation and safe over time.

Our pneumatic manipulators, designed and manufactured according to specific movements are studied on the functional needs of the production processes of each individual client. So, over the years, DALMEC has become a widely recognized and established supplier of solutions designed to optimize human resources in any production or logistics chain, with an immediate impact on work quality and profitability.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution with a load balancer.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Gypsum plasterboards

- Handling of gypsum plasterboards.

Handling system for boards. Venturi vacuum suction system coupled to Manipulator Parter Equo for lifting and handling of gypsum plasterboards having different dimensions.

Characteristics: Max weight capacity 135 Kg – Max working radius 3100 mm – Vertical lift 2250 mm

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

Every project is developed according to the instructions given by the Directive 2006/42/EC on machinery and after a careful and a methodical analysis of the risks.?Each manipulator ensures security and safety of operation.?We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Metal grids

- Material handling – metal grids

Partner Manipulator column mounted version, equipped with suitable tooling to grip metal reinforcements for the building industry.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Pallets

- Pallets handling – Dalmec Industrial Manipulators for the building industry – packaging.

DALMEC has been able to offer solutions that allow continuous operation and safe over time.

Our pneumatic manipulators, designed and manufactured according to specific movements are studied on the functional needs of the production processes of each individual client.

So, over the years, DALMEC has become a widely recognized and established supplier of solutions designed to optimize human resources in any production or logistics chain, with an immediate impact on work quality and profitability.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development. .

Panels

- DALMEC has been able to offer solutions that allow continuous operation and safe over time.

Our pneumatic manipulators, designed and manufactured according to specific movements are studied on the functional needs of the production processes of each individual client.

So, over the years, DALMEC has become a widely recognized and established supplier of solutions designed to optimize human resources in any production or logistics chain, with an immediate impact on work quality and profitability.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Sanitaryware handling

- Sanitaryware handling – Partner Equo running overhead manipulator.

Pinch jaws gripping system with pinch jaws gripping device applied to Partner Equo Manipulator for the lifting and handling of sanitaryware. The gripping system is designed to grip raw toilets of different sizes and place them in special shelving.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of your new zero balancer.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Scaffold props

- Gripping system for scaffolds props

New Equo Partner manipulator, column mounted fitted with pinch jaws tooling for handling “Christs” or props used in the building industry. The tooling allows to pick the prop from a basket and to maintain it in a balanced condition during the cleaning and check.

A pneumatic device allows the continuous rotation of the prop.

Each manipulator ensures security and safety of operation.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

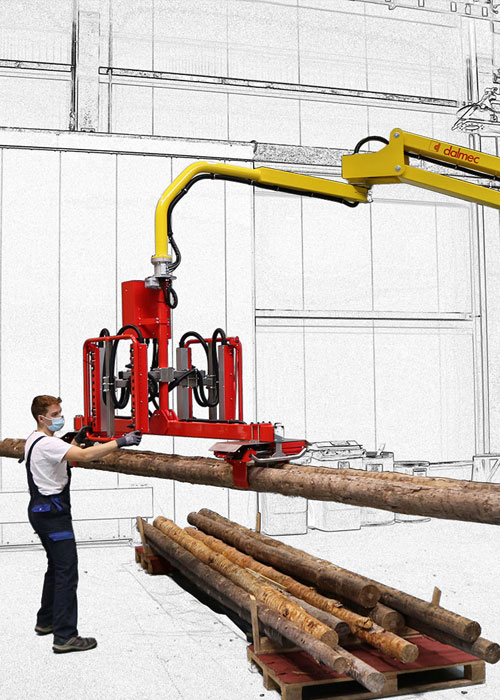

Wooden doors

- Lifter for panels.

Manipulator fitted with adjustable suction cups tooling designed to pick and place wooden panels.

Our pneumatic manipulators, designed and manufactured according to specific movements are studied on the functional needs of the production processes of each individual client.

So, over the years, DALMEC has become a widely recognized and established supplier of solutions designed to optimize human resources in any production or logistics chain, with an immediate impact on work quality and profitability.

Hundreds of Dalmec manipulators are used for handling reels in the leading industries all over the world. Our manipulators are equipped with different types of gripping devices able to lift, rotate and tilt reels of all sizes and materials with a weight from 5 Kg to 900 Kg.

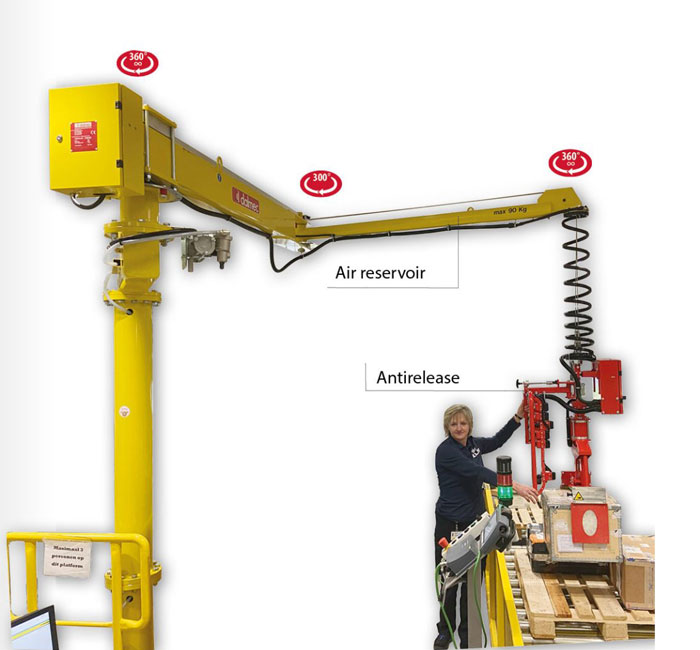

Partner PSC for bags

- Manipulator Partner standard for bags.

Manipulator Partner PSC column mounted version, for bags. This manipulator is suitable for palletizing/depalletizing bags which are stacked up to about 2 metres from floor level. The suction cup gripper is equipped with lowered controls.

Hundreds of Dalmec manipulators are used for handling bags – sacks in the leading industries all over the world. Our manipulators are equipped with different types of gripping devices which are able to lift, rotate, tilt reels of all sizes and materials with a weight from 5 Kg to 900 Kg. Well-trained design staff are able to develop state-of-the-art equipment, which ensure the operators ergonomic use of the Manipulators.

Manipulator Partner PSC type, column mounted version, designed for palletizing/depalletizing bags which are stacked up to about 2 metres from floor level, the suction cup gripper is equipped with lowered controls.

Characteristics: Max weight capacity: 50 Kg – Max working radius: 2900 mm – Vertical lift: 2000 mm

Well-trained design staff are able to develop state-of-the-art equipment, which ensure the operators ergonomic use of the Manipulators.

Every project is developed according to the instructions given by the Directive 2006/42/EC on machinery and after a careful and a methodical analysis of the risks.

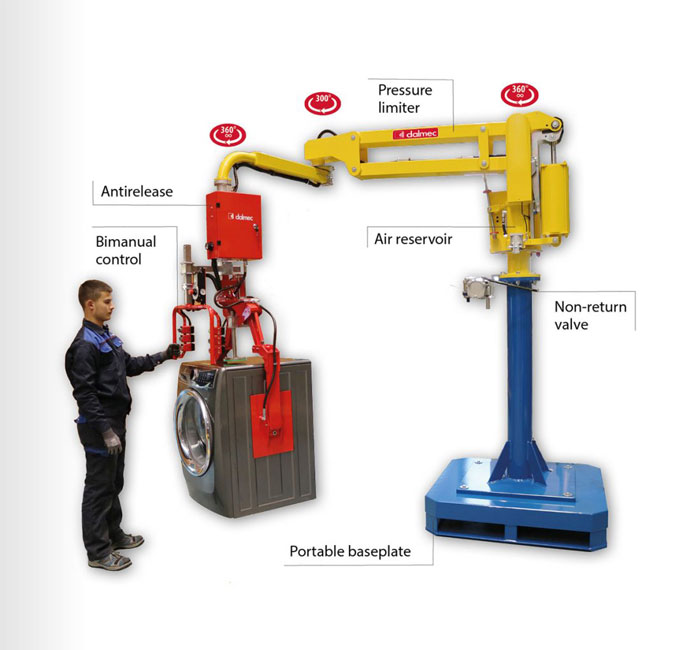

Bags Partner Equo

- Industrial manipulator for bags.

Industrial manipulator for bags Dalmec type Partner, column mounted, equipped with suction head to pick bags from a pallet and to load them to a mixer. The manipulator is provided with a autostable baseplate to allow displacements with a forklift truck.

Hundreds of Dalmec manipulators are used for handling bags and rubber bales in the leading industries all over the world. To obtain the vacuum to perform the gripping of the bag is normally used an electric vacuum generator or an ejector “Venturi”.

Partner manipulator, column mounted version, suitable for palletizing/depalletizing bags which are stacked up to about 2 metres from floor level, fitted with lowered controls.

Characteristics: Max weight capacity 50 Kg – Max working radius 2500 mm – Vertical lift 1900 mm.

Well-trained design staff are able to develop state-of-the-art equipment, which ensure the operators ergonomic use of the Manipulators.

Every project is developed according to the instructions given by the Directive 2006/42/EC on machinery and after a careful and a methodical analysis of the risks.

Wooden doors

- Lifter for panels.

Manipulator fitted with adjustable suction cups tooling designed to pick and place wooden panels.

Our pneumatic manipulators, designed and manufactured according to specific movements are studied on the functional needs of the production processes of each individual client.

So, over the years, DALMEC has become a widely recognized and established supplier of solutions designed to optimize human resources in any production or logistics chain, with an immediate impact on work quality and profitability.

Hundreds of Dalmec manipulators are used for handling reels in the leading industries all over the world. Our manipulators are equipped with different types of gripping devices able to lift, rotate and tilt reels of all sizes and materials with a weight from 5 Kg to 900 Kg.

Simple to use, they allow the operator to move loads of all sizes and materials with a weight from 5 Kg to 900 Kg throughout the working area quickly, accurately and safely.

Dalmec Manipulators are custom-built, with specially adapted design, dimensions and picking systems to suit the specific requirements of the users and the various environmental conditions available.

Chemistry

Dalmec – solutions for the chemical sector

For the chemical sector, Dalmec has designed and manufactured tailor-made Manipulators enabling to solve the more difficult handling problems in particular working environments. Every Dalmec zero balancer is custom-made to fit each specific situation.

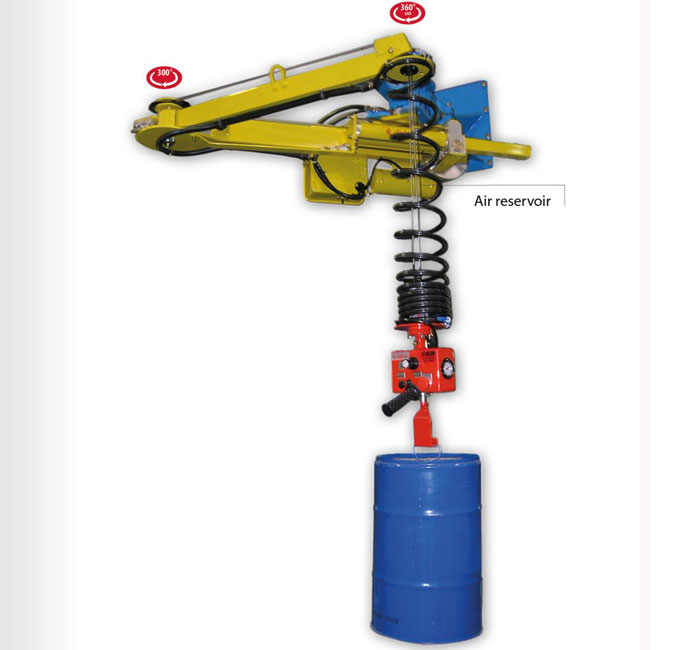

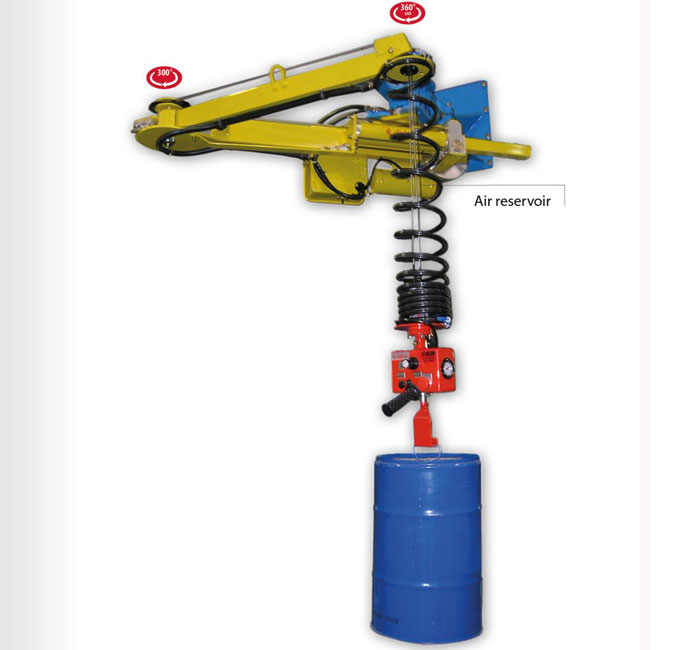

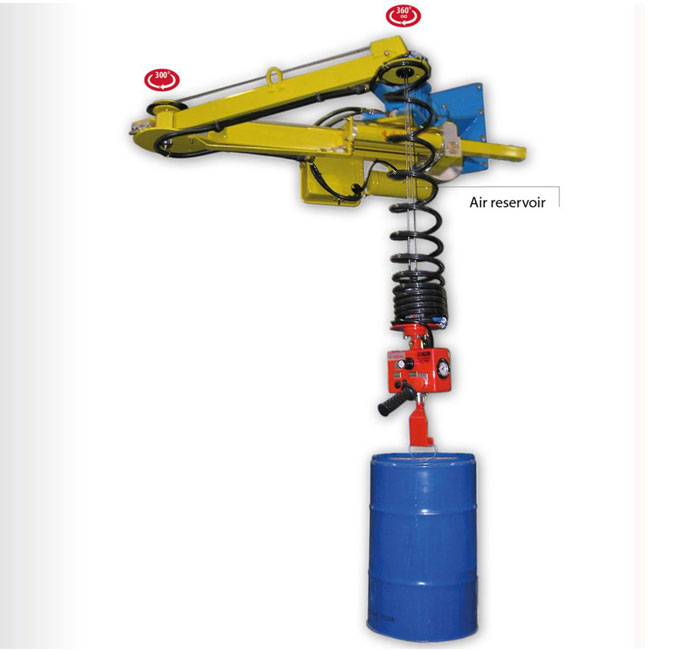

Drums

- DALMEC has been able to offer solutions that allow continuous operation and safe over time.

Our pneumatic manipulators, designed and manufactured according to specific movements are studied on the functional needs of the production processes of each individual client.

So, over the years, DALMEC has become a widely recognized and established supplier of solutions designed to optimize human resources in any production or logistics chain, with an immediate impact on work quality and profitability.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution with a zero balancer.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development. .

Rubber

- Loads lifter for rubber bales

Manipulator with tooling for handling rubber bales equipped with two independent and articulated suction cups.

Our pneumatic manipulators, designed and manufactured according to specific movements are studied on the functional needs of the production processes of each individual client.

So, over the years, DALMEC has become a widely recognised and established supplier of solutions designed to optimise human resources in any production or logistics chain, with an immediate impact on work quality and profitability.

Hundreds of Dalmec manipulators are used for handling loads in the leading industries all over the world. Our manipulators are equipped with different types of gripping devices able to lift, rotate and tilt reels of all sizes and materials with a weight from 5 Kg to 900 Kg.

Electromechanics

Dalmec – Solutions for the electromechanical sector

Dalmec Industrial Manipulators, equipped with special gripping devices, solve the ergonomic handling problems of TV-tubes – air-conditioners – electrical appliances – washing machines – televisions and many other products in the electromechanical sector all over the world.

Electric motors

- Handling of electric motors or components – Industrial Manipulators Dalmec for the electromechanical industry.

Well-trained design staff are able to develop state-of-the-art equipment, which ensure the operators ergonomic use of the Manipulators.

DALMEC has been able to offer solutions that allow continuous operation and safe over time.

Our pneumatic manipulators, designed and manufactured according to specific movements are studied on the functional needs of the production processes of each individual client. So, over the years, DALMEC has become a widely recognized and established supplier of solutions designed to optimize human resources in any production or logistics chain, with an immediate impact on work quality and profitability.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution with a load balancer.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

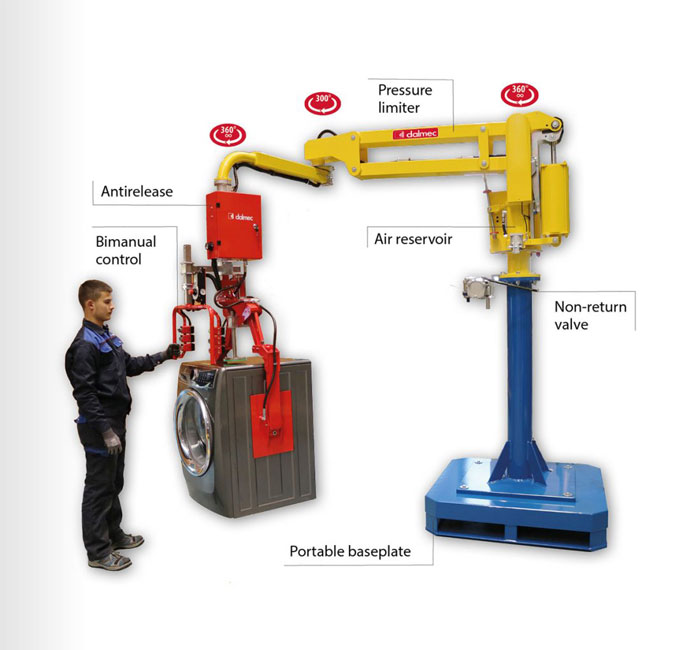

Electrical appliances

- Handling of electrical appliances or parts of household appliances – Industrial Manipulators Dalmec for the electromechanical industry.

Dalmec presents a wide range of versatile solutions to allow the lifting of products weighing from 10 up to 900 kilograms.

Well-trained design staff are able to develop state-of-the-art equipment, which ensure the operators ergonomic use of Dalmec handlers.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

Metal cabinets – electrical cabinets

- Manipulator for metal cabinets.

Pneumatic manipulator Maxipartner column mounted version for handling big metal cabinets, equipped with suction cups tooling to turn the load of 360°. The suction cups are adjustable in order to allow the gripping of cabinets having variable dimensions.

The gripping, overturning and release of the load are pneumatically operated.

Characteristics: Max weight capacity 900 Kg – Max working radius 4500 mm – Vertical lift 2200 mm.

Dalmec manipulators allow you to lift and handle heavy products with the greatest ease. Whatever industry you work in, we always have a tailored solution for you.

Hundreds of Dalmec manipulators are used in the leading industries all over the world. Our manipulators are equipped with different types of gripping devices which are able to lift, rotate, tilt reels of all sizes and materials with a weight from 5 Kg to 900 Kg.

Photovoltaic panels

- Photovoltaic panels handling device.

Suction cups gripping system Dalmec mounted on manipulator Partner type especially designed for handling and manual tilting of photovoltaic panels.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.?We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Silicon round bars handling

- Load compensator for silicon round bars.

Dalmec gripping system with a suction cups device applied to Partner Equo Manipulator for the lifting and handling of silicon round bars.The gripping device is equipped with more interchangeable gripping heads and it is designed to grip round bars of different sizes and weights.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Food

- Dalmec has produced hundreds of Industrial Manipulators now in use in the best industries throughout the world for the handling of cheeses – hams – pasta packages – bottles and/or their packing – carton boxes – containers – tanks – bags etc. Dalmec manual lift assists represent smart and ergonomic solutions.

Barrels

- Zero balancer for wooden barrels.

Pinch jaws gripping system with telescopic controls combined to the zero balancer – manipulator Partner Equo, column mounted, for the handling of wooden barrels.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Bottles

- Handling of bottles – Dalmec industrial Handlers for the Food sector

Well-trained design staff are able to develop state-of-the-art equipment, which ensure the operators ergonomic use of Dalmec handlers.

Every project is developed according to the instructions given by the Directive 2006/42/EC on machinery and after a careful and a methodical analysis of the risks.

Each manipulator ensures security and safety of operation.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Hundreds of Dalmec manipulators are used for handling reels in the leading industries all over the world. Our manipulators are equipped with different types of gripping devices which are able to lift, rotate, tilt reels of all sizes and materials with a weight from 5 Kg to 900 Kg.

Our manipulators enable you to lift and handle your products with the upmost precision.

DALMEC continuously strives to find the best solution to allow the handling of loads without any effort in accordance with the ergonomic criteria.

Cheese

- Handling of cheese with or without packaging – Dalmec Industrial Manipulators for the food sector.

DALMEC has been able to offer solutions that allow continuous operation and safe over time.

Our pneumatic manipulators, designed and manufactured according to specific movements are studied on the functional needs of the production processes of each individual client. So, over the years, DALMEC has become a widely recognized and established supplier of solutions designed to optimize human resources in any production or logistics chain, with an immediate impact on work quality and profitability.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Chocolate containers

- Gripping system for chocolate containers

Gripping system for chocolate containers. Dalmec Pinch jaws gripping system designed for the simultaneous gripping of seven jars containing hazelnut- chocolate spread, with rotation, alignment and pneumatic compaction for their storage into boxes.

Dalmec is present in food companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development.

Cold meat – salami

- Manipulator for cold meat – salami

Dalmec Manipulator equipped with particular stainless steel hook for picking and handling of cold meat – salami.

Our pneumatic lifters, designed and manufactured according to specific movements are studied on the functional needs of the production processes of each individual client.

So, over the years, DALMEC has become a widely recognized and established supplier of solutions designed to optimize human resources in any production or logistics chain, with an immediate impact on work quality and profitability.

Hundreds of Dalmec manipulators are used for handling reels in the leading industries all over the world. Our manipulators are equipped with different types of gripping devices able to lift, rotate and tilt reels of all sizes and materials with a weight from 5 Kg to 900 Kg.

Drums

- DALMEC has been able to offer solutions that allow continuous operation and safe over time.

Our pneumatic manipulators, designed and manufactured according to specific movements are studied on the functional needs of the production processes of each individual client.

So, over the years, DALMEC has become a widely recognized and established supplier of solutions designed to optimize human resources in any production or logistics chain, with an immediate impact on work quality and profitability.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution with a zero balancer.

We consider safety a matter of utmost importance and a fundamental component common to all products that we manufacture in conformity with the UNI EN standards and in compliance with the EC Atex directives and with all safety guidelines and markings. Functional analysis, design, study of the different technical solutions available, simulations and prototypes creation are all phases in the production process that DALMEC carries out in close partnership with the client, with continuous controls and reviews during project development. .

Foundry

- For the foundry industry, Dalmec has designed and manufactured many different manipulators with special toolings for the handling of rims – foundry pieces – moulds – precision castings, having different dimensions and weights.

Compensating arm for alloy discs

- Compensating arm with tooling for gripping and pneumatic rotation of alloy discs.

Handling of alloy discs – compensating arm Partner type, column mounted version, equipped with pinch jaws tooling designed to grip alloy discs on their external diameter and after a 180° pneumatic rotation, to place them on a pallet.